In this article, we will look at, − How to replace steering rod silent blocks on a VAZ 2109, VAZ 2110, VAZ 2112, Daewoo Lanos, Daewoo Nexia, Daewoo Sens.

This is the kind of car where rubber bands are used everywhere, serving the same purpose, but in different places. Wear of the steering rod silent blocks will not force you to listen and will make itself felt immediately by the appearance of knocks that occur in the area of the steering rack; an unpleasant vibration occurs on the steering wheel, which still interferes while driving. One good thing is that replacing these fire blocks is not difficult or expensive. In addition, in this article we will look at how to replace the steering rod silent blocks on a VAZ 2109, VAZ 2110, VAZ 2112, Daewoo Lanos, Daewoo Nexia, Daewoo Sens with your own hands. To replace silent blocks you do not need any super professional equipment and therefore I advise you to get down to business as soon as possible.

Which steering rod silent blocks are better?

Recently, there have been many samples of low-quality products, especially in the range of auto parts. Among the main manufacturers of high-quality auto parts, the following Korean and Polish companies can be distinguished: CTR, GUMEX. The main thing is not to fall for cheaper Chinese-made analogues. The part must be manufactured with high quality and meet the necessary requirements, both in size (width and diameter) and rubber quality. for a beginner to decide on a quality part, so you should rely on the seller’s recommendations.

I would like to note that steering rod silent blocks for VAZ-2110, VAZ 2111, VAZ 2112, Balakovo (BRT) production fit perfectly into steering rods of Daewoo Lanos, Daewoo Nexia, Daewoo Sens, ZAZ Sens (ZAZ Sens).

What tools are needed to replace steering linkage silent blocks?

— it is desirable to remove the steering tips, but no one canceled the old, good hammer;

It is better to replace the steering rod silent blocks of VAZ 2109, VAZ 2110, VAZ 2112, Daewoo Lanos, Daewoo Nexia, Daewoo Sens in an inspection pit or, if possible, on a lift. In case of replacing the silent blocks of steering rods with an 8-valve engine, the replacement of the silent blocks is carried out from above.

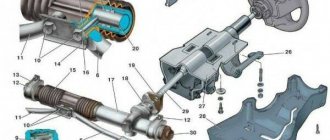

Replacing silent blocks in the steering rod on a VAZ 2110, VAZ 2111, VAZ 2112

Welcome! Steering rod silent blocks - They consist mostly of rubber, the rubber hardens over time, which is why it cracks later, which is why there is play in the steering wheel (If the silent blocks are in good condition, then take a look at the steering rack, because of it too there may be some play, read the article: “Adjusting the rack on the tenth family”) and by the way, if the rods in your city don’t cost much money, then we recommend that you immediately buy them entirely with silent blocks, because when everything is manufactured at the factory, it will be better.

Note! To replace silent blocks, you will have to remove the traction from the car and, using a head of a suitable diameter, press out the silent blocks; the tools you will need are: A large set of keys, screwdrivers, special tools. a puller for pressing the steering tip out of the hole, pliers and a hammer!

Summary:

Where are the silent blocks located in the steering rods? One at a time, the silent blocks are located in the steering rods, and they are inserted into those places where the rod is bolted to the steering rack, this hole is indicated by a red arrow in the photo below for clarity, and the silent block itself is shown in a small photo in the lower left corner of the picture (It taken in a large photo from the draft).

When do you need to change silent blocks in steering rods? It is not possible to see the silent block in the steering rod without unscrewing the bolt that secures it, so in order not to tinker with these bolts from time to time, wait for a symptom to appear, namely, when play in the steering wheel appears, knocking sounds will appear in the steering rack, when this everything starts to be felt, unscrew one bolt at a time (After unscrewing one bolt, immediately screw it into place, looking at the silent block, you don’t need to unscrew both, because the locking plate will fall) that secure the rods, to do this, pry up the locking plate using a flat screwdriver (see . photo 1) and unscrew the bolt you need, which secures one of the rods, holding the rod with your hand, carefully lower it and look at the condition of the silent block, there should be no cracks on it, the rubber should not harden too much (It should be alive, fresh ), if everything is in order with the silent block, look at the other link and at the end, install the locking plate in its place; if everything is in order with the silent blocks, and there is play in the steering wheel, then look at the steering rack.

How to choose a steering rack

In the case where a defect in a unit does not allow for easy repairs, it is more advisable to completely replace the unit. But here you will have to shell out a considerable amount: a standard VAZ rack will cost about 3,000 rubles, tuning versions cost much more, up to 15,000 rubles.

That’s why the number one question is the correct choice of reiki, so as not to get into trouble.

- It is better to give preference to original parts rather than copies, as they guarantee not only perfect compatibility, but also good quality. Although today there are a lot of companies and small businesses that sell cheap copies under the brand of the originals. Therefore, you should not purchase components from dubious shops and markets, but from serious and trusted sellers.

- Don't pay attention to parts that are too cheap, as they are unlikely to last long.

- When choosing a rack for a ten, it is necessary that the product number ends with “10”, remember that the steering rack is a purely individual part, there is one for each model, so don’t go wrong.

- Of course, it is necessary to conduct a visual inspection of the product before purchasing to identify defects, damage to anthers and other components.

How to replace silent blocks in steering rods on a VAZ 2110-VAZ 2112?

1. First, remove the steering rod you need, or both at once, to remove them, you will need to unscrew the bolts that attach the rods to the steering rack (How to do this is explained above), then you will have to remove the tie rods from the holes and you can remove the rods (Regarding tips, it is written in the article: “Replacing steering tips on a VAZ”).

2. After which you will have to use a bolt of the appropriate size, the bolt that secures the wheel (One of the fastening bolts), it will need to be inserted into the hole of the silent block and using a hammer, you will have to hit the bolt several times and it, together with the silent block, will come out , but just keep in mind that you need to hit in such a way that the silent block can be pressed out without problems, that is, putting a rod on the asphalt and hitting the bolt with a hammer simply won’t work, you will have to either look for a vice and knock out the silent block as shown in the photo below, or just a couple of bricks Place it side by side, they will replace the same vice and the silent block will easily come out the third or fourth time (Instead of a bolt, you can use a head of a suitable diameter).

3. To press in a new silent block, lubricant will be needed for them, any long bolt of the same size (So that the silent block fits into the hole), one nut for this bolt and a washer, when you have stocked up with all this, lubricate the inside of the steering rod, where the silent block will be installed (see photo 1) and collecting special. a device made of a bolt, nut and washers (see photo 2), install the silent block in its regular place, while holding the bolt itself with the help of a head and a wrench from turning and at this moment tightening the nut, which will press the silent block into its regular place.

Additional video clip: Watch a video that shows the process of replacing silent blocks on steering rods from a VAZ 2108 car, in these rods the silent blocks are used, but they are changed in exactly the same way as on the tenth family of cars, but only in this video everything is done with a hammer is done, we do not advise you to press the new silent block as shown in the video, because it can be damaged very easily.

Source

How to make repairs

- Fix the rail in a vice in a vertical position. Clean the surfaces with a brush or cotton cloth previously soaked in white alcohol.

- Take out the steering rods. To do this, unscrew the bolts on the bracket that hold the rods, bend the force at the locking plate using a 22mm wrench.

- Remove the plate rods - locking and connecting.

- Pull out the tie rods.

- On the right side of the steering assembly housing, remove the retaining ring and support.

- Cut off the clamps that hold the protective cover. These are disposable items made of plastic. Replacing them is very easy and cheap.

- Remove the cover.

- On the left, remove the support and protective cap.

- Armed with a 17mm wrench, unscrew the nuts that are located on the rack stop. Remove it, take out the spring and ring.

- Knock the rack stop out of the socket. Hit the crankcase against a wooden base. To seal the groove, install a rubber ring on the stop.

- Remove the seal, remove the gear boot by prying it off with a screwdriver.

- Remove the lock washer.

- Using a 24mm wrench, unscrew the nut that holds the gear bearing.

- Remove the nut from the shaft.

- Using a 14mm wrench, unscrew the gear from the crankcase, simultaneously with the bearing itself.

- Remove the rack and remove the bushing. The element is pryed off with a screwdriver so that the protrusions fit into the holes in the crankcase. This will allow you to get the part without any problems.

- Install a new bushing. It is recommended to attach new damper rings made of rubber to it. This must be done so that the thin part of the ring is opposite the cuts in the bushing, and the protrusions on the bushing are freely placed in the crankcase hole.

- The rings need to be cut along the edges of the sleeve and the excess elements removed.

- Remove the retaining ring from the gear shaft.

- Use a two-jaw puller to compress the wide bearing.

- Press out the needle bearing with the same device, or make two holes with a diameter of 2 mm in the end of the crankcase, and then the bearing will come out onto the ring.

- Rinse the crankcase thoroughly, press in the needle bearing using a piece of pipe. Treat the holes made with cold welding.

- Using Fiol 1 lubricant, treat the bearings, rack and gear teeth. Place UNIOL 1 grease into the cavity under the nut securing the drive gear bearing.

- Reassemble the structure in reverse order.

- Place the new cover in place.

- Be sure to try to maintain a gap of 0.12 mm between the rack stop nut and the stop itself.

- Tilt the nut after adjusting the gap, which will prevent it from unscrewing.

If such a DIY repair of the steering rack on a VAZ 2110 does not give the desired result, simply replace the element. You have already become familiar with the process of dismantling the rail. Having taken out the old unit, put a new one in its place, following a strict sequence of steps.

To illustrate the repair of the steering rack on a VAZ 2110, we recommend watching the video. With their help, the process will not seem as complicated as described above. The work will take some time, but you won't have to hang around in the garage all day.

Silent blocks, purpose and installation locations

In the front suspension of the car, silent blocks are installed in the arms. Using silent blocks, the levers are connected to the wheel hub and the car body. Such a connection is movable and elastic. Sometimes silent blocks are installed at the junction of the anti-roll bar with the lever - if the suspension design provides for this. The silent block can also be installed on the shock-absorbing strut - in the lower part, where the strut connects to the hub.

If we talk about the rear suspension, then silent blocks are installed on the transverse and trailing arms, at the junction of the torsion beam and the body, as well as on the shock absorbers. In general, the number of silent blocks depends on the design of the car suspension.

On the VAZ 2110, silent blocks are located in the following places:

• Cross arms (attachment points to the body). • Anti-roll bar ends (attachment point to front control arm). • The lower part of the shock absorber strut is where it attaches to the wishbone). • Cross arm extension (at both ends – the connection points with the cross member and the lever).

In total, there are 5 silent blocks in the front suspension of the VAZ2110. At the rear of the car there is a torsion beam, so there are only 4 silent blocks. Two of them act as fastenings of the beam to the body, two more are located in the lower parts of the shock absorbers. Another place where silent blocks can be installed is the steering. In some car models, the hinge is used as an element of an elastic movable connection between the steering mechanism and rods. The average service life of a rubber-metal joint is about 100,000 km. Of course, this is not an exact indicator; it depends on the operating conditions of the car, the quality of the road surface and the quality of the part itself. Since domestic roads are far from being in the best condition, silent blocks usually withstand no more than 50,000 - 60,000 km. After this, it is advisable to replace them.

Signs and causes of failure of the VAZ 2110 steering mechanism

- Increased free play of the steering wheel. The reason for this may be an increase in the gap between the rack stop and its nut. Associated reasons may be wear of rubber-metal parts, loosening of the ball rod nuts, and the appearance of a gap in the hinges.

- Noise and knocking in the steering. Very often, in addition to the reasons described in paragraph 1, the source of the problem may be a weakening of the steering mechanism or the bolt securing the lower flange of the elastic coupling to the gear shaft.

- Stiff rotation of the steering wheel. The source of the malfunction may be damage to the bearing of the upper steering column shaft, a defect in the support sleeve or in the rack stop. The reason may also be wear of the bearing of the upper support of the suspension strut, failure of parts of ball rods or a telescopic strut.

It is also worth saying that troubleshooting the steering rack is a priority task for auto repair, because... otherwise it can be fatal.

At the initial stages of operation, knocking in the rack is eliminated by tightening the corresponding thrust nut. However, after 200 thousand km. To eliminate the play, you will need to replace the VAZ 2110 steering rack.

Replacing silent blocks VAZ 2110

Car silent blocks require monitoring and timely replacement. The service life of a silent block is up to 100,000 km , but Russian conditions dictate their own rules; silent blocks have to be replaced every 50,000 km .

Broken silent blocks of the front suspension arms on VAZ-2110 vehicles are indicated by a characteristic knocking or grinding sound that is heard when the car is moving. The car not only begins to rattle, but also loses stability on the road and becomes more difficult to control. It happens that when a car undergoes a wheel alignment, it is discovered that the silent blocks are faulty.

It is quite possible to change the silent blocks of a VAZ 2110 with your own hands. Of course, you will have to get dirty and spend several hours of your time to repair the car. The same procedure for replacing a set of silent blocks at a service station will cost 1100-1400 rubles . You can decide whether to take on the work yourself or entrust it to others after viewing this photo report.

It is worth noting that the photo instructions are based on the experience of car enthusiasts and contain tips for drivers with a minimum set of necessary tools. In the repair instructions you can find another solution to this problem.

Main faults of the VAZ 2110 steering rack

In modern VAZ 2110 cars, breakdowns of the steering rack and power steering are a very common occurrence. The reasons may be the following:

- Frequent driving on uneven roads, getting the car into potholes at high speed, active (uneconomical) driving style. In such a situation, the steering rack and power steering will quickly fail, an annoying knock will appear, and controllability will deteriorate. The result is failure of the unit;

- sudden acceleration when the steering wheel is in the extreme right or left position. This driving practice negatively affects the life expectancy of the steering rack;

- Regular trips to curbs are a big load for such an important mechanism.

Fans of such “obstacle driving” will very soon have to spend money on repairing the steering rack.

We have identified the main reasons. But how to determine whether a steering rack is faulty in practice? For what symptoms? We will look at this issue in more detail.

Polyurethane silent blocks, what is the advantage

The service life of the hinge is influenced by a number of other circumstances. For example, the rubber used in the silent block design is very badly affected by petroleum products and chemicals used to treat the road surface in winter. Temperature changes also have an extremely negative effect on the part - in the summer the rubber softens, and in the winter it begins to freeze and becomes too hard. Under conditions of severe mechanical loads, rubber begins to wear out, “age”, lose elasticity, delaminate, and fail.

How to check silent blocks on a VAZ 2110

You can determine that the silent block requires replacement visually by driving the car to a pit, overpass or lift. If during inspection a part is found to have cracks, scratches, dents, or other damage, it must be replaced as soon as possible. Another simple method for checking the condition of silent blocks is to use a regular mount.

To do this, the tool is used to forcefully rock the suspension elements in which the silent blocks are installed. If the mount moves freely, or impacts, knocks, or grinding noises are heard during the process, the hinge must be replaced. It should be noted that silent blocks are not replaced one at a time, but only in pairs, even if the second element on the suspension does not show signs of malfunction.

Tools, accessories, consumables, pro tips

The work itself of replacing silent blocks is not difficult, but special tools may be needed to press out the hinges.

In total for work you will need:

- actually, new silent blocks

- spanners and open-end wrenches of the required size (heads and ratchet)

- puller for silent block

- lubricant (soap solution)

- jack

- vice

- hammer, small chisel.

The hinge fits very tightly into place, and to dismantle it, most likely, you will need a special puller. A necessary condition for high-quality replacement of hinges is their correct selection. Before you go to the store, you need to find out which silent blocks are most often installed on the BA2110, their serial number, size parameters, etc. Let us repeat, the hinge fits very tightly, and a discrepancy in size of just a few millimeters will result in the new silent block simply not being pressed in.

For this work, special pullers are used, with the help of which it is easy to remove the old part and press in the new one. Sometimes it happens that to replace the silent block you have to remove a suspension element, for example, a lever. In this case, the puller can be successfully replaced with a conventional bench vice. True, in this case it will be quite difficult to remove the silent block. Then you can simply burn it out with a blowtorch or over an open fire. Sometimes craftsmen cope with it using a sledgehammer and a metal punch.

Before installing a new part in place, it must be lubricated with soap or a soap solution. This will make installation very easy. You cannot use lubricants made from petroleum products - grease, litom, oil, etc., as they have a negative effect on the rubber. This does not apply to polyurethane hinges, which are practically unaffected by petroleum products. To make installation even easier, a small chamfer can be removed from the rubber surface of the part from the end. The main thing is not to overdo it and not to cut off too much.

Puller for silent blocks - principle of operation and device

You can buy such a device at an auto parts store or make it yourself. The simplest puller consists of a nut, a long bolt, several pieces of pipe of different diameters and several thick washers.

The principle of its operation is extremely simple: To press out the old silent block, take a bolt onto which a washer is placed. Its diameter should be slightly smaller than the rubber insert of the hinge. The bolt is passed through the hole in the hinge. On the other hand, a piece of pipe is thrown onto the bolt, the diameter of which should be equal to the diameter of the lever, that is, the pipe rests against the lever. After this, another washer is placed on the bolt, the diameter of which should be larger than the diameter of the pipe section. Now you can screw the nut onto the bolt.

Then the device works like this: when screwed, the nut rests against the washer and begins to gradually tighten the silent block. Cutting the pipe, in turn, allows the hinge to gradually come out of the socket without resting against another washer.

Pressing is done in exactly the same way, only in this case it is not necessary to use a piece of pipe, since the new silent block will rest against the washer when it is already in place. You can press the hinge with a regular vice, but it will not sit completely in place, as it will rest against the jaw of the vice, and it will have to be pressed.

A few words about signs of silent block failure

If you notice:

- Creaking of rubber when driving over uneven surfaces;

- Knocking while driving over uneven surfaces;

- Backlash in connections when checking the chassis;

- Deterioration or cracks in silent blocks;

- Uneven tire wear disrupts wheel alignment.

It is necessary to take immediate action and replace faulty silent blocks.

To work you will need:

- New lower control arm silent blocks - rubber or polyurethane;

- Set of keys, hammer;

- Soap solution;

- Liquid WD-40;

- Lift or inspection hole;

- A device for pressing out and pressing in silent blocks or, in extreme cases, a vice and tubes with washers of the appropriate diameter for pressing in silent blocks. If you don’t have either one or the other, you can make just such a “device” that works 100% and costs a penny. It consists of several washers, a piece of pipe and a long “12” bolt - see photo.

Replacing rubber joints on the rear suspension

More on how things are changing. First, let's look at how to replace the rear silent blocks of a VAZ-2109. To perform the operation you will need:

- Inspection hole;

- Jacks;

- Tools (key sets, hammer, attachments);

- Bench vice;

- Mount;

- Spring ties;

- Soap solution;

- Pullers for rubber joints;

First, the silent blocks of the rear beam of the VAZ-2109 are replaced. For this:

- We put the car in a pit, jack up the rear on one side, remove the wheel;

- Unscrew the nut of the bolt securing the beam to the body, remove the bolt;

- Using a pry bar, we press the beam down to remove it from the bracket, fix it in this position (by installing a wooden spacer between the beam and the body);

- Using a hammer, carefully knock out the worn hinge;

- Using a device (a long bolt with a nut, two wide washers and a piece of pipe), we press in a new element, having previously generously lubricated the seat and the hinge itself with soapy water;

- We install the beam into the bracket and fix it with a fastening bolt;

Replacing the silent blocks of the front upper arm

The procedure is as follows:

The front wheels are lifted with a jack and fixed. The front wheel is removed. The upper arm is removed. Before dismantling it, you need to check whether the silent blocks inside the lever do not slide; they must sit there tightly.

In order for the upper arm to be removed freely, the upper support must be removed. This is quite difficult to do, since it is very difficult to unscrew the nuts. To do this, turn the wheel out and lightly hit the bipod with a hammer. After this, the support should pop out without problems. Unscrew the upper bolt of the lever. It is long, so the operation will take some time. After the bolt is removed, you can remove the lever and begin replacing the silent block.

Axial play, what is it and how to eliminate it

This is a fairly common “disease” of the lower arm of domestic cars, and the VAZ 2110 is no exception. Backlash occurs when the bracket on the body to which the lever is attached has loosened for some reason, and a gap has appeared between the lever and the bushing, which is why the silent block begins to move inside the lever.

Axial play has a very negative effect on the operation of the front suspension, so, of course, it should not exist. If there is a backlash, it can be eliminated in several ways. First, you can try to slightly compress the bracket on the body. It will be very difficult to do this, because it is undesirable to hit the body with a hammer, and in order to use pliers or a clamp, you will need a fair amount of physical strength, and it will be inconvenient to work under the car with these tools.

It is much easier to eliminate axial play by placing several washers between the bracket and the silent block. Although according to the rules it is necessary to replace the entire lower arm along with the silent block.

Why are silent blocks needed in the front suspension?

Some novice drivers, of whom there are quite a few VAZ-2110 owners, believe that when repairing the front suspension, you should first of all pay attention to the levers, beams and shock absorbers. Such inconspicuous and simple details as rubber silent blocks are often simply ignored. Nevertheless, it is these parts that ensure a reliable connection between the suspension arms .

Although silent blocks are not a consumable material, rubber tends to break down over time. Severe operating conditions, especially on roads with poor quality surfaces, also affect these parts. Failure of the silent block can cause friction between the metal parts of the suspension and their failure. Therefore, it is important to monitor the condition of these rubber suspension parts.

Diagnostics of silent blocks

If the silent blocks are badly damaged, the wheel begins to touch the fender liner.

In order to check the condition of the front beam silent blocks, you can proceed in two ways:

- The easiest way to diagnose the suspension is at a service station. Although some unscrupulous craftsmen may “discover” many problems, in the hope of getting more money for repairs.

- An experienced driver only needs to drive the car for several kilometers, listening to how the front suspension works, to understand what the problem is.

When listening to the suspension work, you need to pay attention to the following nuances:

- While driving, a characteristic squeaking of rubber is heard . These sounds may be barely audible, but their presence most often indicates wear of the silent blocks. In this case, the car is driven into a pit, and the rubber parts are checked for tears or cracks. If a silent block with a crack can still serve for some time, then the torn part should be replaced immediately.

- If characteristic metallic knocks appear in the area of the front suspension , you need to drive the car to the inspection hole as quickly as possible. As a rule, this indicates maximum wear of the rubber suspension parts.

If you delay replacing worn silent blocks, the front beam may fail, and in some cases it will have to be completely replaced.

Tips for choosing a mechanism, repair kit

Long-term operation of the mechanism after restoration or repair depends not only on the correctness of the work, but also on the quality of manufacture of the mechanism or repair kit.

If you purchase cheap products, it is likely that in the near future problems with the mechanism will arise again; the repair work performed will simply be a waste of time and money.

Therefore, the choice of mechanism or repair kit should be approached responsibly.

When replacing a steering mechanism, most car enthusiasts advise purchasing either a mechanism made by the manufacturer or a mechanism produced by SS 20, a company that produces components for domestic cars.

But car enthusiasts do not favor the mechanism produced by Fenox; very often they come across defective ones or quickly fail.

But when purchasing a new mechanism, you should inquire about the quality certificate and see if the packaging has marks from the quality control department.

Suspicious steering mechanisms, without any marks, even if it’s not worth taking the cheaper ones, as a rule, they immediately start knocking.

The same applies to restoration kits; often, a cheap repair kit can restore the functionality of a mechanism only for a short time.

Replacing the front lower arm silent block

To replace the lower arm bushing, you must first remove the arm itself. To do this, first unscrew the nuts of the extension, ball joint strut and stabilizer. The lever must be removed from the ball joint using a puller.

Lastly, the nut securing the lever to the body is unscrewed, the bolt is pulled out, after which the lever can be removed. After this, you should remove the stretch. Since it is already disconnected from the lever, all that remains is to unscrew the nut that secures it to the cross member. Lastly, the stabilizer is dismantled. It is attached to the arms via struts on both sides, so you can either unscrew it from the other side and start removing it, or unscrew the nut that attaches to the strut and remove the arm and brace later.

Having unscrewed the stabilizer from the arms, all that remains is to unscrew the nuts securing the body brackets and remove the stabilizer along with the bushings. After the necessary suspension elements have been removed, you can begin to replace the silent blocks according to the scheme described above.

Video on replacing the front lower arm silent block on a VAZ 2110 using a puller:

Carrying out replacement work

Again, watch the video on how to repair the steering rack on a VAZ 2110 with your own hands. This will make it easier to go through each stage.

Before pulling the steering rack off your VAZ 2110, treat all fastening joints with WD40 . Wait an hour and a half and repeat the procedure again. This must be done a day before the repair itself. This will make it easier for you to unscrew all connections.

Proceed in the following sequence:

- Before repairing the steering rack, your VAZ 2110 must be firmly fixed so that the car does not move.

- Place supports under the rear wheels.

- Put the car on the handbrake.

- Lock the steering wheel.

- Disconnect power from the battery.

- Place the car on a jack.

- Remove the front wheels.

- Buy a new boot for the rack in advance, as it will require replacement. Even if its condition is satisfactory, it is better to change it immediately.

- Unscrew the nuts from the ends.

- Remove your fingers from the strut levers. To do this you will need to arm yourself with a puller. It is mounted on the lever, the screw is tightened until it stops and the lever is hit with force with a hammer. In this case, be sure to hold the puller screw with a wrench.

- Unscrew the nuts from the clamps.

- Unscrew the bolt located in the passenger compartment on the steering floor near the floor.

- Pull the bar towards you using progressive and oscillatory movements.

- Please note that disconnecting the gear shank from the shaft is problematic. When the rail is just detached through the hole, tilt the assembly to the right side and remove the entire structure. Make sure the splines on the element are intact.

- Through the right hole on the body, remove the entire assembly.