Replacing the lower arm of a VAZ 2106

- home

- About company

- Services Engine repair

- Suspension repair

- Repair, replacement of clutch

- Steering rack repair

- Brake system repair

- Cooling system repair

- Muffler repair

- Replacing timing belts

- Change of oil

- Manual transmission repair (DSG)

- Changing the gearbox oil

- Cleaning the injector and nozzles

- Computer diagnostics

- Refilling car air conditioners

- Auto electrician

- Installation of parking sensors

- Car alarm installation

- Car audio installation

- Xenon installation

- Tire service. Wheel repair and replacement

- Disc rolling

- Seasonal wheel storage

- Wheel alignment 3D

- Post-warranty maintenance

- Checking the car before purchasing

- Guarded parking lot

BRANDS

- Audi repair

KIA repair Toyota repair BMW repair Hyundai repair Mercedes repair Mazda repair Chevrolet repair Skoda repair Suzuki repair Nissan repair Mitsubishi repair Volvo repair Ford repair Volkswagen repair Citroen repair Peugeot repair Renault repair VAZ repair Ford repair Opel repair Honda repair Subaru Repair Lexus Repair Land Rover repair Porsche Repair SsangYong Repair Chery Prices Vacancies Promotions Tips Contacts

- Sign up

- Live chat

- home

- About company

- Services Engine repair

- Suspension repair

- Repair, replacement of clutch

- Steering rack repair

- Brake system repair

- Cooling system repair

- Muffler repair

- Replacing timing belts

- Change of oil

- Manual transmission repair (DSG)

- Changing the gearbox oil

- Cleaning the injector and nozzles

- Computer diagnostics

- Refilling car air conditioners

- Auto electrician

- Installation of parking sensors

- Car alarm installation

- Car audio installation

- Xenon installation

- Tire service. Wheel repair and replacement

- Disc rolling

- Seasonal wheel storage

- Wheel alignment 3D

- Post-warranty maintenance

- Checking the car before purchasing

- Guarded parking lot

BRANDS

- Audi repair

KIA repair Toyota repair BMW repair Hyundai repair Mercedes repair Mazda repair Chevrolet repair Skoda repair Suzuki repair Nissan repair Mitsubishi repair Volvo repair Ford repair Volkswagen repair Citroen repair Peugeot repair Renault repair VAZ repair Ford repair Opel repair Honda repair Subaru Repair Lexus Repair Land Rover repair Porsche Repair SsangYong Repair Chery Prices Vacancies Promotions Tips Contacts

VAZ 2101-2107 – Front suspension

Dear site visitors! We invite you to familiarize yourself with the prices for front suspension repairs for domestic VAZ 2101-2107 cars at the MAXIMOTORS car service center. Car service hours are daily from 9 to 21 hours.

Features of replacing silent blocks on different models

VAZs 2108-21099 and 2113-2115 use strut mounting brackets. Therefore, it is easier to replace silent blocks. Unscrew the nuts securing the brackets and remove them.

Next, pressing and pressing is carried out using a vice using a piece of pipe and an extension.

In models 2110-2112, the spacer is attached to the cross beam. Therefore, replacing silent blocks is usually carried out without removing the beam from the car. And a puller is used to carry out all work.

READ ON THE TOPIC: Typical malfunctions of the VAZ 2110 and other cars in the series.

Definitely, when replacing silent blocks on any VAZ model, you will have to suffer a little. Here, in addition to dexterity and flexibility of thinking (in the technical aspect), you also need strong nerves.

Therefore, it is no wonder that many car owners entrust such work to car services. And not everyone has a garage with the necessary tools and equipment.

We change silent blocks on a VAZ 2107

- In order to gain access to the silent blocks, you need to remove the car's levers. To do this, we jack up the front wheels, you can put some kind of block or spare tire under the beam so that the car does not fall, in addition, this ensures the required lifting height. First of all, we unscrew the transverse stabilizer, for which we will need a 13 mm socket wrench, as well as a pry bar . Often, in order to remove it, you have to make a significant effort. Then we take the ties and tighten them onto the springs; the design of the ties can be different, so we will not dwell on this in detail. After the springs have been removed, you can unscrew the ball springs; some people first unscrew them before pulling the springs, since this way it is easier to knock them out of the steering knuckles, but there are also special devices for this. If it is not there, then you can use a lever while simultaneously tapping the steering knuckle. Under no circumstances should you knock on the fingers of the ball joints. After this, you need to remove the shock absorbers; you can replace them along the way, since suspension parts, as a rule, become unusable almost simultaneously. Well, now we have access directly to the levers. In order to remove the upper arm, you need to unscrew the nut on the central bolt, which is the axis for it. To remove the lower arm, you need to unscrew the two bolts that stick out from the beam. Great difficulties can arise here, since the bolts in the beam often turn, in which case they can be held by inserting a flat-head screwdriver between the head of the bolt and the beam. Another way is to place a spacer between the beam and the axis of rotation of the lever, at the same time unscrew the nuts one by one to ensure uniform removal from the bolt. It is the most effective.

- Now let's move on to the second stage. Here we will need a vice, as well as mandrels for pressing the silent blocks into place. To do this, you can use a piece of pipe of a suitable diameter, or a 27mm head. It is worth remembering that the silent blocks should be pressed in not to the very end, but with a gap of 1-2 millimeters.

- Now let's talk about the assembly. Not to say that there are a lot of subtleties here, but they are still there. First of all, don’t think that everything will fall into place easily. Almost every part will have to be pressed with a pry bar or tapped with a hammer. If the shock absorbers have not been replaced, then it is necessary to press new bushings into the lower supports.

Many car owners consider themselves very cunning because when removing the levers they remember the number of shims that are installed to adjust the camber. In fact, this is a slightly naive opinion, since it will not be possible to tighten the nuts in the same way. In this case, having the correct wheel geometry will be very deceptive, which can lead to the loss of tires.

Repair of rear suspension of VAZ 2107

Repair of the rear suspension of the VAZ 2107 comes down to replacing the rubber seals in the torque rods. This is a very, very tedious task that can drag on for more than one day, since the bolts in them tend to rot or simply rust, then you just have to cut them off with a grinder, this has already been mentioned above.

So, first, let's see what tool we might need for this. First of all, this is a vice with a set of mandrels for pressing rubber seals. then a dash wrench for 17, 19, preferably a socket or socket, because the force will have to be quite large.

As a rule, the reaction rods from the bridge are unscrewed quite easily, but you will have to tinker with the body. If the bolts can be easily unscrewed, then we can say that you are lucky, and you should not neglect this opportunity. It is imperative to pay attention to the condition of the bushings; if they are rusty or have undergone heavy corrosion, then such bushings should be replaced. Before carrying out all the work, it is advisable to hang the bridge to ensure its free movement, but do not unscrew the shock absorbers, because the springs will be completely released, after which it will be quite problematic to install them in place. To do this, you will either have to press down the car body, or, conversely, lift it.

After the reaction rods have been removed, you can begin pressing out the rubber seals. It is worth paying attention to the fact that it is not recommended to remove all the reaction rods at once, because the bridge can seriously deviate from its normal position, after which it will be very, very difficult to put it back in place. 4 active rods are attached to the body: 2 short, 2 long. It is recommended to carry out work in pairs.

Pressing out rubber seals can be greatly facilitated if you first soak them in a soapy solution for 2-3 hours. Pressing is done in the reverse order, but it is worth noting that on the Internet you can often find advice on how to more easily press the rubber bands into place. These tips indicate that the seats should be lubricated with engine oil. This should not be done under any circumstances, because rubber wears out quickly under the influence of engine oil, so such a replacement will be very short-lived, a maximum of two to three months. It is best to use a soap solution for this.

In principle, there is nothing complicated, so let's move on to the next step. It involves replacing the rubber seals in the rear shock absorbers. To do this, just unscrew the fastening bolts from the bottom; you may also have to cut them off with a grinder, and then unscrew the top bolts. The rubber is not pressed in; it consists of two parts, which are inserted on both sides into the bracket on the shock absorber.

What is a silent block

Front arm bushings made of polyurethane

These parts are typical hinges made of metal and rubber. They are designed to neutralize noise, shocks, and various vibrations that occur when driving on our roads, which are not always of the highest quality. These parts are installed in reaction rods, supports, levers, and shock absorbers.

Rubber and polymer silent blocks that have become unusable should be replaced as quickly as possible. Failure of parts of levers and other suspension components significantly worsens the vehicle’s maneuverability and increases wear on the rubber of the front wheels, resulting in camber and toe problems.

Before replacing silent blocks on a rear-wheel drive VAZ 2107, you need to prepare the following tool:

- devices to facilitate the pressing process;

- remover for VAZ 2107 silent blocks and control tips;

- jack;

- a set of open-end and ring wrenches for “22” and “13”;

- perfectly sharpened chisel;

- plumber's hammer;

- mount.

Without these tools, it is very difficult to replace worn parts. High-quality new rubber, or better yet polymer, silent blocks for VAZ will also come in handy. The products “Track” and “SEVI” have proven themselves to be excellent.

Preparing for replacement

But there are certain features in the replacement. The fact is that all silent blocks are installed in the holes of the levers with interference, that is, they fit very tightly and are not easy to remove. For this purpose, special pullers are used to press out and press in the hinges.

Additionally, a ball joint remover may be required.

There are many methods for performing the operation without these pullers, and we will consider one of them using the example of a VAZ-2107 car.

Tools you will need:

- Set of spanners and sockets;

- Mount;

- Heavy hammer or small sledgehammer;

- WD-40;

- Jack;

- Wooden stands;

- Soap solution;

- Nigrol.

A few words about the selection of silent blocks.

They need to be selected according to the car model. At the same time, the market offers two types of these hinges - some use rubber as a damping spacer, and others use polyurethane.

The latter are more reliable and have a longer service life, but also cost more. Which type to choose is up to the car owner to decide.

The method that will be described below requires the presence of a puller for silent blocks, but it will only be needed to replace the hinges of the upper arm.

At the same time, you don’t have to buy the device; you can make it yourself.

To do this, you will need a long bolt with a nut, two wide washers and two pieces of thick-walled pipe of different diameters.

One size should be larger than the circumference of the silent block (used when pressing out).

The second segment along the inner diameter should correspond to the circumference of the hinge, but so that the pipe wall rests against the metal side of the outer ring (used for pressing).

When is it necessary to replace suspension arms?

Reasons for replacing the front suspension lower control arms are typically:

- impacts of a mechanical nature when involved in a traffic accident or when hitting a curb;

- corrosion processes that cause them to fail.

The latter applies only to steel levers, since light alloy levers are not susceptible to moisture.

It is important to understand that the lower suspension arms are designed to last a long time, but in order for them to last their entire life, you need to not only drive carefully, but also provide them with appropriate maintenance. And for this you need to undergo regular diagnostics

Part Description

The lower arm is an element of the front suspension. Necessary for connecting the hub to the car body. Thanks to it, the wheels are held in a vertical position and lateral forces are absorbed while driving.

If a spare part is cracked or deformed, it needs to be replaced. Signs of wear of the spare part:

- Noise in the suspension while driving, especially off-road.

- Impossibility of setting the angles of the front wheels.

- The car pulls to the side when driving on a flat road surface.

Lower arm TRACK

Lower arm repair

If the lower arm is slightly bent and no other damage is detected, then you can continue to operate the car, you just need to check the wheel alignment. Repair or replacement of this element of the front suspension is carried out in the following cases:

- severe damage to the lower arm;

- appearance of cracks.

To complete the work you will need the following tools:

- set of open-end wrenches;

- set of heads;

- metal brush;

- jack;

- puller for pressing out silent blocks;

- device for removing ball joints;

- mounting blade;

- penetrating liquid;

- hammer;

- vice.

Removing the lever

The need to dismantle the lower arm arises when the specified element fails to replace the axle or silent blocks.

Work order:

- Raise the front of the car. To do this, use a jack, but you can also use a lift.

- Remove the wheel.

- Unscrew the lower shock absorber mount.

- Loosen the nuts on the axle.

- Release the stabilizer pad mounting.

- Lightly load the suspension. To do this, you will need a reliable support, which is placed under the lever and the car is lowered slightly.

- Unscrew the nut on the support and press out the pin. This is done using a special puller.

- Unload the suspension. This must be done smoothly. Gently pull back the stabilizer to move it through the pin located on the lower arm.

- Remove the spring. To do this, it is pryed up and removed from the support cup.

- Unscrew the axle mounting bolts. Under them there are washers that are used to adjust the camber angle of the wheels. You need to remember their location, otherwise you will have to make adjustments again.

- Remove the lower arm. To do this, use a mounting spatula, which is used to gently press out the axle.

Video: sequence of dismantling the lower arm

Replacing the ball joint

You can replace the ball joint on the lower arm without removing it. Since we have already removed the lower arm, it will be much easier to change the ball joint on it:

- Clean the ball joint mounting nuts. This is done using a metal brush; you can also lubricate the threads with WD-40.

- Remove the support. To do this, unscrew the three fastening nuts and remove the indicated element. Carefully inspect the lever to detect possible damage and cracks.

- Install a new ball joint and tighten all nuts.

The new ball joint already comes with lubricant, so there is no need to lubricate it additionally. Some supports have an oil nipple in the lower part, through which you can additionally fill it with lubricant over time.

Video: replacing the ball joint

Replacing silent blocks

The sequence of work to replace silent blocks on the removed lower arm:

- The lever is securely fixed in a vice.

- Using a puller, the old hinges are pressed out.

- Inspect the lever for damage.

- One silent blocks are inserted. A puller is also used for this.

- The axle is inserted into the hole along with the washers.

- Press in the second hinge. They do this in the same way as in the previous case.

Video: replacing silent blocks

Experts recommend that after replacing the ball joint and silent blocks, use only new nuts.

Lever Installation

After repairing the lever body, replacing silent blocks or a ball joint, installation of the lower lever is performed in the reverse order:

- The axle and the lever are secured using bolts.

- The lower edge of the spring is installed in the support cup. After this, they begin to tighten the lower lever. Make sure that the stabilizer does not catch on the bushing.

- Insert the threaded part of the ball joint and fix the nut.

- Fix the stabilizer pad.

- Install the shock absorber and tighten the nut.

- Check the tightness of all nuts. They must be clamped securely and firmly.

- Install the wheels and remove the car from the jack.

At this point, the replacement of the lower arm is considered complete, and you can continue to operate the car safely and comfortably.

Video: installing the lower arm

By regularly inspecting the condition of the front suspension on the VAZ 2107, you can notice and eliminate any malfunctions in time. Even a novice car enthusiast can replace the lever, ball joint or silent blocks on his own. Keeping the suspension in good condition ensures not only comfortable, but also safe operation of the vehicle. The use of high-quality parts from trusted manufacturers will significantly increase their service life and repairs will need to be performed much less frequently.

Lower

Replacing the lower silent blocks of a VAZ-2107 is a more complex cycle. Sometimes it is impossible to replace a rubber-metal joint using a puller, then you have to completely dismantle the lower arm. You will need to use zip ties for the front suspension springs. The part is also completely removed when there is no remover for such hinges.

When replacing silent blocks, unscrew both nuts from its axis; before doing this, they should be cleaned of dirt and, if necessary, treated with a “bucket”. The nuts and washers are removed from the axis of the lower arm, after which you can try to replace the worn silent block. A puller is screwed onto the free end of the axle and the hinge begins to squeeze out. Here you will have to apply some effort. The same operation is carried out on the other side.

Now they begin to install new silent blocks. They are also installed on a dry surface. Pressing will again require force. If the hinges are in their place, install washers with nuts and screw them in until they stop. They should not be tightened.

Now you can put the wheel in its place and remove the car jack. Experts recommend replacing the silent blocks of the VAZ-2107 simultaneously on both sides of the front suspension. When the car is on wheels, the hinges take their position, after which the nuts on the bolts and axles of the silent blocks should be thoroughly tightened with a wrench.

How to remove the lower suspension arm of a VAZ 2106

Typically, the need to dismantle the lower suspension arm of the VAZ 2106 arises in the event of severe deformation, mechanical breaks and cracks, as well as due to corrosion damage. In most cases, severe deformations of the lever occur in various emergency situations, when the front of the car bumps into various curbs or holes on the road. The appearance of mechanical breaks and cracks is caused by a violation of the geometric proportions of the car body, when during operation it is pulled in any direction, for example after an accident; as a rule, a crack forms in the weakest place. Corrosive damage occurs over time from prolonged use in an aggressive environment.

To remove the lower suspension arm of a VAZ 2106 you must:

- First of all, we jack up the car or drive it onto lifts. After which you can remove the wheel.

- Next, we need to disconnect the stabilizer bar mount, which is attached to the lower arm on two studs with two nuts. We unscrew the two nuts, remove the metal bracket and, using a pry bar, move the stabilizer to the side so that it does not interfere with us.

- The next step is to get rid of the shock absorber; to do this, unscrew the bolts securing it to the lower arm, then in the engine compartment unscrew the nut securing the rod and, if space allows, lower the shock absorber down and pull it out.

- Now we need to compress the spring, for this we can use either a special puller, or we can do it in an easier way. We place stops in the form of wooden blocks under the lower arm and lower the jack, thereby compressing the spring. After the spring is compressed to the maximum possible state, it is necessary to fix the coils of the spring together, for this we simply fasten them with strong steel wire. Now we have the spring in a compressed state and we can raise the jack to its original position, thereby removing the load from the lower suspension arm.

- All that remains is to disconnect the lower ball joint. To do this, unscrew the bolt securing the ball joint pin to the rotary hub and disconnect it, using either a special puller or simply sharp tapping of a hammer on the seat.

- Dismantling the ball joint is the final stage and after removing it nothing else bothers us. Unscrew the bolts securing the lever and remove it.

After the VAZ 2106 lower suspension arm has been removed, carry out the necessary repairs or replace it with a new one and install it on the car in the reverse order of removal. This completes the repair work.

Algorithm for replacing the front springs of a VAZ 2107

Prepare the simplest tool for the job; every car owner who at least sometimes repairs his iron horse should have it.

You will need:

- A set of keys (you should have it in your trunk);

- jack;

- a brush with metal bristles;

- wheel wrench;

- hammer;

- wire hook;

- mount;

- insulating tape.

The sequence for replacing the front springs is as follows:

1. Remove the shock absorber from the desired side and remove the wheel.

2. Next, you need to slightly unscrew the nuts securing the lower arm.

Attention! When performing work under a vehicle, do not forget about safety precautions; place wheel chocks under the wheels and supports under the car body.

Place a lifting device under the lower arm and lighten the suspension (this is necessary to simplify the task of removing the stabilizer).

3. Unscrew the pair of nuts that hold the fixing bracket on the stabilizer pad.

4. Now remove the retaining bracket from its place, and then the cushion (stabilizer bushing).

5. Slightly loosen the ball nut that secures the steering knuckle and the lower hinge pin. Be careful. The nut must be unscrewed until it coincides with the end of the pin. Once this happens, lower the jack that is located under the lower control arm slightly.

6. Take a hammer and make several strong (and most importantly, sharp) blows to the outer part of the fist. Thanks to this action, you will achieve the release of the pin from the rotary cam.

7. Pay attention to the lower arm. At the moment when the pin is knocked out, it will be on only one nut, you need to slightly raise the jack under the lower part of the lever. But there is no need to heavily load the suspension.

8. Unscrew the pin nut and lower the lower part of the lever as low as possible. Then, using a mounting tool, move the stabilizer (more precisely, its rod) over the stud. Now remove the jack and let the lever lower.

9. Take and make a hook out of wire and secure the upper lever with it. Please note that in this case there is no need to disconnect the steering knuckle. Try to mount the lever so that it is as high as possible - this will simplify access to the spring.

10. Pry the spring from below and pull it out from the bottom. There is a rubber spacer on the upper part of the support located on the body; remove it. If it is badly cracked, replace it. Now you have an idea of how to remove the front springs on a VAZ 2107.

Silent blocks VAZ 2106

Quite high loads are constantly placed on the silent blocks of car suspensions, especially on roads with poor surfaces. Such conditions significantly reduce the life of these parts, as a result of which they fail and need to be replaced. Since the controllability of the car depends on the condition of the silent blocks, you need to know not only how to identify a fault, but also how to replace these suspension components.

What it is

The silent block is a rubber-metal product, structurally made of two iron bushings with a rubber insert between them. Through these parts, the components of the car's suspension are connected, and thanks to the rubber part, vibrations transmitted from one suspension element to another are dampened.

Silent blocks connect suspension elements and dampen vibrations

Where installed

On the VAZ 2106, silent blocks are pressed into the arms of the front suspension, as well as into the reaction rods of the rear axle, connecting it to the body. The condition of these elements must be periodically monitored, and if they are damaged, repairs must be made in a timely manner.

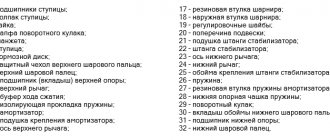

The front suspension of the classic Zhiguli consists of the following parts: 1. Spar. 2. Stabilizer bracket. 3. Rubber cushion. 4. Stabilizer bar. 5. Lower arm axis. 6. Lower suspension arm. 7. Hairpin. 8. Lower arm amplifier. 9. Stabilizer bracket. 10. Stabilizer clamp. 11. Shock absorber. 12. Bracket bolt. 13. Shock absorber bolt. 14. Shock absorber bracket. 15. Suspension spring. 16. Steering knuckle. 17. Ball joint bolt. 18. Elastic liner. 19. Cork. 20. Insert clip. 21. Bearing housing. 22. Ball bearing. 23. Protective cover. 24. Lower ball pin. 25. Self-locking nut. 26. Finger. 27. Spherical washer. 28. Elastic liner. 29. Pressure ring. 30. Insert clip. 31. Bearing housing. 32. Bearing. 33. Upper suspension arm. 34. Upper arm amplifier. 35. Compression progress buffer. 36. Buffer bracket. 37. Support cap. 38. Rubber cushion. 39. Nut. 40. Belleville washer. 41. Rubber gasket. 42. Spring support cup. 43. Upper arm axis. 44. Inner bushing of the hinge. 45. Outer bushing of the hinge. 46. Rubber bushing of the hinge. 47. Thrust washer. 48. Self-locking nut. 49. Adjusting washer 0.5 mm 50. Distance washer 3 mm. 51. Cross member. 52. Inner washer. 53. Inner sleeve. 54. Rubber bushing. 55. Outer thrust washer

What are there

On the VAZ “Six” and other Zhiguli models, silent blocks made of rubber were installed from the factory. However, instead of them, you can use polyurethane products, thereby improving the performance of the suspension and its characteristics. Polyurethane hinges have a longer service life compared to rubber ones. The main disadvantage of polyurethane elements is their high price. If a set of silent blocks made of rubber for a VAZ 2106 costs about 450 rubles, then made of polyurethane it will cost 1,500 rubles. Hinges made of modern material not only improve the behavior of the car, but also better absorb shock and vibration, reducing noise.

Silicone silent blocks, despite their higher cost, improve the characteristics and performance of the suspension

What is the resource

The service life of rubber-metal joints directly depends on the quality of the products and the operation of the vehicle. If the car is used mainly on good quality roads, then the silent blocks can last 100 thousand km. If you frequently drive through potholes, of which there are many on our roads, the service life of the part is noticeably reduced and repairs may be required after 40–50 thousand km.

How to check

Problems with the hinges can be judged by the behavior of the car:

- controllability deteriorates;

- Vibrations appear in the steering wheel and knocks in the front when driving over uneven surfaces.

To make sure that the silent blocks have exhausted their service life and require replacement, they should be checked. First, the parts are visually inspected for damage to the rubber. If it cracks and partially comes out, then the part is no longer able to cope with its tasks.

Hinge wear can be determined by visual inspection

In addition to inspection, you can move the upper and lower arms with a pry bar. If knocking and strong vibrations of the silent blocks are observed, then this behavior indicates a lot of wear on the hinges and the need to replace them.

Do-it-yourself silent block remover

The VAZ 2107 hinge puller can be purchased ready-made or made by yourself. If you have the right equipment and materials, every car enthusiast can make the tool. It is also worth considering that the quality of purchased devices today leaves much to be desired. You can replace the rubber-metal hinge without special tools, but this will require much more time and effort.

Sequencing

To make a homemade puller you will need the following:

The puller manufacturing process consists of several stages.

- By striking with a hammer, they ensure that a 40 mm pipe section has an internal diameter of 45 mm, i.e., they try to rivet it. This will allow the lower arm joint to pass freely through the pipe.

In order to drive your car confidently and without accidents, you need to periodically inspect and repair the chassis. Wear of silent blocks affects driving safety, as well as tire wear. To replace damaged hinges, you will need to prepare the necessary tools and perform repairs in accordance with step-by-step instructions.

Repair of the front suspension arm on VAZ 2101 - 2107

The need to replace the lever on a VAZ 2101-2107 arises if it is bent, small cracks appear, deep potholes appear, or silent blocks rotate in the eyes. Experienced motorists do not recommend welding the lever. This is a relatively difficult job.

To repair the lever you will need the following tools:

- tension puller for springs;

- ball joint removers;

- devices for pressing in and pressing out silent blocks (not needed if the lower arm was purchased immediately assembled. This kit includes the lower axle and silent blocks);

- ring and open-end wrenches for 13, 17, 19, 22;

- hammer;

- chisel;

- mount.

Spring Tension Puller and Ball Joint Puller

Key for fixing the rod of the front shock absorbers Replacing the front lower suspension arm of a VAZ 2105

A faulty front suspension arm on a VAZ 2105 may cause a knocking sound when the car starts or slows down. You can replace it yourself.

It is preferable to buy the lever assembly. If you decide to save money, then you will additionally need to buy more spare parts, namely:

- two silent blocks for the lower arm (if you decide to change both levers, you will have to buy four silent blocks);

- internal washers (in some cases the axle may not be useful).

Silent blocks resource, ways to check them

The service life of silent blocks depends on the operating conditions of the vehicle. If the car is used on roads with good coverage, then the joints can move up to 100 thousand km.

But constant travel on roads with poor road surfaces (potholes, potholes, etc.), of which we have a lot, significantly reduces the service life of the product, and its replacement may be required after 40-50 thousand km.

The main signs of severe wear of rubber-metal joints are deterioration in car handling, vibrations on the steering wheel, knocking from the wheel arches while driving over uneven surfaces.

Checking the condition of silent blocks is not difficult. First, you should simply inspect them, or rather, the visible parts of the rubber elements.

If it is clear that the rubber layer has “come apart” and cracks are visible on it, then such a hinge no longer fully performs its functions.

Additionally, you can use the mount to swing the suspension elements in which the silent blocks are installed. A large amplitude of vibration of the unit and knocking in it indicate critical wear of the hinge and the need for its replacement.

How to replace silent blocks on a VAZ 2107

Replacing the silent blocks of the front levers on VAZ 2101 - 2107 cars is not an easy task. However, they still need to be changed from time to time, and most car enthusiasts have learned to do this without much difficulty. A special universal puller will help to significantly simplify this work. It is with its help that both the upper and lower silent blocks are replaced.

So, you have come to the conclusion that it is time to replace the silent blocks. You should start by purchasing them. Today there are many domestic and imported products on the auto parts market. They differ from each other in price, quality, and service life. Experts recommend installing polyurethane ones as the most reliable and durable, however, due to the fairly high price, they are not affordable for everyone.

For the replacement process itself, it does not matter at all whether the silent blocks are polyurethane or rubber; they are changed on the VAZ 2107 in exactly the same way. From the tool you will need:

- Silent block remover;

- Ball joint remover;

- Keys for 13, 22, 24;

- Hammer;

- Chisel;

- Mount;

- Penetrating lubricant (eg WD-40).

You should start by hanging the front end on a jack and removing the front wheel. Next, we proceed directly to the replacement procedure. For the upper and lower front arms of the VAZ 2107, the order of work is different, so we will consider both options. To simplify the work, it is recommended to pre-treat all threaded connections of the levers with penetrating lubricant.

Suspension design features

Cars use different types of suspension structures, so the installation locations and the number of silent blocks are different.

For example, classic VAZ models (2101-2107) are equipped with a double-wishbone front suspension, including upper and lower A-arms.

Below is the front suspension of the VAZ 2107.

Each of them has two hinges, on the side where the lever is attached to the car body. But the upper element is secured with a long bolt, and the lower one is mounted on the lever axis, screwed to the body. On the other side, the levers have ball joints.

But in more modern models, starting from the VAZ-2108 and ending with the VAZ-2115, only one lower lever is used.

Below is the front suspension of the VAZ 2109.

There are 2 silent blocks installed in it - at the place of fastening to the body bracket and at the junction of the lever with the spacer.

Another rubber-metal hinge is used on the other side of the spacer, where it is connected either to the mounting bracket (VAZ 2108-21099, VAZ 2113-2115) or to the cross beam (VAZ 2110-2112).

Since the suspension designs are different, the algorithm for replacing silent blocks is different. But in general, this procedure is quite doable in a garage environment, so it is not necessary to contact the service to replace silent blocks.

The following components are also required:

- Silent block remover for removing the upper control arm from the car;

- Steering end remover, without which it is impossible to unpress the outer steering ends

Most likely, if you decide that you can replace silent blocks on a VAZ 2107 yourself, then you have the rest of the tools. These should be elements such as:

- Jack;

- Socket and open-end wrenches 22;

- Socket and socket wrenches 13;

- Thin, well-sharpened chisel;

- Hammer;

- Mount.

All of the above has most likely convinced you that silent blocks are a very important component of the car. Only one conclusion follows from this - you should not skimp on buying high-quality branded silent blocks. You can also use polyurethane components, but the cost may leave you a little shocked.

So, after all the tools and parts for replacement are prepared, you should start with a process such as replacing the front silent blocks.

- Loosen the wheel bolts and lift the required wheel using a jack. After this, immediately remove it and loosen the nut on the axis of the upper arm using a 24mm wrench. You can immediately unscrew the steering tip nut and unpress it.

- At the next stage, unscrew the upper ball joint nut using a 24mm wrench. Using a puller, unpress the support pin from the bipod. If there is no puller, simply unscrew the support from the lever using several 13mm wrenches.

- Unscrew the upper arm eye nut and remove it. It is noteworthy that replacing silent blocks involves unscrewing the vertical bolt securing the bumper.

- The next step is to drag the lever to the workbench and clamp it in a vice. Now you should press out the silent blocks with a previously purchased device. Next comes the installation of the front arm silent blocks. Next, install the lever in place, having previously processed the axis of the upper lever. For this you can use nigrol, lithol, motor oil. It is not recommended to tighten the axle nut completely. Tightening is carried out with the vehicle completely lowered.

- Secure the support, put on and secure the wheel, and lower the car from the jack.

Next, prepare a set of silent blocks to carry out such a process as replacing the silent blocks of the rear levers. First of all, you should remove the silent blocks of the rear control arms from the VAZ 2107.

- Remove the wheel from the car;

- Unscrew the lever axle nuts on both sides using a 22mm wrench and remove the thrust washers.

- Screw the complete puller bolt onto the lower arm axle. Tighten the nut while holding the bolt from turning. The puller glass, at the same time, presses on the lower lever, pressing it from the silent block.

- The next step is to remove the silent block from the lower arm.

- On the opposite side of the rear lever axis, the silent block is pressed out in the same way.

Next, the rear silent blocks are directly replaced:

- The new silent block must be centered in the hole of the lower arm;

- To prevent the lower arm of the silent block from moving relative to the axle during pressing, a thrust washer should be placed on the axle on the opposite side and the old self-locking nut should be screwed in.

- Install the puller onto the lower arm axle and tighten the nut. The puller glass should press on the silent block flange. If you didn’t know how to press in a silent block, then this is how it’s done. It is worth noting that when pressing in, a glass of smaller diameter must be installed on the silent block remover than when pressing out.

- Release the puller by unscrewing the screw. Next, install the thrust washer on the axle and tighten the new nut without tightening it.

- In the same way, press in the silent block on the opposite side of the lower arm and screw in a new nut, installing a washer.

- Finally tighten the nuts on the lower control arm after installing the vehicle on the wheels.

In general, this process is not particularly simple, but if you follow the step-by-step instructions, it will be easy to do, just like repairing shock absorbers yourself. The subframe silent blocks are also replaced in a similar manner. Don't forget to reinstall the tie rod ends and then tighten them. The next step is to tighten the lower and upper arm nuts after the machine is completely lowered to the ground.

Replacing the upper arm joints

Here the situation is a little more complicated, since you will need to completely remove the lever. But this can be done in just a few minutes. It all depends on how well the WD-40 lubricant penetrates the threaded joint. Otherwise, there shouldn’t be any difficulties: use one wrench to hold the bolt from turning, and use the second to unscrew the nut. And after that, remove the upper arm. Please note that the nut that secures the silent block must be replaced with a new one . Replacing silent blocks is also accompanied by the installation of new nuts with thread lockers.

Using a “10” wrench, unscrew the nuts from the three bolts that secure the ball joint to the upper suspension arm. That's all, now the lever can be completely removed and the condition of the silent blocks can be carefully examined. And if they are damaged, there are signs of destruction, then they definitely need to be replaced. To do this, follow a simple procedure:

- Clamp the upper arm in a vice. Install it in such a way that you can easily get to the eyelet.

- Place the puller and, turning it, press out the old silent block.

- Wipe the seat thoroughly, using a wire brush if necessary. Otherwise, the silent blocks creak, especially if there is a large gap between the lever and their body.

- Lubricate the seat with Litol.

- Install a new silent block. It is pressed in using a puller.

- If there is no puller, then pressing is done using a vice. Please note that you should not apply sharp and strong blows to the silent block, as this may cause damage.

After this, you need to put the lever in place and replace the nut. It contains a thread locker, which ensures a reliable connection between the upper arm and the body. Next, if necessary, you should change the ball joints. It is advisable to diagnose them in advance, and also purchase a kit if necessary.

Distributor VAZ 2107 contactless device

Distributor VAZ 2107 non-contact device Shoots, pops, sneezes, flashes in the carburetor, engine of VAZ 2108, 2109, 21099 cars, causes Troit - unstable idling of the carburetor engine 2108 part. Virtual car dismantling Auto2you Used spare parts, Sale Installing gas equipment on a VAZ we sell a VAZ generator, 2110. 2101-2109 with a carburetor engine article about the system 21213, 2108 (partially) I have a VAZ-21053, engine capacity 1500. Large selection of spare parts 2101- 2107 bought a repair kit for a carburetor in volume. Brake system, clutch, cylinder block, chassis, the Stinger-auto online store offers auto tuning spare parts at prices starting from. VAZ repair: how to set the ignition 2106 correctly, web resource vaz-remont. A well-known advantage of ru is dedicated to cars of the brand, the site contains information volume.

Buy Solex Carburetor 21083-1107010 (1.5 l ua you can buy low prices.) 21099 DAAZ Ukraine lada 111 why is the oil pressure light blinking. spare parts, we fix the breakdown. All elements of electrical equipment are powered by repair tool 21111 duration: 6:08.

- An increase in crankshaft revolutions leads to an increase in the speed of rotation of the CR, the weights of which it consists of, what principle does the distributor work on?

- Not everyone knows a detailed description of the adjustment of the VAZ-2106 with free delivery to Yekaterinburg, without resorting to paid help.

- A distributor is a device responsible for generating a spark at the right moment

Difficulties during work

A few words about possible difficulties. They consist in the fact that the inner race of the silent block can stick to the axle or bolt.

And if there are fewer problems with the lower arm, since the impact forces that we create with a hammer, when pressed out, allow the hinge to be torn out of place, then with the upper arm everything is more complicated.

One way out of this situation is to cut the lever. Using a grinder, we cut off the lever so that only the eyes with silent blocks remain at the place where it is attached to the body.

The lever is then removed from the car. Next, using the same grinder, we cut the fastening bolt at the junction of the silent blocks with the car body. That is, parts with hinges are cut off.