The domestic car Lada Granta (in Russian Lada Granta) is equipped with a power unit with fuel injection. This configuration requires clear interaction of all sensors.

One of the most important controllers of the electronic system of this car is the speedometer. The article will answer the question - why the speedometer does not work on the Lada Granta. The principle of operation of the entire speed calculation system, symptoms of malfunction and causes of breakdowns will be considered.

Types of speedometers

There are currently three types of speedometers:

- mechanical;

- electrical;

- electromechanical.

On a mechanical type device, speed is transmitted from the gearbox using a cable. The distance traveled on the odometer is set by measuring the revolutions. Each revolution corresponds to a certain amount of mileage. The mileage traveled is reflected on the dial.

Mechanical device dial

In the electromechanical version, improvements have been made that eliminate the shortcomings of the mechanical device. The mechanical flaw was the cable, due to which the information was often incorrect. The electromechanical device is supplemented with a speed sensor, the signals from which are transmitted to the electric motor that rotates the gearbox.

All modern cars are equipped with an electronic device. The electronic speedometer measures the number of revolutions of the wheel. The mileage traveled is calculated by analyzing the wheel circumference and the number of revolutions. The information is reflected on the display.

Photo gallery “Speed indicators”

Design and operation of an electronic speedometer

Electronic speedometers are more accurate than mechanical ones and can have components from an electromechanical speedometer, such as the more familiar drum distance counter.

The electronic speedometer is based on converting the rotation of the gearbox output shaft into pulses of 1-5 volts, followed by conversion to speed or distance traveled without the use of electric motors. It makes no sense to go into detail about their work; this is the prerogative of engineers.

The distance is determined by counting pulses. 6000 rectangular pulses, in accordance with international standards, are equal to 1 kilometer. The readings can be displayed either on an electronic display or via a drum counter.

When displaying speed, pulses are converted into current; the more pulses per unit of time, the greater the deflection of the arrow and, naturally, the higher the speed.

Possible device malfunctions: signs and causes

One of the reasons for speedometer and odometer malfunction is a broken cable. This can be detected by the characteristic sound that is heard in the area of the shield. After a break, the steel ends of the cable touch the sheath, and noise appears.

If the pointer is faulty, the needle either shows incorrect readings or it lies down and does not rise. The cause may be the speed sensor. If it is broken, you need to replace it.

If the speedometer on a Priora does not work, first of all you should check the fuses, they could have blown. In addition, you need to test the wiring and make sure the quality of the contact connections. If the device does not work, it must be replaced.

How to check the device for functionality?

Before changing or repairing the speedometer, you should find the reason why it is not working. First you need to diagnose the speed sensor, since it is most often the cause of the pointer not working.

First of all, you should inspect the regulator for mechanical damage. In addition, you need to check the integrity of the wires and the quality of the connections. In the event of electrical failures, a “Check” warning is usually displayed on the dashboard.

It is difficult to check the functionality of the controller board at home, since special equipment is required. You can check the condition of the gears. If there are nicks or chips, parts need to be replaced (the author of the video is Avtoelektika HF).

Basic faults

The Lada Kalina speed sensor can easily fail. Every car enthusiast can notice the problem. The main “symptoms” indicating the development of the problem are identified, including:

- lack of movement of the arrow (it just lies there);

- the pointer makes sharp jumps;

- the arrow freezes at speed even in the absence of movement;

- The electric power steering fault icon is on.

If the speedometer does not work, the most common reason for this phenomenon is a malfunction of the speed sensor. It is located on the gearbox, secured with one screw. There are three main wires connected to it. If it is a Lada Kalina with a 16-valve engine, you can find the device on the washer side. In the version with 8 valves, it is necessary to remove the bellows of the engine air filter.

To determine the device number, simply remove it and rewrite the numbers. There is no need to rush into buying a new part; first you need to check all contacts. In some cases, the malfunction is due to oxidation of the wires or damage to the wiring. Perhaps the problem is hidden in the presence of metal shavings or other particles.

Many experts have noticed that the malfunction of the speed sensor on Kalina is associated with problems with the electric power steering. If, after replacing the element, it still does not work, the device may be defective or unsuitable for the vehicle. Therefore, it is necessary to select it according to the assigned number.

Instructions for replacing the device yourself

Replacing the drive on Kalina is simple, you need to perform the following steps:

- Using a wrench, unscrew the screw securing the device to the gearbox.

- Next, use a screwdriver to carefully pry the hole and remove the speedometer.

- At the next stage, the removed drive should be inspected for defects and contamination. It is also necessary to check the seat and clean it of dirt.

- When inspecting, pay attention to the gearbox. If oil stains are found, the O-ring must be replaced.

- We install the repaired or new speedometer in its original place.

- We assemble the drive in the reverse order of removal.

After final assembly, the operation of the drive should be checked.

What to do if the instrument panel fails?

If the speedometer on the Lada Kalina does not work, this may be due to a breakdown of the instrument panel. It is supplied to the automotive market only assembled, so it needs to be changed completely.

Before replacing, you should check the reliability of the fasteners that go to ground; this may be the cause of the breakdown.

The procedure for removing and replacing the instrument panel consists of the following steps:

- The steering wheel must be moved to the down position.

- Next, the mounting bolts are unscrewed.

- Then, overcoming the resistance of the latches, we pull the cover towards ourselves and remove it.

- Use a Phillips screwdriver to unscrew the center console mounting bolts.

- Having tilted the shield, we disconnect the connector with wires from it. To do this, you need to move the latch.

- We carry out the installation in reverse order.

The procedures for replacing the instrument panel and speedometer are simple and can be done independently. Thus, there is no need to waste time and money visiting a service station.

Removing and installing the electronic power steering control unit on the Lada Kalina

For this repair you will need a Phillips screwdriver, the whole job will take at least half an hour, as you will have to. After you have “got rid of it”, you can move on.

- First, unscrew the three bolts securing the plastic trim below the panel:

- After it is removed, the control unit becomes accessible, as shown in the photo below:

- The next step is to disconnect all the plugs and wires, out of three. They are attached as usual using latches and are very easy to remove.

- Now you can unscrew the two mounting bolts with a Phillips screwdriver, which are shown in the photo below:

- After this, we take it by the upper part and lower the electric power steering control unit down, since it is still attached to the plate. It lowers simply, just apply a little effort and it will be almost at the very pedals, it is clearly shown below:

- And there is very little left to do - unscrew the three bolts securing the power steering unit from the plate on which it is installed:

- And holding it from below, we take it out freely. For reference, my 2022 Kalina has a used unit made in Korea. And thank God it’s not ours, the quality of the Korean assembly will be better than that of our craftsmen. At least, I never had any problems with the electric booster in 2.5 years of use.

New Lada: Buy a used LADA (VAZ) Kalina station wagon at a price of 140,000 rubles in the Krasnodar region - more than 33 used Lada Kalina station wagon on Avto.ru

If replacement is required, install the new module in the reverse order of removal. But it is advisable that you do not have to change this element in the electronics on Kalina, which is quite expensive, around 5,500 rubles according to some official online stores.

Video “Removing the instrument panel on the Lada Priora”

This video shows the process of removing and replacing the Priora instrument panel (the author of the video is “In Sandro’s Garage”).

To record the exact speed of movement, use the Lada Granta speed sensor (abbreviated as DS or DSA). It is located at the gearbox. Despite its small size, it is one of the main devices of the vehicle.

The Lada Granta engine management system is equipped with 7 main sensors: engine temperature sensor, oxygen sensor, speed sensor, as well as crankshaft position, phase, detonation and mass air flow sensors. The reliability and safety of the vehicle unit directly depend on the condition of these devices.

Malfunction in the instrument cluster

Often the speedometer stops working due to a malfunction of the instrument panel itself. The easiest way to check this is to temporarily connect a known working panel. It is also worth checking the reliability of the contacts on the back of the dashboard. You can also check the vehicle speed readings on the on-board computer.

If the dashboard was tuned (disassembled), then the arrow motor may have been damaged during the work, or the speed arrow is set too deep (the arrow touches the panel trim).

Have you encountered speedometer problems? How did you manage to solve it? Let us remind you that solutions to other faults can be found in the category repair and operation of Lada Granta, Lada Kalina or Lada Priora.

Keywords: instrument panel Lada Kalina | dashboard of Lada Granta | dashboard of Lada Priora

10

0

How to determine that the DS is faulty

The principle of operation of the speed sensor is as follows: there is a certain mark on the gear wheel of the gearbox that generates an impulse using the DS when the wheel rotates. The speed of the vehicle is determined based on the frequency of the received pulses. As the frequency increases, the speed of the machine increases. The signal from the speed sensor, as well as from many others, is displayed on the instrument panel.

The fact that the DS on the Lada Granta is located low indicates that it is strongly exposed to water, sand and dirt. This is the main reason for its failure. The following symptoms indicate that the sensor responsible for the speed of the Lada Granta car is faulty:

- the speedometer needle is at zero while driving or does not always work;

- unstable idling;

- The speedometer readings do not correspond to reality;

- fuel consumption increases;

- engine thrust decreases.

The tachometer stopped working - possible reasons

The revolutions may “go up” due to problems with the internal combustion sensor - then the indicator gives incorrect readings. If this is the problem, installing a new device will correct the situation.

Often a malfunction occurs due to a screen failure. To detect the problem, look at the LED display. If the numbers are not visible, install a new display.

And, of course, check the ground and voltage on the wires. Most often, such diagnostics are enough to identify the source of the problem.

How to check and replace the sensor

This type of speed sensor is present in all VAZ cars

Check the continuity of the electrical circuit, because a break in it can lead to a malfunction of the DSA. Disconnect power. Inspect the contacts carefully. If there is oxidation or dirt, they need to be cleaned. Pay special attention to the wires located near the plug; they are bent in this place and can fray the insulation.

- We measure the resistance in the grounding circuit. Should be 1 ohm.

- If the circuit and resistance are normal, we check the operation of the DS itself.

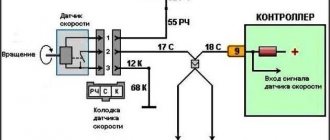

The Lada speed sensor, installed on all AvtoVAZ cars, operates using the Hall effect, i.e. one full revolution is equal to 6 pulses. It has 3 contacts: ground, voltage, pulse signal. We ring the contacts for the presence of grounding and voltage (12 V). If the voltage is absent or less than 12 V, it means that either the power circuit is faulty, or the battery is discharged, or the ECU is broken. The output-to-ground voltage should be in the range of 0.5-10 V. The easiest way to check the operation of the device is to replace it with a properly functioning one.

To remove the DS you will need: a flat screwdriver, a 10mm wrench (ideally a head with a ratchet). In a Lada Granta car, the sensor responsible for speed is located extremely inconveniently, so replacing it is quite difficult. To improve access, first disconnect the thick pipe going to the throttle body from the air filter. Then:

- Disconnect the power plug from the DS. Bend the plastic retainer and immediately pull the shoe up to remove it.

- Unscrew the DS mounting bolt with a wrench.

- Pry up the DS body, because it is tight, and remove it.

We install a working speed sensor in the reverse order and carry out diagnostics.

Some car enthusiasts advise that after removing the DS, carefully inspect it, dry it and apply sealant around its perimeter. After this, reinstall the sensor. But it is better, of course, to replace it with a new one.

It must be remembered that erroneous data from the Lada Granta speed sensor can lead to significant malfunctions in the operation of the engine and vehicle components.

For the information of car owners of cars equipped with ABS: on your Lada, the DS on the gearbox is disabled, and the speed is read from the anti-lock braking system sensors.

How to tighten the electric power steering rack?

The appearance of a knocking sound in the operation of the electric power steering is associated with the need to tighten the steering rack.

New Lada: Grant generator mount 8 valve

How to do it right:

- First you need to disconnect the battery; to do this, disconnect the terminals from it. Unscrew the battery mount; to do this, you need to unscrew two more nuts located at the edges. After this, the battery is removed and put aside.

- Then you need to lift the plastic stand, there are four more screws under it, they can also be unscrewed.

- Having done this, it is necessary to move this stand forward until the platform is disconnected from the air filter housing retainer pad. After this, the trim can be moved back, this will provide freer access to the rail itself.

- At the next stage, you will need to crawl your hand under the rail. Directly below it, as shown in the photo, there is a rubberized cap; it will need to be removed, this will allow the key to access the adjusting nut.

- To perform adjustment work, you will need a special wrench to tighten the rack; without it, the adjustment procedure will not be possible. Using this wrench, you need to crawl under the car rail to install the tool in the required hole.

- When adjusting, be careful not to overtighten the rack. If its tightening is very strong, then when cornering the rack will bite, and this, in turn, may affect the safety of movement. The angle of adjustment is always different, it depends on how much the nut is loose, but usually when performing such work the nut is tightened by approximately 30 degrees. This should be enough to get everything right. After the adjustment is completed, it will be necessary to check that this task was performed correctly. That is, you will need to make sure that the steering wheel turns normally to any position all the way and there is no knocking. If the knock remains, then the adjustment continues.

Lada Granta speed sensor: how to check and replace

To record the exact speed of movement, use the Lada Granta speed sensor (abbreviated as DS or DSA). It is located at the gearbox. Despite its small size, it is one of the main devices of the vehicle.

The Lada Granta engine management system is equipped with 7 main sensors: engine temperature sensor, oxygen sensor, speed sensor, as well as crankshaft position, phase, detonation and mass air flow sensors. The reliability and safety of the vehicle unit directly depend on the condition of these devices.

How to determine that the DS is faulty

The principle of operation of the speed sensor is as follows: there is a certain mark on the gear wheel of the gearbox that generates an impulse using the DS when the wheel rotates. The speed of the vehicle is determined based on the frequency of the received pulses. As the frequency increases, the speed of the machine increases. The signal from the speed sensor, as well as from many others, is displayed on the instrument panel.

The fact that the DS on the Lada Granta is located low indicates that it is strongly exposed to water, sand and dirt. This is the main reason for its failure. The following symptoms indicate that the sensor responsible for the speed of the Lada Granta car is faulty:

Please note that unstable engine idling and increased fuel consumption can also be due to a malfunction of the Lada Granta oxygen sensor, which consists of two devices: a control catenary collector located in the upper part, and a diagnostic one installed in the catenary collector behind the converter. They operate on the same principle and are interchangeable. The control oxygen sensor monitors the adjustment of the composition of the air mixture supplied to the injectors. The diagnostic oxygen sensor signals the presence of oxygen in the exhaust gases after the converter.

How to check and replace the sensor

This type of speed sensor is present in all VAZ cars

Check the continuity of the electrical circuit, because a break in it can lead to a malfunction of the DSA. Disconnect power. Inspect the contacts carefully. If there is oxidation or dirt, they need to be cleaned. Pay special attention to the wires located near the plug; they are bent in this place and can fray the insulation.

The Lada speed sensor, installed on all AvtoVAZ cars, operates using the Hall effect, i.e. one full revolution is equal to 6 pulses. It has 3 contacts: ground, voltage, pulse signal. We ring the contacts for the presence of grounding and voltage (12 V). If the voltage is absent or less than 12 V, it means that either the power circuit is faulty, or the battery is discharged, or the ECU is broken. The output-to-ground voltage should be in the range of 0.5-10 V. The easiest way to check the operation of the device is to replace it with a properly functioning one.

To remove the DS you will need: a flat screwdriver, a 10mm wrench (ideally a head with a ratchet). In a Lada Granta car, the sensor responsible for speed is located extremely inconveniently, so replacing it is quite difficult. To improve access, first disconnect the thick pipe going to the throttle body from the air filter. Then:

- Disconnect the power plug from the DS. Bend the plastic retainer and immediately pull the shoe up to remove it.

- Unscrew the DS mounting bolt with a wrench.

- Pry up the DS body, because it is tight, and remove it.

Possible breakdowns

Troubleshooting in the speed calculation system must be looked for in the electrical circuit. It is better to start work with the fuse.

Fuse

A 10 A fuse is responsible for protecting the instrument panel. It is located in the fuse block and is marked “F1”. It is necessary to remove the element and visually inspect for a break in the internal jumper. If there is no break, but there is melting of the case, then the protection device must be replaced with an exact analogue of 10 amperes. Additionally, you need to inspect the fuse contacts, eliminate any defects, and clean them.

After installing a new fuse, you need to check the circuit for electric current. To do this you need:

- Turn on the ignition.

- Set the multimeter to DC voltage measurement mode.

- Connect the red test probe to the fuse output.

- Black dipstick with ground.

The tester should show a voltage similar to the battery charge. It is prohibited to connect the power circuit directly without a protective device, through twisting, or to insert foreign metal objects between the contacts, as this may lead to a fire.

Sensor

If after replacing the fuse and checking the circuit, the problem with the speedometer does not go away, you need to check the speed sensor. This requires:

- Loosen the clamps securing the air purification filter pipe and remove it.

- Disconnect the EMF power plug.

Both halves of the connecting plug must be checked for dirt, oxidation, and broken contacts. Next, the voltage supply to this plug is checked. Necessary:

- Connect the red measuring probe to terminal “1”.

- Black probe to terminal “3”.

- Turn on the tester in DC voltage measurement mode.

- Start the power unit.

The tester should give a result of 12 volts. Such data will indicate the supply of voltage to the sensor terminals. If there is no voltage, then you need to determine the damage by inspecting the wires for a break. Any damage should be repaired by replacing the faulty wire.

Terminals “1” and “3” can be checked for resistance. Switch the tester to resistance measurement mode and connect the test probes to the indicated terminals. The operating resistance of the sensor varies between 3–10 ohms. Any deviations confirm a malfunction of the EMF.

After checking the incoming voltage, it is necessary to test the operation of the EMF. First, you need to inspect the device. If there are cracks, chips or complete breakage of the plastic housing of the sensor, it must be replaced with an exact analogue. If the case has no visible damage, then a performance test is carried out. To do this you need:

- Raise the drive wheel on a jack.

- Connect the wire from the “+” battery to terminal “1” of the sensor.

- Connect the ground wire to terminal “3”.

- Switch the tester to constant voltage testing mode.

- Connect the red test probe to terminal “2” on the sensor itself.

- Connect the black test probe to ground.

- Spin the drive wheel of the car.

The tester should show voltage that increases as wheel speed increases. The voltage is not stable, since it will be output in jumps due to the fact that the sensor creates pulses.

Similar testing can be done using a 9 volt light bulb. It needs to be connected in the same way as the tester. As the drive wheel rotates, the lamp will blink, increasing the cleanliness parallel to the speed of rotation of the wheel.

If there is no pulse voltage, the sensor will have to be replaced. This is not difficult to do. You need to unscrew the mounting bolt to “10”, turn the sensor slightly and remove it from its seat. When replacing, it is also necessary to change the spacer ring, having first cleaned its seat from oil and dirt. It is also recommended to insulate the sensor connector. This is done using silicone sealant.

Wiring

Often the cause of electronic speedometer malfunction is wiring. It needs to be inspected for the integrity of the insulation. Any damage must be repaired. Damage to the insulation leads to short circuits to ground. This happens especially often after washing the car or in damp weather. If there are broken connections or oxidation on the contacts, install new wiring or solder the old one with insulation of the connections.

Drive unit

There are 2 ways to check the operation of the drive. The first involves simply resetting the odometer. After resetting, the button must be kept closed and the ignition turned on.

The tachometer and speedometer needles must go from 0 to maximum and return to their original position. If this does not happen, then the reason lies in the device itself. Additionally, you can check by disconnecting the speedometer power plug. Next, you need to connect “+” from the battery to terminal “26”. The arrow should respond to a light touch with the wire by deflecting. If this does not happen, the problem lies in the drive - the receiver.

Also, the cause of the speedometer needle “freezing” may be a previous replacement or repair of the dashboard. Insufficiently deep seating of the arrow on the stem may cause it to touch the protective glass. Also, a deep landing may result in touching the scoreboard itself. Dismantling and reassembling the dashboard will help resolve the problem.

Where is the speed sensor on the Lada Granta: photo and price

Car: Lada Granta. Engine: 21116. Asked by: Damir.

Yesterday I came home, started climbing onto the curb and slightly hit the bottom of the car. And then it started. The speedometer needle began to dance, at first it seemed to me that it was even accompanied by music. Then it twitched at zero, twitched to 200, and fell again. No errors occurred; the engine warning light did not light up on the instrument panel.

She didn't get up again. I drove around the yard, looked smartly under the hood, and screwed in all the chips I saw. Did not help.

Knowledgeable people said that the speed sensor was broken, quite logical, but where is it located? I went to a car store to buy a new one to check, the store is good, they accept returns if there was no loss of presentation. And the seller told me that when the speed sensor breaks down, the electric power steering also doesn’t work, but for me it works.

Speed sensor location

An expert on Lada cars with many years of experience. I own a Lada Granta car, I collect cramps based on the Priora. Sometimes I stay overnight in the garage. My wife is more jealous of cars than of women.

The speed sensor on the Lada Granta is located between the BDZ (throttle valve unit) and the brake fluid reservoir.

Replacing the speed sensor

- The sensor can be removed by removing the air filter and inlet pipe.

Remove the pipe and move the air filter housing to the side

Nut 10 and the chip is removed

After you have removed the sensor, clean it; debris may have gotten on it. Since its body consists of a magnet, it could become clogged when it hits a curb.

New and old speed sensor

However, this is unlikely; most likely it has failed and requires replacement. But if there was dirt on it, then there is a chance that it is working. Put it back, connect the chip and test drive it to check.

Electric power steering failure due to speed sensor failure

Indeed, if the speed sensor breaks down, the electric power steering in some cars fails, and error P-0501 (Vehicle speed sensor signal outside the permissible range) should appear on the instrument panel. That's why the steering wheel refuses, so that the car understands that the sensor is broken. In your case, the nature of the failure said that the sensor shows zero speed.

Failure of the electric power steering may indicate a breakdown of the speed sensor!

Sensor price

A speed sensor costs from 300 to 600 rubles.

Speedometer twist for Lada Granta ABS video + instructions

In this article we will talk about winding the speedometer on a Lada Granta car with ABS (also without ABS), and will clearly demonstrate in a video how to wind the speedometer on a Lada Granta with your own hands.

All Lada Granta cars, regardless of the configuration and year of manufacture, are initially equipped with a digital CAN bus, and the car also has a diagnostic connector. The diagnostic connector is located “at the passenger’s left foot” under the trim casing of the heater control console. The video clearly shows the location of the Lada Granta diagnostic connector.

The speedometer knob for the Lada Granta is connected directly to the diagnostic connector and, regardless of the configuration and year of manufacture, DOES NOT REQUIRE additional wires. To start the process of winding up the speedometer on the Lada Granta, you just need to turn on the ignition and insert the screw into the diagnostic connector of the Lada Granta. At the same time, the speedometer needle will deviate to the maximum, and kilometers will begin to add on the Grant’s odometer. The winding speed coincides with the maximum speed value on the Lada Granta speedometer, which is about 200 km/h. After completing the required number of kilometers, turn off the ignition and pull out the speedometer knob from the OBD2 diagnostic connector.

Lada Granta speedometer does not work - reason - Telegraph

Why does the speedometer not work on Lada Granta, Kalina or Priora?

=== Download file ===

Place an advertisement on the site. Lada Club News Shop Discounts Join the LADA 4×4 Anniversary Club! Password Registration Gallery Help Calendar. A couple of weeks ago strange glitches in the behavior of the car began. At times the speedometer stops working. At the same time, the electric power steering works at full power, the steering wheel becomes very light and not at all informative. Miracles also begin with the gas pedal, the acceleration when pressed is too sharp, the movement is jerky. After some short time, everything goes away on its own, the speedometer needle shows the speed, the steering wheel becomes heavier, the gas pedal behaves adequately. The STATE does not see any errors in this. As far as I managed to understand, when the speed sensor dies, the speedometer turns off and the power steering does not work at all. For me it’s the other way around. What else could be the reason for this strange behavior? The car is under warranty, but there is no point in going to the dealer, since the malfunction is not permanent, but rarely appears, but is quite unpleasant. Yes, most likely there is a speed sensor. It doesn't cost much money. DmDmT View profile Find more posts by DmDmT. Where is the speed sensor located? I have the same problem. Nikolay77 View profile Find more posts by Nikolay Oleg08 View profile Send a private message to Oleg08 Find more posts by Oleg The other day the same problem appeared. In the first minutes after starting, the speedometer worked, after which the needle fell and did not rise again. When I looked at the speed sensor, I immediately realized what the problem was. As a result, I pulled out the sensor, wiped it, dried all the contacts, put it back together and that’s it, the speedometer is alive again. I removed the sensor from above, nothing difficult, just a little inconvenient. Added after 1 minute Oh yes, I have a standard grant, the sensor is on the box. VOVAN View profile Find more posts by VOVAN I won’t say that this was a problem, but it’s kind of strange. Sometimes on a STANDING car, with the engine running at XX, the speedometer needle twitches, indicating a speed of about km. What could it be? Vitaly View profile Send a private message to Vitaly Find more posts by Vitaly. Added after 1 minute the same garbage. Vitaly, this happens to me sometimes when starting the engine. I think that there is no jamb in this. Oleg64rus View profile Send a private message to Oleg64rus Find more posts by Oleg64rus. Lada Granta 1. Same symptoms - problems with the gas pedal, the speedometer needle is at zero but the tachometer is fine, the EMI becomes too light. I also noticed that there is no sound signal for an unfastened seat belt, although the light on the dash is on. So what's the problem, the speed sensor? Happybox View profile Find more posts by Happybox. Theme options Printable version. View options Linear view Combined view Tree view. Headlights, lanterns, lamps, interior lighting, controls. Feedback – Official Lada Granta Club LADA Granta Club – Archive – Up. Page 1 of 2. Problems with the speedometer A couple of weeks ago, strange glitches in the car’s behavior began. Send a private message to STAS. Find more posts by STAS. SY Astyon, 2wd, diesel, automatic transmission Messages: Problems with the speedometer Yes, most likely there is a speed sensor. Send a private message to zver. Find more posts by zver. Problems with the speedometer Quote: Find more posts by DmDmT. Problems with the speedometer Hello. Find more messages from Nikolay Granta-Sport was an automatic transmission Messages: Message from Nikolay77 Where is the speed sensor, otherwise I have the same problem. Send a private message to Oleg Find more messages from Oleg Rostov-on-Don Gender: Problems with the speedometer The other day the same problem appeared. Find more posts by VOVAN Problems with the speedometer Hello everyone! Send a private message to Vitaly. Find more posts by Vitaly. Find more posts by victor victor. Problems with the Vitaly speedometer, this happens to me sometimes when starting the engine. Send a private message to Oleg64rus. Find more posts by Oleg64rus. Problems with the speedometer The same symptoms - problems with the gas pedal, the speedometer needle is at zero but the tachometer is fine, the EMU becomes too light. Message from zver Yes, most likely there is a speed sensor. Find more posts by Happybox. Your rights in the section. You cannot create new topics You cannot reply to topics You cannot attach attachments You cannot edit your posts BB codes On

The tachometer needle jumps: causes and troubleshooting

A tachometer is a special device that informs about the speed of the engine crankshaft. Based on its readings, it is easier for the driver to select the engine operating mode. What to do if the tachometer needle jumps? In such a situation, it is difficult to read readings from the device, and the information received is unreliable. Below we will consider the design of the tachometer, its types, main malfunctions and ways to eliminate them.

Types of tachometers

Today there are two types of such devices:

- Analog - devices based on an induction-type magnetic coil. Thanks to its action, the instrument needle moves along the scale and informs about the crankshaft rotation speed. This type of device is usually installed at the factory and is used on most cars. Its dimensions are most often the same as the speedometer, and on the dashboard they are located next to each other. This arrangement is convenient, because the necessary information is in front of your eyes, and there is no need to be distracted from the road.

- Digital. The main difference between such devices is the display of crankshaft speed data on a diode or LCD display. Information is transmitted by a special sensor, which can be magnetic or electronic. In the first case, the device records the passage of the crankshaft at a certain point near the control device. In a situation with an electronic sensor, information is obtained using a beam of light, which is reflected from nearby devices and helps determine the rotation speed. A digital tachometer is most convenient when you need to adjust the operation of the engine or perform any work on the electronic ignition unit.

All tachometers differ in their mounting location. They come in two types - factory (standard) and remote (purchased by the car owner). Analog tachometers are most often used as standard instruments.

On some cars, the manufacturer does not provide a device indicating the frequency. In this case, you can purchase a remote tachometer and install it in a convenient place. Such devices are often used on racing cars, where it is important to have accurate crankshaft speed readings. It is these that the driver focuses on when changing gears. Moreover, special alarms are installed that report when a specific speed has been reached.

Practice has shown that information from pointer instruments is read and perceived better. But if the tachometer needle jumps, it is more difficult to navigate the information. From the point of view of accuracy, digital devices outperform their “brothers” in this regard. But, under normal operating conditions of a car, this is not so important.

Device

With the help of a tachometer, the person behind the wheel receives accurate information when it is better to change gears and provide the engine with the most economical operating mode. Having such a device helps novice drivers, because they can navigate by the arrow and make a decision about the need to change gears. If the pointer approaches the red area, you need to move the gearbox selector up one step. The device can also be used to solve other problems - adjusting engine operation in idle mode, as well as obtaining information about the crankshaft rotation speed while driving.

From a reliability standpoint, analog tachometers outperform digital devices due to their simplicity of design. These devices are based on the following elements:

The operation of the device is based on the electronic principle. Data from the crankshaft is transmitted through wires to the microcircuit, thanks to which the needle moves along the scale. Information about the rotation speed can be taken from various devices, be it a generator, crankshaft or other power take-off shafts. The received data is converted with a certain coefficient.

Malfunctions and ways to eliminate them

If the tachometer needle jumps, this indicates a car malfunction. Eliminating the problem depends on the cause that led to its occurrence. Let us highlight the main causes of the malfunction and solutions:

- Loss of the signal source that goes from the engine to the device, which is caused by deterioration in the quality of contact connections. In such a situation, check the condition of the electrical wires. If a break or damage is detected, replace the faulty elements. A poor contact connection may indicate the presence of oxidative processes. To restore the tachometer to working order, just clean the contacts.

- Low tension. Measure the voltage at “plus” and “minus”, as well as in relation to the body (“ground”) of the machine.

- The tachometer needle does not drop to zero and floats after starting the engine. One of the likely causes of the malfunction is sensor failure. In such a situation, the device needs to be changed.

- LED screen does not work. The malfunction is typical for digital tachometers, and the reason may be the long service life of the device. It is not possible to repair the display, and the only solution is to replace it with a known good part.

- The tachometer needle jumps to XX. If a symptom is detected, it is necessary to check the condition of the distributor. Inspect the condition of the contact group. The reason is the failure of the capacitor, which is installed on the distributor cover and, under certain conditions, can break through.

- The tachometer needle jumps in different operating modes. As a rule, this is caused by a malfunction of the ignition system. To fix the problem, check the system and fix the problem.

- The tachometer needle jumps after replacing the device. In such a situation, set up the device, adjust the position of the arrow and bring it to the zero position. After this, you need to check that the device is connected correctly. For adjustment, a toggle switch is used, which is installed on the back of the device.

- The tachometer needle jumps at high speeds. Here the cause of the malfunction may be a broken switch. It cannot be repaired, so the only solution is to replace the device. The problem is often caused by an engine malfunction, but the breakdown can only be detected by a specialist using special equipment. Another reason may be damage or wear to the wires that supply voltage to the spark plugs. The malfunction is eliminated by replacing the failed element.

- The arrow falls down and twitches slightly due to the appearance of short-term pulses on the coil. The reason may be incorrectly selected standard wires that have inappropriate resistance. To eliminate the breakdown, it is necessary to reduce the value of the external resistor, which is located on the tachometer board.

The tachometer malfunctions discussed above most often occur during operation, and any car owner can solve the problem that has arisen. If the work performed does not allow you to restore the normal functioning of the device, you should contact a service station. Special services have everything necessary for diagnostics, which allows you to quickly identify and fix the breakdown.

when driving, it shows just 1000 rpm more (for example, idling on a warm engine 1800-1900, although you can hear that the engine is running at 800-900 rpm, that is, at idle). Is this due to problems with the tachometer itself or are there other reasons? Is it possible to somehow adjust the correct readings or do I need to change the instrument cluster?

I repeat - when the engine is turned off, the needle shows 1000 rpm and does not drop to 0)))

Weight of output stages

This is interesting: The clutch drives in a Lada Granta car

Lada Granta why the speedometer does not work

I have a Kalina from the 10th year, I’ve already changed 2 sensors, they stopped working, I don’t have any chips, many people say that just remove the chips and the problem will go away, it didn’t help me, there are no chips, I had to install a new one

07.12.2017 – 23:21 Zhanar Davletova

I have a Lada 21901 about two weeks ago when a grinding noise appeared when the clutch was released at reverse speed, other speeds are on normally, please tell me what the reason is. year of manufacture 2013 cable clutch.

05.12.2017 – 13:09 Sasha Garkush

24.11.2017 – 21:14 Almas Kurmashev

I also changed the speed sensor at 30,000 thousand mileage

26.10.2017 – 03:23 Valera Kulik

the same crap happened, bought a sensor for Kalina2, installed it, it shows less, but it turned out that I had a Priorovskaya box, I had to take another one

10/14/2017 – 04:11 Valera Kulik

everything with the first numbers 1118 is a viburnum, and the rest of the numbers are similar, I encountered this too, on my viburnum there are 2 pillars Priorovskaya box with the first numbers 2170, and the rest are the same as with the Kolin sensor

04.10.2017 – 13:56 Yuri Meleshkin

Thanks for the video I replaced the sensor and the machine works correctly again

09/15/2017 – 12:24 Ilya Valinurov

The author easily and simply took out the sensor, but for me it barely came out, I suffered for two hours.

08/21/2017 – 21:08 Andrey Platov

Rocker box? I have a cable one, I poured oil through it when I changed it, there’s just no dipstick on the cable one, my sensor is small, the ball on the bottom looks different

08.08.2017 – 18:57 ertai usenov

Good afternoon, could you please tell me if I have a Lada Granta 2012, I lose speed when driving, I take my foot off the gas and put it back on, I continue driving, what is causing this, thanks in advance

07/22/2017 – 13:35 Vladimir Smir

Good evening. Tell me, where did you buy this computer?

07/19/2017 – 05:41 Uraxa 32

For e-gas, even if you remove the plug for a month, the error will not go away. The ECU is designed differently; it has energy-independent memory. forget about the terminals.

06/30/2017 – 02:04 Andrey S

changed 5 dachas in four years

02.06.2017 – 10:15 Erbol Taldybaev

Good evening, I have a grant of 14 g, mileage is 38 thousand, the speed shows that no, it writes an error of 500, tell me, beaver people, what’s going on

05/08/2017 – 14:31 Viktor Sankov

Very good and useful video. My Lada's speedometer doesn't work either. I will repair it the same way. Thanks to the author of the video.

04/16/2017 – 18:36 Viktor Sankov

I have a question for the author of the video. When you remove the sensor, you first need to separate the electrical wires. How to remove the wires? Just pull them up or something else? there is a bracket or some kind of clamp, what should I do with this figurine? Explain, please.

04/14/2017 – 10:45 Alexander Glazkov

04—manufacturer -Kursk, 02—manufacturer Kaluga, don’t look at the numbers at the end, but just look for the Prior sensor. Don’t repeat my mistake, I walked around half the city looking for exactly the same sensor as the one I had. In the end, I bought the exact same one, and it’s from Kalina. It didn’t fit - the number of pulses is 3 times less, the speed shows accordingly.

04/05/2017 – 11:38 Azamat Karatayev

Hello Alexander, please tell me what signs you had when the sensor broke down? By the speedometer?

03/22/2017 – 01:22 Azamat Karatayev

Thank you It’s just that the EUR failed for me too. I think that’s where my legs grow too

02/20/2017 – 03:21 Alibek Kozhanov

Hello Alexander, my speedometer sensor fell off, I bought it without diagnostics and put it back in place