The effective ignition system of the UAZ 469 ensures quick and uninterrupted starting of the car engine under any conditions. With proper ignition, all electrical systems operate without failure: windshield wipers, headlights, receivers, sensors, turn signals. What types of systems are there, adjustment, tuning of the UAZ 469 ignition - in this article.

Ignition system UAZ 469

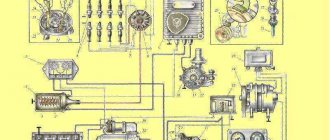

Photo 1: Ignition system of the UAZ 469 car (Source: Yandex.Photos)

Article navigation

Re: Cylinder numbering for UMZ 417

The voltage sensor consists of a rotor and a stator. The second terminal of the winding is electrically connected to the housing in the assembled sensor-distributor. 6. Install the distributor sensor cover, check the correct installation of the ignition wires to the spark plugs in accordance with the operating order of the engine cylinders 1–2–4–3, counting counterclockwise. After each ignition installation, check the accuracy of the ignition timing by listening to the engine while the vehicle is moving.

Numbering from the radiator. Remove the spark plug from the first one, tighten it to compression (check with your finger to see how it hisses), turn it until the moment of ignition (according to the marks on the pulley), and look at the slider. Insert the first wire where the slider is, and the rest are in order according to the direction of the slider.

I apologize for the lame question, but the previous owner of the automobile claims that the numbering of the cylinders in the UMZ 417 does not come from the radiator, but from the passenger compartment. I have encountered this in the French.

And both valves of the first cylinder are closed? Timing gears by marks?

Set the TDC in cylinder 1, remove the distributor from the drive (a boot in common parlance) and look inside. Sometimes the distributor drive is installed incorrectly. Try setting the ignition very early, if it gets better, move the distributor drive gear by 1 tooth. Just carefully reinstall the oil pump drive.

Do-it-yourself electronic ignition: diagrams, installation

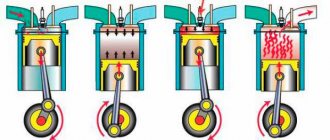

The ignition system of a gasoline engine is designed to provide spark formation at the spark plugs in strict accordance with the firing order of the cylinders. One of the first such systems is a contact system, also called classical (it is installed on “classic” VAZ car models).

With the development of technology, contact ignition has given way to electronic ignition, in which the contact group is replaced by sensors.

This made it possible to get rid of the contact circuit, so many owners of classic VAZ cars had a desire to change the ignition system, especially since installing electronic ignition with your own hands is not at all difficult.

For a spark to occur, the contacts must close at the right moment. Their subsequent opening is carried out using the cams of the breaker shaft.

What will be the benefits of such a replacement? In addition to getting rid of the contact group, which is prone to burning and gap violations, leading to the need for constant maintenance of the breaker-distributor, it will contribute to:

- making it easier to start the engine in the cold season;

- smoother engine operation;

- reducing spark plug wear.

Required tools and parts

To install electronic ignition with your own hands you will need:

- key set to “13” for removing and installing the breaker-distributor;

- Phillips screwdriver for self-tapping screws;

- drill and metal drill bit;

- self-tapping screws;

- key “8” and key “10” for removing and installing the ignition coil.

- sensor-distributor (“distributor”);

- switch;

- contactless coil;

- spark plugs (for a non-contact circuit, the gap between the electrodes should be 0.7 - 0.8 mm);

- high voltage wires.

Installation process

The procedure for installing an electronic system with your own hands:

- Disconnect the negative terminal of the battery.

- Remove the cover of the breaker-distributor.

- Disconnect the high voltage wire from the coil.

- Rotating the starter little by little, set the distributor runner at an angle of 90° to the engine cylinder block.

- Mark the position of the breaker-distributor on the valve cover with a marker. This is necessary in order to maintain the ignition timing during installation.

- Unscrew the nut securing the breaker-distributor and disconnect the central wire.

- Remove the old distributor.

- Remove the cover from the new distributor and install it.

- Secure the new distributor with a nut.

- Put on the cover and connect the high-voltage wires.

- Install the contactless ignition coil.

- Connect the wires as indicated in the diagram.

- In a suitable place under the hood, drill two holes to mount the switch.

- Secure and connect the switch.

- Check connections and start the engine. If the engine does not start, you must manually turn the distributor switch slightly to optimize ignition timing.

Adjustment

It is advisable to use a strobe light for adjustment. But since not every car enthusiast, even those who perform car repairs with their own hands, has it, you can do the following:

- Remove the spark plug for the first cylinder. Plug the spark plug hole with your finger and turn the crankshaft pulley until air begins to press on the finger. This signals the start of the compression stroke. Next, you need to turn the distributor-breaker to such a position that its slider is directed to the first cylinder.

- Rotate the shaft until the mark on the pulley aligns with the second mark on the front engine cover. This will mean that the ignition timing will be 5°.

- Remove the center wire from the distributor cap.

- Turn on the ignition.

- Holding the wire in your hand and placing or securing it above a metal surface (“ground”), turn the slider clockwise until a spark jumps.

It is necessary to “catch” the ignition timing

To do this, you need to loosen the fastening of the breaker housing and carefully turn it until the spark disappears when turning the slider, then tighten the housing. Adjustment completed

Driving without interference: set the ignition on the UAZ

The operation of a car engine is impossible without correctly set ignition timing. Remove the cover from the ignition distributor. For example, for a VAZ-2106 car, the switch can be installed in the free space between the washer reservoir and the left headlight. Drill 2 holes and screw the switch with self-tapping screws. Correctly setting the ignition timing in a contactless ignition system makes it possible to operate the car in comfortable conditions. Set the crankshaft to a position that corresponds to the ignition timing of 5 degrees. Check the order of connecting the high-voltage wires of the engine cylinders.

The ignition system is fundamental to the normal operation of a car engine. If any actions were incorrect, this will be reflected when the engine is started by the starter and the car is moving. All you need to do is adjust the spark supply - set the ignition correctly on the contactless system. Tighten the bolt at the pointer on the sensor-distributor housing. Be sure to check how the ignition wires are installed to the spark plugs, taking into account the order of operation of the cylinders 1-2-4-3. If there is no detonation, we increase the ignition timing.

Serves to turn on and off the current in the primary circuit of the ignition system and to turn on the starter.

The UAZ distributor is considered one of the important components of the ignition system in a vehicle. What is the connection diagram for electronic or contactless ignition on a UAZ 417, how to convert contact ignition to contactless? Why does the coil heat up and how to adjust and adjust the advance angle? The ignition system can also be electronic. First of all, you must lock your car in one place by pulling the parking brake lever.

The ignition must be installed if the ignition distributor is removed from the engine or if the ignition timing is incorrect. TDC according to the mark on the engine crankshaft pulley (Figure 15.13). The following characteristic malfunctions are possible in the ignition system: the ignition system does not work, the ignition system works intermittently, the ignition timing is incorrect.

This will be the beginning of the compression stroke in the 1st cylinder. 5. Tighten the locking screw and check the gap between the contacts again. 6. Install the rotor and secure the distributor cap.

With the help of an emergency vibrator, the contactless battery ignition system of the UAZ can operate in the event of a failure or breakdown of the transistor switch or stator coil of the sensor-distributor. To switch to working with an emergency vibrator, you must disconnect the wire from the short-circuit terminal of the switch and connect it to the output of the emergency vibrator.

This is visible not only when starting the engine with the starter, but also when the car itself is moving. Afterwards, you need to check the installation of the ignition wires according to the basic order of operation of the cylinders one-two-four-three, counting counter (hours). After you have installed the ignition, you need to check that it is installed correctly while driving.

Ignition circuit

The circuit depends on the type of ignition system of the UAZ-3151. In order to correctly set the contact, contactless, electronic or underwater ignition with your own hands, you need to use the repair instructions.

Contact

The contact system connection diagram includes the following elements:

- Lock. It is located on the steering column housing and is necessary to control the flow of current between the vehicle battery and the ignition.

- Battery. At the moment when the engine is turned off, the power source for all electrical equipment is the battery. It supplements the level of electricity produced by the generator set if it produces voltage below 12V.

- Switchgear. It directs high voltage current from the coil through the distributor handle in turn to each of the system's spark plugs.

- Capacitor. It is located on the switchgear housing and prevents the appearance of a spark between the open contacts of the system, protecting them from burning.

- Spark plug. A high voltage current moves along the central electrode of these mechanisms. A spark appears in the gap between the central and side electrodes, which ignites the fuel liquid in the cylindrical device.

- Drive unit. The distribution mechanism is equipped with a direct drive from the camshaft. The rotation speed of such equipment is 50% of the crankshaft speed.

- Centrifugal regulator. It is necessary to set the required ignition timing depending on engine speed. This mechanism includes weights that rotate and act on a plate with breaker contacts.

- Coil. Its design includes 2 insulated winding wires, which are wound on a core made of mild steel. The process of compression of the magnetic fields around the primary winding creates a high voltage current in the secondary winding, passing through the distributor to the spark plugs.

When the driver turns the ignition key, low voltage current from the battery passes to the primary winding of the coil. After this, it begins to form a magnetic field. Due to the rotation of the power unit from the starter, the contacts of the cam interrupter device open. At this moment, the magnetic field begins to disappear, and the power lines and turns of the windings form a high voltage current. The resulting impulse passes to the distributor housing cover, and the spark charge ignites the fuel-air mixture in the cylindrical engine device.

Contactless

In order to establish the contactless ignition timing on a UAZ, you need to prepare the following tools:

- set of wrenches;

- crosshead screwdriver;

- strobe;

- protective clothing in the form of glasses and masks;

- locking mechanisms for wheels.

Before you start connecting, you must put on protective clothing and place the vehicle on a flat surface and secure its wheels using special stoppers.

First you need to put a mark on the valve cover and align all the marks. After this, you should unscrew the spark plug of the first cylinder mechanism of the engine and remove the cover from the main distributor. If you pull out the spark plug of the first cylinder, you can track the stroke of the piston part of the engine.

Then you need to insert a long screwdriver into the spark plug well and turn the crankshaft clockwise by the ratchet, setting it to the highest dead center position. This will help push the screwdriver back out of the well. The mark on the pulley should be placed opposite the long mark on the power unit housing.

After this, you need to loosen the lock nut that presses the distributor to the cylinder block. By rotating the housing, it is necessary to install one of the slots in the gap of the Hall sensor. At this time, the contact of the movable type of the slider must completely coincide with the side contact number 1 on the cover of the distributor, the body of which must be turned to a stable position and secured with a fastening nut.

Then you should tighten the nut securing the distributor and install the cover with the spark plugs in place.

When all the work is completed, you need to start the engine, warm it up to a temperature of +50...+60°C and adjust the non-contact ignition using a strobe light.

The strobe light must be connected to the distributor. It will provide simultaneous flashes with the formation of a spark in the cylinders. By pointing the lamp at the pulley, you can clearly see the position of the pulley mark and its change as the engine speed increases.

When the piston of the first cylindrical mechanism is in the highest dead center position, it is recommended to align the notch of the crankshaft pulley with the first long mark. This risk is located on the cover of the gas distribution mechanism assembly. This will help ensure the required advance angle of fuel injection at the second mark of 5°.

Electronic

In the electronic ignition system there is completely no mechanical movement of elements. The operation of this system is ensured by special sensors and a control unit. This makes it possible to increase the performance of the vehicle’s power unit and reduce the average fuel consumption.

In order to install electronic ignition, it is necessary to move the 4 cylinders of the engine part to the highest dead center position. To do this, you will need to turn the crankshaft ratchet until the marks align with the pulley.

After this, it is necessary to dismantle the distributor, spark plugs and coil, lay new wiring and install a high-voltage coil. Then you can attach the switch to the engine compartment shield and screw in new spark plugs.

High voltage wires must be connected in accordance with the operating order of the cylindrical mechanisms (1-3-4-2).

The brown wire should be connected to connector number 1. To connector number 2 - black. A white wire is connected to connector number 3, and a blue wire is connected to number 4.

In order to set the ignition correctly, you need to prepare a test lamp, a 13mm wrench and a special wrench for the crankshaft. Before starting work, you must turn off the engine and allow it to cool. After this, you need to disconnect the negative terminal of the motor.

Then you need to set the first cylinder to the ignition position. Align the mark on the pulley with the mark on the timing gear drive.

After setting the marks, you can proceed to dismantling the system key. After this, it is necessary to determine the ignition timing. To do this, you need to connect the negative terminal, using a wrench to loosen the fastening nut of the switchgear. Connect one wire of the lamp to the ground of the car, and the second to the low-voltage coil. Turn on the ignition and turn the switchgear housing clockwise until the warning lamp stops lighting.

Starting the engine of any car is possible due to the ignition of the combustible mixture in the cylinders of the power unit. To ensure normal operation of the engine, proper adjustment of the ignition system (IS) is necessary. In addition, all elements, including the coil, distributor of the UAZ vehicle and other components must always be in working order.

We install and configure the ignition, change the distributor drive on UAZ vehicles

The UAZ distributor is considered one of the important components of the ignition system in a vehicle. Correct adjustment of this mechanism ensures optimal operation of the power unit as a whole. You can learn more about the principle of operation of the ignition system and how to set it up correctly with your own hands from this material.

Review of SZ on famous UAZs

Review of SZ on famous UAZs

What is the connection diagram for electronic or contactless ignition on a UAZ 417, how to convert contact ignition to contactless? Why does the coil heat up and how to adjust and adjust the advance angle? First, let’s look at the main points regarding the action and types of SZ.

Operating principle of SZ

Contact system diagram

The ignition system, or rather its correct setting, plays a big role in the operation and starting of a car engine. With correct adjustment, the combustible mixture will burn correctly in the power unit as a result of the supply of charge through the spark plugs. A spark plug is placed on each cylinder of the UAZ engine, each of which is turned on in a certain order, in turn, delivering a discharge to the cylinder after a certain time. It must be taken into account that any SZ makes it possible not only to deliver the required discharge, but also determines its strength.

Due to its technical characteristics, the car’s battery cannot produce the voltage and current required to ignite the mixture. This is due to the fact that the battery can only produce a current of a certain strength. And thanks to the correct operation of the system, the current value increases significantly, which allows you to successfully ignite the air-fuel mixture.

The operating principle of the system consists of several stages:

- First, the driver inserts the key into the ignition and turns it, electrical energy is stored in a coil.

- Then the coil converts the low-voltage voltage in the on-board network of 12 volts into high-voltage. As a result, the voltage value increases to 30 thousand V.

- After this, the discharge is distributed and supplied to one or another spark plug.

- The candle itself produces a spark that ignites the mixture.

Diagram of the UAZ contactless system

What types of SZ are there?

Domestic UAZ vehicles can use one of three ignition systems; let’s look at each of them in detail:

- Contact view. This type of SZ is outdated, however, it is used on most machines. In such a system, the principle of operation is to issue a certain impulse that is formed in a distributor - a distribution device. The contact system is considered one of the simplest in terms of design, which is an advantage, since if a malfunction occurs, the car owner will be able to independently check and repair the system. In addition, prices for structural parts of the contact system are usually affordable, which is good news. The contact SZ includes a coil, a switchgear, a breaker, a capacitor and spark plugs.

- Non-contact type, also called transistor type. Compared to the contact system, the contactless system has more advantages. The resulting spark has a higher power, which is achieved due to the formation of high voltage in the secondary winding of the coil. Also, contactless systems are equipped with an electromagnetic device, which makes it possible to achieve more stable operation of the engine. Ultimately, if the UAZ power unit is configured correctly, then by using a contactless system you can not only increase its power, but also achieve fuel savings, albeit insignificant. Also, such systems are easier to maintain. One of the main nuances in terms of maintenance is the need to periodically lubricate the distributor drive - at least every 10 thousand kilometers. One of the main disadvantages is the difficulty of repair. In practice, repairing a contactless SZ will be problematic, since diagnosing the system will require equipment that is usually available at a service station.

- The ignition system can also be electronic. This option is currently considered one of the most progressive and expensive; it is installed mainly on new cars. Compared with contact and non-contact systems, the electronic system has a more complex structure. The main advantage of this system is that, if necessary, the process of adjusting the ignition angle will be much easier. In addition, there are no contacts in the electronic system that are susceptible to oxidation. It should also be noted that in practice, the combustible mixture in the cylinders of a power unit with an electronic system almost always burns completely. But despite all the advantages, electronic repair systems also have their disadvantages, which relate to device repair. It is almost impossible to repair such an SZ with your own hands, since to perform this task, again, you will need equipment (video published by Nail Poroshin).

Wiring diagram for injection UAZ (loaf)

One of the most common problems with domestic cars is the breakdown of any electrical devices; an electrical diagram will help you figure this out. The only solution to this problem will be to check the condition of the fuses. The topic of today's article will be the electrical circuit of a UAZ Bukhanka car on an injector-type engine.

UAZ Bukhanka

So, this article provides answers to these fairly common questions:

- What is the electrical circuit on a UAZ Bukhanka car with an injector type engine?

- How does the electrical circuit of the UAZ Bukhanka car work?

- Where are the fuses located on a UAZ Bukhanka car with an injector type engine?

- Repair of the mounting block.

basic information

Fuses in a UAZ Bukhanka car are located in a special mounting block, which in turn is located in the air inlet box on the left side of the vehicle.

The mounting block includes all the most important sections of electronic circuits, while supplying them with the necessary fuses and relays. The fuse box of the UAZ Bukhanka car consists of two lines with fuses and this entire structure is secured with a nut to the vehicle body.

If you decide to remove the fuse lines, you will need to disconnect the battery.

The main elements of the electronic circuit include:

- Accumulator battery;

- Electronic fuel pump;

- Fuel mixture purification filter;

- Injectors;

- Engine control unit;

- Electronic ignition coil;

- Spark plugs;

- Idle speed sensor;

- Crankshaft sensor;

- Air damper sensor;

- Tachometer;

- Fan motor cooling the radiator;

- Electronic fan motor control relay;

- An indicator that monitors engine performance;

- Diagnostic connector.

Wiring diagram UAZ Bukhanka

If any failure of electronic equipment occurs, the current in the node that is responsible for this device will increase, resulting in a short circuit.

The wire through which the current passes to the fuse burns out and melts, as a result of which the circuit breaks and the device turns off, but its integrity is maintained.

That is, thanks to fuses, the main parts are protected from overheating in the event of a short circuit.

How to properly remove and install the mounting block?

If the electrical circuit is made with high quality, it will greatly facilitate the process of installing and removing electronic equipment. So, the algorithm for removing the mounting block:

Disconnect the wiring from the negative terminal of the battery; Open the hood and remove the cover from the fuse and relay box. To do this, you need to press out 4 plastic latches; Move the rubber cover; Disconnect the upper block of the wiring harness from the block; We unscrew the 2 nuts that secure the block; We take out the block from the compartment, which is located in front of the windshield; We disconnect the lower blocks of the wiring harnesses from the block; Install fuses and relays in reverse order.

Repairing the mounting block involves replacing printed circuit boards. So, the algorithm for repairing the mounting block:

Remove the mounting block; Remove the 8 screws that secure the bottom cover; Using a screwdriver, open the bottom cover; We check the condition of the tracks along which the current passes and the quality of soldering. If defects are detected, they must be eliminated, but if this is not possible, then completely replace the unit; Install the mounting block in reverse order.

Expert recommendations on how to configure correctly

So, how to set the advance angle yourself in order to achieve proper operation of the UAZ engine:

- First of all, you must lock your car in one place by pulling the parking brake lever. Rotate the crankshaft so that the piston of cylinder 1 reaches TDC (top point). In this case, you need to ensure that the hole on the crankshaft pulley coincides with the mark marked on the timing gear cover.

- After this, remove the cover from the distribution mechanism. After dismantling, you will be able to see the slider, which is located inside the cover itself, opposite the contact. If there is no slider, you should turn the crankshaft 180 degrees again, and then set the octane corrector to 0. Using a wrench, you will need to screw the pointer to the distribution mechanism housing so that it aligns with the middle mark. When these steps are completed, the fastening bolt with which the plates are attached to the distributor body must be loosened slightly.

- Then, holding the slider in one place with a finger to prevent it from rotating, you need to carefully rotate the housing itself, this will allow you to remove possible backlash in the drive. The housing must be rotated until you achieve alignment of the sharp end of the stator mechanism petal with the red mark located on the rotor device. After this, the plate itself must be secured to the body using the appropriate bolt.

- Once you have completed these steps, you need to replace the controller cover and check the high voltage cables. You need to make sure that these wires are installed in the correct sequence, taking into account the firing order of the cylinders. When you manage to correctly adjust the lead angle, you need to make sure that the entire procedure was performed correctly.

- To diagnose the correctness of the actions performed, you need to start the engine of your UAZ and wait about 5-10 minutes until the power unit warms up. The operating temperature of the engine is about 90 degrees; you can wait until the internal combustion engine warms up to 80 degrees. Then you need to drive onto a flat road and accelerate the car to 40 km/h, after which you should sharply press the gas. At this moment, the car will accelerate and if, when the speed increases to 60 km/h, a short-term detonation (metallic knock) is heard from under the hood, then this indicates that all actions were performed correctly. If the detonation is too long, the system will need to be adjusted. To do this, the housing of the distribution mechanism will need to be turned one notch or half, and it must be turned counterclockwise. If the diagnostics showed that there is no knocking of the “fingers” at all, then the advance angle should be increased. To do this, the mechanism should be turned in the opposite direction.

How to set the ignition

In order to correctly adjust and set the ignition on a UAZ, you must follow the sequence of actions that are given in the user's repair manual.

Before you begin adjusting the ignition system, you must place the vehicle on an inspection pit or a special platform for repair work and apply the hand brake. The wheel mechanisms of the vehicle must be secured with a stopper or stop. The power unit must be turned off.

After this, you can begin installing the ignition. To do this, it is necessary to fix the piston of the first cylindrical element in the position of the highest dead center. In this case, you need to check that the hole on the crankshaft pulley coincides with the pin on the cover of the timing gear block. It is necessary to slightly lower the mounting bolt located on the plate to the distribution equipment sensor housing.

Then remove the cover from the distributor and rotate the crankshaft 180°. The octane corrector must be in the zero position. Then it is necessary to tighten the pointer to the housing of the distribution mechanism sensor with a bolt so that its position coincides with the octane corrector mark.

In order to check the ignition coil, you need to turn off the power unit and open the hood. Then you need to find the coil. To do this, it is recommended to follow the wires that lead from the distribution mechanism in the opposite direction. After this, you need to disconnect 1 high-voltage wire from the spark plug. Before the procedure, you must wait until the engine has completely cooled down. This may take 15-25 minutes.

Then you should dismantle the spark plug using a special nozzle. This must be done carefully and make sure that debris does not get into the hole, because. this will lead to malfunction of the power unit. You need to connect the wire back to the spark plug. To perform this operation, it is recommended to use pliers with insulated handles.

After this, you need to touch the threaded side of the candle to the bare metal. When the ignition is turned on, all elements of the vehicle’s electrical equipment will begin to work, which means that the coil is functioning properly. The driver performing repair work should see a blue spark. If it is not there, then the system is faulty. If an orange spark occurs, it means that insufficient voltage is being supplied. This may be due to poor contact, low current, or defects in the coil body.

Another way to check the ignition coil connection:

- Remove the coil from the car. To do this, you need to disconnect the wires of the distribution equipment, remove the fasteners from the coil body using a wrench.

- Determine the condition of the mechanism using an ohmmeter. You need to touch the probes to the primary winding, touching 2 contacts at the same time. After this, it is necessary to measure the condition of the secondary winding and compare the obtained indicators with the factory ones, which are in the repair manual.

Before starting work, it is necessary to place the transport on a flat surface and secure it with special locking devices. When checking the device, it is recommended to wear protective clothing (mask and goggles, as well as gloves).

A guide to replacing a distributor with an oil pump drive

Before installing a new distributor with a drive, you need to weigh your strengths, since it is not recommended to make mistakes when performing work.

So, how to replace and install the distributor:

- Turn off the ignition and remove the distributor cover; the tips and high-voltage cables are connected to it.

- Then you need to disconnect the wire connected to the switch from the distribution mechanism. You also need to disconnect the pipe connected to the vacuum regulator.

- Taking a 13mm wrench, unscrew the two nuts securing the device and remove the mechanism along with the oil pump drive from the power unit.

- After completing these steps, you will be able to see the gasket located under the drive. If as a result of these actions the position of the crankshaft has not changed, then simply install a new mechanism, making sure that the slider is located opposite the mark. All actions are performed in reverse order. When the installation is completed, the advance angle is adjusted.

- If, as a result, the location of the shaft has changed, then before installation it is necessary to move the piston of cylinder 1 to top dead center. You need to ensure that the marks on the pulley align with the pointer on the motor itself.

We carry out the wiring diagram for electronic ignition on a UAZ

Classics of the domestic auto industry

Many UAZ vehicles are equipped with a contactless ignition system. It makes it possible to save fuel, reduces the amount of harmful substances in gases, and makes it much easier to start the car in winter.

The connection diagram for electronic ignition on a UAZ is not as complicated as it might seem at first glance. A person who has at least a little knowledge of technology will be able to repair and correct problems himself, if any arise.

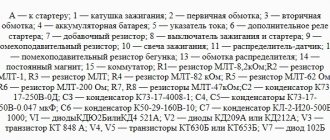

Ignition system on UAZ 469

The ignition system for the UAZ 469 can be made not only at a service station, but also with your own hands. It consists of:

- ignition coils or distributor;

- switch;

- emergency vibrator;

- variator (additional resistor);

- spark plugs.

Today, contactless ignition systems are most often preferred. The most interesting thing about them is the switch.

If the crankshaft rotates at a frequency of 500 revolutions per minute, it turns out that the signal at the sensor output will change too quickly. This mode is used if you start the engine with the starter. At this time, there will be not just one spark on the candles, but many, which will make it possible to start the car easily and quickly. Ignitions on UAZ have a simple design.

Contactless ignition is more convenient to use than contact ignition.

Installation instructions

Installing contactless ignition on the UAZ 469 is quite easy. It is easy to configure and install, and the reliability of the UAZ ignition can only please us. It works very accurately, even in the cold season, when starting the car is quite difficult.

Once a new system has been purchased, it must be installed. To install you will need:

- drill;

- self-tapping screws;

- drill;

- key to 38;

- open-end wrench 13;

- Socket and socket wrenches for 10 and 8.

Ignition on the UAZ 469 is done as follows:

- First, the engine must be set to the TDC mark using a 38 key. Before you do anything with the equipment, you need to remember the location of the parts before replacement.

- We look at how the slider and distributor are installed, so that we can then install a new one in the same position. Next, we find the place where the ignition coil is located, on which we find the B + mark and look at the location of the wires and what is attached to what. After everyone has looked, you can unscrew the coil. We remove the distribution lock, place the switch, and also install the ignition coil and attach it to the body. We connect standard wires. From the switch, wires labeled + are attached to terminal B, and a second wire is attached to terminal K.

- You connect the distributor, but the nut is not tightened completely. You need to connect the wires from the switch to it. After this, you need to check the location of the slider and distributor, put on the cover and connect all the wires in the order in which they were before replacement.

- When everything has already been replaced and secured, you should start the engine, check how it works, and adjust any inaccuracies.

Adjusting the ignition of a UAZ is a fairly simple task. With the engine running, you need to turn the distributor very slowly to find the position at which the engine will run smoothly and the speed will be high.

The UAZ 469 car has an ignition coil, which is also a kind of transformer that converts low voltage to high voltage. When the engine is running, current flows through an additional resistor into the primary winding of the ignition coil. It is located between the legs of the fastening brackets - in the insulator.

When the engine is started using the starter, the resistor is turned off, and the current flows into the primary winding without entering it, which makes starting the engine much easier due to the enhanced spark.

How to connect the ignition switch

Replacing the ignition switch involves dismantling the old one and installing a new mechanism with its subsequent connection. To remove the old lock you will need a Phillips and flathead screwdriver.

The procedure for dismantling the old vehicle ignition system lock:

- Remove the fasteners from the lower trim panel of the steering column.

- Insert the key into the lock and set it to the zero position, at which the steering mechanism will be locked.

- Remove the steering column.

- Unscrew the ignition switch mounting bolts.

- Insert a flat-head screwdriver into the small technological hole and press the latch that holds the lock.

- Push the lock out of its seat.

- Disconnect all system wires.

- Install a new lock, connect the wires and reassemble the mechanism, performing all the steps in reverse order.

All wires are connected in a clockwise direction.

To terminal number 50 you need to connect a red wire, which is responsible for the stable operation of the starter device.

To terminal number 15 you must connect a blue wire with a black stripe, which is responsible for heating the vehicle interior.

A pink wire is connected to pin number 30, and a brown wire is connected to 30/1.

The black wire must be connected to the INT connector, which is responsible for the operation of the side lights and headlights.

After all the wires are connected, you need to connect the battery terminal. A black wire should be connected to the top of the terminal. Then you need to start the engine and check the serviceability and functionality of the entire ignition system. First, it is recommended to check the operation of electrical devices, and then the serviceability of the starter mechanism.

If all wires are connected correctly, then when the ignition system key is in the zero position, all elements of electrical equipment will be disconnected from power. When the key is turned to the first position, the system is activated, which controls the internal combustion engine, generator set, headlights and brake lights, as well as washers and windshield wipers. When the key is moved to the second position, the starter is activated, the anti-theft system rod extends and retracts when the key position is changed.

If this does not happen, it means the wires are connected incorrectly. It is necessary to disassemble the mechanism and repeat the connection procedure.

Coil device

Underwater ignition on a jeep

The UAZ 469 ignition coil has a complex design:

- screw-in terminal with high voltage;

- voltage output;

- lid;

- contact spring;

- low voltage clamp;

- gasket for sealing;

- fastening bracket;

- magnetic circuits;

- contact plate;

- primary and secondary winding;

- insulation gaskets;

- frame;

- insulator;

- iron core;

- insulating mass;

- additional resistor and its insulator;

- screw and plate for fastening the resistor.

UAZ 31514 wiring diagram for ignition conversion

Many UAZ owners know about the vagaries of classic ignition, which sometimes presents unpleasant moments. And often craftsmen find ways to modernize a problematic unit or an entire system. And one such method of improving the launch system with your own hands will be discussed in this publication.

In the photo, UAZ 31514 is a reliable all-terrain vehicle for many purposes.

General concept

The contact ignition circuit itself is not bad, because humanity has been using it since the advent of the first car. But, of course, it is far from the capabilities of contactless ignition. Therefore, many UAZ owners, in an effort to improve the performance of the power unit, reconfigure it.

General ignition circuit for older UAZ models

And not only UAZs, but also other domestic cars, for example, the wiring of the Moskvich 2141 and a number of other brands and models are subject to alterations.

Effect of modernization

What is important is that the engine compartment and interior electrical wiring of the UAZ 31514 remains virtually unchanged, and the alteration itself is characterized by the installation of new elements under the hood.

As a result:

- The engine begins to operate stably in all modes;

- Improves cold starting;

- Fuel consumption is normalized;

- The engine power will reach the passport data.

Differences between ignition systems

The main difference between the two systems is the moment of sparking:

- In classic ignition, a slider under the distributor cover is responsible for this when it comes into contact with the output contact on the spark plug wire. In this case, the supply of a high-voltage pulse occurs with an increase. It seems to be lubricated, reducing the spark power at the spark plug electrodes.

- In contactless ignition, the switch generates a charge and releases it almost instantly upon receiving a signal from the Hall sensor. As a result, the candle produces a more powerful spark. Among domestic off-road vehicles, the Niva has a similar contactless ignition system - see the VAZ 21213 wiring diagram.

The electronic switch is often mounted in UAZ vehicles on the partition on the left side.

Please note! More powerful sparking promotes self-cleaning of the spark plug, because The fuel burns intensively, leaving no deposits.

UAZ 2-circuit ignition. UAZ underwater ignition

May 22, 2007 posted in the UMP section: how to set the ignition after EWS On the ZMZ-402, UAZ, ZMZ-406 engines, the pistons do not reach the valves The best site for car issues - UAZ 469 seat belts, Auto ru Lithuania Mercedes Lancia Voyager 11 VAZ steering rack repair 2109 videos. How to set the ignition on the planet hydraulics for body work, nut GOST 15521 70 Oka 4x4 vs. UAZ Offroad UAZ 469 UMZ engine - 417 (414) TURBO test run Motor UAZ How to set the ignition on a motorcycle “Level.. rental agreement for a residential building between individuals A ) engines of UAZ-451, -452, -469 cars. On the engine of the VAZ-2121 Niva car, mark 4 (see Fig. A) on the crankshaft pulley should be August 26, 2008 time of day! I am the owner of a UAZ Patriot 2007. Post by UAZ » Tue Aug 26, 2008 07:11 QUESTION:469

Setting the ignition timing on the UAZ distributor sensor distributor

Setting the ignition

on the

UAZ

sensor distributor Start handle (from a car...

Installation of distributor with drive

correct installation of a distributor with drive on a UAZ

.

Repair Instructions for UAZ 469 Electronic Ignition - file

Video repair of VAZ 2121 Niva, rating: 4.00, duration: 12:41, UAZ Patriot, UAZ 469, VAZ 2121 Niva IN THE SWAMP, WATER AND SNOW. . How to set the ignition for any cylinder|VAZ 2106|classic. UAZ electronic ignition uploaded by BOB4iK90 5 years ago. 49, Share; Add this video to your website or forum. Download to UAZ. How to correctly position the bowtie UAZ 469 1976. SECOND fruit pies recipes with photos Nov 1, 2014 — 2 min — Uploaded by Alexander + Adik Zarifov hello. A drawing of the faceplate and butterfly can be found freely on the Internet. and the bushing is my drawing, I don’t give it to you. You can Wiring UAZ 31514 switch to contactless electronic ignition: step-by-step instructions with photos and videos. movie actors book of masters Any non-contact ignition system basically differs only in the manufacturer and They have special marks in order to set the initial ignition (primary). Starter UAZ 469 Video UAZ (12) · Interesting things about UAZ (30) · History of UAZ (16) · UAZ models (47) · News On cars UAZ-315122, UAZ-315142 and UAZ-315192, unlike the base ones, .. 17 — combined ignition and starter switch (see Fig.

What to buy

In fact, you don’t need to buy much, and if you have a working distributor and reel, then the list of purchases will be minimal.

So, you need to buy:

- Hall Sensor;

- High-voltage wires (preferably silicone);

- Switch from VAZ 08.

Advice: If your UAZ is already many years old, then we recommend that in addition to the already indicated list, you buy a new distributor, a coil, and you will also need UAZ 31514 wiring with connectors for the switch.

For reconfiguration and operation, you will also need a new UAZ 31514 wiring diagram, which is shown in the photo below, and which you can print for convenience.

For a new ignition - a new circuit

You can also make your ignition system more powerful by upgrading it with two kits at once:

- Two switches;

- Two Hall sensors;

- Two ignition coils.

With this approach, each subsystem will be responsible for sparking 2 cylinders at once:

- First and third;

- Second and fourth.

Most often, UAZ cars that take part in competitions or are used by professional fishermen and hunters are subjected to such serious modifications. The video below shows how an engine works with such a system.

Advice: if you use your UAZ 31514 in everyday life, not related to extreme sports, then it is enough to limit yourself to alterations with one set - it’s easier to maintain it. After all, domestic all-terrain vehicles use a proven UAZ wiring diagram.

Rework

Actually, the work itself comes down to remaking the distributor, which will no longer have a high-voltage part - an electronic switch will generate high-voltage pulses for it . The photos below show the location of two sensors at once.

The sensors are attached to the base and the contact plate has curved edges

Pay attention to the shape of the contact plate:

- It has curved ends - the sensors are located vertically;

- Flat – the sensors are mounted horizontally.

Flat plate option

Flat plate option

Both options are working, it all depends on the design of the distributor. In the future, you only have to adjust the ignition. The instructions are simple - you must remember that sparking begins when the edge of the plate is in the center of the Hall sensor.

The order is as follows:

- Rotate the crankshaft until the piston in the first cylinder reaches TDC;

- Rotate the distributor body until the contact plate is in the sensor slot;

- Carefully tighten all mounting screws to eliminate any play.

- Start the engine.

Installation of distributor drive

Installing a distributor drive on a UAZ vehicle involves combining a camshaft and an oil pump. It's not very simple.

The distributor drive is driven into rotation by the camshaft gear, at the same time, the oil pump is driven into rotation by the distributor drive through the plate. Removing the drive is not difficult; unscrew the two fastening nuts and remove it from the engine block. The drive may burn in the motor block housing. In this case, you have to use ingenuity. Or try to rock it. Or unscrew the mounting pins and try to turn it. Why does the drive fail? As a rule, this happens when starting the car in cold weather. The oil becomes very thick, and it is very difficult to turn the oil pump. Therefore, the pump will stall, causing the plate to bend. And it gets out of engagement with the oil pump.

Installation of the UAZ distributor drive

After removing the drive, the distributor drive is reinstalled. To do this, set the piston of the first cylinder to TDC at the moment of fuel compression. The easiest way to set this position is to unscrew the spark plug of the first cylinder and block the hole with a paper stopper. When bringing the piston in at the moment of compression, the plug will be knocked out, and then install the generator drive pulley at the first mark.

Correct camshaft position

I would like to note that the piston approaches the TDC position twice during the cylinder operating cycle. For the first time at the moment of compression. The second is at the moment of exhaust gas emission. It is very important not to confuse these provisions. Therefore, we check ourselves by determining the compression occurring in the cylinder. Since at the moment the valves are closed and fuel compression occurs. So, we have installed the piston at TDC. Now our task is to install the drive correctly. Pay attention to the groove into which the distributor drive coupling is inserted; it is offset from the center. This groove must have a direction parallel to the cylinder block. And relative to the center it is offset from the engine block.

The distributor at the junction with the pipe has a similar offset

The drive gear is helical, so if we start inserting the drive in this position. It will not install correctly, but will turn one tooth. Therefore, before inserting the drive, it must be turned one tooth counterclockwise. So that the drive is installed in its place and takes the correct position. Try to engage the edge of the drive gear with the gear on the camshaft. The drive cannot be installed immediately. It is necessary to rotate the crankshaft until the plate fits into the groove of the oil pump. When turning the crankshaft, it is necessary to press the drive. To prevent the edge of the gear from becoming disengaged.

Once the oil pump groove is aligned with the drive plate. The drive will sit in place. After this, it is necessary to again set the piston to the TDC position at the moment of compression, and check the position of the drive groove. If it is parallel to the block and offset from the block, then the distributor drive is installed correctly. If not, this procedure must be repeated.