06.12.2019

| (Votes: 1, Rating: 5) |

Issues discussed in the material:

- Why do you need to periodically clean fuel injectors?

- How to understand that the time has come

- What methods are there for cleaning fuel injectors?

Uninterrupted engine operation is possible only if the fuel system is clean. If it is clogged, the car owner will face higher fuel consumption and difficulty starting the engine. Timely maintenance is important for fuel injectors; most often, cleaning and flushing are enough to restore normal operation. In this article we will talk about what cleaning fuel injectors is.

Why do you need to clean fuel injectors?

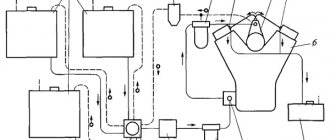

The injectors operate as follows: an electrical impulse from the ECU arrives at the injector connector, activating the electromagnet winding (coil) and exciting the electromagnetic field. The field influences the electromagnet in such a way that it moves and lifts the spray needle above the seat, opening the nozzle. After the nozzle opens, fuel is injected into the intake manifold. When the electrical impulse stops, the pressure spring returns the injector needle to its original position, stopping fuel injection. The pulse lasts about 2-3 ms.

The burning air-fuel mixture leads to the formation of a tar deposit that settles in the engine combustion chambers and injector nozzles. Coke deposits contaminate the nozzles, narrowing their diameter and changing their shape. As a result, not only the amount of fuel entering the internal combustion engine is reduced, but the atomization process changes.

The air-fuel mixture ceases to be homogeneous; instead, streams of fuel enter the engine. The concentration of oxygen or gasoline may increase, which negatively affects the operation of the power unit, fuel consumption, etc. Due to less efficient evaporation of fuel in winter, the process of contamination of injectors occurs faster.

Having noticed that sharply pressing the accelerator leads to jerks and dips in the engine, instability of its operation at low speeds or at idle, as well as when power decreases and fuel consumption increases, you should check the condition of the injectors. The listed problems may indicate their coking, i.e., severe contamination with solid combustion products that prevent free fuel injection.

Cleaning fuel injectors is not always able to solve the problem. Since these symptoms may be caused by other reasons. However, flushing itself is a fairly simple and economical way to eliminate a possible source of trouble.

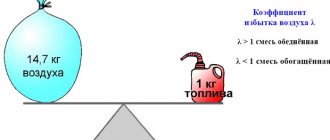

If the injector spray is incorrect, the formation of the air-fuel mixture is disrupted - fuel and air are mixed in the wrong proportions. The better the atomization, the smaller the size of the fuel droplets; accordingly, the contact area between fuel and air is larger, and the mixture formation is more efficient.

We recommend

“How to wash injectors: a review of methods and auto chemicals” Read more

For the spray, its uniformity is essential. A sign of a clogged fuel injector is the injection of a jet instead of spraying the mixture. The formation of coke results from the combustion of resins contained in the fuel. The worse the quality of the fuel, the higher their concentration in it. Cleaning fuel injectors can remove coking and restore normal functioning of the vehicle's fuel system.

Which injector cleaners are best?

Today there is a large selection of chemicals on the market for cleaning the fuel system, ranging from universal cleaners to more highly specialized cleaners. For example, there are separate cleaners for cleaning fuel injectors.

Some of the best injector cleaners are those made with a fantastic chemical called polyetheramine. Today it is the only substance that best removes carbon deposits in the engine.

The polyetheramine cleaner breaks down carbon deposits by breaking them down into small particles that eventually exit through the vehicle's exhaust system.

That is, polyetheramine-based injector cleaners completely solubilize deposits in the engine, fuel injectors, valves, etc., which makes it easy to wash off and burn these deposits during the combustion process in the engine.

But that is not all. In addition, injector cleaners prevent the formation of deposits in the future. Moreover, they do this better and more efficiently than any other additives added to fuel.

You may ask, how do you clean the old classic injector cleaners, which are cheaper? In principle, it can be noted that most modern injector cleaners are quite consistent with their quality and do a good job of removing carbon deposits. But unlike polyetheramine cleaners, older classic cleaners tend to remove carbon deposits in large chunks, which can clog injectors and linger in catalytic converters and, in addition, settle on exhaust valves.

Thus, we believe that today it is better to overpay and buy a polyetheramine-based injector cleaner.

How to tell when it's time to clean your fuel injectors

Experts recommend cleaning fuel injectors every 30 thousand km.

The need to clean fuel injectors is indicated by:

- Difficulty starting the engine despite the starter being activated;

- vibrations during operation of the power unit;

- instability of idle speed;

- reduction in engine power;

- significant increase in fuel consumption;

- increased exhaust smoke;

- extraneous sounds when accelerating.

The listed symptoms do not appear all at once. Most often, problems with injectors occur after a mileage of about 100 thousand km. The use of low-quality fuel contributes to faster failure of injectors.

Fuel injector contamination can be divided into three stages:

- Small stage . Injector performance drops by 5–10% with a simultaneous increase in fuel consumption by 1–2 liters. There are no interruptions in the operation of the power unit.

- Middle stage . The reduction in productivity reaches 10–20% with an increase in fuel consumption by 2 liters. The engine shakes during operation. Exhaust gases acquire a characteristic pungent odor. There is a noticeable decrease in acceleration dynamics.

- Strong stage . Performance deterioration of up to 50% or more. A strong knocking sound from the engine is noticeable, caused by the failure of 1-2 cylinders, which do not receive fuel due to coking. A sharp press on the accelerator is accompanied by popping noises. Symptoms characteristic of the middle stage appear more clearly.

Flushing the injector: on your own or at a service station?

To use cleaning additives for preventive purposes, the motorist does not need to go to a service station. In this case, the main thing is to follow the manufacturer’s instructions. Solutions are poured directly into the fuel tank. The effectiveness of such flushes only appears on non-coked injectors. For older engines, it is better to use more effective cleaning using an alternative fuel system. If you perform unqualified flushing, you can damage the gasket materials of the engine, which will also require repairing the internal combustion engine.

In a car repair shop, it is possible to check the effectiveness of spraying, as well as complete removal of plaque. In addition, the auto repair shop will provide a guarantee on the work performed. In addition to cleaning the nozzles, service stations also restore other injector systems, which is extremely difficult, and in the case of some engines, even impossible, to do at home. Well-known car repair shops employ experienced technicians. This is another argument in favor of professional injector cleaning.

So, by performing timely or preventative cleaning of the injector, the motorist not only prevents damage to expensive injectors, but also other engine parts.

Here is a short video about how ultrasonic injector cleaning works:

High-quality Cleaning of Injectors on an Ultrasonic Stand!

How to clean fuel injectors

Cleaning fuel injectors involves removing accumulated deposits from their channels.

You can clean the injectors by:

- ultrasonic cleaning (carried out at the service center);

- special fuel additives;

- washing fuel injectors using special liquids on a stand (performed at a service station);

- manual washing using special liquids.

The most effective way is to manually clean fuel injectors with special liquids. Washing injectors on a special stand copes well with contaminants, and you can use improvised means.

Ultrasonic cleaning of fuel injectors can only be performed using special equipment; in addition, it is more aggressive than using flushing liquids. This method is effective provided that the coking of the injectors is high and the liquid is not able to cope with it. Some experts say that when using ultrasound, the internal part of the elements is destroyed. Therefore, this method should be used only in cases where others are powerless.

We recommend

“Replacing Volkswagen injectors: when is it required and how to do it” Read more

The use of additives added to fuel to clean injectors without dismantling them is ineffective, and therefore is of a preventive nature. But even for prevention, it is worth using additives carefully, since the “chemistry” in the exhaust gases does not have the best effect on lambda probes.

To perform the operation of cleaning fuel injectors, you need to stock up on:

- flushing liquid;

- silicone tube, the internal diameter of which is approximately 5 mm;

- two wires of the same size;

- button;

- source of electricity (battery);

- electrical tape;

- tools.

The effectiveness of various flushing liquids is approximately the same. Choose products labeled “Carburetor Cleaner”, “Throttle Body Cleaner”, “Injector Cleaner”. It is better to purchase a couple of small cans (250–300 ml) rather than one large one (500 ml), since the pressure in it will decrease as the liquid is consumed. You can use two small cans to clean the injectors and throttle valve.

Current methods of combating pollution

Having encountered a similar problem for the first time, car enthusiasts are interested in what is the best way to wash their injector nozzles, and which methods to give preference to.

In fact, all techniques can be divided into 2 main categories.

- Ultrasonic method. This method is based on the phenomenon of cavitation. With it, ultrasound affects the liquid, which provokes the formation of microexplosions. The purpose of cleaning is to place the sprayers in a special bath with a cleaning agent in the form of a liquid, and apply ultrasound. This type of injector cleaning is very effective, but you won’t be able to do it yourself. Special expensive equipment is required, available only in car service centers. Moreover, not all service stations offer such services, and their price seems too high for some car owners.

- Liquid method. Another option is how you can wash the injectors. But the advantage of the method is that special equipment is not required. Although car service centers use liquid cleaning stands. Whether you perform liquid flushing with your own hands or at a service station, the meaning remains the same. Contaminants are removed using a flushing agent supplied under pressure.

How to prepare injectors for cleaning

Before flushing, the fuel injectors must be removed. They are not attached to the power unit, but are pressed against the intake manifold using a fuel rail.

Nuts are used to secure the rail to the manifold. They need to be unscrewed and the fuel rail with injectors removed, carefully removing them from the mounting holes in the manifold. After this, the injectors are removed one by one from their mounting sockets.

Before removing the fuel rail, it is necessary to remove the attachments that interfere with its removal. The fuel line is disconnected from the injector connectors.

In most cases, the fuel pressure regulator is mounted on the fuel rail. It is necessary to either remove it from the rack, or dismantle the vacuum hose and “return”.

Areas where fuel leakage is likely (for example, the junction of the fuel rail and line) should be covered with a rag. It is better to start cleaning fuel injectors when the car has been standing for several hours, in this case the pressure in the system will decrease, minimizing the risk of fuel leakage.

How to preserve your engine as much as possible

All owners of gasoline cars should understand that their car will sooner or later encounter carbon problems in the engine. Therefore, every car owner should remember to periodically clean the engine from formations and deposits using special chemical cleaners.

Speaking of products, many car enthusiasts, as we mentioned earlier, are unjustifiably afraid of such products and consider them unsafe for the engine and other components of the car. But this is all a myth. In fact, all injector cleaners presented on the sales network today are completely safe for engines.

Cleaning fuel injectors

Before you start flushing, you need to tightly connect the can of flushing liquid to the nozzle using a silicone tube. Tightness is necessary because the product must enter the injector under pressure.

One end of the tube is connected to the can; if necessary, the diameter of the nozzle of the can is increased until it matches the inner diameter of the hose. This can be done using electrical tape. If there is no nozzle, the diameter is added to the tube that comes with the product.

The other end of the silicone hose is put on the side of the nozzle that is inserted into the rail. Due to the elasticity of the tube, difficulties usually do not arise.

For flushing, an electrical impulse must be supplied to the injectors. Wires are used for this purpose. But you will have to perform some manipulations, thanks to which the electricity will flow in pulses.

One of the wires is cut and supplemented with a button that will close the circuit, sending an impulse to the injector and opening it. To close the circuit, the button is pressed, to stop the supply of electricity, it is released. The second wire remains unchanged.

It does not matter which wire you connect to the “+” and which to the “-” battery, which serves as a power source.

Keep in mind that the battery power is 12 V, while the injector needs 9 V. In this regard, you should not apply an electrical pulse to it for too long, as this may cause the internal wiring of the injector to melt.

One end of the wire is connected to the battery, the other to the fuel injector connector. Pay attention to the o and “–” on the injector body. Observe the polarity of the battery and injector.

Before you begin cleaning the fuel injectors, it is necessary to remove the rubber seals from the elements, the removable filter mesh, and also remove external contaminants from the injectors. Do not allow the cleaning agent to come into contact with the rubber elements, as they may become deformed.

Now you need to place the elements of the cleaning installation and start washing the injectors. The photo shows how they should be positioned.

The cleaning process imitates the operation of injectors, however, it is not the air-fuel mixture that is injected inside, but a flushing agent.

The flushing liquid enters the nozzle under pressure and remains inside until the injector opens. Having given an electrical impulse to the nozzle, you need to press the button to open it. After opening the element, the product under pressure will be sprayed from the back side.

See if the spray is evenly distributed. The cleaning procedure must be carried out until the stream is sprayed evenly. If it initially had the correct shape, then the injectors were not dirty.

Cleaning each fuel injector takes 2-3 minutes at short intervals. After washing all the injectors, the procedure must be repeated. When cleaning the injectors, the flushing liquid remaining in the first of them will corrode the remaining deposits, therefore, when flushing again, they will be removed.

After cleaning the fuel injectors is completed, it is necessary to reassemble all the elements in the reverse order. If the rubber seals are in normal condition, they need to be treated with lubricant and put in place. If they show signs of wear, they should be replaced. Deformed elements can cause fuel leaks or allow air into the fuel manifold.

After assembling the engine, you need to turn on the ignition to activate the fuel pump for a few seconds and increase the pressure in the power system (there is no need to start the car). The ignition should be turned on several times, building up pressure. After this, it is checked for leaks in the fuel system. If they are absent, you can start the power unit. Most often, cleaning fuel injectors is carried out simultaneously with flushing the throttle valve.

How to clean injector nozzles?

If we are talking about the chemical method of washing the injector, you need to buy a special product, a fine filter and new sealing rings.

This method is not suitable for ceramic, old and heavily soiled injectors - there is a serious risk of damage.

They sell cleaning liquid for flushing, that's what it's called. You can purchase it at any auto store or gas station. If for some reason such liquid is not on sale, then it can be replaced with “carb cleaner” - a liquid for cleaning carburetors. Its chemical composition is exactly the same. The best way to rinse is up to you. You can read reviews about this or that composition on the Internet in specialized forums. Flushing fluids for diesel and gasoline injectors differ.

Be careful! These liquids are very aggressive and flammable. Protect your eyes and wear rubber gloves.

There is also liquid to add to the fuel. But more on that below.

Car owners' opinions on cleaning fuel injectors

- Cleaning the injectors will not be superfluous “The injectors need to be cleaned. However, until they are completely out of order, you may not know about the need for cleaning. But then we’ll have to remove them and take them for ultrasonic treatment.”

- Prevention is the best remedy for problems

“Every 30–40 thousand km you should use Wynns cleaning agent. There is no need to remove the injectors, but at the same time the combustion chambers are cleaned. Wynns burns at a higher temperature than gasoline, so some of the carbon will burn off. The product is poured into the tank at the rate of 1 liter per full volume. You just need to drive until the entire tank is used up. Liquid cannot be left in the tank for a long time, and it is better not to drive short distances.” - Pour the “chemistry” and you will be happy

“An acquaintance who drives a Volvo 240 station wagon uses LAVR to flush the fuel system twice a year.” While the carbon deposits are leaving the injectors, he pours it into the cylinders for decarbonization. The engine runs normally, without interruptions, consumption has decreased, now on the highway at a speed of 100–130 km/h it consumes about 6-7 liters of gasoline.” - We need an integrated approach

“In my free time I do diagnostics, I made a stand for cleaning fuel injectors. For washing I used solvent “P12”. Serviced four Lacetti, four Volkswagen B, one Kia. I also washed the chokes with it. In one Lacetti, gasoline consumption in the city decreased from 12-14 liters to 9-10 liters, and the dynamics improved. Kia's consumption on the highway decreased from 10 liters to 7-8 liters, the automatic transmission began to work normally, and acceleration improved. On another Lacetti, flushing the throttle improved the operation of the automatic transmission (I did not flush the injectors). In other cars from this manufacturer, traction increased slightly, but consumption remained at the same level.We recommend

“Cleaning fuel system injectors: choosing products for gasoline and diesel” More details

For the Passat “B” everything remains unchanged. I think you need to look at the throttle, assess its condition, and possibly wash it. You can wash the injectors, but it is not necessary. If he thinks for a noticeably long time or the consumption is very high, then you should definitely try cleaning the injectors.” - Purifier is our everything

“It is better not to use ultrasonic cleaning; it has a bad effect on the injectors. On my 940 I did this cleaning twice, both times one injector failed. The stand is the only advantage of ultrasonic cleaning, since it allows you to evaluate the operation of all injectors, whether they work simultaneously and how they do it.In general, I use LIQUI MOLY for cleaning, in their line of cleaners there are products for three stages of pollution. The third one should not be used, it is very aggressive. But the liquid for the second stage needs to be poured a couple of times, and there will be an effect.

So far I have only used an additive for cleaning fuel injectors for the first stage, pouring it twice into each of my three cars. There was always a result - at least the float in the tank began to work, obviously, the dirt was removed from the coil and the indicator showed normally. The injectors were probably also cleaned, but without a stand I don’t know, it’s not clear. If there was a stand, I would appreciate the work before and after cleaning.”

Should I change the oil after flushing?

After flushing the fuel injectors, car owners have questions about the need to change the oil. “Is it necessary to change the oil after adjusting the valve clearances?” - they ask a car service specialist. Drivers have similar questions after replacing the timing belt, camshaft oil seal or replacing spark plugs.

Engine oil is replaced in cases where engine repairs (maintenance) have directly or indirectly affected its composition and changed the characteristics of the lubricant.

The injector cleaning procedure, both chemical and ultrasonic, does not change the composition of the engine oil. As a result, there is no need to change the oil after flushing the fuel system.

In engine maintenance, there is a technique for “decarbonizing” the piston rings, piston crowns, combustion chamber and valve guides with a special liquid. The technique is based on the slow dissolution of solid resinous deposits in a “steam bath” environment. To create such an environment, by rotating the crankshaft, the pistons are installed in one row on the middle line of the cylinders in height, and by turning out the spark plugs, liquid is poured into the cylinders in equal parts. The engine must be at maximum operating temperature. After filling the liquid, the spark plugs are wrapped and the “steam bath” process begins, which continues until the engine temperature drops to 15-20 degrees. The engine starts again and warms up to operating temperature at idle speed. Do I need to change the oil in this case?

Using the “steam bath” engine decoking technique changes the composition of the engine oil, since the waste liquid with dissolved resin fractions flows into the engine crankcase and, accordingly, requires its replacement.

The question arises: is it necessary to use the above method of steam treatment of resins when chemically washing injectors? Chemical cleaning of injectors with a solvent allows you to clean not only the injectors. Since the procedure is performed with the engine running and at different speeds, there is no urgent need for additional decarbonization and oil changes.

Stages of injector clogging

In order to promptly respond to clogged injectors, it is important to understand what stages of their clogging exist and when measures should be taken. There are 3 main stages of injector clogging:

- Small. At this stage, the injector performance decreases by only 5–7% and the driver may not even notice it. In this case, the engine usually runs smoothly, but gasoline consumption may increase slightly.

- Average. At this stage, fuel consumption is already noticeably increasing; at idle speed the engine may throttle, and acceleration dynamics are deteriorating. This stage is characterized by a decrease in injector performance by 10–15%. There will be a strong acrid smell from the exhaust pipe.

- Critical. At this stage, the engine will noticeably jerk, strong popping noises will be heard when you press the gas, and injector performance will drop by 20–50%.

If you notice any of the problems listed above, then it’s time to flush the injector. The sooner the procedure is performed, the better. There is no need to wait until the critical stage of contamination. It is optimal to carry out cleaning activities at the stage of medium clogging.