Signs of a faulty diesel engine injector

Most often, a malfunction of diesel injectors is detected very quickly by the driver. But if the owner of a diesel car has no experience of owning such a car, then he may not immediately recognize the breakdown. The first thing you should pay attention to is the operation of the engine. At the first stages, no signs of breakdown appear. On the contrary, the car starts to drive a little better than usual. Yes, I didn’t make a mistake now. Everything is exactly like that. The fact is that due to faulty injectors, more fuel than required may enter the combustion chamber. Because of the rich mixture, the car starts to drive better.

If you miss this moment, then a smooth ride will gradually develop into a larger breakdown. After some time, you will begin to notice that the car began to smoke when starting, and the idle speed became unstable, and the speed began to fluctuate.

At the most advanced stages, fuel consumption increases significantly, and the car begins to smoke even when driving or sharply pressing the gas pedal. Gradually, as the injector pours fuel, it will begin to flow through the rings into the oil. This may cause the engine oil level to increase and its properties to deteriorate. And this can already lead to serious repairs.

How to identify a leaking nozzle?

Savings persuade many motorists to purchase a car with a diesel power unit. But new diesel power systems can spoil all the advantages due to their high cost, because new injectors cost a lot.

Manufacturers claim that the injector is designed to operate for 100-150 thousand kilometers. But in fact, they can work even more, but then you need to be vigilant so as not to miss the moment of nozzle failure.

Why do injectors break?

As soon as the engine begins to develop insufficient power, when the load on the engine increases, dips and jerks appear, and at low speeds the operation of the power unit becomes unstable, then you should immediately think about going to a service station for repairs or to an auto shop to buy new injectors.

Most often, injectors break due to various types of contamination. Since these parts are constantly exposed to high temperatures, the resins contained in the fuel become coked at the nozzle. These hard deposits can block the spray ports, causing the needle valve to become unsealed. This can lead to the fact that even high-quality Denso injectors begin to spray fuel poorly or even leak. A clogged fuel system can cause other injector components, such as the passages or filter, to become clogged. Most often, common rail injectors are repaired using ultrasonic cleaning.

The first signs of a leaking nozzle

A pouring nozzle is a nozzle that does not spray fuel well or simply drains it in a stream into the combustion chamber. What are the signs that the injector is not working properly? First of all, you can feel twitching at idle or during low load modes. When the engine warms up a little, the twitching will decrease, because in a warm engine the fuel evaporates much better, even if the atomization is disrupted.

If the car does not start on the first try, but only on the second or third, and before it always started normally even with a similar temperature outside, then this is also a sign of a leaking injector. The thing is that if the injector is flowing, it lets fuel through even when the engine is not running. Due to this, the pressure in the ramp drops very significantly. And due to the fact that the fuel pump only works for a few seconds during start-up and then turns off at the software level, this is not enough to ensure that there is the required pressure in the fuel rail. That is why the engine has to be started several times in order for the pressure to equalize to the required level.

In addition, if at least one of the injectors is leaking, the air-fuel mixture becomes very lean. It is known that such a mixture burns much worse and is more prone to detonation. This can be noticed by the knock sensor, but many car enthusiasts simply do not pay attention to it, mistakenly believing that it is the sensor itself that is broken.

Sometimes a flash occurs in the engine when the starter has not yet worked. This is also one of the signs that fuel is leaking from the injectors. This pop most often means that an idle spark from the ignition ignited the leaking fuel.

Why do injectors on a diesel engine fail?

The injectors on a diesel engine come out faster than on a gasoline engine. This is due to the fact that these motors have different operating principles. But in both cases, the culprit is low-quality fuel or untimely replacement of the fuel filter. If you service the car on time, the injectors should work for at least 150,000 km without replacement or repair. If you also use high-quality fuel, then the factory injectors should last 200-300 thousand km.

But, as a rule, the fuel used is not of the highest quality, and filters are rarely changed. Therefore, the injectors in modern diesel engines hardly last 150 thousand km. Then they become dirty and begin to dose fuel incorrectly. To fix this, you will have to at least mechanically clean them of deposits and dirt. It is better not to put this procedure on the back burner, but to entrust the work to people who understand this.

Therefore, fill in high-quality fuel and do maintenance on time. High-quality, timely car maintenance will help you avoid unpleasant breakdowns in the future.

How to clean the fuel supply device yourself

The same stand has a nozzle cleaning function. But if desired, this can be done in a garage. A standard cleaning liquid and a simple device assembled from improvised materials are used.

The homemade installation is a car electric fuel pump placed in a vessel with injector cleaner. The hose from the pump is connected to the injector inlet fitting, and power from the battery is supplied to its supply connector through a push-button microswitch.

This is interesting: How to properly tow a car with automatic and manual transmission

By repeatedly driving a liquid containing powerful deposit solvents through a sprayer, you can achieve a significant restoration of the spraying properties of the device, which will become clear from the change in the shape of the torch.

An injector that cannot be cleaned will have to be replaced; its defect is not always associated with contamination; corrosion or mechanical wear is possible.

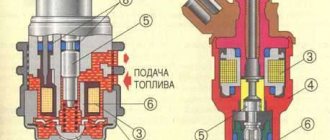

Operating principle of a diesel engine injector

Let us describe the design of the part using the example of a primitive mechanical injector with 1 spring. In the side part there is a channel that provides a continuous supply of diesel fuel. Inside the nozzle chamber there is a movable barrier with a spring and a needle, which lowers as pressure increases. The needle rises, clearing the path of fuel to the atomizer.

Additionally, more advanced types of nozzles can be noted:

- Piezoelectric: the spring pusher is lowered under the influence of a piezoelectric element. This technology ensures high intensity of opening of the nozzle: fuel savings are achieved, while the internal combustion engine operates more smoothly.

- Electrohydraulic: the design includes inlet and drain throttles, as well as an electromechanical valve. The operating mode of the components is regulated by the engine control unit.

- Pump injectors: used in engines that do not have a high pressure fuel pump. Fuel is supplied directly to the injectors. Inside such spray devices there is its own plunger pair, which generates the pressure necessary for injection.

Due to excessive loads, the injector may fail due to a violation of the engine operating mode. Manufacturers claim a parts life of up to 200,000 km, but due to negative operational factors, wear of parts appears much earlier.

Causes of injector malfunction

Repair of diesel injectors may be required for the following reasons:

- Low quality diesel fuel: the scourge of all diesel drivers. Due to impurities in the fuel, the atomizer becomes clogged; the dosage and fuel supply mode are violated.

- Poor assembly quality of the injection component or manufacturing defect: the injector does not withstand operating conditions, the part as a whole or individual components fails.

- Mechanical damage caused by incorrect operation of adjacent internal combustion engine systems.

Usually the breakdowns are of the following nature: the spray angle and the amount of fuel supplied changes, the integrity of the housing is compromised, and the needle stroke worsens.

Cleaning the nozzle without removing it

In this case, cleaning can be carried out using several methods:

conclusions

Problems with the operation of the injectors are not a critical failure, but if they occur, we recommend that you do not delay checking and eliminating the malfunction. In most cases, repair work can be carried out independently using the methods described above. Timely checking and diagnostics of injectors will allow you to avoid problems with the operation of the machine. Prevention will cost you less than repair work on injectors or other engine components. We recommend that you clean the injectors every 30.35 thousand kilometers of your car, regardless of their condition.

Source

Checking the functionality of the injector

There are several methods for checking the functionality of the sprayer. The easiest way to check the injector is with the engine running:

- Start the engine at idle speed.

- Start unscrewing the nozzles one by one.

- If after removal the engine performance deteriorates, then the removed injector is operational and should be returned to its place.

- By process of elimination you will find an injector, the removal of which will not change the operating mode of the internal combustion engine. This will be a broken device.

You can use a multimeter for diagnostics. In advance, you need to disconnect the battery terminals and disconnect the injector wiring, and then “check” each part with the device. On high resistance injectors, the device values will be in the range of 11 - 17 ohms; at low impedance the multimeter will show up to 5 ohms.

Tip: Having a maximeter will be a big advantage. The device is able to show the current pressure at which the sprayer is activated. It will also help identify defects regarding the spray angle and injection jet configuration.

Checking injectors at home with an ear and a screwdriver!

- Start the engine and let it warm up.

- Then take the largest long screwdriver and place it in the base of the fuel injector.

- Be careful! When checking the injectors using this method, your clothes, hair, etc. should not hang over the moving parts!

- We put our ear to the handle of the screwdriver and listen carefully to the sound.

If, when listening to the fuel injector, you hear a continuous series of clicks that are uniform and not very loud, then you can assume that the injector is working properly and is working as it should.

If the clicks are intermittent, irregular and with pauses, most likely the injector is stuck or jammed and requires flushing or even replacement. At a minimum, such an injector should be removed for further diagnostics.

We carry out the described procedure for each injector, after which we decide whether there is any point in visiting a service station or not. This method does not provide 100% confidence, but a preliminary conclusion can be made. Moreover, it is free and available to everyone. If there are errors indicating problems with the injectors, then this method will, at a minimum, help verify that there really is a problem.

After such a diagnosis, you can try to restore the operation of the injector using flushing fluid, or you can stop by the station and carry out a full cleaning of the injectors on an ultrasonic stand.

Source

Troubleshooting

A faulty injector must be inspected. First, we look for leaks in the part body. If there are none, we proceed to disassembling the part. We fasten the part in a vice and knock out the spray nozzle by gently tapping it. Next, you need thorough cleaning: soak the parts of the nozzle in diesel fuel or solvent to remove carbon deposits. We remove soot and deposits with a fine steel grater. After cleaning is completed, you need to check the nozzle on the maximeter. If optimal injection parameters are achieved, the device is ready for installation in the engine.

In other cases, it is necessary to completely replace the nozzle on the defective nozzle. When installing a new part, carefully remove all factory grease, otherwise the device will not work.

If the nozzle continues to “flow” even after replacing the nozzle and thorough cleaning, pay attention to the performance of the spring with the pin - they may be worn out.

To clean the sprayer, use a compressor - the air pressure will knock out hard-to-reach dirt.

Nozzle installation

Before dismantling the device, mark all parts with a marker to avoid confusion. Be especially careful about marking high-pressure hoses. The nozzle is screwed in by hand as far as you can. Further tightening is performed with a dynamometer wrench. The tightening values are indicated in the motor manual. When installing the injector, bleed the air from the fuel system. On modern cars, this is enough to turn the starter several times; or use a manual pump (if available).

Cases when the nozzle needs to be completely replaced

Let's list the main features:

- the resource declared by the manufacturer has been exhausted;

- there are breakdowns or other leaks in the housing;

- burnt nozzle nut: if the problem is not corrected at an early stage, the nozzle itself will become unusable.

Please note that on some engines, after installing a new injector, it is necessary to “bind” it to the engine: make changes to the settings of the control unit.

It is better to install the nozzle at a service station, since the station has bench equipment for adjusting and assessing the current condition of the part.

How to restore the performance of a VAZ-2114 engine: expert advice

Automotive repair experts recommend that motorists use several tips to restore the functioning of a VAZ-2114 engine that is tripping.

First tip: check and replace the electronic control unit.

Second tip: check and replace the oxygen sensor.

Third tip: check the functionality of the crankshaft position sensor. This can be done using the electronic control unit. This device will generate an error if the crankshaft position sensor is faulty. This means you will have to replace it with a new one.

Fourth tip: check and replace the ignition coil.

Fifth tip: check and replace the air filter.

Sixth tip: check the correct placement of the timing belt.

Design

The injector is the most important element in the injection system of gasoline engines. This is a solenoid valve that operates “under the command” of the ECU, the electronic engine control unit. After receiving pulses of a certain frequency, the ECU “measures” the dose of the required fuel, depending on the engine load and coolant temperature. The precise and well-functioning operation of this mechanism allows the engine to operate properly for a long time: lower fuel consumption, greater power and torque, easy engine starting at any temperature - all these are advantages of the well-functioning operation of the injector, but any malfunctions in its operation worsen the performance of the entire engine. Very often, the faulty operation of a gasoline engine is caused by electromagnetic injectors that do not perform their functions or are partially faulty. This is due to the fact that there is no electrical impulse to open the valve, perhaps the solenoid winding has broken, or the internal valves may be dirty. Dirty internal valves most often make themselves felt to the car owner in winter when starting an injection engine.

How to check functionality?

The check is quite easy to do yourself. With the engine running, it is necessary to turn off each of the injectors in turn. If, when you turn off any injector, the engine continues to operate without noticeable changes, this will indicate that the problem lies precisely there. It will be necessary to find out the reason for its failure. The nozzle design allows you to do this without additional equipment, with your own hands. To do this, voltage from the battery is supplied to its terminals. When the nozzle fires, characteristic clicks should be clearly heard. If you can hear them, then the device is working properly, and the problem most likely lies in contamination of the nozzle. In this case, you just need to clean it. If, on the contrary, the device does not react in any way when it is connected to the battery, then such an injector will have to be replaced with a new one.

Cleaning injectors

There can be many different options for the “behavior” of a car when the pump injectors fail or there is another problem in the operation of the fuel system. But with almost any of them, you will always have time to get to the service station. Here are examples of the most common signs that will allow you to determine that your truck requires fuel system repair.

In this case, there are 3 possible causes of the malfunction: 1. Lack of Low Pressure

For the full functioning of the machine, it is necessary to fill the pump injectors with fuel.

This function is performed by a low pressure pump. The minimum pressure that the low pressure pump should produce at idle speed is 2 bara. If the pump does not produce pressure, or the pressure relief valve in the low pressure system is faulty (low pressure approaches zero), it may happen that one of the pump injectors does not have enough fuel to fill completely. Consequently, there is no volume of fuel supplied through the atomizer. In this regard, one or more pump injectors, and therefore engine cylinders, may not work. The result

is jamming of the engine motor.

The solution

is to replace the low pressure pump or pressure relief valve. Or both.

2. Mechanical failure of the pump injector

Such a malfunction, as a rule, can be mechanical wear of the solenoid valve (valve assembly), or wear of the atomizer. In the first case, the pump injector cannot create high pressure, because the valve does not close at all. Consequently, there is no supply to the cylinder. In the second case, a breakthrough of gases from the engine cylinder is possible due to the fact that the nozzle does not close. Consequently, the pump injector is “aired” and the amount of fuel supplied to the cylinder again tends to zero. Result

- the car is shaking.

The solution

is a major overhaul of a failed pump injector.

The result of this malfunction is either a burnt-out magnet (solenoid) or a lack of contact in the contact group of the pump injector. A screw has come loose or there is a break in the electrical circuit. Due to the fact that the electromagnetic unit does not perform its functions, there is no fuel supply to the cylinder completely. The result is that the car stalls. There may be other options. But they are not typical and need to be considered individually. Result

- the car is shaking.

The solution

is to contact an electrician.

EXCESSIVE FUEL CONSUMPTION, INCREASED SMOKE FORMATION, BUT THERE IS DRAFT

Most likely, the hole in the nozzle is worn out, and fuel is supplied to the cylinder at reduced pressure. If the machine still “pulls” well, it means that the remaining components of the system - the plunger pair and the control feed valve - are not critically worn. In this case, you can get by with replacing the atomizer and drive another hundred thousand kilometers until the pump injectors are overhauled. But it is not a fact that the valve is still in order. Both the valve and the nozzle may be worn out. And the paradox of this situation is that computer diagnostics will show that everything is in order. The fact is that computer diagnostics are performed in idle mode and record the amount of fuel entering the cylinder, namely at idle speed. If the nozzle holes of the atomizer are very worn out and the valve assembly is completely worn out, then the average amount of fuel at idle speed will be approximately the amount of fuel supplied by a working injector pump (with unworn nozzle holes and an excellent solenoid valve). For this reason, in this case it is quite difficult to determine malfunctions in the fuel system through diagnostics.

– The real picture of the condition of the unit injectors can only be shown by removing them and diagnosing each unit injector separately.

THE CAR DOES NOT PULL AND OVERCONSUMPTION OF FUEL

This indicates that all components of the pump injector are worn out. In this case, it is necessary to overhaul the pump injector or replace it with a new one. At the same time, the car, in theory, should not smoke. There is no fuel, nothing to smoke. - Why is this happening? — Lack of the required amount of fuel in the cylinders and the required fuel injection pressure. If the car still smokes a lot, then the problem is most likely in the engine air supply system (see turbine sensor, turbine, intercooler)

THE CAR STARTS FROM QUICK START (ON AIR)

This means that absolutely ALL pump injectors are worn out. In this case, we recommend changing them URGENTLY. Since fast starting has a very bad effect on the operation of the engine as a whole.

EVERYTHING KNOCKS, EVERYTHING SMOKES, TROUBLES, Puffs...

. And in general, it’s even scary to stand next to the car... This indicates that the pump injector atomizer has failed. The atomizer is the most vulnerable part of the nozzle, since it is located in the combustion chamber and is the most loaded unit in the system. If the sprayer body is split, the machine begins to behave in the manner described above. This situation often happens in winter when water gets into the fuel.

Or so let’s say, let’s make some clarifications. In general, pump injectors work independently of each other, and if one or two fail, the car will move. The computer will simply turn them off, and the car will reach its destination. Worn pump injectors can be detected long before they fail completely. We recommend replacing the entire set at once, because, as a rule, the service life of the injectors is approximately the same. And additional removal and installation in case of repeated application is double costs in this case. But if diagnostics show that some of the injectors are in good condition, you can replace them selectively for now. If your car has a fuel system equipped with pump sections, read about its functions and repairs in the article “Diagnostics and Repair of a Fuel System Equipped with Pump Sections.”

We wish you never to break down!

How to find the cause of the breakdown?

This is done using a special tester; first, they check the voltage supplied to the injectors (normal pressure is from 0 to 2-3V); if there is voltage, then everything is in order with the injector. Next, the injector valve windings are checked. During normal operation of the injectors, they have a resistance of 12-16 Ohms, in systems with turbocharging - 4-5 Ohms, and in systems with a monoinjector - 4-5 Ohms. The mobility of the injector solenoid valve is determined by instantly connecting the injector terminals to a power source, for example, to an engine battery. A normally operating injector will click slightly, this will indicate normal operation of the valve, and if the valve works but the cylinder does not, it means the injector is very dirty. At service stations, the level of contamination of injectors is checked using multitesters based on the duration of the pulses that the ECU sends to open the valve. If the nozzle is dirty, the pulse time increases. Also, if irregularities are detected in the engine’s operation, the toxicity of the exhaust gases can be checked. Their toxicity increases when the mixture is over-enriched, mixture formation deteriorates, and the combustible mixture cannot be ignited. If a three-component catalyst is installed in the car, then an increase in the content of nitrogen oxides can be an indicator of deterioration in the operation of the injectors. Moreover, if the foreign car is new, then unused fuel in the form of gases can quickly damage the catalyst.

How is diagnostics carried out?

You should know that car injectors are classified into several types. Today, two of them are in use: conventional and electric injection elements (magnetic).

Electric or, more correctly, electromagnetic injectors (EMF) are equipped with a special valve that supplies fuel. It, the valve, is controlled by the power unit ECU using sent pulses.

As for mechanical injectors, they open as the gasoline pressure in the injector increases, i.e., automatically.

On modern cars, the first variants of injectors are often installed - EMF.

Checking the injector itself without removing it

Injector testing can be done in several ways. However, the simplest of them is in use, and this is not surprising. It makes it possible to quickly test the injectors without even removing them from the car. The fundamental factor in such diagnostics is the analysis of the noise emitted by the motor during operation.

Checking the injector

If a muffled high-frequency noise is heard from under the hood, this indicates the importance of cleaning the injectors or a problem with one of them.

Checking power supply

It is recommended to check how the power is going. This test option is carried out only when the injectors themselves are functioning flawlessly, but difficulties are observed with starting.

Here's how this kind of diagnosis is carried out:

According to the result, the following conclusions are drawn:

Another test option involves using an ohmmeter. This method allows you to measure the resistance on the injectors, and draw conclusions accordingly.

This is done as follows.

In this way, you can measure the compliance of the resistance indicator with the required one. If deviations from the norms are noticeable, the faulty injector is removed from the vehicle and replaced with a known good one. After this, you can check the resistance again, and be sure to evaluate the operation of the motor. If everything was done correctly, the engine characteristics should change.

Analysis of the operation of injectors on the ramp

This method already involves dismantling the fuel rail.

The injectors, of course, are removed along with the ramp. Then reconnect all electrical contacts to the ramp (after all, they are thrown off during dismantling). The negative terminal of the battery, which was removed earlier, also returns to its place. Anyone can check the injector nozzle with their own hands. It is not necessary to go straight to a car service center if you encounter another problem. An experienced motorist should be able to do some repairs himself.

Causes of clogged injectors

Poor quality fuel is one of the main reasons for injector failure. A huge amount of resins that settle inside the injectors reduce the throughput, they do not allow the valves to close hermetically, and thereby the angle of the injected fuel jet changes. When starting the engine in winter, a failed valve causes the mixture to become over-rich, resulting in increased fuel consumption and increased toxicity of exhaust gases. If fuel is sprayed incorrectly, disturbances occur in the mixture formation process, and this is the first reason for the deterioration of almost all engine performance. Clogging of injectors occurs when using fake fuel filters, or if the car owner simply forgot to change the filter. With pressure in the fuel system, the filter may simply rupture, and dirt will naturally enter the injectors.

How to check an injector nozzle for serviceability

Problems with injectors occur both on cars powered by diesel fuel and on gasoline-injected cars. An injector is a part responsible for injecting fuel under a certain pressure. It is useful to know how to check the injector nozzle if starting difficulties occur.

Causes and symptoms

Accurate metering of fuel, tightness of hoses and seals, activation of the injector at the right moment are prerequisites for stable and trouble-free operation of the engine. If the injection part leaks, as they say, then the efficiency of fuel atomization deteriorates, i.e., the shape of the flame is upset and the power unit smokes, either black or gray, it is difficult to start, consumption increases, and power is lost.

“The injector is leaking” is an expression that means fuel is leaking at a time when it is not needed.

There are many culprits for poor performance. For example, a dirty filter, a non-working fuel pump or bad spark plugs. The same thing happens due to the fault of a failed reel or due to problems with the timing belt.

The most important symptom of a non-working injector is difficulty starting the internal combustion engine. This is especially true for a “cold” engine. In addition, as mentioned above, symptoms include increased fuel consumption and unstable engine operation in idle mode. The last symptom generally resembles almost a tripping of the engine, as if one of the cylinders is not working.

As for the driving signs of a non-working injector.

Defects in injection elements should be corrected immediately, otherwise it will negatively affect the service life of the engine and gearbox. Experts also do not recommend driving with a faulty injector, because it is simply dangerous. On steep climbs, when maneuvering and overtaking, a car with a failed injector can play a cruel joke on the driver.

How is diagnostics carried out?

You should know that car injectors are classified into several types. Today, two of them are in use: conventional and electric injection elements (magnetic).

Electric or, more correctly, electromagnetic injectors (EMF) are equipped with a special valve that supplies fuel. It, the valve, is controlled by the power unit ECU using sent pulses.

As for mechanical injectors, they open as the gasoline pressure in the injector increases, i.e., automatically.

On modern cars, the first variants of injectors are often installed - EMF.

Checking the injector itself without removing it

Injector testing can be done in several ways. However, in use

the simplest of them, and this is not surprising. It makes it possible to quickly test the injectors without even removing them from the car. The fundamental factor in such diagnostics is the analysis of the noise emitted by the motor during operation.

If a muffled high-frequency noise is heard from under the hood, this indicates the importance of cleaning the injectors or a problem with one of them.

Checking power supply

It is recommended to check how the power is going. This test option is carried out only when the injectors themselves are functioning flawlessly, but difficulties are observed with starting.

Here's how this kind of diagnosis is carried out:

According to the result, the following conclusions are drawn:

Another test option involves using an ohmmeter. This method allows you to measure the resistance on the injectors, and draw conclusions accordingly.

This is done as follows.

In this way, you can measure the compliance of the resistance indicator with the required one. If deviations from the norms are noticeable, the faulty injector is removed from the vehicle and replaced with a known good one. After this, you can check the resistance again, and be sure to evaluate the operation of the motor. If everything was done correctly, the engine characteristics should change.

Analysis of the operation of injectors on the ramp

This method already involves dismantling the fuel rail. The injectors, of course, are removed along with the ramp. Then reconnect all electrical contacts to the ramp (after all, they are thrown off during dismantling). The negative terminal of the battery, which was removed earlier, also returns to its place.

Anyone can check the injector nozzle with their own hands. It is not necessary to go straight to a car service center if you encounter another problem. An experienced motorist should be able to do some repairs himself.

If you find an error, please select a piece of text and press Ctrl+Enter.

Source

Injector flushing

Separately, I would like to note that in foreign cars with high mileage, cleaning with additives can completely disable the entire system, when all the dirt from the unwashed system is washed off the walls of the fuel tank, and rushes to the filter, and then into the injectors. The mesh on the injectors becomes clogged and fuel stops flowing. Another method is to flush the injector without dismantling it, i.e. the injector remains undisassembled. First, turn off the gas tank, then the standard fuel pump, and close the fuel drainage channel into the tank. At the same time, the fuel line of the machine is connected to a professional stand, which supplies a special liquid to the system. Two fluid runs with two breaks - 15-20 minutes for every 15-20 thousand kilometers, and your fuel system will be prepared for winter. An ultrasonic stand is another cleaning method. The nozzles are removed and placed in a bath of cleaning solution, where even the strongest deposits are destroyed under the influence of ultrasound. At the same stand you can check the quality of cleaning. Experience has shown that the ultrasonic method is the most effective, and it can even bring back to life injectors that are no longer repairable.

Sources: drive2.ru, motorsguide.ru, oils-market.ru.

How to troubleshoot injector problems?

To identify the causes of an injector malfunction, you need to go through half of the car. It takes a lot of time and effort. Special diagnostic equipment is required.

Advanced cases occur among drivers who do not monitor the condition of the car. Requires time and material costs to fix the problem.

Many drivers have an indecently dirty injection system. Lack of competent maintenance and low-quality fuel take their toll.

Computer diagnostics.

The beginning of any renovation. Clarifies the causes of malfunctions. Special equipment is used.

Fuel injection system.

Represented by nozzles prone to contamination. It has a complex design, which makes it difficult to perform maintenance on your own without outside help.

Failure to promptly replace the fuel filter results in small dirt particles entering the injector nozzles. Normal supply of gasoline is difficult. Ultrasound is used to remove dirt and the filter is replaced.

Fuel pump.

Located in the fuel tank. Serves to supply gasoline to the injectors. Long-term operation of the pump leads to wear of its working elements.

A typical malfunction is an insufficient amount of fuel supplied to the injectors. This leads to unstable operation of the injection system. The pump cannot be repaired and must be replaced together with the fuel tank.

The injector is a reliable fuel supply system. She lost the fight to new technologies. The new generation ICE (internal combustion engine) has low fuel consumption and lower emissions of harmful substances. The injector is prone to contamination and high fuel consumption.

Thank you for your attention, good luck on your journey. Read, comment and ask questions. Subscribe to fresh and interesting articles on the site.