You will learn how to adjust the carburetor 4178 on a UAZ in this article.

Many problems are associated with the malfunction of such a part as the carburetor; for example, high fuel consumption and difficulty in gaining speed; this problem occurs due to a malfunction or poorly configured carburetor. Which carburetor to choose, how to install it and what is required for this, we will tell and show you in this article. And in the end, we will give an example (review) of the result of replacing an old carburetor with a new 4178 on a UAZ, what effect a person achieved when he changed it.

Many UAZ owners are interested in choosing the right carburetor for their car. The DAAZ 4178 carburetor is the most popular choice, improving the dynamic characteristics of the car and reducing fuel consumption. It will be useful to know: Adjusting engine valves 4216

DESIGN AND PRINCIPLE OF OPERATION OF THE IDLE SYSTEM

The engine requires only a very small amount of mixture when idling at minimum speed. Under such conditions, a fully closed throttle valve is observed. But at the same time, the level of vacuum in the diffuser is not enough to start the GDS.

For this purpose, the DAAZ 4178-1107010-30 carburetor has an idle system in its design. Its task is to prepare a mixture that allows for stable operation of the engine with the throttle completely closed.

The idle system channels combine a special cavity behind the throttle bodies and the upper part of the chambers. When the engine is idling, a fairly high vacuum is created under the damper. When exposed to it, fuel flows from the emulsion channel into the idle system channel. The ratio of fuel to air in the mixture depends on the capabilities of the jets. Then the mixture enters behind the throttles, where it is then mixed with air, for which there is a technological gap between the damper and the walls of the chamber, which can be adjusted with a quantity screw installed on the damper lever in DAAZ 4178-1107010 carburetors.

The amount of mixture that passes through the channel into the throttle space can be adjusted using a special quality screw with a conical nozzle. If you twist it, the cross-section of the channel decreases. If the throttle valve opens more smoothly, then the amount of air increases significantly, but the volume of fuel remains the same as it was. The GDS still does not enter into this process due to lack of rarefaction. The result of this is a lean mixture and failure of the engine.

TRANSITIONAL SYSTEM

For a smoother transition from idle to medium operating mode, the DAAZ 4178-1107010-40 carburetor is equipped with a special transition system. It connects with its channels to the channels responsible for idling. There is a special hole here, which is made in such a way that after opening the damper it falls into the zone of maximum vacuum. This channel also supplies some of the mixture to the chambers. Thanks to this, there is no sharp transition between engine operating modes. At idle, when the throttle is completely closed, air is added to the mixture. The composition is compensated by the presence of jets. If you tighten the screw responsible for the amount of mixture, then the damper will open. The gap between the damper and the chamber increases, and the amount of air decreases. At the same time, the crankshaft speed increases. If you unscrew the screw, the frequency will decrease.

Setting up the mechanism

Next we adjust the DAAZ-4178 carburetor. The calibration process involves a few simple steps. First you need to warm up the power unit well. The screw responsible for the quality of the mixture on the carburetor must be unscrewed almost completely, and then tightened about 2.5 turns.

The screw responsible for the amount of fuel mixture is necessary in order to set the speed. To do this, you need to rotate the screw until the revolutions are about 850-950. Next, using the same quality screw, we will find the highest revolutions, then use another adjusting screw to return it to 900 revolutions again. These steps must be repeated until the rotation of the quality screw increases the crankshaft speed.

If the rpm starts to drop, then you have found the transition from richer to leaner. All that remains is to tighten the quality screw and leave it at this mark. Now you can no longer touch the DAAZ-4178 carburetor. Its adjustment is completed. But this is true if, when you press the accelerator sharply, the transition from maximum speed to idle goes well. If this is not the case, then you need to slowly turn the quality screw.

So, we found out what technical characteristics the DAAZ-4178 carburetor has.

STARTER DEVICE

When the engine starts, the crankshaft rotates at low speeds. The vacuum in the intake chamber is quite low, and the fuel evaporates very poorly. Also, if the engine is cold, fuel vapors condense in the intake tract. To make the starting process more stable, it is necessary for the DAAZ 4178 carburetor to prepare a richer mixture. So, the air damper closes and the throttle opens. To make the engine easier to start, carburetors are equipped with a special starting device.

ECONOSTAT

designed to further enrich the mixture when operating at maximum loads. This is a sprayer that is installed at the very top of the mixing chamber. Fuel is supplied to the econostat through the channel where the fuel nozzle is installed.

ECONOMIZER OF POWER MODES

In order for the engine to produce maximum power, the mixture must be very rich. To prepare it, the DAAZ 4178-1107010 carburetor and all other models are equipped with a so-called economizer. This system allows for additional fuel to be supplied to the atomizer. But it does not pass through the main fuel jet. A special drive is used to turn on the economizer.

INSTALLATION OF CARBURETOR DAAZ 4178 – 1107010 ON UAZ

does not involve complex alterations.

It should be noted that a thick insulating gasket from the K126 carburetor on the UAZ will be required. Failure to install the gasket will result in damage to the accelerator pump drive.

Step-by-step instructions for installing the DAAZ 4178 - 1107010 carburetor on a UAZ involve the following steps:

— the air filter with the housing is dismantled and the standard carburetor is removed;

— the mounting studs are unscrewed from the manifold and replaced with new, shorter ones;

— the electro-pneumatic valve is dismantled, and an additional switching relay is attached in its place;

— a new carburetor DAAZ 4178-1107010 is installed (a thin gasket is installed first, and then a thick gasket from K 126. If you do not install a thick gasket, the accelerator pump foot will rest against the manifold);

— the fitting on the carburetor is connected to the fitting on the ignition distributor via a hose;

— the electrical control circuit of the forced idle economizer (EFS) is being reinstalled;

— the quality and quantity screws set the optimal speed and regulate the stable operation of the engine.

Installation

Installing the unit is easy. Even a novice car enthusiast can handle it.

- We remove the standard device;

- We change the mounting studs in the manifold (shorter ones are required);

- We dismantle the energy-pneumatic valve (in its place we install a switching relay);

- We install gaskets (thin, then thick). If not installed, the pump drive may be damaged;

- We install DAAZ-4178;

- We connect the fittings of the unit and the ignition distributor with a hose;

- We lay out a new electrical circuit for economizer control (EPCH);

Even a novice car enthusiast can cope with installing the DAAZ-4178 on a UAZ

ADJUSTING THE CARBURETOR DAAZ 4178 – 1107010 FOR UAZ

Using the quality and quantity screws, the idle operating mode of the UAZ engine is set. The idle mode is quite unstable, and without proper settings the car will be impossible to operate.

Adjusting the idle speed on a UAZ car comes down to the following steps:

1. The engine of the machine needs to be warmed up well; to do this, the quality screw is completely unscrewed and then tightened 2.5-3.5 turns.

2. Using the speed screw, the engine idle speed is brought to 850-950 rpm.

3. Using the quality screw, the maximum engine speed is found, and then using the quantity screw, the position is returned at which the speed will again become 850-950. The action must be repeated until turning the quality screw no longer leads to an increase in engine speed.

4. The transition from enrichment to combining the combustible mixture is found if the engine speed begins to fall. It is up to this moment that the quality screw should be tightened and set at this mark.

5. Carburetor adjustment on an UAZ can be considered complete if, when you sharply press and release the gas pedal, the transition from high speed to idle goes well. Otherwise, it is necessary to unscrew the quality screw little by little.

Conclusion

We talked about how to set up a DAAZ-4178 carburetor on a UAZ. As you can see from the description, there is nothing complicated. Conduct setup and maintenance of the unit in a timely manner and the “good old” DAAZ-4178 will never let you down.

Perhaps you have experience installing and adjusting a carburetor on an UAZ? Share your knowledge with our readers in the comments. Any information would be very helpful.

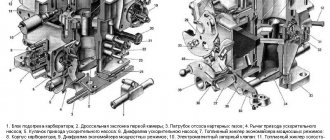

Carburetor 4178 (DAAZ) is an integral part of many cars. The UAZ is no exception, which is equipped with equipment from the Dimitrovgrad Automobile Plant. Such a complex unit operates in a wide variety of modes, and therefore constantly needs adjustment and configuration. Using the UAZ as an example, let's look at how the DAAZ 4178 carburetor is adjusted and configured, as well as the technical characteristics, what it consists of and how it works.

The content of the article:

MAIN FAULTS DAAZ 4178 – 1107010 ON UAZ

The most common malfunction is wear of the needle valve in the float chamber. With this malfunction, excess fuel impairs engine idle performance. The solution to the problem may be to replace the valve.

Various valves and holes tend to become clogged over time, which leads to a narrowing of the cross-sections of the channels and holes. To ensure that engine performance does not deteriorate, regular washing and cleaning of the carburetor is required. This procedure can only be done by completely disassembling the carburetor, otherwise you simply cannot get to all the valves and holes.

Maintenance tips and tricks

The main enemy of every mixer, regardless of brand and modification, is low-quality and dirty fuel with which the system is filled. Systematic clogging makes it difficult for gasoline to flow through the channels; the engine is forced to expend more effort and power to overcome the barrier and deliver fuel to its destination. Therefore, before uploading, make sure the quality of the content.

Do not fill the tank with various types of chemical additives to restore the octane number or increase properties. Supplements have never brought any benefit, only harm. Chemical reagents corrode pipes, contribute to incomplete combustion of the combustible mixture, the formation of soot, excessive sulfur content, metal oxides, and a rapid decrease in fuel level. All of the above leads to premature wear of parts, failure of units, and sudden overhaul of the engine.

Carburetor DAAZ-4178

The DAAZ-4178-1107010 carburetor of the Dimitrovgrad Automobile Unit Plant is designed for UAZ-4718 car engines. An improvement in the dynamic characteristics of the car and a reduction in fuel consumption to 11 liters per 100 km are declared.

Installs without complex modifications. Requires a thick heat-insulating gasket from a 126 carburetor. Connection diagram.— It is necessary to use non-normally open, normally closed contacts for the relay (that is, those that open when voltage is applied to the relay). The correct circuit and principle of its operation is described below.

Instructions for installing the DAAZ-4178-1107010 carburetor and adapting the EPHH control system

- Remove the air filter with housing.

- dismantle the K-151V carburetor

- Unscrew the carburetor mounting studs from the manifold and install other smaller ones.

- dismantle the electro-pneumatic valve EPHH and attach the additional switching relay in place.

- install the DAAZ-4178 carburetor in place by first installing a thin gasket, then a thick textolite gasket (as under the K-126) and another thin gasket. Failure to install the gasket will damage the accelerator pump drive.

- Connect the fitting on the ignition distributor with the fitting on the DAAZ-4718 turboburetor (the fitting near the quality screw) with a hose.

- Reinstall the EPHH control electrical circuit. a) disconnect the connector with two wires from the contact of the EPHH microswitch of the K-151V carburetor. Bite the connector off the wires and by adding a third wire 80 cm long, restore the connector. b) connect the three-wire connector to pin 86 of the additional relay. c) connect the free connector of the third wire to contact 30 of the relay. d) connect a single wire from the carburetor EPHH microswitch to contact 87 of the relay. e) reconnect the connector with two wires from the contact of the electro-pneumatic valve EPХХ to the contact of the electromagnetic valve EPХХ of the DAAD-4718 carburetor. f) prepare a wire of the required length, equip it with connectors and connect contact 85 of the relay with the contact of the DAAZ-4718 carburetor switch.

- Use the mixture quality and quantity screws to set the engine speed and regulate stable operation.