Silent blocks are elements of a car's suspension, consisting of two metal bushings separated by a rubber or polyurethane insert, designed to make the car's movement more comfortable and reduce noise when driving. These parts are installed in the moving parts of the suspension, and they are constantly exposed to mechanical stress. In VAZ 2101-2107, the front silent blocks most often suffer under loads, and the problem can be solved independently, without resorting to the use of special tools and the services of service station technicians.

Where are silent blocks installed?

On the VAZ "Seven" silent blocks are installed in the front and rear suspension. At the front, levers are attached using this part, and at the rear, reaction rods (longitudinal and transverse) connect the axle to the body. To ensure that the car's suspension is always in good condition and handling does not deteriorate, you need to monitor the condition of the silent blocks and replace them in a timely manner.

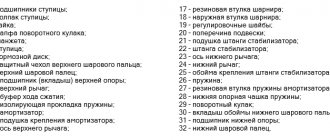

The front suspension of the classic Zhiguli consists of the following parts: 1. Spar. 2. Stabilizer bracket. 3. Rubber cushion. 4. Stabilizer bar. 5. Lower arm axis. 6. Lower suspension arm. 7. Hairpin. 8. Lower arm amplifier. 9. Stabilizer bracket. 10. Stabilizer clamp. 11. Shock absorber. 12. Bracket bolt. 13. Shock absorber bolt. 14. Shock absorber bracket. 15. Suspension spring. 16. Steering knuckle. 17. Ball joint bolt. 18. Elastic liner. 19. Cork. 20. Insert clip. 21. Bearing housing. 22. Ball bearing. 23. Protective cover. 24. Lower ball pin. 25. Self-locking nut. 26. Finger. 27. Spherical washer. 28. Elastic liner. 29. Pressure ring. 30. Insert clip. 31. Bearing housing. 32. Bearing. 33. Upper suspension arm. 34. Upper arm amplifier. 35. Compression progress buffer. 36. Buffer bracket. 37. Support cap. 38. Rubber cushion. 39. Nut. 40. Belleville washer. 41. Rubber gasket. 42. Spring support cup. 43. Upper arm axis. 44. Inner bushing of the hinge. 45. Outer bushing of the hinge. 46. Rubber bushing of the hinge. 47. Thrust washer. 48. Self-locking nut. 49. Adjusting washer 0.5 mm 50. Distance washer 3 mm. 51. Cross member. 52. Inner washer. 53. Inner sleeve. 54. Rubber bushing. 55. Outer thrust washer

Upper

Important! When working, the car should be placed on stands to prevent it from falling, and the rear wheels should be braked with a hand brake. Using a car jack, lift the side of the car where the worn silent block will be replaced, remove the wheel

Now you should free the bipod from the upper ball joint. Unscrew the support nut with a 22mm wrench and press it out with a special puller. Experienced car enthusiasts use a heavy hammer to do this, hitting the protrusion on the bipod, after which the ball joint pin comes out of its socket

Using a car jack, lift the side of the car where the worn silent block will be replaced and remove the wheel. Now you should free the bipod from the upper ball joint. Unscrew the support nut with a 22mm wrench and press it out with a special puller. Experienced car enthusiasts use a heavy hammer to do this and hit the protrusion on the bipod, after which the ball joint pin comes out of its socket.

Now you can begin removing the upper arm. For the VAZ-2107, before this you need to remove the upper bumper mounting bolt. After removing the bolt, use keys 22 and 24 to unscrew the nut and knock out the bolt. After this, the part will remain in your hands. A puller is used to remove silent blocks from their sockets to press in new ones. If this fails, they are simply burned out.

Replacing the silent blocks of the upper arm of the VAZ-2107 must be done on a dry surface:

- They are pressed into the sockets of the upper arm of the VAZ-2107, after which they take their place.

- Do not overtighten the nut of the lever mounting bolt; this is done last.

- Now install the upper ball joint.

Replacement of the upper arm silent block is completed.

What are silent blocks?

In addition to the purpose of silent blocks, you need to know that these products can be made of rubber or polyurethane. It is generally accepted that replacing rubber suspension components with polyurethane ones, where possible, will only improve the characteristics and performance of the suspension.

Silent blocks made of polyurethane are characterized by a longer service life, unlike rubber ones.

The disadvantage of polyurethane elements is their high cost - they are about 5 times more expensive than rubber ones. When installing polyurethane products on a VAZ 2107, you can improve the car's behavior on the road, reduce deformations in the suspension, and also eliminate the so-called squeezing, which is characteristic of rubber elements. This means that the suspension will operate in the condition intended by the designers at the factory. With the correct selection and installation of polyurethane parts, noise and vibration are reduced and shocks are absorbed, which indicates the better performance of such hinges compared to rubber ones.

Silent blocks made of polyurethane are considered more reliable than rubber ones, but are much more expensive

Jet thrust malfunctions and possible consequences

If the load causes the axle to sway or shift, the impact will be taken by the jet thrust. The appearance of defects in parts leads to a deterioration in the overall behavior of transport. Damaged parts need to be replaced as quickly as possible.

The following factors often cause breakdowns:

- Exposure to chemicals from road compounds in winter;

- Impact of torsional loads. Occurs more often when colliding with obstacles. Only reducing the speed before these elements reduces the risks;

- Static loads. This factor is only reduced by the absence of overloads; it is impossible to completely get rid of it when operating rods on a VAZ 2107.

It is important to detect deformation, chips and cracks in a timely manner, for which periodic inspection of the entire system is organized. Welding seams and silent blocks are weak points that receive the most attention during inspections.

Silent blocks of any type are rubber, so they wear out faster than metal parts. Due to their wear, backlashes appear, becoming an obstacle to the stabilizing function. Welded joints, when they break, also lead to unpleasant consequences. It is recommended to remove them as quickly as possible.

With broken parts, driving is worse. Added to this is the unstable behavior of the body when defects appear in the jet rods.

Why silent blocks fail

When encountering failures of silent blocks for the first time, it is quite difficult to imagine what can happen to these products after long-term use. Over time, the rubber begins to tear, resulting in the need to replace the hinge.

There may be several reasons why a product becomes unusable:

- High mileage of the car, the consequence of which was the drying out of the rubber, loss of its elasticity and the appearance of cracks and tears.

- Contact of chemicals with the rubber of the silent block. Since the suspension element in question is located near the engine, it is likely that it will be exposed to oil, which leads to the destruction of the rubber.

- Incorrect installation. Fastening the bolts of the levers should only be done after the car is installed on the wheels and not hung on a lift. If tightened incorrectly, the rubber of the silent block becomes strongly twisted, which leads to rapid failure of the product.

Selection of thrust rods

The parts come from different manufacturers, the prices of which often differ several times. Production involves the use of spring steel as a base. Even when purchasing, it is easy to identify the presence of a defect in one case or another. It is necessary to inspect the part, especially in the welding areas. If there are chips and cracks, it is recommended to refuse the purchase. The fastening must not be damaged.

It is better to contact representatives of trusted stores. The main thing is not to forget to take a receipt, which simplifies the procedure for processing a return if necessary.

Checking the silent blocks

It would be a good idea for the owners of the “Seven” to know how to determine that the silent blocks need to be replaced. High-quality products last for quite a long time - up to 100 thousand km. However, due to the condition of our roads, the need to replace them usually arises after 50 thousand km. You can determine that the rubber joints have become unusable by how you feel while driving the car. If the car begins to handle worse, the steering wheel is no longer as responsive as before, then this indicates obvious wear and tear on the silent blocks. To be more confident, it is recommended to visit a service station so that specialists can diagnose the suspension.

If visible signs of wear appear, the part needs to be replaced.

The condition of silent blocks can be determined independently by visual inspection. To do this, you will need to drive the car onto an overpass or inspection hole, and then inspect each of the hinges. The rubber part should not have cracks or tears. One of the signs of failure of silent blocks is a violation of wheel alignment. In addition, a sign of wear on the part in question is uneven wear on the tire tread. This phenomenon indicates an incorrectly adjusted wheel alignment, which may be causing the vehicle's suspension to malfunction.

There is no point in delaying the replacement of silent blocks, since over time the seats in the levers become broken, so the lever assembly may need to be replaced.

Purpose of thrust rods on the VAZ 2107

Tie rods provide protection against swaying and loss of control on the road, during sharp turns and obstacles. Even earlier versions of the car had similar problems. But inside the cars there were only ordinary springs; no one knew anything about the system with rods.

It is for this reason that the vehicle caused many problems when driving. Only over time the suspension was modified. A system was installed with several long rods. This part carried the main load.

Classic VAZ 2107 cars and other models contain the following version of the torque rod kit:

- Long.

- Short.

- A large transverse one, which also serves as the basis for the entire system.

Installation location - near the car axle located at the rear. The system is visible only from the inspection hole, where repair work is usually carried out if the reaction rods are replaced.

Do-it-yourself silent block puller

To replace silent blocks on cars of the VAZ 2101-2107 family, there is no need to buy the appropriate puller; you can do without it, especially since it costs money. But with such a device it is much easier to carry out planned repair work.

It’s quite possible to assemble a silent block remover with your own hands at home, and for this you only need a few parts:

M12 bolt with fine thread, the length of which is at least 7 cm.

A piece of pipe has the following dimensions: length 3 cm, internal diameter 40 mm, and external diameter 50 mm.

Washer with an outer diameter of 50 mm minimum.

Two pieces of pipe with the following dimensions: length 10 cm and diameter 40 mm.

Do-it-yourself silent block puller

When all the components for implementing a homemade puller are ready, you can begin to implement the idea:

Increase the internal diameter of the pipe from 40 mm to 45 mm.

To use the device to press out old hinges, you will need to put a washer on it.

The bolt must be placed inside the device, and then a large-diameter mandrel must be placed on the outside. This mandrel will rest against the wall of the lever. To press the part, you will need to put on the washer and screw the nut.

The device can be made at home using improvised materials, which is what many actually do. Implementing such an idea will not be difficult, but you can significantly save money on purchasing a factory puller.

Replacing jet rods on a VAZ 2107

It is necessary to prepare a kit with tools and consumables in advance. Their main list is as follows:

- Hammer;

- Set with open-end wrenches. The reinforced double type parts are sometimes difficult to remove without additional tools;

- Blades for installation;

- WD-40 – this composition removes rust;

- A set with new reaction rods, including a transverse one.

When everything is ready, they begin the work itself.

Removing jet rods

Removing old parts is the first step where work begins.

The process involves the following sequence:

- A wire brush is used to remove rust and dirt from threaded connections. Then WD-40 is used for processing. You will need to wait some time before the work can continue. The instructions are also relevant for the classic model.

- Completely unscrew the nut, due to which the washer is held on the free side. This process is difficult, it is better to take a long wrench and, if necessary, re-treat the surface with WD-40.

- Dismantling the bolt and nut, moving to the other side. The rear parts are dismantled in almost the same way.

- Unscrewing the nut from the lower shock absorber mounting. The bolt with the spacer sleeve is also removed.

- Shift towards the shock absorber itself. Otherwise you won't be able to access the second bolt.

- Clean the bolt threads with a wire brush, then apply WD-40 again.

- Unscrew the nut and pull out the bolt. The elastic band also changes if necessary.

The bolt is simply cut off if the nut cannot be unscrewed. Removing the reaction rods involves using a spatula for installation. Remains of the fastening must be removed if the bolt had to be cut off.

Reverse welding of cracks will not help when they appear on the surface. The seam then still cannot withstand the load. Such parts can only be replaced in full.

Security measures

When performing repair work, do not forget about basic safety measures:

- Before hanging on a jack, the car is placed on the handbrake, and wheel chocks are placed under the wheels;

- In parallel with the jack, a safety support is installed under the body of the suspended car;

- When working with a hammer, for example, pressing a ball joint out of a bipod, use safety glasses;

- Wear gloves to protect your hands from damage if the wrench may slip off the nut.

A little theory

The silent block is one of the critical parts of the suspension of the VAZ-2106 car, with the help of which fastening elements of such units as:

- shock absorbers;

- anti-roll bar;

- gear box;

- jet thrust;

- beam supports;

- rear suspension rods.

Despite the apparent simplicity of the design, the rubber-metal hinge in the VAZ-2106:

- ensures the mobility of suspension parts relative to each other;

- withstands axial, radial and angular loads;

- absorbs vibrations simultaneously in all planes.