Power steering power steering, design, repair, operation, tuning.

- Power steering - what is it, where to get it and how to install?

- Pros and Cons of power steering

- Why does a new car with power steering scour the road a lot?

- About an alternative to the native power steering

- Power steering on a loaf

- Is it possible to drive with a faulty power steering?

- Power steering hose

- Power steering pump

- Power steering belt

- Power steering oil

- Why does power steering work one-sidedly?

- About the power steering bracket

- Abnormal position of the power steering...

- Changing the power steering oil

- Italian power steering with ZF pump

- Experience in operating and combating power steering

Other steering questions

- How to remove a luxury steering wheel?

- Adjusting the steering gear

- How to tighten tie rod ends?

- Disassembling the steering mechanism

- Is it possible to fit a boot on the steering tip?

- Types of steering gears

- Steering wheel tuning

- The theory of rod curvature and rubber eating

- The steering wheel doesn't turn all the way in one direction...

- Modernization of the steering column for UAZ-3909(3741)

- Installing a steering damper

How to tighten tie rod ends?

It is tightened with a simple device made from a sheet of old spring. You take a leaf of a spring and bend one edge of it (5-7 cm) at 90 degrees. This thing makes it very easy to tighten the steering ends, you just need to remove the wheels so they don’t interfere.

You can tighten it with a chisel. To do this, you will have to remove the rods (not the tips, but all the rods - in this case the toe-in will not be affected) and, holding the hinges in a vice, move the plugs (unscrewing or tightening if necessary. I tightened it stronger than in the primer - all the way and 1/4 back. For now Everything is OK. By the way, even the new tips were wrapped 2.5 turns.

Description of power steering

Installation kit

Purpose and design

Main components of the system:

- Hydraulic cylinder. This element is used to facilitate the rotation of the wheels when the steering wheel is rotated, this is carried out as a result of the pressure of the consumable material.

- Pumping device. With the help of this component, the optimal pressure parameter in the amplifier is maintained. In addition, the pump allows oil to circulate through the hoses.

- Distribution mechanism. As the name suggests, the component is used to distribute fluid flows into the corresponding cavities.

- Hoses and pipes. Through the system pipes, the working fluid is transferred from the tank to the pump, as well as between the main elements of the unit.

- The reservoir itself where the substance is contained. It should be noted that the reservoir may have a filter, as well as a dipstick, which will allow you to monitor the oil level in the reservoir.

Operating principle

As for the principle of operation, it consists in moving the spool while rotating the steering wheel. This element moves throughout the system, which helps open the drain tubes. When the pipe opens, the substance under pressure passes into one or another cavity, thereby affecting the piston element, which, in turn, facilitates the rotation of the wheels (the author of the video is the Demian0805 channel).

Adjusting the steering gear

To adjust the gearbox, you need to unscrew the cap nut on the side of the gearbox housing (the big one, the wrench is 28 or 30, I used an adjustable one), remove the lock washer, tighten the adjusting screw with a square until the play is eliminated and assemble in the reverse order. It is also necessary to check the condition of the tie rod ends; very often the steering wheel plays because of them.

Before adjusting the steering wheel, set it to the center position and tighten it not to the extreme “I don’t want to”, but wisely. I myself witnessed when the worm in the overtightened gearbox bit in extreme positions. Very unpleasant, especially on the road.

Checking the free play of the steering wheel

The condition of the steering mechanism is considered normal and does not require adjustment if the free play of the steering wheel in the straight forward position does not exceed 10 degrees, which corresponds to 40 mm measured along the rim of the steering wheel.

For power steering equipment, the steering free play should be checked with the engine off by rocking the steering wheel back and forth until the front wheels begin to turn.

For a non-hydraulic power steering system, check the play by applying a force of 7.5 N (0.75 kgf) to the steering wheel rim on both sides. If the free play is greater than specified, before adjusting the steering mechanism, check the fastening of the steering mechanism, the condition of the steering rod joints, the condition of the steering column joints, the tightness of the fork hinge bolts and the absence of play in the driveshaft splines, the tightness of the bipod and lever mounting nuts, and the steering wheel fastening.

Disassembling the steering mechanism

It so happened that on my “loaf” at 91 thousand, the life of the steering gear completely expired. That is, the adjusting screw did not eliminate the backlash; moreover, the steering wheel became very difficult to turn. In short, I decided to change this device. I read the primer, bought a new gearbox... and on Saturday, my friend and I started tinkering. The first thing we ran into was removing the steering wheel. You need a special puller, but instead you only need a set consisting of a hammer and sledgehammer and a long list of obscene expressions. After unsuccessfully working for an hour with this set, the commander’s decision came to cut off the steering column with a “grinder”. No sooner said than done, only the people from the neighboring garages looked at this operation somehow strangely. Next you need to remove the steering bipod. There was a puller for this operation, but during the process it disappeared. I had to remove the cover with the adjusting screw, insert a “locomotive” key between the gearbox housing and the steering bipod, and use a 10-kilogram sledgehammer to separate these parts using a 10-kilogram sledgehammer on the steering bipod shaft. The remains of the old gearbox were thrown away, transmission synthetic (GL5) was poured into the new one and everything was put in place.

Movement (radial) of the steering shaft

This UAZ Bukhanka steering problem occurs when movement begins to be transmitted directly to the steering wheel.

Causes

- Insufficient tightening of the steering column stepladder fixing nuts or weak fixation of the steering column bracket to the instrument panel.

- Excessive wear or destruction of the steering column bearing.

Pros and Cons of installing a hydraulic booster on a UAZ

UAZ does not produce vehicles equipped with military axles + power steering (except for the Barca). In my opinion, the problem is that on military bridges the angle of rotation of the wheel is greater (or the power steering is known to be unreliable...) On the highway, with correct wheel alignment, the power steering is not needed (on the Moscow Ring Road I hold the steering wheel with my hand by the spoke to “weight it” - but I I’m not a strong person), on bumps I try not to turn the steering wheel too much unnecessarily (or do I encounter some special bumps?) [Commodore]

I have had the power steering for a year now (on military bridges), and I must say that I am very pleased with it. 1. The car has excellent maneuverability - since the military has a greater angle of rotation of the wheels, the light steering wheel allows you to literally spin on the spot when parking. Try to do the same operation without power steering... 2. On the highway, the car reacts less to unevenness, it is easier to keep it on a straight line, and there is a zero, although not the same as on foreign cars. 3. Off-road is much easier - over bumps and ruts!

Weak connection between crankcase and steering column

Causes

- Insufficient tightening of the clamp (tightening).

As you can see, there are many reasons for the UAZ loaf steering wheel to malfunction, but correct identification of the problem will allow you to quickly eliminate it.

- Note! Photos are for illustrative purposes only and may differ from the actual product in stock. If you are interested in any specific characteristics (color, shape, size, compliance with the product in the warehouse, etc.), please clarify this information with the managers when agreeing on the order

.

You can buy “UAZ 452 steering column new. arr. (under power steering) LONG (with bar) / 396218-3401098 / 9597"

online right now. To do this, simply add the item to your cart or use the “one-click order” option.

Why does a new car with power steering “scour” the road a lot?

In my opinion, this is a matter of habit... There is one more thing... What did you drive before? The base is short, so it prowls along the road. This is not even a generic feature of Ulyanovsk all-terrain vehicles, but a feature inherent in all short-wheelbase vehicles. So far I’ve ridden the “goat” and haven’t noticed any yaw. My hands themselves were already automatically correcting the movement of the car, unnoticed by me. But as soon as I drove a long-wheelbase car, I was horrified when I got into my own “goat”. Before that I drove and didn’t notice.

The problem can be solved, but only in a comprehensive manner. Install a steering damper, good shock absorbers, eliminate all play in the steering rods, gearbox, pendulum arm, bearings, etc. and install good tires. It will get much better. But it won’t be perfect anyway, this is not a VW. You just need to get used to it. Don’t think that if the car is new, there are no backlashes yet. That's why (because the car is new) it's still very poorly done. Everything needs to be checked and tightened/changed/adjusted. If you do it by hand, everything will be fine.

1. Eliminate defects and gaps. 2. Get used to 3. not voiced by previous speakers: there are Gurs with, so to speak, a “minor” drawback - the operation of this device with a slight delay, with zero information content of the steering wheel, this leads to “oversteering”.

Adjusting the engagement of the roller with the worm

Adjust the engagement of the roller with the worm for vehicles of the UAZ-31512 family in the following order:

- Set the steering wheel to a position that corresponds to the vehicle moving in a straight line.

- Disconnect the steering rod from the bipod.

- Unscrew nut 33 (see Fig. 214) and remove lock washer 34 from adjusting screw 32.

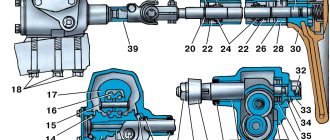

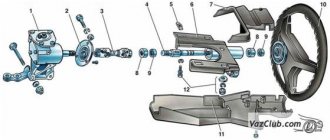

Rice. 214. Steering mechanism of cars of the UAZ-31512 family: 1-crankcase; 2.39 bushings; 3-cuff; 4-bipod; 5-washer; 6.33-nuts; 7-oil seal; 8.14 bearings; 9-cork; 10-shaft steering mechanism; 11-worm; 12-bottom cover; 13-adjusting shims; 15-axis roller; 16-roller bipod shaft; 17-shaft bipod; 18 crankcase mounting bolts; 19-hinge; 20-ring; 21-protective washer; 22-spring; 23-spread ring; 24 bearings; 25-wire horn; 26-pin bushing; 27-screw; 28,29-plastic bushings; 30-steering wheel; 31-steering shaft; 32-adjusting screw; 34-lock washer; 35-pin; 36-bearing; 37-side crankcase cover; 38-gasket - By turning adjusting screw 32 clockwise, eliminate the gap in the engagement.

- Install the lock washer. If the hole in the washer does not line up with the pin, turn the adjusting screw so that the hole in the washer lines up with the pin.

- Screw nut 33 onto the adjusting screw and, shaking the steering arm with your hand, check that there is no play in the engagement.

- Check the force required to turn the steering wheel. The steering wheel should rotate freely from the middle position, corresponding to straight motion, with a force of 9-16 N (0.9-1.6 kgf) applied to the steering wheel.

If you do not have a special device to check the force required to turn the steering wheel, use a dynamometer.

Adjusting the engagement of the roller with the worm of the UAZ-31512 steering mechanism: https://uaz.service-manual.company/regulirovka-rulevogo-mehanizma-uaz-tipa-chervyak-rolik/regulirovka-zatsepleniya-rolika-s-chervyakom-rulevogo-mehanizma -uaz-31512/

uaz.service-manual.company

About an alternative to the native power steering

In fact, it is more reliable, and by the way, cheaper, imported from disassembly, for example from Chevrolet. Vadik has one like this on the Black Cuttlefish, for example, after two of our untimely deaths.

I fitted myself a hydraulic unit for a UAZ with a W-123 body from a Merc. I installed the gearbox without any problems, but I had to tinker with the pump. I installed it together with the steering column and all the switches and the ignition switch! And it took about two days, taking into account all the preparatory work!

Installation of a hydraulic booster from a BMW 7 series on a UAZ.

Power steering based on mechanisms from Audi-100.

GUR 31608-3400500 manufactured by Avtodetal-Service OJSC

A product of joint production of Avtodetal-Service OJSC (Ulyanovsk) and (Germany) for the production of a power steering mechanism (31608-3400500) (hereinafter referred to as the “Mechanism”) for UAZ cars: passenger cars 3160, 3162, 3163 and trucks UAZ 2360 -"Pickup".

The “Mechanism” package includes parts manufactured by ZFLS (Germany): a high-pressure pump, a distributor with a screw and a piston - with a rack assembly, needle injection and drain hoses, an oil tank, a tank mounting clamp, a bracket, a pump holder, a poly-V-ribbed pulley , fasteners

The new product, a hydraulic steering mechanism and components for installation on a vehicle, have a high service life. They have advantages over steering mechanisms produced in Russia, such as: 1. High durability (double service life - over 400,000 km) and trouble-free operation. 2. High information content (feedback from the road through the steering gear and mechanism to the driver, i.e. ensures driver safety), in domestic models the information content is insufficient. 3. No oil leaks in the units and connections of the hydraulic booster, pump and hoses - all seals are made in Germany. 4. High efficiency (high quality parts allow you to achieve minimal wear and reduce energy losses of the “Mechanism”). 5. Stable and smooth operation of the unit provides confidence and safety to the driver when driving a car, including at maximum speeds. 6. Reliable operation of the high-pressure pump (Germany), ensures stable operation of the “Mechanism”, noise during operation is reduced by 2-3 times. 7. Ease of adjustment of the gearing: rack - piston - bipod shaft. You can adjust without removing the mechanism from the car, without disconnecting the hoses and without draining the oil from the “Mechanism”. 8. No noise in the steering mechanism due to throttling of the working fluid when turning the steering wheel.

Test tests gave the following results (tests were carried out on a serial UAZ-31622): 1. Force on the steering wheel: left 2.0 kgf; to the right 2.6 kgf; 2. Steering wheel self-return speed: 246 degrees/sec; 3. Rearrangement speed: 76.1 km/h; 4. Turn speed R 35 m: 69.5 km/h; 5. Steering gear ratio: 17.23. Tekhresurs LLC sells a complete set of power steering gear.

Power steering pump UAZ-2206 Euro4 YuBei

Catalog number: 31623-3407010-10

STUD MOUNTING

A special feature of the spacers presented in this section of the catalog is the presence of wheel studs in their design. This gives a great advantage when installing spacers on cars in which the wheels are secured with nuts, since there is no need to replace the standard studs. To secure the spacer to the hub, special low cone nuts are used. The wheel rim can be attached to the spacer using standard nuts if they match the thread pitch with the studs on the spacer.

The two most common reasons for installing spacers are:

Wheel offset (ET) discrepancy (wheels touching non-moving parts of the car).

In order to choose the right spacers in case of wheel offset mismatch, you need to know the factory offset parameters of the discs recommended by the car manufacturer, and the offset parameters of the discs that you are going to install. For example, if the factory setting for the disc offset on your car is ET 47, and the discs you want to install are ET 37, then in this case you need to install a 10mm thick spacer.

When choosing spacers to extend the wheelbase (the aesthetic appearance of a car), you need to select spacers so that they do not touch the car’s wing arches. To do this, you need to measure the distance between the wheel and the inner surface of the car's fender arch (necessarily at full load)! That is, if you need to select spacers for the rear axle of a car, then you need to put a load of 250-300 kg in the trunk of your car, or put 3 adults in the back seat of the car, only then take measurements. Spacers for the front axle are selected by analogy with the rear axle. This is done so that when the car is fully loaded, the wheels do not touch the stationary parts of the car.

| Car model |

| Manufacturer |

Power steering - what is it and where to get it?

UAZ hydraulic boosters are produced in the Republic of Bashkotorstan, Sterlitamak. What is included in the Sterlitamak power steering kit: 1. Steering mechanism with hydraulic booster 2. Cardan joint of the steering shaft There are two options. The “long” one, also known as the “old” steering one, is a solid pipe almost up to the gearbox with a shaft inside. Connects to the gearbox with ONE universal joint. The “new” one, also known as the “short” one, consists of a short steering shaft (the same pipe as in the long one, but it ends at the exit from the cabin to the engine compartment). Next to the gearbox is a CARDAN SHAFT with a splined connection. The last column is more progressive in design and safer from injuries, and also allows you to change the position of the steering wheel within a certain range. By the way, the new one allows you to lift the car. Even with a 6.5 cm lift, there are enough cardan splines. 3. Steering bipod Called bipod 3160 - suitable for 31519. 4. It is better to immediately install a bourgeois, toothed pump drive belt, length 1175 (1150 fits at the limit) 5. Power steering pump (with bracket, fasteners, bracket spacer and “angle” » spacers) But once again I strongly recommend that you immediately strengthen the pump mounting bracket in some way. This is the second time I have had it burst right at the bend, near the platform for attaching the entire structure to the cylinder head. Even the welded “kerchief” didn’t help. I think that you can weld a steel block into the corner in order to relieve the stress from the very bend of the metal of the bracket. And it wouldn’t be a bad idea to come up with something that would limit the displacement of the entire “hanging” part of the bracket towards the radiator. The standard emphasis does not help in this matter. 6. with bracket, tank clamp 7. Oil filter 8. Connecting hoses 9. Sets of fastening and connecting parts. 10. Spacer for the fan with fasteners (this remote one is an aluminum cylinder with five holes, it moves the fan, otherwise it gets caught on the belt) 11. Additional pulley with fasteners (when installing, be careful - it is placed in only one position - a dot on it and the TDC mark must match)

A complete list of components, as well as a drawing and description of the power steering, installation procedure, operation and maintenance of the power steering HERE.

According to rumors, the Sterlitamak one is of better quality than the Borisov one, although it is “tighter” (the gear ratio is smaller). The external difference is that the Sterlitamak hose goes from above one after another, while the Borisov one has one on top and one on the side.

According to Ulyanovsk craftsmen, Borisov power steering is more reliable. Also, power steering, in my opinion, differ in the number of steering wheel revolutions (3 and 5).

Borisov power steering is really very powerful, even on 35s with -19 discs it turns without feedback. But Sterlitamak is much more informative.

See also the article about power steering for UAZ.

"Autohydraulic booster" 222120, Borisov, Minsk region. Chapaeva 56. Tel. (01777) 3-51-36, marketing department 3-16-25.

Official representative of Borisovsky for the North-West region, BaltPromServis LLC, tel. (812)-466-65-00, (812)-116-35-56. [email protected]

Power steering power steering for UAZ loaf

The plant does not make carriage-type cars with power steering - the issue is being resolved; does not do cars with a carriage layout, on gear axles and with power steering (and without power steering) at all.

Everything turned out surprisingly well for me. Although at first I learned that power steering is not installed on a loaf. But I didn’t have the strength to fight the steering wheel (especially off-road) and decided to attach a regular UAZ hydraulic booster using a tricky bracket. They brought me a factory kit from Ulyanovsk for installation on the UAZ-31514. When I found out that these hydraulic boosters are made here in Belarus in the glorious city of Borisov, we decided to go to the factory with a mechanic to consult. And lo and behold, it turns out that a month ago the factory workers made 5 hydraulic boosters specifically for loaves and went to Ulyanovsk to offer them to UAZ, but UAZ refused this development under the pretext that the body stamping needed to be changed to accommodate this hydraulic booster. So they came back with these hydraulics (luckily for us). Long story short, we bought one for ourselves for $50. Became like family. I went a little crazy with the steering column - I installed a MAZ one with an adjustable tilt. As for the stamping, there was no need to trim the floor because... The car is lifted to fit 33 tires.

Types of steering gears

There is the most traditional rack-and-pinion worm gearbox, which is good precisely because it is lightweight - it’s easy to spin in place and on the highway, and it returns to zero on its own, just hold it. The same thing is bad - on bumps it “responds” with lightning speed and mercilessly - I, having broken two fingers with an old three-spoke steering wheel, installed a weighted two-spoke one (in general, in my opinion, it is the most comfortable one that currently exists).

The second option - the Borisov or “luxury” one has a powerful gearbox, due to it it is less sensitive, does not hurt your hands, and does not require strong steering on the highway at high speeds. But it spins harder than the first and returns to zero less intensely, which, at least, annoys me.

| Steering mechanism 3151-3400014 produced by Borisovsky | |

| Full angle of rotation of the output shaft, degrees | 2x40 |

| Permissible load on the steered axle, kg | 1200 |

| Gear ratio | 20,5:1 |

| Output torque Nm | 1100 |

| Weight, no more, kg. | 10 |

| Additionally: , | |

The third option is a power steering gearbox.

| Power steering mechanism ShNKF 453461.130-10 manufactured by Borisovsky | |

| Maximum load on the steered axle, kg. | 1200 |

| Maximum torque on the output shaft of the mechanism at a maximum pressure of 10 MPa, Nm | 770 |

| Mechanism gear ratio | 17,3:1 |

| Full angle of rotation of the shaft sector, degrees. | 80 |

| Hydraulic play, no more than a degree. | 6 |

| Capacity of the pump used with the steering mechanism, dm?/min. | min 5, max 7.5 |

| Additionally: | |

UAZ power steering hose

I installed a hose from the Volga, it is much more reliable. The end going to the steering mechanism is bent, which is quite significant. The relatives leak at the crimping point, and the Volgovsky one is crimped with rubber on top.

This is where the pressure hose is changed to Volgovsky. But when buying a Volgovsky, be careful - it must consist of the hose itself and a screw-in tip (the Uazovsky is one-piece). After installing the hose, do not touch anything, otherwise it will rub off.

I installed a high-pressure power steering hose from Volga - the car was simply unrecognizable. The delay (free play), and as a result, the yaw of the car disappeared, the free play remained, but it was not excessive and controlled, steering became simply pleasant. The reason for the yaw of a car with its original hose is extremely simple - the hose does not hold pressure enough. When the steering wheel was turned, the UAZ hose began to inflate (increased in diameter along the entire length by about 1:2 mm), working as a damper. After the hose was inflated, the wheels began to turn, this happened very abruptly, this moment was not felt on the steering wheel, the car moved sharply to the side. The amount of oil spent on inflating the hose was not constant - it depended on the force required to turn the front wheels, and accordingly, the free play on the steering wheel depended on the speed and what was under the wheels. To install a new hose you need: - power steering high pressure hose from 3110 (nut-nut) complete with an angle (screw-end for the bolt); — adapter angle 3110 (screw-screw); - two copper washers. Hoses 3110 are available in almost all Volgov stores - you need to take them complete with an angle! It is better to install it this way: - on the gearbox - place the corner towards the left mudguard, direction - forward, pass the hose next to the side protection of the radiator, then above the hoses of the power steering reservoir; — the corner on the pump should also be placed towards the left mudguard; — THE GAP between the hose, angles and the body, frame, and other parts MUST BE AT LEAST 10 MM, THE HOSE SHOULD NOT TOUCH ANYTHING DURING OPERATION!

Power steering hose UAZ (Volga) - holds 80 atm. UAZ ones flow shamelessly, from the Volga it’s a little better, but one hell of a G... (it also costs from 500 rubles (2001)) The cheapest (50-70 rubles) replacement power steering hose from ZIL-130, If it doesn’t fit on the pump side, then cut off a pipe from old UAZ and weld it to it. The most interesting thing is that it’s almost the same from Kamaz, but it costs 500 rubles. :-))) This is how I connected it to Merino’s pump. So far, at the disassembly, 5 pieces from relatives have not been presented.

I installed the power steering myself (Borisov), I installed the high-pressure hose from a BMW 520 e 32 (Error! E32 is the body index of the 7 series BMW. Therefore, the 520 E32 cannot be. Most likely it should be E34 (the fifth series of the same time) fits 1 20 convenient units worth disassembling to 1. Service life 2 years, ATF DEXTRON fluid.

My power steering pump is leaking. How to remove leakage?

In general, there are two types of pumps: round and ribbed (presumably Podolsky). It is round, assembled with two bolts and its tightness is achieved by rubber seals and flat surfaces. They are not the same, they do not hold anything (the planes are due to poor processing, the rubber is due to weak bolting). Problems begin in winter when the oil freezes and with high pressure it begins to be squeezed out through the cracks near the impeller. If you use liquid oil, it seems better. This is what I did: I removed the pump, washed it and reassembled it with silicone sealant. It helped. But probably only until winter ;-(. I dream of trying the Podolsk pump, it has a more solid design, but I haven’t been able to buy it yet. In general, from my experience with the Sobols, the pumps are complete crap... 50% of the defects are especially round, but sometimes you’re lucky...

And another tip: don’t tighten the belt too much.

, so at the slip level, then there is less chance that it will also leak through the oil seal.

Power steering pump ShNKF 453471.094 produced by Borisov Double-acting Vane Pump. Designed to work in the steering system of luxury cars. *Connecting the injection hose is a fitting, thread M 16. Installed on UAZ vehicles. Weight, kg - 3.2.

| Performance characteristics of power steering pump ShNKF 453471.094″ | |

| Maximum volumetric flow, no more than, dm3/min. | 12,0 |

| Pressure, MPa | 9,0+(-)0,5 |

| Input shaft rotation speed interval, min.-1 | 600-7500 |

| Theoretical working volume, cm3 | 8,7 |

| Working fluid temperature, C | -20+90 |

| Nominal volumetric flow at: 800 rpm, not less than dm3/min, 2000 rpm; no more, dm3/min. | 5,4; 9,0 |

| Additionally: | |

Power steering belt

The kit comes with a belt 1150 mm long - SMALL. Need 1175 mm.

Why does the power steering operate “one-sidedly”?

I opened my power steering. Let me remind you that in his life he only helped to the right (like the vast majority of power steering after 30 - 40 thousand km). The simplicity of the design did not give him a chance to remain undetected.

The spool consists of two tubes. One smaller one fits into a larger one. They have through and non-through holes, which, overlapping, direct pressure to the desired area and at the same time open the drain from the opposite side (relative to the piston). This spool can neither clog nor break. Even more one-sided. The minimum hole is 3mm. The torsion bar also cannot in any way affect the strength of the power steering. When I figured it out, it became clear to me the reason for such a one-sided kerdyk of all the Gurs. Let me explain. There is some semblance of ring cuffs, only polyvinyl. They do not grip the shaft, but only strive to reduce the gap as much as possible. They, of course, miss, but the whole question is how much. In normal power steering there is a dynamic balance. That is, these rings allow passage, but still the pressure and flow rate of the pump is enough to pump the desired area. When the rings wear out, leaks increase, power steering becomes weaker, but only to the left, and here's why.

Cavities A and B are very different. They are responsible for left and right turns respectively. Cavity B has only one leak - through the piston rings, since the pressure area is located on the right. And cavity A, in addition to leakage through the piston rings, also has leaks on the left at the end of the axis (directly into the drain line), and part of the pump pressure enters from the opposite side of the piston (in B) and prevents it from moving. When the rings wear out, leaks increase, power steering weakens, but only to the left. Blue arrow - inflation when turning right (it is also drained in the opposite direction). Green arrow - inflation when turning left (it is also drained in the opposite direction). Red arrows indicate leaks. Gray squares are O-rings.

Read Why does the power steering stop “assisting to the left”?

About the power steering bracket

When installing the pump bracket, do not tighten it with a spacer, otherwise it may crack.

It is better to immediately weld a “kerchief” onto the bracket so as not to remember about it during operation.

Modified power steering bracket for 4178 engine

Power steering oil

If you pour what the factory recommends: oil P or its dubbing (made by Nizhny Novgorod Aviatechmash) oil A, then the pour point is -40, and the kinematic viscosity at 40C is 17-22, at -20C 1600. You can understand the numbers yourself while (in winter) with a blowtorch If you don’t warm up the belt, it’s better not to put it on the pump. I'm pouring Dextron II (red)

I just arrived from Borisov, where I went on the occasion of the death of GUR. I talked with the designers of this glorious product and learned some interesting information. It is unacceptable to use a spindle in this system (only if in an emergency for a short time), because, unlike P-type oil and Dextron, it (the spindle) does not contain anti-foaming and extreme pressure additives. The formation of foam (air bubbles) leads to dry friction, and there is nothing to say about scuffing. This leads to a decrease in the life of the pump and its failure (which is what happened to me). The steering mechanism, however, is less susceptible to these processes. They advised to use oil R or Dextron 3.

The other day I noticed that if you turn the steering wheel on dry (without ice) asphalt (especially to the left), then the steering wheel turns normally (easily) for about one turn, but for the last 0.5 turns it turns with several times more force. Sometimes this effect disappears, sometimes the ratio shifts. The pump belt seems to be tensioned normally, the oil is Dextron. What could it be? Has the power steering really gone bad?

This is a power steering property. The instructions for the UAZ-3160 say that abnormal conditions occur in extreme positions. Therefore, it is not recommended to hold the steering wheel in extreme positions for a long time. In this case, my car experiences a certain noise and the steering wheel turns a little tighter.

Steering wheel tuning

I did the following: I removed the rubberized braid from the old car, put it on the steering wheel and wrapped it with electrical tape. I bought a black rubberized braid with three zones for hand massage and pulled it onto the steering wheel, arranging the massage zones so that there was a massage zone under the left hand at around 10 o’clock. The thickness of the steering wheel has become 6-7 cm in diameter, you can steer without squeezing the steering wheel with your fingers, i.e., your fingers do not come out from the inside of the steering wheel, while the grip has increased (the massage area is made up of rubber pimples ~5-6 mm high), your hands are not they get tired after a long ride on a gravel road (previously it was difficult to unclench your fingers after a ride). Another plus is that the location of the massage zones allows you to determine the position of the front wheels in mud.

The theory of rod curvature and rubber eating

Science knows 4 parameters for wheel installation: 1) camber; 2) toe-in; 3) longitudinal angle of the axis of rotation (castor); 4) transverse angle of the axis of rotation. Violation of these angles causes all sorts of misfortunes.

The transverse angle is not adjustable anywhere (except, it seems, by ZIM), and is never checked.

Castor is also never checked, but on cars it can be adjusted. Some people, when doing repairs at a service center, force you to do this operation and say that there is an effect. True, the serviceman has to explain the difference between castor oil and castor oil

Camber and toe are parameters of practical interest. Misalignment causes the wheels to “look in different directions.” It is important to note that toe-in is a property of BOTH wheels, that is, toe-in of ONE onto two wheels is a parameter characterizing their relative position. Therefore, other things being equal, a violation of the toe leads to simultaneous wear of both wheels along the edge (inner or outer, depending on whether the toe is insufficient or excessive), since in order to achieve straight-line movement we slightly turn the steering wheel so that the wheels are positioned incorrectly, but both are symmetrical. For the same reasons, due to a misalignment, the car does not PULL to the side, the steering wheel is simply slightly crooked when moving in a straight line. It’s already crooked for all of us. If the toe-in is significantly disrupted, overall stability is lost (the car wanders along the road).

The camber is different for each wheel. Therefore, if it is violated, the car begins to be pulled to the side, to overcome which you have to turn the steering wheel, as a result of which the wheels are installed asymmetrically. It starts to eat both wheels, but in different ways. Since both should go straight, one is tilted (camber) and turned to the side, while the other is simply turned. The camber on iron cars is not adjustable. It is broken due to bending of the stocking. It can also pull due to a violation of the suspension geometry due to the displacement of the spring mounting relative to the bridge. Since we are again treating the deviation with the steering wheel, and with force, the wheels will again eat a lot, but in different ways.

The steering wheel does not turn completely in one direction

Clean up the dirt. First, check that the limit bolt has not come out (although this is unlikely). Didn't you bend the rods? Is the CV joint intact too? Is there any extraneous noise when the bridge is on? Then I would advise you to unhook the connecting rod from the gearbox - it will turn normally - look in the steering axles (here you will have to unhook the connecting rod and, after hanging the axle, check each side separately), no - the gearbox is to blame. What could have happened? Well, for example, clay has accumulated somewhere and is now sticking. Or the water is frozen.

I have a similar defect on FROST - it turned out to be related to the presence of water in the steering mechanism. Drive into a warm place and warm up, then be sure to change the oil in the steering mechanism.

Changing the power steering oil, how often should it be changed?

I read a book on UAZ, where the process of changing the oil in the power steering for some reason suggests that the old one is no longer in it - what is it like? I did this: I removed the incoming hose into the tank and brought it out into a large bottle. I started the engine and, as soon as the old oil was gone, I began adding Dextron. At this time, a comrade was turning the steering wheel. As soon as the obviously pure Dextron started running, the car was turned off. The replacement took 1.3 liters of oil. Then he blew out the air.

I did this - drained the old one, turned the steering wheel (more came out), washed the filter in gasoline and filled it with Dextron

Italian power steering with ZF pump

I bought an Italian power steering with a German ZF pump at an auto parts store for a UAZ. Installed, installation requires:

- welding the tube into the frame and welding an additional ear for attaching the steering gear;

- crossing the Volgov corner of the high-pressure hose and the UAZ hydrach fitting. We get the opportunity to use Volgov power steering hoses;

- purchasing a steering cardan for the original power steering and replacing the fork;

- manufacturing the pump mount based on the standard bracket.

I’ve never driven with power steering before, but now I really like it. Megarulez, how I lived without him before is not even clear.

Experience in operation and repair of power steering

Background. We have a UAZ 315192, less than 3 years old, purchased from a “rich grandfather” with a mileage of 20 tkm. It was serviced at the “living” directly in the Sterlitomak steering gearbox, which my grandfather had replaced at the service a year ago under warranty.

Part 1.

We are trying to solve the problem. Since after buying a car, all the money-intensive options like “throw out the gearbox along with the pump and install a new one” are completely unrealistic, and driving “as is” is simply dangerous, I’m trying to solve the problem without significant financial expenses. costs. Firstly, I changed the hose (it was swollen and served as a damper), and secondly, instead of dirty gray liquid, I filled it with Dextron (ZIC, as the cheapest). Thirdly, I adjusted the gearbox itself, as described in the documentation (essentially everything is the same for both the Borisov and Sterlitomak gearboxes, a very, very labor-intensive undertaking), the method for adjusting the latter is available on UAZ online. The result is unsatisfactory. We managed to reduce the play to about 12 degrees, the ride became, of course, more pleasant, but no more...

Part 2.

There is a way. In the process of studying the amount of play depending on the position of the steering wheel, it was discovered that if you turn the steering wheel to the right (from the middle position) by about 120 degrees, the play becomes noticeably less and begins to increase with further rotation of the wheel (we have a minimum of play slightly to the side of the middle). This effect is not observed when turning left. Doubt has crept in that either this is the official “middle point” or that this particular area was not damaged during the wear process. Quickly, I quickly dropped the rod (the one that clings to the bipod at one end) from the side of the right wheel and screwed the steering knuckles into the rod “as best I could” (there was a reserve on each side), thus shortening the rod by 12-15 mm. The consequence of this simple operation was the magical disappearance of the backlash precisely when the wheels were positioned in the corresponding linear motion. We check the maximum rotation angle, everything is fine, the wheels rest tightly against the stop bolts, apparently there is still some reserve. To celebrate, the steering wheel was rearranged (actually a cardan, this is faster to do than tearing off the steering wheel with a puller) and the new position was declared correct.

Conclusion.

More than a month and 3 tkm have passed. The flight is normal, the play is approx. 6 degrees. I made one more conclusion for myself, it is not obvious - down with the dirty gray liquid!

Device

The working pair of the steering gear is a globoidal worm and a double-ridge roller. A worm pressed onto a hollow shaft is installed in the steering gear housing on two tapered roller bearings.

To ensure the reliability of the connection between the shaft and the worm, a keyway is made and splines are cut on the worm shaft. A double-ridge roller is in constant engagement with the worm.

Its annular grooves located inside provide a working surface for a double-row ball bearing. It is mounted on an axis, which is mounted in the head of the bipod shaft.

This shaft rotates in two bearings at once: a bronze bushing pressed into the crankcase and a cylindrical roller bearing. This element is installed in the crankcase cover on the side of the steering gearbox.

The shaft head shank fits into the groove of the adjustment screw. It is screwed into the crankcase cover on the side. The adjustment screw is secured with a pin and a lock washer, which are pressed into the cover. The mechanism is closed with a nut and cap.

With its upper end, the steering shaft enters the bearing, rotating on it. The bearing is pressed into the column housing. The bearing spacer is prevented from moving by a special spring.

Power steering on AUZ 469

Hydraulic amplifiers operate from fluid pressure on drive units. The pressure is created by a pump that operates through a belt drive from the engine crankshaft pulley. Hydraulic power steering requires an extended belt and modification of the pulley. Therefore, the old drive belt, fan impeller, and crankshaft pulley must be removed.

The fluid pump is unscrewed and the radiator impeller is secured to the wheel hub. For further operations, you need extended bolts for the power steering and a spacer, which is included in the kit. The long belt is pulled onto the new pulley. The fuel filter bracket is removed. The power steering pump for the UAZ 469 will be installed here. The price of the UAZ hydraulic booster in Moscow ranges from 15 to 40 thousand rubles.

The power steering kit includes a bracket. It must be installed in place of the pump stud. Secure the bracket and pump bar to the locknut. After installing the belt, you should adjust the correct tension. To maintain it, there is a special tension roller used in the design of many cars.

Correct adjustment of the power steering drive belt is carried out as follows. When pressed with a finger, its deflection should be 10-15 mm. The belt should rotate at an angle of 90° relative to the plane of the pulley. The fuel filter is placed in its regular place, in a square hole.

To install the oil tank, you need to drill two holes in the left engine mudguard using a drill.

We use nuts, bolts, and a clamp prepared in advance to install the oil reservoir. The tank is connected to the pump using a polymer hose. Transmission oil is poured into the system. Once again, you should check that all parts are installed correctly and you can start the car.