When driving in rainy conditions, the windshield becomes covered with raindrops or snow, which causes limited visibility and jeopardizes driving. The question often arises about the performance of the unit designed to clean the windshield from precipitation particles. We will try to find out in detail how to check the windshield wiper motor and monitor its working condition.

What is a windshield wiper motor?

All cars, trucks and other vehicles are already equipped from the factory with mechanisms for cleaning glass, including windshield wiper blades. In its standard form, it consists of two holders with rubber bands on the windshield and one holder on the rear window (for cars with a station wagon or hatchback body). All windshield wipers have three modes of operation, during which they move quickly, slowly or at an intermittent pace.

All windshield wipers are equipped with a special electric motor with geared torque transmission. Two mechanisms designed to operate the windshield wipers are attached to the motor shaft. One rotates the wipers to a certain position on the windshield, and the second is responsible for moving the wipers to their original position. The lever system supports the wipers throughout operation.

In fact, the electric motor rotates without stopping, and a special mechanism is responsible for moving the wipers, which allows them to rotate and quickly return to their original position. This mechanism is called a trapezoid wiper. It consists of a set of levers that move the wipers across the windshield.

In addition to the windshield wipers, the glass washer system is also responsible for a normal view of the front of the road. It is a tank with a special liquid, which, under the action of a pump installed in the tank, is pumped into the system and sprayed on the windshield. It is extremely important that these mechanisms are always in good working order. This is due to the fact that on the planned day of the trip the weather can easily turn bad and driving with a faulty windshield wiper system can become very dangerous.

Replacing the wiper motor yourself

Let’s assume that the results of diagnosing windshield wipers that have lost their functionality indicate a failure of the corresponding motor in a VAZ 2114 car. The problem can be solved by replacing it, which requires the following tool:

- flathead screwdriver;

- a wrench with a set of heads or wrenches for 10 and 13;

- good gear motor.

Since not all drivers can change the windshield wiper motor on their own, let’s next talk about the actions necessary for a successful result:

- Disconnect the negative terminal from the car battery.

- Place the windshield wiper arms in a vertical position.

- Unscrew the lever fasteners.

- Remove the levers from the drive rollers.

- Remove the caps covering the drive.

- Remove the nuts securing the gear motor bracket.

- Remove safety washers.

- Raise the hood and leave it like that.

- Disconnect the connector with contacts for controlling the motor.

- Open the fuse compartment cover and remove the relays that block access to the gearmotor mounts.

- Remove the screw holding the bracket.

- Remove the plastic wiring retainer.

- Remove the fastening of the wires in the technological opening.

- Unscrew the 3 bolts connecting the motor and trapezoid arms.

- Remove the windshield wiper motor.

That's all the operations necessary to dismantle the wiper drive motor. When installing a new one, they are performed in the reverse order.

An important nuance of installing a new motor is to set the correct position of its shaft before connecting to the crank mechanism. For correct positioning, the gear motor without attachment to the trapezoid is switched on intermittently. Then wait for the shaft to stop in its extreme position. This will be the desired position.

After installing a new motor, you should definitely check its operation in all possible modes. If the problem is not solved, for example, the windshield wipers still stop at the extreme point, you need to diagnose the electrical part of the system. Trapezium limit switches and control relays are the most common sources of problems.

Important advice for those drivers who want to extend the trouble-free operation of their windshield wipers. It is useful to carry out an annual overhaul of the wiper system in order to check the wear of all components and parts. This way you can detect bending of the rod or play in the moving joints. Minor mechanical faults identified and corrected in a timely manner reduce the load on the gear motor and, as a result, contribute to its trouble-free operation.

Windshield wiper malfunctions and repairs

There are many reasons why a windshield wiper may not work. First, always check the condition of the electric motor. Malfunctions include poor contact between the brushes and commutator, interturn short circuits in the stator or rotor windings, or jamming of the rotor and stator as the motor support bearings wear out. In addition, the malfunction may affect the contact connections between the engine and the electrical supply wires. However, if eliminating these faults does not lead to a positive result, we recommend carrying out a major overhaul of the electric motor.

In cases where the problem lies in the condition of the electric motor, there are a number of other reasons why the windshield wiper may not work. There are cases when the cause of a malfunction may be jamming of working parts. To prevent further damage, a bimetallic fuse is triggered, which protects the motor transmission mechanism from damage. If the fuse trips, then further use of the windshield wiper is impossible. Check the condition of the working parts and, if necessary, carry out appropriate repairs on the levers. After this, replace the used fuse.

If the windshield wiper mechanism operates at only one speed, then you should pay special attention to the condition of the switch or special resistor and, if necessary, replace it. It is not uncommon for windshield wipers to make strange sounds during operation. Creaks and knocks - all this can be the cause of a malfunction of the mechanism's hinge unit. If you are sure that such sounds have nothing to do with dust under the rubber bands or with the glass coating, then purchase a repair kit for the windshield wiper mechanism and replace the problematic hinges.

However, if repairing the mechanism does not give a positive result, it is recommended to replace the windshield wiper motor. It often happens that the motor bearing begins to become loose and makes extraneous noise during operation. At the same time, it compromises the reliability of the windshield wipers.

How to remove the windshield wiper gear motor?

To remove the gear motor, we only need to unscrew 4 fasteners! But there are two nuances:

- not convenient location;

- you need to remember the position of the crank.

The crank is a curved rod from the motor to the trapezoid rods. If you do not install the crank correctly, there is a high probability of damaging the teeth on the new motor.

So:

- Open the hood, disconnect the wiring block from the fuse block to the gear motor.

- We remember (indicate with a marker) the position of the crank.

- We unscrew the fastening of the piston to the motor with a key set to “13” and remove it.

- Using a “10” wrench, unscrew the three bolts securing the gear motor to the trapezoid.

- We take out the gear motor.

If the gear motor cannot be pulled out, unscrew the fastenings of the fuse block and move it away.

Car windshield wiper motors

Most, if not all, purifier motors used today are permanent magnet motors. The motor is connected to the motor through a worm gear to increase torque and reduce speed. For two-speed operation, motors with three brushes can be used. Normal speed is ensured by two brushes placed opposite each other as usual. To operate at higher speeds, a third brush is used, which is placed closer to the grounded brush. This reduces the number of turns of the armature winding between them, accordingly the armature resistance decreases and the current and rotation speed increase.

The normal purifier motor speeds are 45 rpm at normal speed and 65 rpm at high speed. The motor must be able to overcome the static friction of the blade at a minimum speed of 5 rpm.

The characteristics of a typical car cleaner motor are shown in the figure. Two sets of curves show operating modes corresponding to normal and increased speed.

Purifier motors, or more precisely, the circuits associated with them, are usually short-circuit protected. This is necessary to protect the motor in case the brushes become blocked, for example when they freeze to the glass. In this case, a thermal relay or current sensing circuit in the purifier control unit, if equipped, is often used. The maximum time during which the motor can withstand current when the brushes are blocked is specified by regulatory documentation. Usually it is within 15 s.

Source

How to ring a windshield wiper motor

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

car VAZ 21093, 1997 The wipers don't work. They don't move at all. When you turn on the wipers you can hear the relay clicking. I removed the motor assembly with the trapezoid. I checked the bimetallic fuse for the motor mount; it is there.

QUESTION: How can I check if the windshield wiper motor is working properly?

PS

In the connector for connecting the motor I found one + it is permanent, on the other wires there is no plus on any of them, it doesn’t matter whether the brushes are on or off

There are two wires from the motor. Give one a plus, the other a minus and check.

Doesn't it spin in all modes?

take the diagram. smoke it. First of all, check for the presence of + 12V after the bimetallic fuse, if it is external to the motor. If there is no +12V or it disappears immediately after it appears, then: - the bimetallic fuse has blown - the motor or trapezoid (usually the shafts on which the wiper arms are attached) are jammed. It’s better to check them manually right away - they should turn very easily.

Let's move on to the second stage. If the wiper relay clicks in all modes, then two malfunctions appear: - the insides of the fuse block are out of order - check the voltage at the contacts of the upper connector of the fuse block with a tester (better) or a tester. It is better to compare the voltage with the voltage at the battery contacts. If it is significantly lower or absent, then the problem is in oxidized contacts and the insides of the fuse box. — the gearbox of the motor is jammed, its windings are burnt out (checked by a continuity tester), the contacts inside the motor are oxidized, the adjusting screw of the worm gear is overtightened, the bearings are scattered/acidified. Motor disassembly, cleaning, lubrication.

Voltage can be supplied directly to the motor, if in a car, then it’s a good idea to use a fuse or a light bulb in series to prevent a short circuit from happening accidentally (in general, follow safety precautions when working with electrical installations).

Variants and combinations of the above should lead to a positive result.

Source

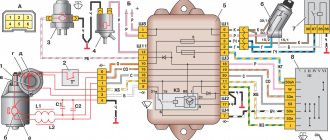

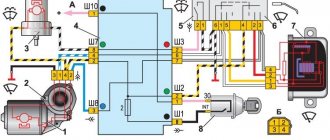

Connection diagram

If you encounter any difficulties, this diagram will help you figure out what you are doing wrong.

- wiper gearbox (1);

- thermobimetallic fuse (2);

- motor (3);

- washer valve (3);

- mounting block (4);

- ignition switch (5) and relay (6);

- switch (7);

- K3 front wiper relay (8);

- “A” – the contacts of the wiper pads are marked;

- “B” – output to pin 30 of the generator terminal;

- a – second speed;

- b – first;

- c – switch spring;

- d and e – his contacts;

- noise filtering capacitors – C1, C2;

- chokes – L1, L2.

Dismantling the device

In rare cases, the front or rear windshield wiper motor stops working due to some manufacturing defect. The problem is extremely rare, however, if you become a victim of it, there is nothing left to do but start special repairs.

To complete the procedure successfully, perform a complete dismantling. It is no secret that such a process is quite troublesome and time-consuming. Especially if you have to repair a part from old cars, such as Tavria, KAMAZ, Priora, and so on. In this case, you will have to use several separate steps, including unscrewing the nuts that act as fasteners for the levers.

In the future, you can begin to remove the levers themselves from the tapered splines of the drive. If you have any difficulties at this stage, the splines can be treated with penetrating lubricant. Next, the lever drives are dismantled by unscrewing the nuts, as well as removing the rubber gaskets and plastic bushings.

In the harness, the wiring block is disconnected and pulled out using the raised edge of the seal, through a special slot in the partition of the engine compartment. The next step is to remove the windshield wiper.

Now you will have to unscrew the washer from the removed device and remove the spring retainer. And also you can’t do without disconnecting the rod. As a result, all you have to do is dismantle three bolts and remove the engine. After a full visual inspection, begin replacing any faulty parts.

If this does not give any results, the only way out of the situation will be to buy a new motor. If the problem is resolved, the glass cleaning system must be reassembled in the reverse order.

Replacement features and diagram

If, after a thorough diagnosis, you were able to determine that the motor is faulty, think about replacing the failed unit. At this stage there are no special difficulties, so even an inexperienced beginner can easily solve the problem.

True, you must understand that the features of the procedure vary depending on the model of a particular vehicle.

Therefore, before performing a series of any actions, pay attention to the technical features of the system, read the service manual for the car

- First of all, you must unscrew the nuts securing the brush arm. The help of a wrench will come in handy here. Then remove them from their installation location. If difficulties arise, use a penetrating lubricant.

- Then you need to remove the lever drives by unscrewing the nuts that secure them.

- The next step is to disconnect the connector with the wires in the harness and lift one part of the seal through the hole formed.

- As a result, all that remains is to dismantle the wiper itself. Then remove the washer and spring mount. After successfully achieving such goals, all that remains is to disconnect the pull rod, unscrew the three screws and remove the motor. Unit repair is characterized by particular simplicity and speed of execution.

- Replacing a car's rear windshield wiper blade yourself

- Replacing car windshield wiper blades yourself

- How to properly remove and replace wipers on a car, mounting methods

Checking and removing the VAZ-2109 wiper motor

An element such as the motor responsible for the operation of the wipers on the VAZ-2109 does not fail very often, but if this does happen, it has to be replaced with a new one. This is actually not difficult to do, but the procedure itself takes quite a lot of time, especially for those car enthusiasts who do not have the proper experience.

How to remove

First of all, it is necessary to de-energize the system. To do this, simply disconnect the negative terminal on the battery.

- set the wiper arms to a vertical position;

- unscrew the nuts and remove them from the rollers;

- remove protective caps;

- twist the nuts (one on each side) securing the brackets at the top;

- dismantle the rubber sealing washers;

- in the engine compartment, remove the wiring harness from the connector;

- unscrew the bolts holding the lower part of the bracket;

- the mechanism rollers are removed from the holes;

- unscrew the nut securing the windshield wiper crank and remove it;

- dismantle the bolts holding the wiper gearbox and the motor in place;

- disconnect the wires from the bimetallic fuse and remove the engine from the bracket.

All that remains is to remove the locking ring and adjusting washers from the gear shaft and install a new motor. Assembly is carried out in reverse order. To make it more convenient to work, we recommend moving the stove fan slightly to the right. Without this, it will not be possible to remove the windshield wiper. You will also need to remove the fuse box cover and all the relays located there.