Hi all! I can’t say that car horn malfunctions occur very often and everywhere. But we cannot exclude a situation in which the signal does not work.

Car horns are safety features. Moreover, they must be present in all vehicles and be in good condition. This will allow you to give a timely signal to other road users, inform about the approach, and prevent collisions and other dangerous situations.

But at some point it happens that the sound signal located on the steering wheel suddenly stops working. It is necessary to address the issue of diagnostics as soon as possible, since it is dangerous to continue operating the car with a non-working horn.

Sound signal on a car: principle of operation, types, installation, malfunctions

Principle of operation

The operating principle of car signals is based on the cyclic closing and opening of contacts. This causes the membrane to vibrate. The volume, tone and strength of the current consumed are determined by the gap between the armature (moving contact) and the core (fixed contact).

Depending on the current consumed, the signals can be switched directly by the switch or via a relay. Sound signals in a car can be hornless (noise) or horn (tone). The set of sound signals includes noise and tones, configured to work together.

The main purpose of the sound signal is to attract the attention of other road users, especially when there is not enough visibility.

Sound signal of vibration type, hornless. The switch with a ring button is installed on the steering wheel. On the VAZ-2101 car, two signals are installed - low and high tones. The signal consists of a housing, an electromagnet 3, an armature 4, contacts 6, a membrane 7 and a resonator disk 5.

When you press the button, the electrical circuit is closed, and current from the battery flows through the closed contacts 6 into the winding of the electromagnet 3. In this case, the electromagnet attracts the armature 4, which bends the membrane 7 and simultaneously opens the contacts 6.

The electrical circuit is interrupted, the electromagnet is demagnetized, and the armature moves back under the action of the elasticity of the membrane, as a result of which the contacts close, a closed electrical circuit is formed again, the armature is attracted again, and the process repeats. This creates frequent vibrations of the membrane (up to 100 vibrations per second) and sound appears.

The sound tone of each signal is adjusted by screw 1 located on the rear wall. When the screw rotates clockwise, the sound intensity increases, and when rotated counterclockwise, it decreases.

Car alarm device

Modern car alarm is a complex system and consists of the following components:

- immobilizer;

- locks and blockers;

- special sensors;

- sound notification device;

- Remote Control.

Car alarm device

Pay attention! The main element of the anti-theft system is the immobilizer. This is a kind of “brain” of a car alarm.

The immobilizer consists of an anti-theft relay and a control unit. These elements are installed in a break in the electrical network. The design of modern systems does not provide for additional wiring to connect the elements with each other, so anti-theft systems are practically invisible. The alarm is triggered by a coded signal emanating from the control panel. Some manufacturers produce systems in which the car owner is recognized using a fingerprint.

Car alarm circuit

Repair and operation of the VAZ 2108 2109 21099 car

The sound signal of the VAZ 2108 2109 21099 is directly related to the safety of driving a car, since with its help the driver comes into contact with other road users. Therefore, the sound signal must always be in good working order.

Steering wheel horn switch

But it often happens that it doesn't work. Let's look at the possible reasons: 1) Fuse F8 has burned out (it may differ depending on the type of mounting block) in the mounting block. 2) Relay K8 is faulty (it may differ depending on the type of mounting block) in the mounting block. 3) The sound signal itself is faulty.

4) Poor contact in the audio signal circuit.

Let's go in order:

1) Fuse F8 protects the K8 relay circuit and the sound signal itself from a short circuit. If fuse F8 has burned out, then you first need to make sure that the electrical circuit of the VAZ 2108 2109 21099 sound signal is not shorted.

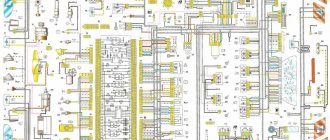

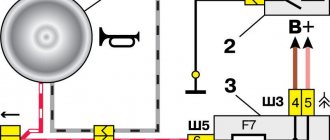

VAZ 2109 sound signal circuit

If the short circuit remains, the new fuse will also burn out. It is necessary to find and eliminate the cause of the blown fuse. 2) If relay K8 is faulty, then when you press the signal on the steering wheel it will not close +12V to the sound signal. A faulty relay must be replaced.

3) The sound signal is located in front of the radiator of the cooling system.

Sound signal VAZ 2109

To get to it you need to bend or remove the decorative radiator grille. Checking the sound signal is simple. One of its contacts is constantly connected to ground; the second contact must be supplied with +12V from the battery. To do this, take a piece of wire about a meter long.

We securely connect one end of the wire to the +12V battery, and connect the other end to the sound signal. If the signal does not work, then it is faulty. The sound signal of the VAZ 2108 2109 21099 has a volume control, you can try turning it. Or disassemble the signal itself; perhaps a visual inspection will help determine the cause of the malfunction.

4) Poor contact means that +12V does not reach the audio signal.

A common reason is poor contact here

If your fuse is intact, the relay is working, the horn itself and the switch on the steering wheel are working, then most likely the problem is in the wiring.

Either in the mounting block, or on the sound signal itself of the terminal oxidation. You can check whether the voltage is coming to the sound signal or not using a multimeter.

One person presses the signal on the steering wheel, and the second measures the voltage on the sound signal in front of the radiator.

It's time to stop

In fact, expressing your displeasure by beeping is completely inappropriate. The taxi driver will continue to behave in the same way on the road, regardless of your signal. In cities, it is illegal to use your horn in a residential area unless there is a traffic situation where you really need to do so, otherwise you will face a fine. In general, beeps are not intended to give your teenage son the opportunity to signal to his girlfriend that he has been waiting for her on a date. A short horn will help attract the attention of a pedestrian who steps out onto the roadway without looking around, or of some mother who is driving her children to the section, chatting on the phone and looking in the rearview mirror at her whining offspring.

The horn is required by law - you need to get it fixed or you won't pass inspection. A zealous inspector might even write you a citation if your horn isn't working properly.

The sound signal does not work • MOYMEKHANIK.RF

A sound signal in a car is an element that the driver may not use for a fairly long period of time (this simply will not be necessary).

And one day, faced with a situation that requires its operation, the driver may suddenly discover that the car’s horn does not work or the engine emits blue smoke. Only a car mechanic knows the reasons.

This is not just an unpleasant fact, but in different situations it can lead to the most unpredictable consequences, because with the help of a sound signal the driver notifies about the approach of a car, potential danger, etc.

To avoid such troubles, it is not so difficult to check its operation every day when leaving home by beeping once or twice. And yet, let's look at the main reasons why a car's horn may not work.

Keep in mind

You can name a number of situations and factors due to which a car’s sound signal can fail and stop working normally. The most common among them:

- blown fuse;

- faults in the signal relay;

- unstable contacts (under the steering wheel hub, in the switch, etc.);

- the signal pressure stand is stuck;

- the signal adjustment is disrupted or the plates inside the mechanism are stuck;

- slipped terminals or breaks in connections;

- the signal connection is loose or the winding is burnt out;

- Dirt and water got inside the mechanism.

To understand how to fix problems that arise, you need to know how a car horn works .

Therefore, if you yourself do not understand the nuances and subtleties of the operation of this element, then you should not experiment; it is better to entrust the process of diagnosing and troubleshooting to specialized specialists.

To anyone who has encountered a similar problem and requires help, the experts from the “My Mechanic” service are ready to offer their services.

Our recommendations

Malfunctions in the operation of the sound signal are usually detected at a time when it is absolutely necessary. And if you are faced with such a problem, you should not delay your trip to a car service center. And although the sound signal does not directly affect the performance of the car and safety while driving, it must be in good condition.

Car horn repair

Car horn

Sound signal operation diagram

How important is it

The technicians from the “My Mechanic” service know how a car’s horn works and determine the possible causes of problems with the horn, following clear operating instructions: checking the fuse for integrity, the serviceability of the relay, the integrity of the contacts, checking whether the engine is overheating or not, etc.

Sometimes it is enough to simply tighten the screws on the contacts, but sometimes you may need to replace the entire signal. It’s better to entrust the process of identifying a malfunction and eliminating it to a technician, then you can be sure that the next time your car’s signal will not let you down if necessary!

Signs that indicate you need this service

- Fuse burned out

- The sound signal does not turn on well

- The sound signal is faulty

Source: https://MyMechanic.ru/services/horn-does-not-blow-inspection/

Troubleshooting alarms on the road

What to do if the alarm system fails far from home, somewhere on the highway? Can it be repaired on the road? There are several procedures that can quickly bring a car alarm into working condition.

If the alarm system breaks down on the road

- Bring the remote control closer to the central unit and press the alarm system disable button.

- Remove one of the battery terminals to force a reset of the entire system.

- Drive to a quieter place if problems with the alarm appear in the area of noisy industrial facilities (signals from the remote control may simply be jammed).

Self-repair of car alarms

Also, while on the road, be sure to check the condition of the battery, because when the charge drops to a certain point, the system is activated. This is a precaution to protect the car from theft by removing the battery terminal. These simple manipulations will help fix car alarm breakdowns on the road if the malfunction is not serious.

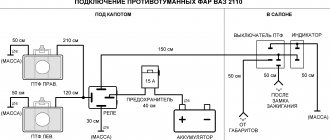

Correctly connect the car signal

Home > On the computer > connect > Connect the car signal correctly

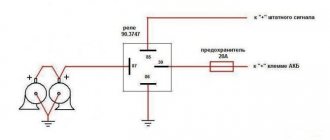

Let's consider a universal diagram of a car sound signal:

- The so-called anchor.

- Device rod.

- Nut for adjustment.

- Lock-nut.

- The first tungsten contact of the horn.

- Another tungsten contact.

- Capacitor element.

- Core.

- The housing that contains all the components.

- Activation button located on the steering wheel.

- Resonator disk.

- Membrane.

- Winding.

- This is a relay contact.

- Another anchor.

- Relay coil.

- Signals.

In accordance with the connection diagram, when the driver presses the control button, a current begins to pass through the winding, which ultimately magnetizes the core, which in turn attracts the armature.

With this anchor, the rod that bends the membrane begins to move, and thanks to the nut, the contacts open, which helps interrupt the electrical circuit. All elements, in particular the disk, rod, anchor and others, return to their original position using a spring and membrane.

In this case, the contacts close, which again leads to the passage of current through the winding. The process of opening the contacts is carried out by pressing the horn button on the steering wheel (the author of the video is the channel pribambas sender).

Possible malfunctions: signs and causes

By what signs can you determine that a car horn needs repair:

- The steering horn does not work. When the driver presses the steering wheel button, the sound device does not work.

- The device sometimes works, sometimes it doesn’t. When you press the button on the steering wheel, the horn first sounds and then disappears.

As for the reasons why a device may fail, there are many:

- A fuse located in the fuse block under the hood or inside the vehicle has blown. In case of such a problem, the operation of the horn can be restored, since it is not damaged. The car may also, in addition to the fuse, have a relay.

- The horn itself is broken. If you replaced the safety element, but this did not help solve the problem, then you need to check the horn itself. To do this, the device will need to be removed, and its contacts will need to be connected directly to the battery. When connected directly, a functional horn will sound.

- In some cases, the reason lies in the appearance of a short circuit in the vehicle's electrical network. A short may affect the connection circuit, so you must first check the functionality of the fuse socket. Sometimes the horn may not work correctly due to circuit damage and current leakage.

- Also, the cause of the malfunction sometimes lies in worn-out clamping contacts located on the steering column. A malfunction of this type is more typical for domestic cars. As a result of long-term use, the springs begin to wear out over time, which leads to the fact that the impulse through them cannot be transmitted from the button to the buzzer itself.

- It also happens that the slip ring wears out right on the steering wheel.

- If the contacts are not worn out, then they could simply oxidize. Long-term use, as well as lack of maintenance, lead to deposits forming on the contacts over time. As mentioned above, this problem can cause difficulty transmitting the signal to activate the buzzer.

- The contact blades are located under the steering wheel hub. This petal may burst over time; sometimes the cause should be sought in the jamming of the pressure rack.

- The horn winding is burnt out.

- Sometimes the horn malfunction is due to a damaged electrical connection or an accidental disconnection of the terminal directly on the signal itself.

- Sometimes the reason for a non-working signal may be a break in the cable on the steering wheel on cars equipped with an airbag (video published by the channel Learning to drive a car. All secrets for beginners).

Do-it-yourself signal diagnostics and repair

How to check and repair the horn yourself? For diagnostics, you will need a tester (preferably a digital multimeter, but if you don’t have one, you can use a regular one), crimping pliers, pliers, and a utility knife. Prepare spare wiring and a service manual for the machine.

Checking with repairs is performed as follows:

- The functionality of the fuse and relay is checked; you need to find the mounting block. A more precise diagram is indicated in the technical documentation, but usually the safety device is located in the power supply unit; it can be installed in the dashboard. Once you have located the block, examine the diagram on the back of the block cover to find the fuse. Dismantle the device that is responsible for the operation of the horn and carefully inspect it - if there is an open circuit, this indicates that the fuse is not working.

- But if the device is intact, this does not mean that it is functional. You need to diagnose it using a tester. Set the multimeter to the resistance measurement mode with sound (if we are talking about a digital tester and it has such a function). If you have an analog multimeter, before diagnosing you will need to calibrate the tester; to do this, short-circuit its probes with each other and move the regulator to zero. Then press the tester probes against the contacts of the safety device. If the part is working, then the multimeter will show 0 Ohm, but if not, then if there is no change on the display, we can conclude that the resistance is too high. This indicates a broken fuse and the device needs to be replaced.

- After this, if the fuse is working, you need to find the relay block, which is located either in the engine compartment or in the interior of the car - use the service book to search. Typically the relays are located in the same fuse box. The easiest way to check the operation of the relay is to swap the devices with other similar parts. In most cases, relays are interchangeable, so if after replacing the device the horn starts working, then you can understand that the reason was in the relay.

- You should also check the steering horn switch; a tester is also used for this. If there is no power supplied to it, then of course the button will not be able to respond to pressing.

How to properly test a relay for functionality with a multimeter

Although electromechanical components are considered the most reliable, they still fail. For example, a relay that fails the least often, but when diagnosing, you need to check it first. You can read below about how to do this correctly.

Relay Test Tool

So, how and how to check the serviceability of a car relay or any other? You will need a regular multimeter, also known as a tester.

There are two main types of multimeters on sale:

- Analog or pointer. Everyone remembers it from school physics lessons: a semicircular scale with an arrow. You can use them only if you don’t have a digital one at hand. Their accuracy, especially the new one, leaves much to be desired, even down to the reading of random variables. The only exceptions are old Soviet multimeters, which still work well today.

VAZ sound signal does not work

VAZ sound signal does not work

Published: September 9, 2015

A non-functioning horn on a car is a very dangerous malfunction. The most unpleasant thing is that they find out about this breakdown just when the signal is needed most - in a dangerous situation on the road. What could cause the signal to fail?

There are several reasons why the horn may stop working. Almost all of them are electrical and simply involve no contact where it should be. Let's go through them all:

Horn fuse blown

The very first and easiest check that can be performed when the sound signal is not working is the integrity of the fuse. If it turns out to be burnt out, then there may be a short circuit in the car.

Try inserting a whole fuse that matches the rating (How to choose a fuse. Colors and ratings). If it burns out in the same way, it means there is actually a short circuit.

If not, then perhaps the fuse has simply exhausted its resource and you should pay attention to other reasons.

The horn button does not work

The signal in most cars is turned on by a button in the center of the steering wheel. There are variations with a button in the steering column switch or a certain position of this switch itself, but this is rare.

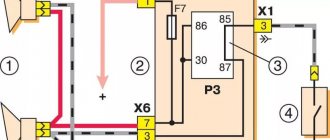

There are actually a whole bunch of places inside the steering wheel where contact can be lost, leading to the failure of the horn. To understand exactly where they can be located, you need to understand how the sound signal in the car turns on. Let's look at the diagram.

Diagram for connecting an audio signal via a relay

This circuit assumes the presence of a signal activation relay. This relay is found on all modern cars. On a certain category of cars (for example, VAZ classics), there is no relay. In this case, the signal is connected directly through the button on the steering wheel.

The diagram shows that there are two electrical circuits: control and power. The power circuit feeds the signal and does not come into the car interior; the control circuit, on the contrary, comes to the steering wheel. When you press the signal button, the control contacts of the relay close, connect the power circuit and the signal turns on. What a relay is, control and power contacts, read the article: how a relay works in a car.

The control current from the relay is transmitted from the steering column to the steering wheel through a floating contact. There may be one, or maybe two. These contacts rub against a special conductive ring built into the steering wheel at the point where it is attached to the steering shaft. Due to the fact that the contacts are spring-loaded, they are constantly pressed against the ring, ensuring the transmission of current to the steering wheel in any position.

Then the voltage is transmitted through a short wire to the button and when it is pressed, the electrical circuit closes to ground - the signal turns on. Now about malfunctions that can occur in the steering wheel.

ATTENTION! It is better to entrust all work related to disassembling the steering wheel on cars with airbags to a car service center. Unskilled actions can cause the airbag to deploy, which can lead to life-threatening injuries!

The pressure contacts on the steering column rub against the slip ring whenever you move the steering wheel and wear out over time.

Sooner or later, a moment may come when they can no longer reach the contact ring on the steering wheel and then pressing the horn button will lead to nothing.

To avoid this, when removing the steering wheel for any repairs, it is necessary to lubricate the contacts and the ring on the steering wheel with a conductive lubricant, for example, graphite. Such treatment will reduce the friction of the contacts on the ring and extend their service life.

– Worn slip ring

Exactly the same malfunction can befall the conductive ring in the steering wheel. It can also wear out and lead to signal failure. The method of struggle is the same - lubricant.

The wear of the clamping contacts or slip ring has an insidious property: due to uneven wear, the contact may disappear only at certain steering wheel positions. For example, when driving straight, the signal works, but when turning, it does not. Such symptoms almost always clearly indicate problems in the contact pair “steering column - steering wheel”.

Worn contacts and a ring in the steering wheel, as a rule, cannot be repaired. Therefore, the best solution is to replace these elements with new ones.

– Oxidized contacts inside the steering wheel

Another “steering” problem is the oxidation of internal contacts. Due to the large amount of oxides, a sufficient amount of current cannot pass through the contacts inside the steering wheel and the sound signal is silent. You need to disassemble the steering wheel and clean the contacts.

Wiring diagram for sound signal without relay

Horn relay or wiring failure

The next group of reasons for a malfunctioning sound signal is broken wiring or a failed relay. The wires in the signal power circuit can be simply broken, pinched, or even disconnected during major repairs. Often during reassembly, the wires are connected incorrectly or not connected at all.

Make sure that all wires responsible for the signal are connected correctly. On a number of cars, the horn is located too low, which is why it ends up in slush and water during transitional seasons. Mixtures that are used to sprinkle roads against ice in winter are also added here.

Under such conditions, the terminals on the signal itself can oxidize and even rot the wires. Check this place out.

If your car has a horn relay, then it is worth checking it. Find where this relay is located using your car's complete wiring diagram and do an experiment: press the horn button and listen. If the relay clicks, it means it is probably working properly. Silent - you need to check the presence of voltage at the relay control contacts when the button is pressed.

Failed horn

If the relay still clicks, check for voltage on the signal itself. Here you will have to work with an assistant: one holds the signal button, and the other checks the voltage.

The test can be done with a regular test light or a multimeter, which is more reliable.

The multimeter is able to show a weak voltage, which will be a sign of heavily oxidized contacts in the signal power circuit or a short circuit.

If voltage arrives, the “mass” signal wire has no oxides and is securely connected to the body, and the signal is silent, it means it has burned out. In this case, as a rule, the “beep” has to be replaced.

Car alarm functions

The purpose of the alarm is to protect the vehicle and property stored in it from theft. Security functions of car alarms include:

- prevention of removal of wheels from the vehicle and its evacuation;

- preventing entry into the interior, trunk or engine compartment of a car;

- notification of mechanical impact on the vehicle.

Car alarm functions

When physical pressure is exerted on the body, special sound and light signals are activated, which have a predominantly psychological effect on the attacker. A loud siren combined with outdoor lighting deters the thief and attracts the attention of everyone nearby.

Principles of car alarm operation

Classification of car amplifiers

Car amplifiers come in several types and differ in the number of receiving and reproducing channels:

- For 2-3 channels. The amplifiers are designed to connect 2 speakers or a subwoofer, and can have advanced functionality: a low-pass filter, an additional bass amplifier. These settings are typical for amplifiers that are designed to synchronize with a subwoofer.

- For 4 channels. The amplifier contains a paired circuit of two 2-channel devices, which are installed in one unit and under one power source. The amplifier operates in tri-mode; three acoustic channels are connected to a single stereo output - two stereo and mono.

- With 5 channels. The amplifier has a built-in 4-channel device circuit plus a fifth channel for connecting a subwoofer.

All amplifier modules are classified according to efficiency and distortion parameters of the reproduced signal. Class A amplifiers transmit minimal distortion of the sound pulse and provide the most comfortable sound. Since amplifiers of this class have low efficiency due to the fact that up to 80% of the power remains in the electrical circuits of the device, and due to the high price, they are rarely installed in cars.

No sound

Neither signal makes any sound other than a squeak? Then the problem lies somewhere in the wiring. Now is the time to check the fuse, which is most likely hidden deep down in the dash, driver's side dash, or under the hood - or just about anywhere in the front half of the car if it's not in one of the obvious places. Find the location of the fuse box and special fuse in the owner's manual.

Inspect the instrument panel cover or check your owner's manual to determine which fuse protects the signal circuits. If the S-shaped strip is broken (fuse on the right), replace the fuse.

If the metal strip inside the fuse appears to be broken, replace it with another of the same amperage rating. It is very rare, but fuses fail for no apparent reason. If the fuse is bad, chances are you have a problem that will cause it to blow again, sooner or later.