A brake control element such as the brake pedal has several states of its position.

The first, which should be normal, is when the pedal is pressed without noticeable changes, without dips, jerks, without applying much effort, etc. The following two states of the pedal position are unpleasant for the driver and cause some concern.

We are talking about when your brake pedal becomes tight or, conversely, your brakes are too soft. In this state of affairs, when the brake pedal stops working in the normal, familiar mode, the driver’s concern is justified. This means that some malfunction has arisen and the brake system needs to be repaired. Without delay.

Why is your brake pedal tight?

There may be several reasons why the brake pedal suddenly becomes tight, and they may not necessarily be traditional and typical for all types and models of brakes. However, let's look at the main, most typical causes and methods for eliminating them.

In most faults that cause a soft brake pedal, either the vacuum booster or the brake master cylinder are to blame.

So, an increase in force when pressing the brake pedal occurs due to:

- The vacuum booster air filter is clogged. In this case, it is necessary to replace the air filter;

- The valve body in the vacuum booster is stuck. The solution is to replace the vacuum booster;

- The vacuum booster diaphragm is damaged. Change the vacuum booster;

- The tip of the vacuum booster is faulty - the tip needs to be replaced;

- the check valve in the vacuum booster is stuck or does not work, the check valve needs to be replaced;

- The check valve of the vacuum booster is faulty (leaky), which allows fuel to enter the cavity of the vacuum booster. It is necessary to change the vacuum booster assembly with the check valve;

- The hose connecting the vacuum booster to the intake manifold is damaged, or the hose fastening on the fitting is loosened. We change the hose or tighten the fastening clamp. Learn more about the brake booster hose. His condition must be monitored systematically. Especially during the cold season. As long as the hose is not warmed up, it remains quite rigid and the brakes work normally. After a short period of engine operation, the hose heats up, becomes more elastic, and if you do not notice its delamination, for example, its throughput decreases. There may be a problem with the brake pedal.

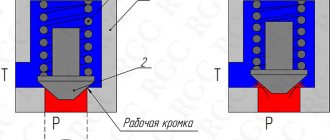

- The sealing rings in the working (wheel) cylinders are swollen. This can happen due to the ingress of fuel and lubricants into them, or the use of poor-quality brake fluid. Repair of working brake cylinders, replacement of brake fluid with that recommended by the manufacturer.

A couple of ways to check the performance of the vacuum booster

Start the engine. A vacuum is created in the system. Now press the brake. A hard brake pedal means a faulty booster or hose. After turning off the engine, wait about 5 minutes without pressing the brake.

Let's specify the problem. Step on the pedal. If the pedal is still hard, the vacuum booster valve is most likely faulty.

One more test. With the engine off, press the brake pedal several times to relieve the vacuum in the brake system. Without releasing the brake pedal, start the engine. If the pedal goes down slightly, then everything is fine with the amplifier.

Why are my brakes soft?

A soft brake pedal can indicate several problems. More precisely, there are several reasons why the brake pedal suddenly became soft. This effect can also be called: brake pedal failure.

Soft brakes have traditional causes:

- “airing” of the brake system. Naturally, air removal is required, i.e. bleeding the brake system. The cause of “airing” may be: depressurization of the system or low level of brake fluid in the expansion tank;

- Master brake cylinder malfunction:

- malfunction of the working cylinder, for example, as a result of jamming of the piston or boiling of the brake fluid. It is necessary to repair the brake cylinders or replace the brake fluid with new one.

Good luck to you in carrying out correct diagnostics and timely maintenance of the car’s brake system. After all, the brakes are our safety.

We recommend: Installing fog lights on Lada Kalina

Why is the pedal soft?

Due to certain problems, the brake pedal frog may also be faulty. Such a nuisance can come “in full” along with other related ones. Very often, a soft brake pedal is the direct cause of a significant deterioration in vehicle control.

A soft brake pedal may be a simple feature of the model. The cause of malfunctions may be air entering the relevant system. Everything is corrected by bleeding the brake itself in order to protect it from possible problems.

In turn, air can enter the system in many ways, and if problems appear with it, then most likely it is to blame. The pipeline may well lose its seal or even burst in this case. Due to a breakdown of the master cylinder, in which the brake fluid begins to boil, corresponding problems also arise. An accompanying failure is often jamming of the piston. It is advisable to diagnose the cylinders and check the brake fluid. It would also be a good idea to do a complete health check of the machine to determine if there are any hidden problems, if any.

Mono: how to change car brake fluid for one person without assistance

There is only one way to solve the question of how to replace brake fluid for one person. His goal is to update the composition in the tank and lines without using the help of a partner. The features of this method are similar to bleeding the brakes:

- To speed up the process, it is recommended to immediately remove the working emulsion from the expansion tank using a bulb or a syringe with a tube attached.

- The preparatory stage consists of purchasing 1 liter of brake fluid and a 1 meter long tube, suitable in diameter to the outlet fittings on the brake cylinders. You will also need a cut-off bottle with a certain amount of working fluid so that air does not pass through the fitting into the system.

- During the process of replacement/pumping, the composition gradually leaves the tank. The level must be replenished regularly, otherwise the system will become airy.

Process technology

The essence of the replacement is the flow of the working fluid under the influence of gravity. After all, the tank is at the highest point. In fact, the operation is no more difficult than checking the injectors of a diesel or gasoline engine. As a result, the set of actions is as follows:

- Empty the expansion tank and fill it with new fluid up to the MAX limit mark.

- Clean all 4 drain fittings and install tubes on them. Place the latter in plastic containers with “brake fluid”.

- Unscrew all the drain fitting nuts one by one:

- right rear;

- left rear;

- right front;

- left front.

- While watching how the composition drains, do not forget to add a new drug to the tank.

- When the volume of liquid poured from the left front wheel reaches approximately 200 ml, tighten the fittings on it and on all other cylinders in the reverse order:

- front left;

- front right;

- rear left;

- rear right.

- Restore the fluid level in the tank.

- Clean the fitting and put a tube on it, lowered into the brake fluid.

- Create pressure in the retarding system.

- Unscrew the union nut and wait until the liquid pressure decreases to low.

- Close the fitting.

- Repeat until liquid comes out without bubbles.

Leveling up

The method is relevant if there is no air in the deceleration system. If there are air bubbles in the unit, the emulsion will not drain under the influence of gravity. Excessive pressure is required to bleed it off - just like in production. In this case, replacing the composition comes down to bleeding the brakes:

Excessive pressure in the system can be created in several ways:

- Find an assistant or pump the brake pedal yourself and press it with a gas stop from the hood/trunk installed between it and the seat.

- Insert the syringe with the emulsion into the lid of the tank and seal it. Having opened the fitting, press the syringe pusher.

- Install the car nipple into the cover. Seal with sealant or superglue. Remove the nipple and install the tube. Install the opposite end of the hose onto the quick-release tip of the pump. Take excess pressure from the spare tire. You can do it even simpler - apply pressure from the compressor to the spool.

The brake pedal fails (the brakes are too soft)

It is worth noting that if you feel weak braking when pressing the brake of a VAZ 2109 or any other model, you need to think about the fact that these may be features of a particular vehicle. Perhaps you just moved from another car, so you feel some discomfort while driving a new car.

On the other hand, such a symptom can also occur when air enters the system. It should be noted that in the event of depressurization of the system, the pipeline may completely burst and completely fail. This can be corrected by bleeding the brakes. At the same time, you should diagnose the cylinders, check the level of the brake fluid, as well as its quality (often air gets into the brake system simply because there is too little fluid) and perform a full check of the vehicle (the latter will help determine the presence of hidden problems) ;

If the pedal becomes soft after replacing the brake fluid, then, as a rule, the problem lies in the use of a low-quality mixture. Alternatively, it is possible that air got into the system during replacement - this is also worth paying attention to.

It is also quite common for the pedal to feel soft after bleeding the brakes. First of all, you should bleed the master cylinder. As a rule, this solves a similar problem. Alternatively, there may be problems with the anti-lock braking system (if equipped). In any case, if the brakes are soft after bleeding, you should approach this task responsibly. Perhaps you should contact specialists who can quickly and effectively fix the problem.

It will also be interesting: The starter takes over the current: what to do?

Video about the operating principle of the brake master cylinder:

Dips when pressing the pedal

High-quality and clean brake fluid is the key to normal brake operation. It is thanks to its high density that the braking force is quickly transmitted to the wheels. Over time, it deteriorates its properties, air bubbles form in it, and moisture accumulates.

If the brake pedal is either soft or hard, check the brake fluid level.

If a slight depressurization occurs in any area, the liquid flows out and air gets in its place. As a result, the brake pedal is either soft or hard. Several gentle pressures lead to the accumulation of pressure in an insufficiently dense liquid. Then it works, and effort appears.

First of all, you need to check the presence of fluid in the expansion tank of the brake system; it is located on the master cylinder. If there is no liquid in it, you cannot drive; simply refilling it will not solve the problem. If you are planning a DIY repair, you will have to find the location of the leak - it could be any of the cylinders or some kind of tube.

If the pedal is not pressed

The pedal force is facilitated by a vacuum booster.

The brake pedal is too tight - check the vacuum booster.

This means that if the pedal has become hard or is pressed too hard, the reason is related to it. This could be a simply disconnected or cracked rubber tube coming from the engine exhaust manifold. Or a breakdown of the device itself, most often associated with its depressurization.

In rare cases, breakage or disconnection of the levers may occur - this will be associated with characteristic sounds when pressing the pedal. Sometimes a foreign object or a bent part of the mat gets under the pedal.

Malfunctions of the "vacuum"

A vacuum brake booster (VUT), or simply a “vacuum booster,” creates in the vehicle’s vehicle the pressure necessary for their proper operation.

If the amplifier is not working well, the pedal simply won't push through. Since the vacuum booster is a rather complex part consisting of many components, a malfunction of any of them can lead to this situation. And since a breakdown of an amplifier component, as a rule, requires its replacement, correct diagnostics will help save the car owner not only time, but also money.

If the filter element of the “vacuum tank” is clogged, it is enough to replace it so that the amplifier begins to function normally again. This also applies to a damaged vacuum booster diaphragm, and problems with the tip or check valve. It is enough to replace one damaged component, and the vehicle will act like new again. It is important to accurately diagnose what exactly needs to be changed.

Sometimes no major replacements are required at all. For example, in a situation where the vehicle is depressurized. The seal can be broken in two cases: either the hose between the “vacuum reservoir” and the intake manifold is damaged, or the clamps are loose. And if in the first case replacing the hose is still necessary, then in the second it is enough to tighten the clamps. This can also be done at a car service center, but the car owner is quite capable of dealing with such a problem on his own.

But it happens that the unsuitability of only one component completely renders the VUT unusable. This most likely occurs in a situation where vehicle malfunctions are ignored for a long time. As a result, a badly damaged valve moves to such a position that it disables the entire “vacuum tank”. An example is damage when a valve jams in the amplifier, and the latter has to be completely replaced. This is one of the most expensive types of vehicle repair.

We recommend: How to replace valve stem seals without removing the cylinder head?

Air in the brakes how to fix the problem

Brake vacuum is the most common cause. It’s another matter if the texture of the sound differs significantly from the ear. That is, the hissing turns out to be quite loud and, as it were, choking.

At the same time, when pressing on the brake pedal when it is cold, we feel its movement being excessively stiff. And also - the buoyancy of the engine speed (and sometimes it can stall). In such cases, you should pay close attention to the vacuum booster as a possible cause of the problem.

Well, a tight pedal, of course, could also be due to frost, for example, until the main one warms up. But the revs and a fairly strong hiss are already direct indicators that you need to look under the hood! How to check it?

The car's braking system is subjected to constant loads, and with the so-called sporty style of city driving, it is also subject to overloads. This happens regularly even with a measured and leisurely rhythm - there is no escape from this problem. Therefore, this unit must be regularly tested to ensure maximum driving safety for the driver and passengers. So it is with the brake vacuum story. As a rule, problems with its operation occur due to the failure of a special diaphragm located inside the device.

It bursts, cracks, and ceases to perform its duties—to create a vacuum. Sometimes the exhaust valve also malfunctions. Checking the functionality of the vacuum on their own, available to every driver, is carried out in the following way. We start the engine and let it idle for a while until it reaches;

- We turn off the engine;

- Press the brake;

- The first press will be no different from the normal one when the unit is running.

- The pedal must be pressed as much as possible: at the same time, the diaphragm in the amplifier is extended and a vacuum is created;

Release the pedal and press it again. If there is something wrong with the system, then during the second approach a vacuum will not be able to be created, and you will tactilely observe an uncharacteristic small stroke of the pedal itself. These changes indicate a breakdown in the brake booster.

Why does the brake pedal sink when the engine is running? Several Possible Reasons

The inability to make an emergency stop is a threat to everyone around you, so you need to find out immediately why the brake pedal falls while the engine is running. Even if the failure was a one-time failure, it cannot be ignored. System failure threatens disaster not only for you, but also for those nearby on the road. Despite the fact that any automaker pays the greatest attention to the brake system and tries to secure it from all sides, the inattention of the car owner and the natural development of mechanisms make the brakes more likely to fail quite high. And before leaving the parking lot or garage, you need to find out what caused the problems and fix them immediately. Why does the brake pedal sink when the engine is running? There may be several reasons. But the main and most common problem is air getting into the system (so-called airing). Moreover, the ways of its penetration may be different. Attention: brake fluid It is most often to blame for the failure of the corresponding pedal. Low level of brake fluid filling in the compensating tank. There is a mark on it indicating the minimum volume required for normal brake operation. If the fluid drops below the line, air enters the system, the pedal stops feeling resistance, and the car stops braking. It is advisable that the brake fluid does not drop to a minimum, since as the pads wear, the pistons push them deeper and deeper, therefore, more fluid is consumed. That is, at any moment it can fall below the required level. You need to check the amount of fluid regularly, even if the corresponding light does not give a signal. The next type of trouble that brake fluid can cause is the result of the negligence of the car owner himself. Filling brake fluid with the wrong class (for example, DOT3 instead of DOT 4) or mixing fluids from different manufacturers leads to corrosion of the cuffs and seals, clogging of the entire brake line or a section thereof. Boiling of the brake fluid leads to the fact that, if it corresponds to the class and the normal level in the reservoir, The pedal stops working right on the move. Everyone knows that overheating your brakes is unsafe. If it is not possible to avoid aggressive driving, especially in the summer heat, it is worth replacing the brake fluid with high-temperature fluid, and the brake discs with cooled and ventilated ones. When checking the level and condition of the brake fluid in case of pedal failure, all hoses, cuffs, gaskets and seals are simultaneously inspected : loss of tightness by the system is the second most likely reason for air from the atmosphere getting into it. Related article - “Where to fill and how to replace brake fluid.” Pads and discs Replacing both over time is required on any car. For some time after this, malfunctions in the operation of the brakes may be observed: vibration on the pedal can be felt, braking may occur jerkily. This is considered normal, since the new parts should get used to each other. But if failures remain even after 200-300 km after installing spare parts, this is already an alarming sign. It indicates improper installation during replacement. Can be:

- displacement of the vertical axis of the caliper relative to that of the brake disc. A deviation of literally 3-4 degrees is enough;

- poor caliper fixation.

So when replacing parts in the brake system, it is especially meticulous to check the alignment of the caliper with the disc. Otherwise, the block will be worn down to half, and by definition you will not have normal brakes. Vacuum brake booster A wonderful invention of mankind, designed to ease the effort during braking. But when the diaphragm wears out, it can cause a lot of thrills. Symptoms of problems with the amplifier are:

- The pedal clearly sinks, but the brake fluid, when the engine is running, remains at the same level;

- If the engine is turned off, the elasticity of the pedal remains normal;

- The situation is explained simply: the amplifier begins to operate only when the engine is running, so in a silent car it has no effect on the brakes. When the amplifier comes into play, due to a torn diaphragm, the required degree of vacuum in the chamber is not achieved, and the pedal goes to the floor.

We recommend: How to replace the instrument panel lamps on a Lada yourself?

Article on the topic: “How to check the vacuum brake booster.” However, before establishing the reasons why the brake pedal fails while the engine is running, you need to be able to stop the car, which becomes difficult - especially in heavy traffic and at speed. The main thing here is not to twitch or panic. If the transmission on the car is manual, you can stop the car simply with the engine, switching to a lower gear with a shift in the throttle. And there is always a working handbrake (which is also recommended to be checked from time to time), which can help out, even if the pedal has completely failed.

Finalization

Many, believing that the brakes are bad and repairs do not help them, decide on significant alterations and tuning. For example, tuning the brake system of a VAZ 2110 may include replacing the rear drum mechanisms with disc ones.

It is especially important to know here that braking of the rear wheels should be softer and occur a little later than the front wheels to prevent skidding.

Another possible idea for tuning is replacing the vacuum booster as well. Instead of standard ones, they are installed from Lada Priora. This usually helps, first of all, in that vibration is not felt and the pedal works with optimal force.

And do not forget - after each intervention in the brakes, they need to be pumped.

You can read more about replacing the vacuum brake booster in this material:

The most important organ in any car is the brake system. It must be in perfect condition, because our lives depend on it. One of the main indicators of the efficiency of this unit is the pedal, which must always differ in the state of pressing that is familiar to the foot. This rule cannot be neglected and if the slightest changes occur, adjustments or repairs must be made immediately. Below we will look at what needs to be done when the brake pedal becomes hard, does not press at all, or grabs at the very end of its stroke. We will also pay attention to the issues of self-diagnosis and study all the reasons for the failure of this mechanism.

Should I be concerned if the brake pedal is stiff or soft after bleeding?

The manufacturer has ensured that the brake pedal is pressed as easily and conveniently as possible. It is important that there is no need to exert significant effort while pressing, and various dips and jerks are unacceptable. Regardless of whether the brake pedal is soft and does not stop well, or there is a problem of some other kind, it is important not to leave things to chance. In general, if the brake pedal fails, then you urgently need to go to a service station or top up the brake fluid yourself. Most likely there is a leak in the brake system.

Both a tight pedal and too easy its movement are an alarming symptom that can indicate a number of serious problems.

How to check the operation of the vacuum booster?

- First, start the car and let it run for a while to allow the car to discharge. Press the brake pedal - if you press too hard, you can safely say that the booster or hose has failed. Now stop the engine and let it sit for a while, after a while press the brake again.

Secondly, without turning on the engine, press the brake a couple of times in a row, this will discharge the brake system and relieve the pressure. Next, without releasing the brake pedal, start the car; in theory, the pedal should begin to gradually move down, which indicates that the vacuum booster itself is working.

Take care of your safety.

Monitor and promptly check your vehicle's brake system. If repairs are required, proceed with them immediately.

All spare parts for repairing the brake system can be found on the AUTOmarket Intercom website or in our spare parts stores for VAZ or foreign cars

. Delivery to any car service is available.

Brake operation when the engine is off

The pressure on the pedal is related to the vacuum booster. And the VU itself can only work with the engine turned on. When parked for a long time, the pressure in the vacuum chamber becomes atmospheric - the amplifier does not work. When you press the pedal, the force is transmitted directly from the levers to the master cylinder. The resistance on the pedal increases by 3-5 times.

A hard brake pedal after parking is normal.

If you start the engine while holding down the pedal, it should fall slightly. You can go safely.

Monitoring the technical condition of a car is a conscious need for any driver who wants to ensure the safety of himself and others.

Diagnosis of the problem

Most brake pedal problems are caused by faulty vacuum boosters. If there is insufficient power transmission, the pedal goes hard, and the other elements receive underestimated pressure. As a result, wheels slip and, along the chain, the steering wheel slips. If suddenly the force begins to be transmitted abruptly, you should also be wary. There may be a depressurization or other problem with the vacuum booster.

The second most important problem in the ranking is brake fluid. As the system is used or the tightness of the system is compromised, the liquid is replaced by air from the atmosphere and minor blockages, which affects the smooth operation. Then there is a feeling of unpredictability in the behavior of the pedal, which either sticks or behaves very softly. Alas, a simple replenishment is not enough here - you need to contact an authorized car service center.

Swelling of rings in cylinders

The condition of the brakes largely depends on what kind of brake fluid is used during operation. If it is a product of a well-established company, the vehicle is rarely damaged or disabled. But if the fluid is of poor quality, one or more cylinders may not function well due to their O-rings swelling. The same thing happens when fuel and lubricant gets on the ring.

Previously, especially in the era of the Soviet automobile industry, the car owner sooner or later had to sort out the working cylinders. Such an activity was long and burdensome even for professionals. But now hardly anyone will do this if the vehicle is faulty. From the point of view of saving time, it is much easier to change them, and at the same time the brake fluid. However, you can avoid unnecessary financial costs if you use high-quality, albeit expensive, liquid from the very beginning, since repair costs are always higher.

Taking into account the above, it becomes clear that any deviations from the norm in the operation of the brake system (either a soft brake pedal, a hard brake pedal, or a combination of problems) require immediate diagnosis. After identifying the malfunction, it is necessary to properly eliminate the problem.

You also need to promptly change the fluid, bleed the brakes, inspect the brake hoses for defects and leaks, install new brake pads, discs or drums in a timely manner, lubricate the brake caliper guides, etc. This approach will allow you to safely operate the car and achieve high-quality performance of the braking system in any conditions.

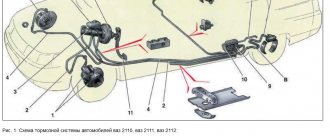

Device

Hydraulic brakes are installed on the machine and operate generally reliably. They are double-circuit and have a diagonal distribution. That is, if one part suddenly fails, then braking by another circuit is possible. For the sake of safety, the VAZ 2110 brakes operate diagonally, one circuit is the right front and left rear wheels, the other is also diagonal.

This device allows you to brake efficiently (without skidding and other troubles) even in the event of a malfunction, if the brakes in one of the circuits are lost.

Let's consider the design of the brake system. The hydraulic drive includes a vacuum booster, as well as a dual-circuit regulator that creates pressure in the rear brakes.

The brake caliper design is described in this article:

In addition, the hydraulic drive is equipped with pipelines divided into two circuits, hoses and brake mechanisms that provide braking to the front and rear mechanisms.

The hydraulic drive is activated by a pedal located in the cabin (middle). Here are the main components of the hydraulic drive:

- Vacuum booster.

It is designed in such a way that it creates pressure on the master cylinder piston, and thus causes braking; Vacuum brake booster - Pressure regulator drive.

It is through it that the working brake fluid flows to the rear brake mechanisms; Brake pressure regulator drive - The pressure regulator itself.

Already from the name it is clear that this device is responsible for the force of pressure, its decrease or increase. He does this depending on how loaded the rear axle of the car is; Pressure regulator - Main cylinder with pistons, equipped with a reservoir.

The filler neck of the tank is equipped with an emergency fuel level sensor; Master brake cylinder - Brake mechanism for the front wheel.

Its main parts are the disc, pads and wheel cylinders. The mechanism also provides an indicator to prevent complete wear and malfunction of the linings; Front wheel brake - Brake mechanism for the rear wheel. Unlike the front disc brakes, the rear ones are drum brakes. This is the factory configuration. However, many car owners believe that their device does not provide high-quality braking, and change them to disc ones.

The brakes require attention. Without waiting for the warning light to come on, indicating a critical level of fuel fluid or wear of the linings, and even more so, without allowing the brakes to completely disappear, you need to carry out preventive checks.

Particular attention should be paid to all connections and hoses, since the “escaped” brake fluid will not make it possible to brake, and from here it’s not far from tragedy.