Wipers do not work on VAZ 2108, 2109, 21099

Failure to operate the windshield wipers is a very common malfunction on VAZ 2108, 2109, 21099 vehicles. Its main causes are problems with the electrical part and mechanical failure of the windshield wiper elements. Let's consider a situation where the wipers have completely failed and do not react in any way to moving the lever in the right steering column switch.

List of malfunctions leading to failure of wipers on VAZ 2108, 2109, 21099

At the beginning of the electrician:

— the fuses in the mounting block have blown;

For the old-style mounting block - 17.3722 these are No. 5 and No. 4, for the new ones 2114-3722010-60, 2114-3722010-10, 2114-3722010-18 - F16 and F7. Fuses No. 5, F16 – cleaner, No. 4b A7 – washer.

If the fuses blow, there may be a short circuit in the electrical circuits of not only the windshield wiper, but also other circuits protected by them. See “Fuses and circuits of mounting blocks they protect for VAZ 2108, 2109, 21099”.

— the windshield wiper relay has failed (52.3747, 525.3747);

The relay should click when operating. If this is not the case, either it itself is faulty, or its contacts have oxidized. Sometimes, to restore its functionality, it is enough to take it out and put it back in several times. We replace the faulty relay with a new one.

You can check its serviceability by moving the steering column switch to the uppermost position. In this position, the brushes should work even if the relay is faulty.

Assignment of windshield wiper relay contacts for checking it: input – 15, output – S.

— the steering column switch for the windshield wiper operating modes is faulty;

The purpose of the switch terminals for checking it is: current input - 53a, 1st speed - 53, 2nd - 53b, intermittent mode input - 53e, intermittent mode output 53.

The faulty switch should be removed, disassembled, the contacts cleaned, or replaced with a new one.

— the connectors in the electrical circuit of the windshield wiper have come off;

In the mounting block these are X1, X2, X3, X4, X11, next to the mounting block there is a connecting block for the electric motor, a block on the steering column switch.

— the contacts in the connectors of the electrical circuit of the windshield wiper have oxidized;

We disconnect all the connecting blocks one by one and clean the contacts with a small needle file. It is better to start with the electric motor block next to the mounting block, as it is constantly exposed to moisture. Here you can check the connection of the “mass” wire of the electric motor.

It will be useful: What is the difference between the Lada Largus and the Lada Largus Cross: similarities and differences

— the windshield wiper motor brushes are severely worn or stuck;

The commutator against which the brushes are pressed may also burn out.

You can check the serviceability of the wiper motor by applying voltage to it directly from the battery. Input: 1st speed - gray wire from the mounting block, 2nd speed - gray-orange wire from the mounting block. Input for intermittent operation - gray wire from the mounting block.

— the brushes are frozen to the glass;

— after a long period of parking, the brushes stuck to the windshield;

— the windshield wiper drive levers are damaged, jammed or incorrectly installed after repair;

— the teeth of the plastic gears in the electric motor gearbox are damaged.

Notes and additions

— Other malfunctions of the windshield wiper (the blades do not work in intermittent mode, stop during operation, do not work synchronously, etc.) of VAZ 2108, 2109, 21099 cars are described on our website in the article “Malfunctions of the windshield wiper of VAZ 2108, 2109, 21099 cars.”

— Fuses, connection block, ground mount, wiper relay

Failure of wipers on a VAZ 2109: how to deal with it?

Proper operation of the windshield wiper is very important during bad weather. It provides good visibility on the road - the safety of the driver and passengers. Failure of wipers to work is a common problem on cars. The article discusses situations when the wipers on a VAZ 2109 car do not work, and how to repair the windshield wiper.

The main purpose of a windshield wiper is to remove dirt, raindrops and snow from the windshield and rear window during bad weather using brushes and washer. If the VAZ wipers do not work, this reduces safety, so it should be brought into working condition as quickly as possible.

In order to identify and eliminate malfunctions, you need to know the windshield wiper design.

Components of a car windshield wiper

In addition, the design of the windshield wiper includes various small parts.

How does a windshield wiper motor work?

Most cars have two blades that provide more effective cleaning of the windshield. The rear window is usually equipped with a single wiper.

The device operates in 2 or 3 modes, which allow the brushes to provide intermittent, leisurely or fast cleaning.

The overall design includes motor (a small engine with a gearbox), a brush return mechanism, a lever system and the wipers themselves. Along with the cleaner, you can use a windshield washer, which supplies water in the form of a directed jet.

One of the most unreliable parts of the system, which often fails, is the motor . If it breaks down, motorists do not know what to do and what the reasons may be.

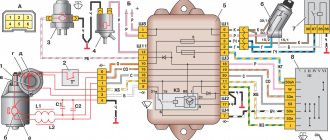

Glass cleaner circuit

The following components are marked with numbers on the diagram: 1 - electric washer motor; 2 – electric motor for wipers; 3 — mounting block; 4 – ignition switch; 5 – relay that relieves the windshield washer switch;

The glass cleaner can operate in three modes. Mode “I” is intermittent. Mode “II” is constant. In this mode, the brushes move at low speed. Also a permanent mode is mode III. It differs from the previous one in the high speed of movement of the brushes. The mode is turned on using a switch (video author - Autoelectrics HF).

READ How to change the door handle on a Chevrolet Niva

How to replace windshield wipers, they are also wipers, they are also brushes on a VAZ 2108-VAZ 21099?

Note! Both wipers are replaced identically, so an example of the replacement will be shown on only one wiper!

Removal: 1) First place the brush in a vertical position. Immediately after that, using a wrench, unscrew the small nut that secures the wiper arm.

Disassembling the electric motor of the windshield wiper VAZ 2108, 2109, 21099

Let's disassemble the windshield wiper electric motor that was previously removed from the car.

This will have to be done if it needs repairs. For example, replacing a licked gearmotor gear, cleaning limit switch contacts, replacing brushes or an electric motor armature, etc.

Required Tools

— Keys for “10” and “13”

Disassembling the electric motor of the windshield wiper VAZ 2108, 2109, 21099

— Disconnect the crank mechanism (levers) from the wiper motor

To do this, use a key set to “13” to unscrew the nut securing it and remove it by sliding it off the axis.

— Disconnect the wiper motor bracket

Using a “10” wrench, unscrew the three nuts securing the bracket and remove it.

We disconnect the crank and bracket of the electric motor of the windshield wiper of VAZ 2108, 2109, 21099 cars

— We disassemble the purifier gear motor

Using a Phillips screwdriver, unscrew the three screws securing the protective cap of the gearmotor and remove it.

We remove the protective cap of the windshield wiper gearmotor of VAZ 2108, 2109, 21099 cars by unscrewing the three screws securing it

Disconnect the lock washer of the gear motor gear shaft. We pry it off with a screwdriver and remove it. We also remove the two washers under it.

Remove the lock washer from the gear motor gear shaft and two simple washers under it

Using a Phillips screwdriver, unscrew the screw securing the wire clamp and remove the gear motor cover.

Remove the cover of the windshield wiper gear motor and take out its gear

We remove the gear motor gear.

— We disassemble the windshield wiper motor housing

Using a Phillips screwdriver, remove the two screws securing the motor housing to the gearmotor. Remove the screw retainers. Remove the housing by sliding it back. If necessary, we replace faulty parts (brushes, armature) with new ones or known good ones.

Disconnect the electric motor from the windshield wiper gear motor and disassemble it

We assemble the windshield wiper motor in the reverse order. When assembling, there are some features without knowledge of which it is not possible to produce it properly. One such feature is described in the notes and appendices.

Notes and additions

— When assembling the windshield wiper electric motor of VAZ 2108, 2109, 21099, it is necessary to install the brush levers in their original position. To do this, we connect the block of wires to the electric motor, turn on the ignition, turn on the windshield wiper with the steering column lever and wait until it stops. Turn it off. We fasten the crank in this position.

Technical characteristics of the gearmotor

Shaft rotation speed at supply voltage 14 V,

moment 0.15 kgf.m

and ambient temperature 25±10°С, min –1

Current consumed under these conditions, A, no more than:

at first speed

at second speed

The purifier has three operating modes, they are activated by the right steering column switch.

Intermittent mode is provided by an electronic relay K2 type 524.3747 installed in the mounting block. This relay also turns on the wiper motor at low speed when the windshield washer is turned on.

The relay must ensure that the electric motor is turned on with a frequency of 14±4 cycles per minute at a gearmotor shaft speed of at least 20 min -1, a temperature of 20±5°C and a supply voltage of 14±0.2 V.

When the cleaner operates at low speed in constant mode, the supply voltage is supplied to diametrically opposed brushes.

When the cleaner operates at maximum speed, “+” power is supplied to the brush located on the side.

To relieve the load on the contacts of the ignition switch, the cleaner is connected through an additional relay K6 in the mounting block.

It is recommended to replace a faulty gearmotor with a new one (cleaning the commutator, limit switch contacts and replacing gears is possible).

Replacing the trapezoid and the wiper motor (windshield wipers)

The design of the trapezoid on VAZ 2109-2108 cars is quite reliable and it is almost never necessary to replace it, or only in exceptional cases. But you will need to remove it if you need to replace the wiper motor. This part fails much more often. Carrying out this repair yourself is quite simple and for this work we will need the following tool:

- open-end or socket wrench 24

- socket head 10

- extension

- ratchet

- flat screwdriver

Complete disassembly of the windshield wiper trapezoid and its repair:

When repairing the windshield wiper trapezoid, do not, under any circumstances, if you do not have the appropriate experience, remove the armature shaft adjustment screw. When it is turned out, the axial clearance at the shaft is violated!

1) First, use a wrench to unscrew the nut that secures the trapezoid crank.

2) And then remove the crank by prying it up with a screwdriver.

3) Now, picking up the wrench again, unscrew the three bolts that secure the motor-gearbox to the bracket.

Replacing the windshield wiper trapezoid with your own hands, without removing the fuse box.

trapezoid replacement process

with your own hands in three and a half minutes.

VAZ 2109

car . my DRIVE 2.

VAZ 2114 replacement of trapezium wipers

4) When the three bolts are unscrewed, use a screwdriver to unscrew the two screws that secure the wires to the fuse, and then disconnect them.

How to Check the Wiper Motor of a VAZ 2109

Checking and removing the windshield wiper motor VAZ-2109

An element such as the engine responsible for operating the windshield wipers on a VAZ-2109 car does not occur often, but if this happens, it must be replaced.

It is essentially simple, but the procedure itself is time-consuming, especially for those car owners who do not have the proper experience.

First, you need to turn off the system. To do this, simply disconnect the negative terminal on the battery.

- place the windshield wiper arms in a vertical position;

- remove the nuts from the rollers;

- remove the protective caps;

- tighten the nuts (one side), the mounting brackets on top;

- disassemble the rubber sealing washers;

- in the engine compartment, the wiring harness has been removed from the connector;

- unscrew the bolts that hold the lower part of the bracket;

- the mechanism rollers are removed from the holes;

- unscrew the nut that secures the windshield wiper handle and remove it;

- remove the bolts that hold the windshield wiper and motor in place;

- disconnect the wires from the bimetallic fuse and remove the engine from the bracket.

All that remains is to remove the retaining ring and washers from the gearbox shaft and install the new motor. Reverse assembly.

For convenience, it is recommended to slightly move the oven fan to the right. Without this, the wiper cannot be removed. You will also need to remove the fuse box cover and any relays located there.

Before removing the wiper itself, you need to move it slightly to the left.

The pads are best numbered to avoid confusion during assembly.

Disassembling the gearbox

If the cleaner does not work due to contamination of the gearbox, it is easy to clean. But under no circumstances unscrew the adjusting screw installed in it. in the event of an unpleasant event, you most likely will not be able to properly return the anchorage gap.

The procedure looks like this:

- remove the protective panel from the gearbox;

- remove the transmission;

- they remove the cage nuts after unscrewing two bolts;

- The gearbox housing is disconnected together with the brush holder from the engine;

- the anchor is removed and cleaned with a compressor.

Removing the rear wiper is usually done the same way, but you will need to remove the door trim to get to the wires and other parts.

Engine repair

Many people think that replacing the engine with a foreign car from a similar engine will solve the problem with the slow operation of the windshield wiper blades, but in fact, the “original” motor is quite easy to clean and lubricate.

If the post causes speed, you should check how easily the armature rotates: if the movement is difficult, you should expect damage or very high wear on the brush. They are easy to exchange for new ones.

This will also help clean the manifold. For this you will need sandpaper. They talk about the need for this procedure:

- visible contamination;

- noticeable scratches;

- grooves on the metal.

The armature or gearbox in combination with the engine assembly must be replaced if the manifold is severely worn or burnt out.

Speed control is necessary if the windshield wiper blades operate very slowly. This is facilitated by:

- inappropriate (very “thick”) lubricant;

- gear wear;

- deformation of rods.

Eliminating these problems basically makes the windshield wipers work faster and, in addition, significantly.

Connection diagram

If you're stuck, this chart will let you know what you're doing wrong.

- Jamit gearbox (1);

- thermobimetallic fuse (2);

- engine (3);

- washer valve (3);

- mounting block (4);

- ignition switch (5) and relay (6);

- switch (7);

- Wiper relay K3 (8);

- "A". The wiper blade contacts are marked;

- "B". output to the 30th contact of the generator;

- A. 2nd speed;

- b. 1st;

- C. spring switch;

- g and d. his contacts;

- filter capacitors. C1, C2;

- chokes. L1, L2.

15.4 Checking the wiper motor

Checking the wiper motor

The wiper motor is located in a waterproof housing under the windshield, and the rear wiper motor is located in the rear gate. To check, remove the corresponding backing. The wiper motor will be considered in the future and the rear wiper will work properly.

- First find out whether the faulty motor is a cleaner motor or voltage. To do this, proceed as follows.

- Disconnect the multi-core connector from the wiper motor.

- Use an auxiliary cable to supply voltage from the positive terminal of the battery to terminal c. (The negative pole of the engine is connected to the battery minus through the housing).

- The wiper motor should now operate at stage 1 (slow). If it doesn't work, it means the engine or 1st gear is faulty.

- Connect the positive cable to the terminal and to the left of the terminal with . The motor should now run quickly in stage 2.

Checking the rear wiper

- Connect the positive battery cable to terminal A and the ground to terminal B of the plug and check that the engine runs.

- Then disconnect the ground from terminal B and immediately connect it to the motor frame. The engine should stop and stop.

- Connect the auxiliary cable from the positive terminal of the battery to terminal B. Connect a ground from the negative terminal of the battery to terminal a. Terminal B is located at the bottom left, terminal and at the bottom right.

- The wiper motor should operate in step 1 (slow). If this does not work, the engine or first stage is faulty.

- Connect the negative cable to terminal C. Terminal c is located above terminal and . The motor should now run the second steps (fast).

Checking the rear wiper

- Connect the positive battery cable to the terminal and . the grounding cable to terminal b and make sure that the engine is running.

- Then remove the ground from the terminal. b and immediately connect to the engine housing. The engine should stop and stop.

- If the windshield wiper motor is faulty, install a new one, see Section. Heater, lighting system, household appliances . Section Removal and installation of the rear windshield wiper motor .

- Connect the front wiper motor connector.

Engines do not work on VAZ 2108, 2109, 21099

Wipers failure. "janitors". a very common malfunction of VAZ 2108, 2109, 21099 cars. Its main causes are problems with the electrical part and mechanical failure of the wiper elements. Consider a situation where the windshield wiper blades are completely out of order and do not respond in any way to the movement of the lever in the right steering column switch.

Motor repair

Many people think that replacing the motor with a similar one from a foreign car can solve the problem with the slow operation of the wipers, but in fact, it is often enough just to clean and lubricate the “original” engine.

If the speed of operation causes complaints, then it is necessary to check how easily the armature rotates: if movement is difficult, damage or excessive wear of the brushes should be suspected. They are easy to replace with new ones.

Cleaning the collector will also help - this will require fine sandpaper. The need for this procedure is said:

- visible contamination;

- noticeable scratches;

- grooves on the metal.

It will be necessary to replace the armature or gearbox along with the complete motor if the manifold is too worn or burnt.

Adjusting the operating speed is necessary if the windshield wipers operate too slowly. This is facilitated by:

- incorrect (too tight) lubrication;

- gear wear;

- rod deformation

Eliminating these problems basically makes it possible to speed up the wipers and, moreover, significantly.

Motor malfunctions and solutions

Let's look at what to do if the windshield wiper motor does not work, and what can cause such problems. There are several options:

1. The electric motor does not work, the bimetallic fuse is inactive, and the fusible insert responsible for powering the wipers is intact. In this case, you need to check the serviceability of the wiring, the quality of connections of all contacts, determine any existing damage and eliminate them.

If everything is fine with the wiring, then you should check the wiper switch. If it acts up, just replace it. The engine itself may not work - this often happens when brushes stick or contact connections burn.

In this case, you need to repair the windshield wiper motor - inspect it, replace faulty elements, and clean dirty components. It is important to check the integrity of the wiring that connects the electric motor and the block.

The next step is to check the bimetallic fuse, which needs to be cleaned, and if repair is impossible, simply discarded and replaced with a new one. If this does not help, check the motor armature winding for integrity. If there is no chain, then it is necessary to replace the armature or the entire mechanism as a whole.

2. The bimetallic fuse works, the motor does not start, and the power fuse constantly blows. The first thing to do is check the integrity of the levers. Often they do not work due to deformation or freezing of the brushes to the windshield.

The worst thing is if the cause of such a problem is a short circuit in the armature circuit. Here, repairing the fault is possible in only two ways - by installing a new armature or replacing the gearbox.

3. Interrupt mode does not work. Here the problem is either the relay or the wiper switch. In the first and second cases, it is better to replace the faulty element.

4. The wipers do not stop in interrupt mode. The reason is a relay failure or a malfunction of the limit switches. In the latter case, the gear cam of the gearbox simply does not press the spring plate. The problem is solved by bending it a little.

Connection diagram

If you encounter any difficulties, this diagram will help you figure out what you are doing wrong.

- wiper gearbox (1);

- thermobimetallic fuse (2);

- motor (3);

- washer valve (3);

- mounting block (4);

- ignition switch (5) and relay (6);

- switch (7);

- K3 front wiper relay (8);

- “A” – the contacts of the wiper pads are marked;

- “B” – output to pin 30 of the generator terminal;

- a – second speed;

- b – first;

- c – switch spring;

- d and e – his contacts;

- noise filtering capacitors – C1, C2;

- chokes – L1, L2.

VAZ 2109: windshield wiper repair - correct execution

Windshield wiper (“janitor”) VAZ 2109

Windshield wipers are designed to clean the windshield from raindrops in bad weather, as well as from dust and dirt and provide the driver with good visibility. At the same time, windshield wiper blades, when installed correctly, clean a large area. The quality of glass cleaning largely depends on how tightly the brushes are pressed against the glass. Of course, we should not forget that the windshield wiper (due to its design) does not clean the entire surface of the windshield, because of this, visibility in snowfall or heavy rain is significantly deteriorated. If there are failures (malfunctions) in the operation of the wipers, you will have to repair the windshield wiper of the VAZ 2109. Do not be afraid to perform this simple procedure yourself, use our article and save your money.

Causes of malfunction

The weak point of this motor is that there are a fairly large number of contacts along the power circuit. This affects both the voltage and the possible causes of malfunctions: the contact on one link of the chain is lost or unstable, and stable operation of the windshield wiper is no longer possible. In this case, it is quite possible that the motor is not at fault. Therefore, before you decide that it needs to be replaced, check the contacts along the entire circuit.

- Fuse. Pay attention to the fuse, it may also be faulty;

- Performance. Next, you should check the switch itself for serviceability;

- Operating parameters. Using an ohmmeter, check the resistance in the circuit breaker between the terminals. If it shows “zero”, you need to change the breaker;

- Correct connection. Without turning on the wiper, measure the resistance between the fourth terminal and ground. It must also be zero. Otherwise, you need to properly restore the grounding;

- Voltage. Turn the windshield wiper to low speed and check the voltage at terminal five. It is equal to the battery voltage, but the gearmotor does not work? It needs to be changed.

Causes of malfunction of the VAZ 2110 windshield wiper motor

How to remove

First of all, it is necessary to de-energize the system. To do this, simply disconnect the negative terminal on the battery.

- set the wiper arms to a vertical position;

- unscrew the nuts and remove them from the rollers;

- remove protective caps;

- twist the nuts (one on each side) securing the brackets at the top;

- dismantle the rubber sealing washers;

- in the engine compartment, remove the wiring harness from the connector;

- unscrew the bolts holding the lower part of the bracket;

- the mechanism rollers are removed from the holes;

- unscrew the nut securing the windshield wiper crank and remove it;

- dismantle the bolts holding the wiper gearbox and the motor in place;

- disconnect the wires from the bimetallic fuse and remove the engine from the bracket.

All that remains is to remove the locking ring and adjusting washers from the gear shaft and install a new motor.

Assembly is carried out in reverse order. To make it more convenient to work, we recommend moving the stove fan slightly to the right. Without this, it will not be possible to remove the windshield wiper. You will also need to remove the fuse box cover and all the relays located there.

The windshield wiper itself must also be moved slightly to the left before removal.

It is better to number the adjusting washers so that they are not confused during assembly.

Disassembling the gearbox

If the wiper does not work due to contamination of the gearbox, then it will not be difficult to clean it. But under no circumstances should you unscrew the adjusting screw installed in it - otherwise you will most likely not be able to properly restore the armature clearance later.

- remove the protective panel from the gearbox;

- remove the gear;

- take out the cage nuts, having first unscrewed two bolts;

- The gear housing is disconnected together with the brush holder from the motor;

- the anchor is removed and cleaned with a compressor.

Removing the rear wiper generally follows the same algorithm, but you will also have to remove the door trim to get to the wires and other elements.

How to remove

First of all, it is necessary to de-energize the system. To do this, simply disconnect the negative terminal on the battery.

- set the wiper arms to a vertical position;

- unscrew the nuts and remove them from the rollers;

- remove protective caps;

- twist the nuts (one on each side) securing the brackets at the top;

- dismantle the rubber sealing washers;

- in the engine compartment, remove the wiring harness from the connector;

- unscrew the bolts holding the lower part of the bracket;

- the mechanism rollers are removed from the holes;

- unscrew the nut securing the windshield wiper crank and remove it;

- dismantle the bolts holding the wiper gearbox and the motor in place;

- disconnect the wires from the bimetallic fuse and remove the engine from the bracket.

Operating principle and purpose of the motor

The windshield wiper motor is one of the main components of the entire system. Its purpose is to ensure the movement of the brushes along the windshield and rear window (if we are talking about a hatchback or station wagon). The windshield wiper motor itself supports operation in several modes - slow, intermittent, and the fastest.

In general, the design of the wipers includes an electric wiper motor with a gearbox, a unit that returns the blades to their place, as well as levers and the brushes themselves. As a rule, a washer device also functions with the brushes, providing water supply to the glass. The windshield wiper motor itself is considered one of the most unreliable components, which fails quite often.

Electric motor for the domestic "ten" in removed form

Let's start the renovation

Our instructions are suitable for the VAZ 21099 repair and replacement of windshield wipers. The windshield wiper mechanism on the VAZ 2109 and other models is removed if a complete replacement is necessary (if they are completely out of order), for repairs or to perform other work when its presence interferes with the progress of their implementation. You will need a set of open-end wrenches and a set of screwdrivers to repair the windshield wipers on a VAZ 2109 yourself, proceed in the following sequence:

- Disconnect the negative battery terminal wire

- We turn both levers of the wiper blades to a vertical position, unscrew the nuts securing them

- Remove the blade arms from the windshield wiper rollers

Unscrew and remove the windshield wiper arms

Note: If suddenly you cannot remove the lever by hand, unscrew the nut securing the wiper arm, but not all the way, to avoid damaging the thread.

Using pliers (pliers), pull the lever off the slots, then completely unscrew the nut. Remove the windshield wiper arm.

- Remove the protective caps, one on each side.

- Unscrew one nut from the upper bracket mounting on both sides

- Remove the special leveling rubber washers located on both sides

- Open the hood of a VAZ 2109 car, disconnect the connector with wiring from the block

- Then we move the heater fan to the right side along the compartment located in front of the windshield; if this is not done, the fan will interfere with us, remove the windshield wiper.

- Remove the cover from the fuse and relay box

- We remove all the relays from the mounting block: since they interfere with the removal of the wiper

Disconnect the connector from the block. We take out all the relays so as not to interfere with the removal of the wiper

- Unscrew the lower mounting bolt from the wiper bracket.

- Squeeze the plastic wire holder and remove it from the slot in the body

- Remove the holder from the wires so as not to lose it

- We remove the rollers of the wiper mechanism from the holes located in the body

- We move the windshield wiper so that its motor is in the wide part of our compartment located in front of the windshield (this is where the heater fan is installed)

- We turn the windshield wiper and remove its motor from the compartment

- Move the wiper towards the fuse and relay box

- We take it out of the compartment

- Unscrew the nut securing the crank of the wiper mechanism

- Remove the crank from the wiper gear shaft by prying it off with a flat screwdriver

Using a flat screwdriver, remove the crank from the gear shaft

- We unscrew the three bolts securing the wiper gear with the electric motor

- Unscrew the two screws securing the windshield wiper motor wires

- Disconnect the wires from the bimetallic thermal fuse

- Remove the windshield wiper motor from the bracket

- Then remove the retaining ring from the wiper gearbox shaft

- Remove the adjusting washers from the gearbox shaft

Tip: Be sure to mark all the adjusting washers so that when assembling the windshield wiper mechanism, install them in the same quantity and in their original places

- Unscrew the three screws securing the wiper gearbox cover

- Removing the gearbox cover

We unscrew the screws (there are three of them), they are indicated by arrows, to remove the gearbox cover

Warning: When disassembling the windshield wiper gearbox, do not unscrew (do not touch at all) the adjusting screw (in the photo above it is marked in red) otherwise you will violate the axial clearance (it is adjusted at the factory) of the armature shaft.

- Remove the panel from the wiper gearbox

- We take out the gear of the wiper gear

- Unscrew two screws (the second is located behind the wiper gear housing) and remove two cage nuts

Unscrew the screws and remove the cage nuts

- Remove the wiper gear housing from the electric motor housing along with the brush holder

- We remove the armature from the wiper motor housing

- After disassembling the electric motor, we blow through the housing with compressed air in order to remove coal dust from it.

- Remove the retaining rings from both rollers of the wiper mechanism

- Then remove the adjusting washers from the two rollers of the windshield wiper mechanism.

- We remove the rods from the bracket and remove the adjusting washers from both rollers

- We remove the O-rings from the special grooves on both sides of the bracket.

It is impossible to further disassemble the trapezoid system; its rods have a completely non-demountable design (photo below):

- 1 – crank designated

- 2 - short wiper rod

- 3 — linkage joint

- 4 is the wiper mechanism roller

- 5 - long pull

Non-removable design of wiper rods

- We check the brush springs; if the electric motor brush springs are damaged or have lost their elasticity, replace the brushes with new ones

- Checking the ease of movement of brushes in the brush holder

- We replace worn or chipped brushes; they should move freely and without jamming

- Solder the leads of the new brushes (when replacing) to the brush holder

We check the elasticity of the springs and the smooth movement of the brushes themselves

- We clean the collector with fine sandpaper if it is dirty or if there are marks, scratches, etc.

- If the collector is badly worn or burnt, replace the armature or gearbox assembly with the electric motor

- Having found traces of jamming on the anchor journals themselves, we clean them with fine sandpaper

The armature journals are indicated by arrows, check the condition of the journals and commutator

- We replace an electric motor gearbox with broken or heavily worn teeth

- We straighten the bent wiper arms. If it is impossible to straighten them, replace the entire windshield wiper trapezoid

- If damage to the splines or roller threads is detected, replace the entire wiper trapezoid

- We clean burnt or oxidized contacts of the self-stopping mechanism using fine sandpaper.

- We replace torn, lost elasticity or cracked rubber cushions and other rubber parts