The car suspension is designed to level the movement on any type of road surface and provide comfort for the driver and passengers. The presence of vibration for a long time negatively affects all components and assemblies of the car - bolted and screw connections are weakened. Serious consequences include bent door hinges, sagging doors, and loose closure of the hood and trunk.

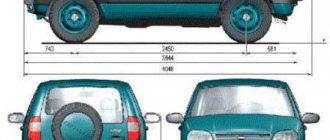

The chassis of the Lada Granta has become more modern and modernized. Especially in comparison with previous AvtoVAZ models - two generations of Samara and first generation Kalina. The car has rear and front suspensions, which differ significantly from each other.

The rear suspension of the Grant is the same for the sedan and liftback. In fact, this is the same beam with springs and shock absorbers that is installed on Kalina, Samara and Samara 2. Instead of a stabilizer, a beam is used, which means the structure is dependent.

Features of the Granta front suspension

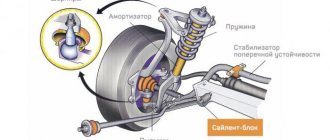

The front suspension is independent, which means that when one of the front wheels falls into a hole, the second one maintains its position. So that when driving on a flat road, both wheels are in the same plane and rotate evenly and parallel to each other, a stabilizer is installed between them. On the front part of the Granta suspension system, the mounting bearing is installed between the shock absorber spring and the body support. As a result, the weight of the machine is completely concentrated on it and keeps it in a compressed position. With this design, the backlash is reduced to zero - extraneous noise disappears.

The independent circuit consists of hydraulic shock absorbers and two wishbones, which are complemented by anti-roll bars. To strengthen the levers, so-called extensions of the upper supports of the front struts are used. They are not installed from the factory, so car owners are forced to install them themselves. The spring has a conical shape, a hydraulic shock absorber is located inside, the pitch of the coils is variable.

The lower part of the rack rests on the steering knuckle. The front suspension is designed in such a way that when the steering wheel rotates, the wheels are turned by the steering knuckle, and the spring and shock absorber turn with them. In this case, the stand of the latter remains in a stationary position. Thanks to this feature, it is possible to increase the service life of shock absorbers.

The designers modernized the block of front strut supports, which made it possible to increase their strength and eliminate squeaks, vibrations and rattling. The anti-roll bar remains unchanged. It is made of hardened steel, attached to the lower arms on the right and left, and rigidly attached to the body in the middle.

Another feature of the updated chassis of the Lada Granta is the increased castor. This is the angle of rotation of the steering wheels, which on Grant is 2° 45`. This solution has both advantages and disadvantages. On the one hand, handling improves; at high speed the car shows a higher level of directional stability. On the other hand, it takes a little more effort to rotate the steering wheel. The steering has also been updated:

- the installed electric power steering has a greater compensating effect;

- a steering rack with a lower gear ratio (short) is used.

The updates have significantly improved the car's handling at different speeds. The steering wheel has become more sensitive, and the number of its revolutions to the full angle of rotation of the steered wheels has decreased due to the short steering rack.

The owners were outraged by the return to using the standard suspension system from Kalina. The steering angle remains the same and no power steering is used. However, this is observed only in minimal configurations.

Rear suspension features

The rear suspension of the Grant is the same for the sedan and liftback. In fact, this is the same beam with springs and shock absorbers that is installed on Kalina, Samara and Samara 2. Instead of a stabilizer, a beam is used, which means the structure is dependent. Structurally, the rear part of the suspension system remains unchanged. Looking under the bottom, you can see the usual picture - a beam fixed in a semi-rigid position. It is attached to the body using hinges.

Support struts (springs with shock absorbers) are attached to the levers on the right and left. Despite the outdated design, a semi-rigid beam with racks has a number of undeniable advantages:

- even the maximum load actually has no effect on its behavior, which confirms the high level of energy intensity;

- maintenance, even according to regulations, should be carried out once every 100,000 km, but this period increases for the entire period of operation;

- Parts can be replaced in a garage even by beginners.

The rear suspension of the Granta has a feature that distinguishes it from the Priora - a negative camber of the rear wheels of 1° is created at the rear. This was done to improve the vehicle's directional stability, but given the design features of the suspension system, this solution is not capable of significantly changing anything.

FakeHeader

Comments 27

With cocked hats it will shake a lot on bumps or am I mistaken?

The factory protection is installed with these levers and a spacer in place of the crabs? Thank you.

The protection is different, the factory boot will no longer fit. My pleasure.

And with a damper, the power steering does not swell - additional effort from it on the power steering?

I drove 10,000 km with it. I haven't heard of such a problem.

Not a problem - it’s just that, in fact, the power amplifier + will overcome the resistance of the damper. Accordingly, increasing the load means the unit will fail faster. My opinion from a sofa expert

It seems to me that the crab spreader does not give much in the same place and is so rigid. Or not? I agree between the levers.

Here is information from the website specifically for this spacer: Improving vehicle handling. Possibility of adjusting the longitudinal inclination of the wheel axis within a wider range. Increasing wheel stabilization by setting the caster angle to 1.5-2 degrees or more. Reducing the minimum turning radius. Reducing the longitudinal movement of the front wheels. The wheels do not touch the arches when braking. Possibility of using wheels of larger diameter. Improving vehicle passive safety. Increased rigidity of the body as a whole and suspension mounting points. Reducing body loads during dynamic acceleration and braking

The car suspension is designed to level the movement on any type of road surface and provide comfort for the driver and passengers. The presence of vibration for a long time negatively affects all components and assemblies of the car - bolted and screw connections are weakened. Serious consequences include bent door hinges, sagging doors, and loose closure of the hood and trunk.

The chassis of the Lada Granta has become more modern and modernized. Especially in comparison with previous AvtoVAZ models - two generations of Samara and first generation Kalina. The car has rear and front suspensions, which differ significantly from each other.

The rear suspension of the Grant is the same for the sedan and liftback. In fact, this is the same beam with springs and shock absorbers that is installed on Kalina, Samara and Samara 2. Instead of a stabilizer, a beam is used, which means the structure is dependent.

Tuning the suspension of the Lada Granta sedan and liftback

The suspension system is modified in a variety of ways, some are trying to radically remake the suspension.

Installation of wishbones

Instead of standard levers, a rigid and durable unit - a triangular lever - can be installed on the Granta's front suspension. It is installed for the following reasons:

- increasing the rigidity of the unit;

- lifting the base up to 3 cm;

- castor adjustment at any time in the range from 1° to 4° in negative values.

The main purpose of the wishbone is to improve controllability. Installation requires removal of the front wheels and crankcase guard. After this, unscrew all the fastening nuts and bolts - braces, front arm brackets, ball joints and stabilizer struts of the Lada Granta.

Next, the standard levers are removed and new triangular ones are installed, with all actions performed in the reverse order. To achieve maximum castor, you do not need to tighten the clutch and install washers for adjustment. Finally, all the bolts and nuts are tightened with the car standing on all four wheels - all that remains is to do the wheel alignment.

Judging by the reviews of the owners, the installation of triangular levers is justified. There is a lack of beating and vibration in the steering wheel and improved handling. It becomes possible to quickly install a castor. The overall smoothness of the suspension on the Lada Grant is noted.

Subframe installation

The new Vesta and X-RAY are already equipped with a subframe from the factory. This element is not used on Grant and other AvtoVAZ models. The subframe has a number of obvious advantages:

- body rigidity increases;

- suspension mounts are more rigid;

- additional engine and crankcase protection;

- increase in castor up to 1.5°;

- increase in wheelbase by 15 mm;

- The likelihood of the front nodding during sudden braking is reduced.

How to improve the motor and accelerator assembly?

Here chip tuning should come to the fore. The basic setting assumes that the electronic control module implements averaged and optimal engine operating parameters that are suitable for the vehicle's running-in process. The modernization procedure involves removing the microcircuit from the ECU and reconfiguring it. You should carry out this activity yourself only if you have certain knowledge and experience in the field of programming. For the average owner of a Lada Grant sedan, such a specific procedure as chip tuning is not available, so its implementation should be entrusted to experienced programmers from specialized studios. If you perform the firmware correctly, it is quite possible to achieve a power increase of 15-20%. An adjustment to the level of fuel consumption may also occur here. This parameter depends on the software version.

Another significant point that can provoke increased attention from the owner is the accelerator pedal. The standard setting of the unit is characterized by a “sluggish” response of the Lada Granta sedan engine to pressing the corresponding pedal. To achieve a sharp increase in speed, you will need to press the pedal deeper, but even here there are delays. This annoying feature can be minimized by tightening the damper cable drive and adjusting the camshaft.

Front suspension

On the Lada Granta and Kalina, the front suspension is independent with hydraulic telescopic shock absorbers, coiled conical springs, lower wishbones with braces and anti-roll bars.

Depending on the vehicle configuration, the front suspension settings are different:

- The caster of the front suspension for the “Norma” and “Lux” modifications has been increased to 2°45'. This improves the vehicle's directional stability.

- On the “Standard” configuration, caster remained at the same level - 1°40'.

Rear suspension

The rear suspension is semi-independent, made on an “elastic” beam with trailing arms, coil springs and double-sided telescopic shock absorbers.

For the first time on the Lada Granta, the rear suspension received a negative camber angle (-1°). Positive (+10') toe-in of the rear wheels is also provided. This allowed manufacturers to improve the vehicle's driving characteristics and vehicle stability on the road.

Basic faults

To recognize faults in the chassis of the Lada Granta, it is not necessary to seek help from specialists. Problems can be easily identified on your own. The main suspension faults are presented in the table:

When the car is moving, a knocking sound is heard from the suspension

Most of the problems described can be easily diagnosed without the need to visit specialized service stations. You can do the repairs yourself, but after all the manipulations you definitely need to do a wheel alignment.

Reviews about the suspension

The owners highlight a number of positive points:

- The suspension is well suited for Russian roads, especially outside the city.

- On the highway, the suspension does its job well, and the car holds the road well.

- The suspension is moderately soft even at -30C.

- After a big hole, we had to change two wheels; we checked the suspension during maintenance - no complaints. On all previous cars with such a mileage it was necessary to completely “shake up” the suspension.

There are also negative points:

- On bumps the suspension is noisy.

- Compared to the Renault Logan, the Lada Granta's suspension is a bit harsh.

Let us remind you that you can get acquainted with the car in more detail from other reviews and tests of the Lada Grant.

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

The rear shock absorbers suffer the most wear because they have much longer stroke. When driving quickly through potholes, the hydraulic fluid may simply boil. This is one of the reasons why a shock absorber fails. But most often it leaks - the valve loses its tightness due to a strong breakdown or impact. As a result, the outer side of the cylinder becomes coated with an oily liquid. How to determine that this element has failed? It’s very simple - you will hear a characteristic knock in the suspension of the Lada Granta. Moreover, it is clearly visible in the cabin. From the outside, you can hardly hear a broken shock absorber. This knock is so strong that even good music cannot interrupt it. You will hear a broken shock absorber immediately.

Also note that the damping element changes in pairs. That is, in the event of a breakdown of the rear left shock absorber, the rear right shock absorber also changes. As for the front struts, they are more durable. Often they are replaced already assembled with a spring, since they fail no earlier than after 150-200 thousand kilometers.

Pulling the car chassis

Pulling the chassis is one of those operations that must be performed at certain intervals. Most often this is 15-20 thousand km, or less when operating in difficult conditions.

The need for broaching is due to the fact that during the operation of the car, especially on our roads with imperfect road surfaces, suspension parts gradually wear out, connections weaken, rubber elements are deformed and change shape and size. To return the suspension to its original position, all major connections must be checked and, if necessary, tightened.

You can do this at a service station or yourself. Typically, broaching the chassis is included in the list of periodic maintenance works. service from most car manufacturers. But it is necessary to understand that the results of this work are difficult to verify if you are not present during the work itself.

Pulling the car's chassis is easy to do yourself. To do this, we will need an inspection pit or a lift, and several wrenches.

Let's look at what connections need to be checked using the example of a standard suspension for all domestic front-wheel drive cars and many inexpensive foreign cars: MacPherson strut suspension in front, elastic beam in the rear.

Front suspension broach

Check the tightness and tighten if necessary:

1 – connection of the anti-roll bar to the front suspension arm

2 – fastening the ball joint

3 — connection of the front suspension extension with the front suspension arm

4 – connections of the rack with the steering knuckle

5 – mounting the stabilizer bar to the body

6 – connection of the front suspension arm to the body

Why is it necessary to increase clearance?

This is a photo from the roads of “Germany”, they have places “like in Russia”. A car with low ground clearance, after falling into such a hole, risks being left without a bumper

Increasing this parameter is necessary in many everyday situations, and not only when you want to stand out in traffic. For example, if a significant load on the rear axle leads to sagging of the car and the risk of damage to the bottom, then increasing the clearance may be the most relevant option.

“Powerful” speed bump with traces from cars. Someone took a good look at it

The need to increase ground clearance most often arises when driving on uneven roads, places with speed bumps, and so on. And, given the quality of the road surface in our country, increased ground clearance can be considered the most popular option, which is sometimes used even on production vehicles aimed specifically at our market.