If you notice that the trunk lid or the fifth door of your Kalina, after unlocking it, rises too slowly to the upper position or even tends to close spontaneously, it is necessary to replace the trunk shock absorbers . This operation is elementary and can be done with your own hands. However, it is better to check the trunk stops for functionality in advance, without waiting for them to completely fail.

How does a trunk gas shock absorber work and why does it fail?

The principle of operation of the trunk lid stop in a car is similar to any other gas shock absorber. In its sealed cavity there are two chambers, separated by a partition with a small hole, filled with compressed gas. It is this that prevents the rapid movement of the rod inside a confined space, slowly passing through the hole.

Gas shock absorbers are quite durable, reliable and less demanding on operating conditions than previously used oil shock absorbers, but even they can fail sooner or later. In the case of trunk stops, this occurs mainly when the seal is destroyed with a subsequent decrease in gas pressure. External damage in the form of deformation of the rod or body is much less common - this usually only occurs as a result of an accident.

How to Determine If Your Trunk Shock Absorber Needs Replacement

Unlike suspension shock absorbers, the trunk struts cannot be checked on a stand or by rocking the car. A visual inspection also does not give any results - the gas that comes out, unlike oil, does not leave any traces. You can only be convinced that the stops require replacement through practice.

Most often, car owners realize this when they unexpectedly receive a blow to the back or head from an open trunk lid (in sedans) or the fifth door (in hatchbacks and station wagons). In order not to risk your health, be more careful about how the trunk lid moves. It should go down from the top position only when force is applied, and rise by itself under the action of shock absorbers. If the cover has to be “helped” to rise, but it tends to come back on its own or with slight pressure from top to bottom, the shock absorbers require replacement.

It is best to check the performance of the trunk shock absorbers at the first frost. At negative temperatures they work worse, and even if they functioned more or less normally in the summer, they may well not be enough for the winter.

Diagnosing and replacing trunk shock absorbers will save you from possible ridiculous injuries and hassles using the trunk. If you do not take care of this in advance, it is likely that when loading the machine you will have to hold the lid with your hands or even ask someone to do it, which is very inconvenient.

Source

Restoring struts: collapsible and non-dismountable shock absorber

A simple automobile shock absorber has the following design:

- lug body;

- rod with casing and mounting eye;

- piston, compression and return valves, rings;

- cylinder with valves;

- seals and fastening nuts.

First of all, the main problem of the shock absorber is leakage of oil or boost gas. As a result, the rack leaks, a knocking sound is heard during operation, and deformation of the rod is also possible. Violations of tightness and defects lead to changes in characteristics (partial or complete loss of performance). As a result, the car handles and brakes poorly, rolls, and does not hold the road, since the struts do not dampen the vibrations and sway of the body.

The main malfunctions include: free movement of the rod in the pipe, play during compression or rebound (workout in the rod or cylinder), damage to the shock absorber valves. It is also impossible to exclude external damage (case cracks, dents, etc.).

To repair, you need to remove the strut, remove the spring and release the shock absorber. Next, you should understand whether the shock absorber on the car is collapsible or non-dismountable. If the body is solid, then such a rack cannot be repaired. It is officially prohibited to open the body and try to weld the shock absorber after repair. If there is a nut or retaining ring in the place where the rod enters the pipe, this stand allows for repairs or maintenance.

- To repair a gas and gas-oil collapsible shock absorber in a garage, you will need a compressor for supplying air (you can use a bicycle pump), a fitting for supplying compressed air, and a pressure gauge. Please note that you will have to work with high pressure; you should protect your eyes, hands, and face in advance.

Repair of a collapsible type rack begins with the rack being clamped vertically in a vice, washed of dirt, and the entry point of the rod is also blown with air. Next, disassembly of the shock absorber begins and the protective cap of the rod is removed. Then you need to fill the shock absorber under pressure; for this you need a pressure gauge.

The shock absorber can be filled with nitrogen, carbon dioxide and compressed air. In the garage, it is optimal to use compressed air for repairs. First, the rack is disassembled, cleaned, the O-rings are checked, and the condition of the inner wall of the pipe is assessed.

If the shock absorber has damage to the rod, seals or valves inside the strut, you can buy a repair kit for dismountable shock absorbers, remove “live” parts from another strut, etc. The main task is to install all functional parts to obtain complete tightness, while cleanliness is extremely important during assembly (debris and shavings will quickly damage the restored rack).

By the way, it is always better to replace the oil seal with a new one, even if the existing one does not cause any complaints. Next, all that remains is to pump oil or air into the shock absorber, after which the strut needs to be pumped.

Bleeding the shock absorber is mandatory. Please note that shock absorber repairs must be done in pairs, just like replacements. In other words, repairing rear shock absorbers or repairing front struts involves manipulating both the right and left sides, that is, you need to restore both struts on the same axis.

- Now let's move on to how to disassemble a shock absorber and how to repair a non-dismountable shock absorber. Let us note once again that such parts are not officially repaired. However, repairs are possible, but they require skills and special equipment. In fact, usually non-separable shock absorbers are simply converted into collapsible struts.

Replacing trunk lid struts

During long-term use and frequent opening of the trunk, gradual wear of the hydraulic struts occurs. This applies to station wagon and hatchback body types. Over time, when opening the trunk, they begin to hold the lid weakly and often you have to support the lid with your hands so that it does not fall.

In this case, replacement of these parts is necessary. This procedure is quite simple. To do this, we need only one open-end wrench for 13, it is desirable that it be as thin as possible. First you need to unscrew the top side. Be careful and immediately support the lid so that it does not fall on your head.

After that, we lower the rack down and unscrew the bottom side, after which we take it out and put a new spare part in its place in the reverse order.

It is better to replace them as a set at once, rather than one at a time, as they usually wear out evenly.

Similar articles

When I had the same problem on a VAZ1117, I removed the gas stop as described above. But there was a problem with the installation: the new stop was clearly longer than the old one (in the unclamped state). I got out of the situation in the following way. I made 2 plates from an aluminum plate and bent them according to the diameter of the balls at the ends of the stop. I drilled 2 holes along the edges of the plates. I placed the plates on the ends of the stop and tied both plates together with strong twine (so that they wouldn’t jump off the stop). In the doorway (there is a regular door in the garage

80 cm) horizontally inserted a stop and a jack. I jacked the stop to a size slightly smaller than needed and tied the twine to a new length. Carefully pressed the jack and got the stop, compressed to a smaller size. I installed the emphasis on the standard places - there is nothing complicated here (if necessary, I slightly changed the position of the rear door so that the emphasis hit the mounting points). After installing the stop, I simply cut the string - I put the device in reserve, maybe it will come in handy someday.

DIY rear door shock absorber repair

In the vastness of the forum, there are different ways to relieve pressure from the rack before disassembling, but there is not a single detailed one. Write down who does it and how, in detail, so to speak “competitively”, so that later you won’t be offended by the repair you just made, or worse, by a damaged eye.

A thin drill bit and a drill at low speed. True, I was dismantling a shriveled gas strut. Otherwise, the GP from the office chair was understood in the same way. Drill so that the future hole is located above the oil level. If you are afraid for your eyes, put a protective shield cut out of cardboard over the drill. However, I drilled without anything and there was nothing but zilch.

Why be wise? Drilled and pricked with a needle. If it didn’t puncture, I still drilled it. Drill 1-1.5 mm. I used to drill with a 0.25 drill bit, but it's difficult without breaking it. It drills where it is cut. And so, my grandfather sawed such a stand on the balcony, using a file in a circle. Then he told how someone fired a gun at him and showed off the bruise. It’s good that he at least said what he did, otherwise I might have believed it.

Where is the sealing ring located on the rod plug? I ask because it is necessary to maintain the maximum length of the pipe. Where should I drill? Here are two photos:

quote: Originally posted by Fake: Drill so that the future hole is located above the oil level

quote: Originally posted by Deni-kin: By the way, how much of this oil is there in general, what should you prepare for?

Honestly, I don't remember. I was drilling a stand that was already leaking, there was a little oil in it, a cube at most. You let it lie down in a horizontal position so that as much oil as possible drains off the top wall. Once the air is released, the oil will no longer flow, it will only ooze. Cover the pipe with rags if you are afraid of getting something dirty, but I don’t think they will be useful. I can’t tell you where to drill - I drilled in the middle, I was just curious what was inside

quote: Originally posted by Fake: You let it lie down in a horizontal position so that as much oil as possible drains off the top wall.

Yes, they drilled her hole and that’s it. There is no more than a couple of cubes of oil. Don't be afraid of it, while you're drilling it will all flow down. The hole definitely won't have it.

quote: Originally posted by Strelok-mod79: Yes, they drilled her hole and that’s it

Judging by the photo, the stand is stretched, made of a round coin, like a 12 gram can. This means the walls are a little thicker, but not by much.

Replacing gas struts in Kalina trunk

Why do you need to change the trunk gas struts ? Firstly, this will make it easier for you to open the trunk; you won’t have to constantly be afraid that its lid will slam shut at any moment. Secondly, the trunk lid will not rattle on bumps in the closed position, since the stops constantly press on it from below. Now let's get down to business.

The trunk gas struts on Kalina, sedan, station wagon, and hatchback change almost the same way. In this case, the work was carried out on a sedan.

I delayed replacing the trunk struts for quite some time. Lately, I even had to pull the trunk lid a little to open it.

After reading reviews about various stops, I decided to buy Aurora stops. They are not the most expensive, but, according to the Internet, they are quite high quality.

First you need to remove the old trunk struts. This is quite simple to do - take a flat-head screwdriver and pry up the fixing bracket. If the bracket does not pull up, it can be removed by pulling it towards the end of the stop (there are special slots there). Thus, you need to remove all 4 brackets from 2 stops one by one.

The stop itself, without staples, should come off easily.

Remove the first one, wipe the seats on the body and trunk lid. The seats on the stops themselves must be lubricated. If this is not the case, lubricate them with thick lubricant - silicone, grease, etc. These stops were lubricated, which undoubtedly pleased me.

Insert the fence and secure it with staples on both sides. It is best to insert the bracket into special slots using the same screwdriver. The second stop needs to be installed in the same way.

At this point, the installation of the gas struts on the Kalina trunk can be considered complete.

Source

Replacing trunk shock absorbers is one of the simplest operations that may be required during the operation of Kalina. However, it is hardly worth rushing things and changing them every year for this reason, because the price of one high-quality stop is on average 400 rubles. At the same time, making trunk shock absorbers serve you for several years is not so difficult.

Car audio

Car audio is not only a reason for pride and an opportunity to show off, but also a kind of modern art. In order to achieve an impressive result, car owners resort to various tricks, and we will consider some of them. Although, if the trunk is intended for transporting potatoes, this is all lyrics.

see also

If the car is for comfort and personal pastime, then you can’t do without music.

There are two options:

- turn your car into a traveling club;

- spend a little money but get good average sound.

For average, but cheap sound, you need an acoustic shelf, it is both sold and easily made independently, put it in place of a standard shelf or convert the standard one into an acoustic one, then problems with fitting disappear completely. It will give a good volume of sound and eliminate unnecessary noise. The shelves that are sold have ready-made cutouts for medium-diameter speakers. Installation will take little time, and the sound will definitely please you.

If you are an avid music lover, then the option with a shelf will clearly not suit you.

Therefore, we will consider the technology of converting the trunk into an acoustic one; this is done in three stages:

- We come up with a design and cut out a pattern from cardboard, transfer the design to plywood and cut it out.

- We glue the edges of the parts with foam rubber, after which we cover the parts themselves with carpet. The structure must be securely fixed in order to eliminate vibration, both from the sound of the stereo system and on bumps.

- We assemble the subwoofer box from blanks and monitor the strength of the structure, because the vibration will be strong and constant. After checking all connections, install the stereo system and enjoy the great sound.

Regardless of the presence of interior decoration, without remote opening of the trunk it is extremely inconvenient, therefore it is important to understand not only how to open it remotely, but also how to move the control button into the cabin.

How to extend the life of trunk shock absorbers

Despite the fact that gas shock absorbers, which are used as trunk stops in Kalina, are considered quite durable and reliable, they fail quite often. The reason for this is, as a rule, insufficient attention to these details and neglect of basic operating requirements.

In fact, gas trunk shock absorbers turn out to be very demanding, primarily in terms of weather conditions. The fact is that at low temperatures the gas pressure drops, which does not have the best effect on their operation. In the cold season, abruptly opening the trunk lid can be detrimental to the stops, so in cold weather it is better to lift it smoothly, without rushing.

It is undesirable to help the shock absorber open the trunk quickly and in warm weather - this will also have a negative effect on its condition. In general, the more often the trunk opens and closes, the less the shock absorbers will last, which is quite logical.

The weight of the fifth door or trunk lid is also important. If a spoiler is installed on it or additional sound insulation is made, which increases the weight of the part, the standard shock absorber may no longer cope with its functions. In this case, it is necessary to replace it with a more powerful one, but identical in length and fastenings. It is better to replace shock absorbers in pairs at once, even if only one has failed.

How to determine if shock absorbers are faulty

Often, traces of oil appear and disappear over time, and then, when the driver notices a loss of controllability, the strut becomes dry again. To determine its serviceability, you need to grab the roof of the car and try to swing it strongly.

Serviceable shock absorbers should stop the body already on the second swing. If the car continues to rock, the struts need to be replaced.

The problem must be diagnosed at the first sign. There are several symptoms that indicate a damaged shock absorber:

- Knock when driving or extraneous sounds in the suspension. This problem occurs extremely rarely. As a rule, this implies destruction inside the strut housing and the rod simply begins to hit the housing, making unpleasant knocking noises. This sound will appear when driving over both large and small irregularities and will haunt the car owner no matter how much the car rocks.

- Deterioration in controllability. The most dangerous and obvious sign of shock absorber failure. As you know, struts are needed to dampen body vibrations that occur when suspension springs operate. If these vibrations are not suppressed, the car begins to sway strongly at high speed and the wheels may briefly lose traction with the road surface. It is worth noting that this malfunction is quite dangerous.

- Leaks on the rack body. Deterioration in controllability occurs due to internal damage to the shock absorber and its depressurization. Traces of leaking oil, which is the main shock-absorbing component of this part, may appear on the rack.

If, after all, the reason for the knocking on Kalina is in the shock absorbers, then you should select the right new spare parts. Don’t even try to restore them; doing so is impractical, labor-intensive and expensive.

As a rule, shock absorbers are not replaced individually, only in pairs.

How to choose shock absorbers for Lada Kalina

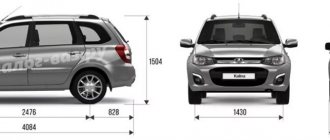

It’s worth mentioning right away that the Lada Kalina racks 1 and 2 are absolutely identical and interchangeable. Therefore, there is no need to look for a shock absorber for a specific model. After all, the bodies are the same. The difference can only be in the catalog numbers, and it is most likely explained by the stiffness of the shock absorbers.

But the selection consists of choosing a company and the appropriate settings. The latter will determine the product catalog number:

- rear shock absorber, Kalina 1 – 11180-2915004-20;

- rear shock absorber, Kalina 2 – 21928-2915004-00;

- front shock absorber, Kalina 1 – 11180-2905002-00;

- front shock absorber, Kalina 2 – 21928-2901031-55.

In fact, there are a lot of catalog numbers and their variations are combinations of rigidity, applicability for the right and left sides, as well as use in a certain modification and the possibility of use in conjunction with other suspension elements. These items are provided as an example.

As for companies, you should pay attention to the following:

Shock absorbers from these manufacturers are considered the best in the world. Shock absorbers for Lada Kalina from KYB (kayaba) are considered to be the most expensive. Kayaba offers a wide selection of shock absorbers and struts for Lada Kalina I and II cars with a wide variety of rigidity parameters.

There is also a budget option - SAAZ. It is stock and often ends up on the assembly line as an original. But the analogs are better than the factory ones, and the durability of the factory racks is nothing more than a legend! It’s up to you to decide whether it’s worth saving, because the cost differs insignificantly.

When selecting shock absorbers, stiffness plays an important role. Here you need to find the right balance. The stiffer the shock absorber, the better it keeps the springs from oscillating, which means the car’s handling increases significantly.

On the other hand, the stiffer the pillars, the worse the comfort in the cabin. The driver and passengers will constantly shake from the slightest irregularities on the road. Therefore, for a more comfortable ride (at the expense of handling), it is better to install softer struts that set the appropriate suspension travel.

Replacing the Trunk Shock Absorbers of a VAZ 2114

innovation shock absorbers on VAZ 2114

Many novice drivers are interested in what springs are on a VAZ. 2114

and why they are needed. Replacement of rear shock absorbers on VAZ 2114. Exceeding the line, VAZ 2114. Replacement. functions shock absorbers are quite wide, they make the car more stable on the road, safer, more reliable, in particular their important role is manifested during sharp turns and when braking. If only the shock absorbers , if this had not happened, the car would have started the same second that the brake pedal was pressed. In addition, the described devices improve the driving process, reduce vibrations that occur on the supporting parts of the car, and prevent accumulation. This is why choosing the right vibration dampening device for your vehicle is so important. See what VAZ 2114 , how to replace rear shock absorbers

what nuances a driver should know

Purpose and types of shock absorbers

Shock absorber. This is a device designed to dampen vibrations and shocks that fall on the bottom of the car, which are then transmitted to the steering wheel and into the cabin. A shock absorber or, as it is also called, a support prevents this process, softens the harshness when driving, making it more comfortable and stable.

In addition, the part in question gives the car maneuverability and reliability. When equipped with good racks, they allow the car to easily make tight turns and withstand any road test. Today the following types of shock absorbers :

Source

How to replace front and rear shock absorbers on Kalina

Before carrying out repair work, it is necessary to properly prepare for this event.

What tool will you need?

To replace shock absorbers on Kalina 1 and 2, you will need the following list of tools:

- spring remover;

- standard set of tools;

- pit or lift;

- jack;

Of course, we shouldn’t forget about the new detail. After everything you need appears, you need to set aside a free day and start repairing.

Removal and installation of front shock absorbers on Lada Kalina

It is most convenient to do this work on a lift, but an inspection pit will also work. You need to perform the following list of actions:

- Hang the front wheel and remove it.

- Unscrew the nut securing the steering end to the strut. Remove the tie rod end (1) using a suitable puller.

- Unscrew the three nuts securing the strut to the side member (2).

- Remove the shock absorber mountings to the steering knuckle (3).

- Remove the shock absorber from the car along with the suspension spring and support bearing.

In order to avoid damage to the brake hose, it is necessary to fix the steering knuckle in the position in which it was standing. This is necessary to prevent it from stretching!

To replace the strut, you need to remove the spring and support bearing (4) from it. To do this, using a puller, the spring is compressed and the nut securing the support bearing is unscrewed. Next, all parts are installed on the new shock absorber, and assembly occurs in the reverse order.

Removal and installation of rear shock absorbers Lada Kalina 1 and 2

The procedure will be the same for hatchback, station wagon and sedan. Necessary:

- Fold the rear seat forward and remove the shock absorber nut cap.

- You need to tighten the spring in advance to relieve tension from the shock absorber and remove it without problems.

- Unscrew the nut securing the strut to the body. To prevent the rod from turning, it can be held using another wrench.

- After this, unscrew the lower mount of the strut to the rear beam.

- Remove the old strut from the car.

Now all that remains is to rearrange the spring and install a new support bearing and rod boot. There is nothing complicated about this. Reassemble the strut as it should sit on the vehicle with a new support bearing and boot.

Mount the strut to the body and ask your partner to tighten the nut securing the shock absorber rod to the rear “glass”. Further assembly occurs in reverse order.

Important note for proper installation

Before installing a new shock absorber on the Lada Kalina, it is necessary to bleed it. The fact is that there is oil inside the rack, which moves through the cavities during operation. Normal operation of the shock absorber is ensured only in a vertical position.

If you place the rack horizontally (as it is transported), then air will get inside, which will have a detrimental effect on the operation of the rack. Installing such a part is strictly prohibited, as it will not last long.

To remove air, before installing shock absorbers, you must perform the following steps:

- Extend the compressed stand from the packaging to ¾ of the length and place the stem down. Wait 5 seconds and squeeze gently.

- Turn the shock absorber over and wait 5 seconds.

- Extend the rod and wait 2 seconds, then flip the post over again and compress.

- Repeat the above 3-4 times.

Practice shows that 70% of people who change stands themselves forget about this important procedure.

After these manipulations, the shock absorber should last as long as the manufacturer guarantees.

Bleeding gas shock absorbers

An effective way to extend the life of gas shock absorbers is to pre-pump them before installation. It is carried out as follows: first, the shock absorber must be installed in a vertical position with the rod down, smoothly compressed until it stops and held in this state for 2-3 seconds. After this, the mechanism is turned over with the rod up, held for 3-5 seconds in a compressed position, and then released until the piston is completely released.

These steps must be repeated 5-8 times immediately before the installation process. It is believed that pre-pumping gas shock absorbers (this also applies to suspension shock absorbers) allows them to last about 40% longer. Naturally, you must follow the above recommendations.

If you want to prevent replacing trunk shock absorbers from becoming as frequent a procedure as changing engine oil , take the time to follow a few simple steps when installing new shock absorbers. Be careful when opening the trunk lid and the fifth door in the cold season.

What happens if you ignore a shock absorber malfunction?

The clearance of the Lada Kalina is adapted to bad Russian roads. Consequently, the car should ride softer, but has a greater chance of losing control. If the shock absorbers are not replaced in time, the driver will have to drive at a lower speed to save his life.

Faulty shock absorbers will rock the suspension on any hole. And when a wheel hits a hole at high speed, the body begins to sway violently, causing a short-term loss of traction between the wheels and the road surface.

Because of this, the axle skids or drifts, which can cause an accident. Also, untimely replacement damages other mechanisms - for example, suspension silent blocks or support bearings.