Do you need an adsorber? This question worries many Togliatti car owners. The VAZ 2114 adsorber appeared after the introduction of Euro-3 environmental standards, which required the installation of devices on cars that allow them to retain evaporating fuel so that it does not enter the atmosphere. The black cylinder installed on the VAZ on the right in the corner of the engine compartment near the radiator is the VAZ 2114 absorber, the design of which we will consider.

Operating principle of the adsorber

Adsorption is the process of absorption of gaseous substances by solids or liquids. For example, the first gas masks used filters in which the adsorber was activated carbon. The same thing is done in a car, but a little more complicated. The cylindrical plastic body of the adsorber contains a special filler that traps gasoline vapors. The VAZ 2114 absorber does not end with just a can of filler; pipes and valves are connected to it.

The VAZ absorber does not affect fuel consumption in any way; it is installed only to improve the environmental friendliness of the engine. As the gas tank empties, fuel vapors rise to the neck and enter the separator. There they again turn into a liquid state and return to the tank. And the part that did not have time to condense ends up in an adsorber filled with activated carbon, which absorbs harmful gases. This happens when the engine is turned off.

When the engine is running, the VAZ absorber is purged using a special valve, and all gases are burned in the vehicle’s exhaust system. As for fuel consumption, it varies within insignificant limits. The main purpose of the adsorber is only to neutralize gasoline vapors. This is a container with activated carbon, equipped with inlet and outlet hoses for gasoline vapors.

Complete removal of the adsorber from the power system

Some VAZ 2114 owners decide to completely remove this part from their car for reasons of savings and to prevent future malfunctions. There are two ways to do this.

Method 1. After completely removing the adsorber from the VAZ-2114, the hose leading to the throttle valve assembly is closed using a plug. A fuel filter from any VAZ carburetor engine is inserted into the hose running from the gas tank to the adsorber.

Method 2. The adsorber is removed along with the support. The hoses previously connected to it are closed using plugs. A small hole (1-2 mm) is drilled in the standard gas tank plug to connect the cavity to the atmosphere. You can also use the cap from a carburetor “eight” or “nine” to depressurize the fuel tank.

After upgrading the power system, it may be necessary to update the firmware of the engine control unit, since it will perceive the absence of an adsorber as a malfunction in the engine and switch to emergency operation. This threatens to significantly reduce the traction qualities of the car.

The adsorber in the VAZ-2114 is an important element in the engine power system, which allows you to slightly reduce fuel consumption and eliminate the smell of gasoline in the cabin.

Why is an adsorber installed on a car? This is a fairly popular question among owners of domestic cars. The device appeared immediately after the introduction of the Euro-3 environmental standard.

The device itself is a black cylinder, which is installed in the right corner of the engine compartment, next to the radiator. In fact, this is an adsorber, the principle of operation of which we will consider in this article.

Possible malfunctions in the operation of the device

The VAZ 2114 absorber, due to its intended purpose, is susceptible to clogging and at some point may become faulty. Problems are not easily determined and often only by secondary symptoms, for example, increased pressure in the fuel tank. It’s just that gasoline vapors, due to wear of the separator, remain locked in the space of the tank and begin to put pressure on its walls. An increase in pressure can be detected when unscrewing the tank cap - a characteristic hissing sound is heard.

Sometimes the gas tank cap simply shoots out of the neck, which means that the pressure has reached a critical level and the adsorber must be urgently changed. If there is a problem with the adsorber, the engine speed begins to jump up and down. Many car owners write on forums that you can remove the VAZ absorber and not suffer. But everything is not so simple, and there are never unnecessary parts in cars.

Removing the absorber alone is not enough; you need to think about what to do with gasoline vapors that have nowhere to be discharged, and that the ECU may also have to be reconfigured. After all, some types of on-board engine processors find a malfunction in the purging of the fuel system and put the engine into emergency mode, in which it will not be possible to drive normally.

As for malfunctions, the problem area of this adsorbent system is the purge valve. You can repair it yourself. All you need is a flathead screwdriver, but be careful when removing it. The problem is the valve fastening; often it is not metal, but plastic; it is not difficult to break. The mount is located on the engine cover. There are also clamps on the valve itself, which also require a careful approach. We remove them and take out the problematic part.

If you blow into the valve and air comes out of it, this means a 100% malfunction. A normal part will not allow air to pass through. If there is a problem with the valve, the car experiences problems when starting the engine hot, and gasoline consumption increases. If the problem is not corrected, there will be a Check Engine and loss of normal driving dynamics. Failure of the adsorber seal and failure of the purge valve can cause unstable engine operation at idle until it stops.

So, let's move on to valve repair. In its upper part there is an adjusting screw fixed with epoxy resin. Screw the screw in until it stops, counting the turns so that if something happens, you can return the canister valve to its original position. You can drop a little carburetor flushing fluid into the valve fittings. Then we blow it in the open position with compressed air. The repairs are done.

The valve can also wear out due to heat near the radiator, and there is nothing you can do to help it. The quality of the material from which the adsorber valve is made is not the best. The only solution can be to replace or change the location to a cooler one, for example, closer to the adsorber itself.

Determining possible damage

We have figured out why the adsorber is needed, now let’s determine the signs indicating its failure. Considering the quality of fuel at gas stations in our homeland, this part often becomes dirty and fails.

Any malfunction of this mechanism can be easily determined by obvious signs:

Damage to the absorber - the fact that this mechanism of your car has problems can be determined by hearing a hissing sound when opening the tank, it indicates the accumulation of an excess amount of gasoline vapor.

Excessive pressure appears in the tank when you open the lid, there is a moment when the contact area with the external environment is small, and the pressure is quickly “relieved” through it, and the tank “hisses”, similar to a bottle of soda.

In the event of a breakdown, the adsorber is often removed completely, we will discuss how to do this below, but there are no unnecessary parts in the car, it is worth remembering. If you don’t want to remove and gut the ECU, you can try to fix everything yourself. The weakest point in the absorption kit is the VAZ 2114 valve.

Before repairing, you need to make sure that the problem is here:

- Use a flat-head screwdriver to unscrew the fastener on the motor cover (be careful, the fastener is plastic, you shouldn’t break it), and then very carefully remove the clamps.

- We remove the part and blow out the valve. If air does not pass through, then the valve is operational, and the breakdown is elsewhere; if air passes through the valve, then you have found the problem.

A valve failure, in addition to unstable idle speed, will soon give you CheckEngine and significantly increased consumption.

Removal Features

The VAZ absorber is sometimes removed completely. To do this, you need:

- replace the gas tank cap with a leaky one;

- plug the supply and discharge pipes;

- often change the ECU firmware.

As mentioned above, you should not approach the adsorber as an unnecessary thing, and if you decide to remove it, remove it correctly so that the gas tank remains ventilated and not tightly sealed, as if there is an adsorber. Those who convert a carburetor engine to an injection engine have an advantage. If they do not touch the tank pipes, they do not disturb the carburetor ventilation system of the tank, so they do not need an adsorber.

How to repair a problem

When talking about repairing the adsorber, the fault should be clearly identified. For example, if we are talking about a purge valve for a subsidized adsorber, the malfunction of which can be indicated by the lack of high-quality gas removal, then a new VAZ adsorber purge valve can be a solution to the problem.

Repairing the canister valve itself involves using a Phillips screwdriver and applying it. The procedure for influencing the Lada Granta adsorber sensor:

1) Remove the terminals so that there are no dire consequences.

2) Use physical force and carefully remove the valve.

3) Let's compare the new valve and the old one, because in life everything happens. Buying an adsorption valve is, of course, not difficult, but there are seller/retailer mistakes that can cause you to mistakenly sell an unnecessary spare part.

4) We insert a new valve, assemble this system, put the terminals in place and enjoy life. The Grant adsorber purge valve, the price of which is almost equally low throughout the Grant sales area, also causes a small, but nevertheless joy.

Throughout the history of the adsorber, one cannot fail to mention the fact that a huge number of Lada Grant owners prefer to get rid of this device. There are two reasons for this action:

- lack of desire to repair

— uncertainty about the possible environmental benefits of installing this device in a car

Work principles

Fuel typically evaporates, and in sealed containers like a tank, the evaporation builds up pressure. From the tank, vapors go to the separator, condense and return back to the tank, excess vapors are sent to the adsorber, where the active element absorbs them.

If you have ever stored gasoline in a canister, you have seen how it swells during long-term storage; if you are not so lucky, you could see how it “explodes,” usually on the lid, but on plastic canisters the weakest point is not determined by the lid.

This is what this process looks like when the engine is turned off, when the engine is running, the system opens the adsorber valve (purge valve), when the valve is open, the vapors do not reach the absorber, but are directly blown into the intake pipe, where the engine successfully burns them.

This algorithm is designed to obtain two advantages of the system:

- Increasing the environmental friendliness of the car due to the absorption of fumes.

- Fuel economy when driving (savings are 1%, but present).

As we figured out, gasoline vapors are absorbed by the adsorber or blown into the intake valve, which is responsible for changing operating modes and controlling the system. It switches during system startup, thanks to the engine start controller; during ignition, it turns on the receiver, the sorbent is purged and unabsorbed vapors are immediately sent to the engine, saving every milligram of evaporated fuel.

In addition to the above advantages, the system also does not allow the smell of gasoline into the lard of the car, but such a system also has disadvantages (albeit controversial), motorists complain that it:

- takes up space under the hood;

- is the culprit of unstable operation when broken;

- Expensive.

Signs of a malfunction of the control unit

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. Indicates that the valve is operating correctly. To avoid confusing this sound with running noise, press the gas sharply. The nature of the tweet should not change. The following symptoms indicate a malfunction of the control unit:

- turning on the CHECK signal on the instrument panel;

- detection of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable minimum;

- increased CO2 content;

- a hissing sound when unscrewing the tank cap (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

“We treat” the adsorber

If a breakdown occurs, the problem needs to be solved as soon as possible, there are four options to solve it, depending on the features, you can: replace the valve, replace the adsorber, try to repair the valve, remove the adsorber, we will consider each option in more detail.

Replacing the adsorber

On a VAZ 2114, replacement is very simple, you can go to a service station, but if you do the procedure yourself it will take about 20 minutes. We dismantle the spare part:

- disconnect the hoses from the throttle;

- disconnect the wires and block;

- remove the purge valve and purge and separator hoses;

- unscrew the three bracket bolts;

- the part has been removed.

- We attach a long pipe to the point where vapor is supplied to the blow-off valve;

- We connect a short hose to the fence from the separator;

- put the spare part in place;

- connect the supply hose to the valve;

- install a purge channel (on the engine cover);

- connect the wiring and block;

- place a tube between the valve and the adsorber;

- the work is finished, connect the power and go.

We repair the valve

The valve is clogged due to bad gasoline, before buying a new one, let's try to fix the old one. If a characteristic smell of gasoline appears in the cabin, then the problem is in the valve pipes, they are replaced by simple replacement, and the problem is revealed by a visual inspection, we look at which pipe has burst, buy a new one and install it.

It happens that there is no breakdown, after visually inspecting the pipes, you may find that everything is intact and working, just one pipe has flown out of its place, in this case, you need to put it in place and tighten the clamp.

- We unscrew the adjusting screw, counting the revolutions (it is filled with epoxy resin, it will be easy to find).

- We drip carburetor flushing into the fittings.

- Holding the valve in the open position, we blow it with a compressor.

- We repeat points 2 and 3.

- We put it in place, screw in the adjusting screw to the previously calculated number of revolutions.

Valve replacement

If the valve breaks due to overheating of the radiator, it cannot be repaired; a new part is needed.

The procedure is simple, let's consider it in order:

- We turn off the power to the car and disconnect the KPA plug.

- We loosen the air control inlet pipe, remove it, and move it to the side.

- We bend the fastening, dismantle the valve (remove the fastening no more than 1 cm).

- Lift the valve along the grooves (you need to pull it up).

- We disconnect the fitting, there are two inlets, the first one can be easily removed, the second one will have problems - on the raised fitting, the fixing tendrils are prying up, on the recessed clamp (it’s easy to do with two people, you’ll have to “sweat” alone).

- We install the new adsorber valve in the reverse order.

Removing the adsorber

This is not recommended, but if there is no money (for a new one) and no desire to understand the problem (fix something), it is removed. In addition to the above-described dismantling of the part, three more procedures need to be performed:

- dig into the ECU (reflash);

- seal the pipes leading to it;

- replace the tank cap (it needs a leaky one).

- The VAZ 2114 adsorber is an important part; it should not be removed.

- You now know how to replace a part, determine if it is broken and try to repair it, so it’s better to do just that.

- If you decide to remove it, remember, now the car is environmentally friendly “Euro 1”, later problems may arise with this.

Removal and installation

Dismantling of the part is carried out according to the following algorithm:

Step 1. Disconnect the clamp from the negative terminal of the battery and block the wheels using the parking brake (“put the handbrake on”).

Step 2. Remove the wire from the adsorber valve (VAZ-2114).

Step 3. Using a Phillips screwdriver, loosen the clamps and remove the hoses from the fittings. The latter are made of plastic and break easily.

Step 4. Use a flathead screwdriver to pry the latch on the valve body and remove it.

Step 5. Loosen the clamp securing the adsorber body and pull out the latter.

Useful video

You can get additional information about the design of the adsorber and options for replacing it from the video below:

According to the requirements of new environmental standards that limit the content of harmful substances in exhaust gases, vehicles must be equipped with an EVAP system. This equipment prevents harmful fuel fumes from entering the atmosphere. The main function in the fuel vapor recovery system is performed by the adsorber. Some people underestimate the importance of this element in the operation of a car. However, a malfunction of this seemingly minor component can lead to damage to the fuel pump and affect the operation of the entire engine. Therefore, experts recommend checking the adsorber valve when signs of engine malfunction appear.

How to understand a malfunction of the absorber

As for the adsorber valve, the symptoms of the malfunction will be fairly standardized, which makes it possible to obtain a fairly detailed description. So, signs of a malfunctioning adsorber valve:

— Constant smell of gasoline in the cabin.

This fact is caused by improper circulation of gases, which may have some leakage. Due to the proximity of the system to the air filter, odors can easily penetrate into the cabin.

Signs of a malfunction of the subsidy canister purge valve is this sound, familiar to all subsidy owners.

(to fix this, you can tighten the nut, or you can buy a new one, since the Lada Granta adsorber valve is available for purchase, the price of which is low)

— Increased fuel consumption.

A malfunctioning canister vent valve cannot control the correct path of gases, which prevents them from being processed in the form of combustion.

— The amount of harmful substances released through the system increases.

When talking about how the canister purge valve works and why, do not forget that improving the environmental performance of the car is an important task that can be solved if the canister purge solenoid valve is faulty.

- It looks like hissing.

A loud hissing sound in the canister tube caused by gas accumulation is not uncommon. Since modern vehicle regulations do not allow gases to be emitted when parked, some accumulation is acceptable.

— Typical sounds from a gas tank.

Speaking about the Lada Granta adsorber, the malfunction of which is always characterized by extraneous noise emanating from the gas tank, it must be said that they are the most typical sign of a malfunction. In this case, the adsorber sensor may not show any signs of malfunction, so it must be replaced.

Therefore, signs of a malfunction of the Lada Grant canister purge valve are quite easy to identify. In addition, they are detected during simple refueling of the car, during which it is necessary to open the gas tank cap.

Purpose and principle of operation of the adsorber purge valve

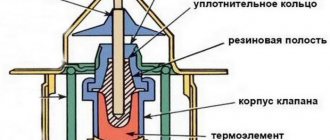

Absorber valve diagram

The EVAP system is installed on gasoline internal combustion engines to prevent fuel vapors from entering the atmosphere. The canister purge solenoid valve is an element of this system. Therefore, to find out what the canister valve is for and how it works, it is important to understand the operating principle of the entire system. The design of the adsorber is a container filled with an adsorbent, most often activated carbon. The device is connected to the fuel tank and the control valve of the vehicle using special tubes.

The canister valve is installed between the intake manifold and the canister and performs the function of ventilation.

Gasoline vapors formed in the fuel tank penetrate the separator, where they condense and are discharged back into the tank. Some of the vapor does not have time to condense in the separator and enters the adsorber through the steam line. In the filter system, they are absorbed by activated carbon, accumulated and then supplied to the intake manifold when the engine starts. The process of absorption of fuel vapors takes place only when the engine is turned off. When the car is running, the electronic control unit opens the canister purge solenoid valve, through which air enters and thus ventilation occurs. In this case, the accumulated condensate along with air is sucked out of the adsorber and again enters the engine, where it is burned out. The canister valve provides ventilation to the entire mechanism and directs fuel condensate back to the engine.

Components

In fact, this is a large plastic jar with activated carbon inside, because it is this composition that perfectly fights gasoline vapors. The main parts can be described as follows:

- Separator + gravity valve

- Pressure meter

- Filter part (usually carbon)

- Connecting tubes

- Solenoid valve

As you can see, there is absolutely nothing complicated. Separator - serves to catch part of the gasoline, then sends it back to the tank. Gravity valve - almost never used, but it is needed in emergency situations, for example during accidents, it prevents fuel from overflowing from the tank (for example, when a car overturns).

Malfunctions of the adsorber valve and their elimination

Almost continuous operation of the fuel vapor absorption system canister can cause damage to the purge valve. A malfunction of the canister valve often leads to damage to the fuel pump. Due to poor ventilation of the adsorber, gasoline accumulates in the intake manifold, the engine loses power, and fuel consumption gradually increases. This may cause the engine to stop completely. The operation of the entire vehicle depends on how the adsorber valve works.

How to check the functionality of the canister purge valve?

Checking the absorber valve

In order to notice and correct problems in time, regular checks of the adsorber valve are necessary. In this case, a breakdown can be identified by certain indirect signs. When the engine is idling or in cold weather, the vapor absorption system makes characteristic sounds, like the canister valve clicking. Some people confuse this sound with a faulty timing belt, rollers or other parts. You can check this by sharply pressing the gas pedal. If the sound has not changed, it means the canister valve is clicking. Experts can explain what to do if the canister valve knocks too loudly. To do this, you need to tighten the adjusting screw, and first it is cleared of epoxy resin.

The absorber valve can be adjusted.

The screw turns approximately half a turn. If you tighten it too much, the controller will generate an error. This adjustment of the adsorber valve will make its operation softer and the knocking noise quieter. However, how to check the adsorber valve for damage? Valve failure can be determined using an error diagnostic system or mechanical testing. Electronic error codes are stored in the controller's memory and indicate electrical damage. To check the valve, it is recommended to pay attention to errors generated by the controller, such as “open circuit of the canister purge valve control circuit.” Signs by which a malfunction of the adsorber valve can be mechanically determined:

- The appearance of dips at idle speed of the engine.

- Very low engine thrust.

- There is no sound of valve operation when the engine is running.

- A hissing sound when the gas tank cap is opened indicates a vacuum in the system. This is a sure sign of a malfunction in the adsorber ventilation.

- The appearance of a fuel smell in the car interior. However, its appearance can also be caused by other reasons.

How to disable or remove the adsorber on a car and do you need to reflash the ECU?

Ignition switch diagram for VAZ 2114 injector: features of connecting the device

You need to understand that when the adsorber is removed, the solenoid valve is turned off, which is directly connected to the controller and controlled by the latter.

This will lead to error p0443, which we already mentioned above. The tubes are also silenced, in particular the one that goes to the intake manifold.

What is the disadvantage of such a shutdown?

The fact is that through the tube that goes to the intake manifold, air is constantly sucked in; even in idle mode, the so-called small purge of the adsorber occurs. At high speeds from 1500 – 2000 and above there is a lot of blowing.

If you plug the pipe, which many people do, a certain amount of air will not flow into the intake manifold bypassing the ECU, but the latter still takes them into account.

That is, the controller takes into account one volume of air, but another (smaller) one actually enters. As a result, the amount of fuel is generated by the ECU based on more air than is supplied. This leads to an over-enrichment of the air-fuel mixture.

As a result, the engine does not work correctly, because the mixture is constantly over-enriched where it is and is not needed, and fuel consumption increases.

It is also worth talking about the transient mode of operation of the engine, which can manifest itself when approaching an intersection, a traffic light, lying to a policeman, at the moment when the gas is released.

At this moment, a failure may occur - a decrease in speed below idle. The engine seems to choke, it doesn’t have enough air, the reason is an over-enriched mixture. After a few seconds, the situation is resolved electronically.

Therefore, it would be correct to disable the adsorber in the following ways:

After removing the device, install a nozzle with a diameter of 1 mm into the tube that goes directly past the mass air flow sensor. This will, at least partially, solve the problem, since only air without gasoline vapors will be supplied in doses.

- The ECU is re-queried (difficult). If it is impossible to remove the Check error, you may need engine chip tuning, which is expensive.

- Dismantling the entire system except the solenoid valve, which operates idle.

- By installing a resistor (valve emulation) in the electrical circuit at 200 - 250 Ohms and 2 watts. To do this, bend the legs of the resistor and insert them into the valve chip. We secure everything with electrical tape. But this doesn't always help.

How to disable the adsorber on a VAZ 2110, 2112, 2114

Taking into account the recommendations above, we do the following:

- Disconnect the power connector from the valve.

- Disconnect all pipes from the adsorber and remove the latter along with the mount.

- We fix the valve in a place where the plug with wires and pipes will reach.

- Connect a hose with a fuel filter to the lower fitting (see photo below).

- To the upper end fitting we connect the pipe going to the intake manifold.

- We put another filter on the pipe going into the tank, similar to the first one.

With this scheme, when the valve opens, clean air enters the system, albeit without gasoline vapors.

We exclude the valve

This method is even simpler. We dismantle everything, including the valve. We put a fuel filter on the pipe coming from the gas tank, and we plug the pipe going to the intake manifold with a bolt and clamp.

The consequences of this method are described above, but this method also has the right to life. As for Priora, Granta, Lada Largus, Gazelle and other cars, the absorber is turned off in similar ways as described above.

Toyota Chaser

It is worth considering one of the foreign cars, for example, the Toyota Chaser.

The shutdown principle is similar to the previous ones:

- Locate the canister valve. It is located near the mass air flow sensor on the air filter housing.

- Disconnect the chip with wires and all pipes from it (Check may light up on the instrument panel).

- Find the adsorber, disconnect the pipes from it and plug it.

- Disconnect the pipe going to the valve from the throttle assembly and plug it with a bolt and clamp.

- Place a fuel filter from a carburetor VAZ on the pipe going to the tank.

What's the catch in flashing from Euro 4 to Euro 2?

Many people change the ECU from Euro-4 to Euro-2, as a rule, they do this when removing the catalyst and installing a blende. At this moment, the canister valve may turn off (on purpose or accidentally), and the ECU does not control the latter and does not control it in any way.

As a result, if the valve malfunctions, the engine will run intermittently, and the error will not be displayed on the instrument panel. To make sure of this, turn off the valve and observe the operation of the motor.

If the version is confirmed, plug the canister pipes and turn off the valve; the controller still does not control it.

Do-it-yourself absorber valve replacement

If signs of malfunction are detected, the valve will need to be repaired or replaced. The adsorber valve is inexpensive and easy to replace. To dismantle you need to have a pair of Phillips screwdrivers and know where the canister purge valve is located. Operating procedure:

The markings on the old and new valves must match.

- Open the hood and find a cylindrical device - an adsorber.

- Remove the negative terminal from the battery.

- Disconnect the wire block by pressing the latch and pulling it towards you.

- Loosen the valve.

- Remove the fittings under the latch and disconnect the hoses.

- Remove the valve together with the bracket from the adsorber.

- The new valve is installed in the reverse order.

Thus, even such a small element as the adsorber valve performs important functions and its malfunction can seriously disrupt the operation of the entire engine. Therefore, it is important to monitor the condition of your car and carry out diagnostics on time.

Valve - as the most important component of the device

When talking about how an adsorption valve works, it is necessary to imagine the device itself. This is roughly a coal can that is equipped with a valve to condense and direct the vapors. The canister purge valve is controlled by the ECU, which sends a signal to open/close it.

Important. The canister solenoid valve can cause inconvenience to the driver. In cold weather, a certain clicking noise may be heard when starting a cold engine. This sound is normal as a cold tube may not function properly.

In order not to confuse this sound with possible failures, it is necessary to apply progassage. If there are no changes, you can safely cancel pressing the absorber.

Price policy

Speaking about the Grant adsorber purge valve, which today can be bought in all large and not very large places where spare parts for the Russian automobile industry are sold, it is impossible not to notice its pleasant price. The Grant adsorber valve, the price of which is equivalent to the probability of its failure, allows for independent replacement and is the simplest mechanism.

Therefore, compliance with Lada Grant environmental standards is the work of man. The adsorber has become a part that, in addition to caring for the environment, can significantly reduce fuel consumption and improve the removal of exhaust gases.

Where is it installed?

As a rule, the adsorber is installed under the hood on the right in the direction of travel of the car, for example, in the VAZ 2110 it is in the form of a barrel.

In other cars, it can be square and installed to the left of the engine (in the direction of travel), under the air duct (Lada Granta), the vacuum brake booster (some Nissan models) or in the radiator area. For VAZ 2114 it is located near the battery and air filter.

On the Volkswagen Passat B3, the adsorber is located under the air filter on the right side in the direction of travel.