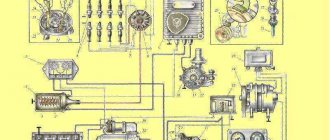

The ZMZ-406 engine is equipped with a microprocessor ignition system, which consists of a control unit for fuel injection and ignition systems, two ignition coils of types 30.3705 or 301.3705, spark plugs, high-voltage and low-voltage wires.

The control unit is installed in the car interior on the right side under the instrument panel, behind the body side upholstery.

The ignition coils are installed on the cylinder head cover.

The control unit receives signals from sensors installed on the engine and, based on this, adjusts the ignition timing, which allows for optimal power, economic and toxicity indicators.

Electrical diagram of an integrated microprocessor engine control system (KMSUD)

Ignition coil

1. Disconnect the wire from the negative terminal of the battery.

2. Disconnect 4 blocks 1 of low-voltage wires and high-voltage wires 5 from the coil.

Unscrew bolts 2, remove bar 3 and coil 4.

3. Remove the second coil in the same way.

Examination

1. Coils 30.3705 and 301.3705 are checked with a spark plug diagnostician 1AP975000 on a car.

To do this, disconnect the high-voltage wires from the coil and connect the diagnostician instead.

Then crank the engine with the starter, while a spark should jump in the diagnostic spark gap in time with the operation of the cylinders.

2. Check the resistance of the primary winding of the ignition coil by connecting an ohmmeter between the low voltage terminals.

The ohmmeter should show a resistance of 0.025–0.03 ohms.

Then check the resistance of the secondary winding by connecting an ohmmeter between the high voltage terminals of the ignition coil.

The ohmmeter should show a resistance of 4000–5000 ohms.

If the measured parameters differ from those specified, the coil must be replaced.

Install the ignition coil in the reverse order of removal.

Connecting high-voltage wires ZMZ 405, ZMZ 406

ZMZ carburetor and Euro-2 engines are equipped with a DIS (Double Ignition System) ignition system.

The DIS system uses ignition coils with two high-voltage wires. Each coil operates a corresponding pair of cylinders.

The first coil works with 1 and 4 cylinders, the second coil works with 2 and 3 cylinders.

How to connect the ignition coils?

The ignition coil of cylinders 1 and 4 is located closer to the intake manifold, the coil of cylinders 2 and 3 is closer to the exhaust manifold.

Low-voltage coil wires must be connected to the coil in pairs. The pair of wires for coil 1-4 is slightly shorter than the pair of wires for coil 2-3.

Within the pair, it does not matter which contact is connected to which wire - the coils are non-polar. Also, within the pair, it does not matter which high-voltage wire goes to which cylinder.

Let's look at an example (see photo)

Coil 1 control (cylinders 1 and 4) – green and yellow wires. This pair connects strictly to the coil of cylinders 1 and 4!

Low voltage circuit - polarity is not important - can be connected:

Option 1: The top coil contact is yellow, the bottom contact is green.

Option 2: The top coil contact is green, the bottom contact is yellow.

High voltage outputs – polarity is not important – can be connected:

Option 1: Top outlet for cylinder 1, bottom outlet for cylinder 4.

Option 2: Top outlet for cylinder 4, bottom outlet for cylinder 1.

Coil 2 control (cylinders 2 and 3) – blue and yellow wires. This pair is connected strictly to the coil of cylinders 2 and 3! Further - similar to pair 1-4 - the polarity within the pair is not important.

The determining factor when connecting pairs of low-voltage and high-voltage wires to the corresponding ignition coil is the correctness of their routing. The wires should not be too tight, bent too much, and should not rub against fixed parts of the engine or other wires.

Another article about high-voltage wires ZMZ 405, 406 - read so as not to repeat this mistake.

CONNECTION FEATURES

The order of connecting high-voltage wires must be strictly sequential, since each cylinder of the engine corresponds to a specific socket on the ignition module. Considering that there is a numbering of the sockets on the ignition module body, the risk of confusing anything is minimal.

The procedure for connecting high-voltage wires of the VAZ 2114 injection type depends on the year of manufacture of your car. Fourteeners before 2004 had 4-pin ignition modules installed, and cars after 2004 had 3-pin coils.

The connection diagram for VAZ 2114 high-voltage wires to the ignition module (until 2004) is as follows:

Connection diagram for VAZ-2114 with ignition coils (after 2004):

In the pictures you can see the numbers of the landing slots. Each number must have a corresponding cylinder connected to it (cylinder numbering is counted from left to right).

To correctly install high-voltage wires on the VAZ 2114, follow the following algorithm of actions:

- Turn off the ignition. Open the hood and remove the power terminals from the battery;

- We remove the old GDPs from the mounting sockets on the module and cylinders;

- We remember the location of the high-voltage wires of the VAZ 2114 and connect new GDPs according to the diagram. Before replacing, it would not be amiss to draw this very diagram by hand on paper so as not to confuse anything;

- We connect power to the battery and, to check whether we did everything correctly, start the engine.

Parameters of the main components of the ZMZ-406 engine

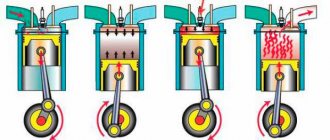

The engine is gasoline, four-cylinder, in-line with an integrated microprocessor control system for fuel injection and ignition.

The ZMZ-406 engine is installed on GAZ-3110 Volga passenger cars and GAZ-3302 Gazelle trucks.

The main design features of the ZMZ-406 engine of the GAZ-3110 Volga, Gazelle GAZ-3302 cars are the upper (in the cylinder head) arrangement of two camshafts with the installation of four valves per cylinder (two inlet and two exhaust).

Increasing the compression ratio to 9.3 (instead of 8.2 on the 402 model engine) due to a combustion chamber with a central spark plug, using a system of distributed (alternately in accordance with the order of operation of the cylinders) fuel injection into the intake pipe using electromagnetic injectors (instead of carburetor supply) .

This made it possible to significantly increase maximum power (about 1.5 times) and maximum torque, reduce fuel consumption and reduce exhaust gas toxicity.

To increase the reliability of the ZMZ-406 engine of the GAZ-3110 Volga, GAZ-3302 Gazelle cars under operating conditions using more power and higher crankshaft speeds, a cast-iron cylinder block without insert liners is used on the engine, which has high rigidity and more stable gaps in friction pairs , the piston stroke was reduced from 92 mm to 86 mm, the weight of the piston and piston pin was reduced, higher quality materials were used for the crankshaft, connecting rods, connecting rod bolts, piston pins, etc.

The engine camshaft drive is a two-stage chain drive with automatic hydraulic chain tensioners; The valve mechanism uses hydraulic pushers, eliminating the need to adjust the gaps.

The use of hydraulic devices and the high degree of boost of the ZMZ-406 engine require a higher quality of oil purification, therefore the engine uses a full-flow oil filter with an additional filter element, which prevents the entry of unclean oil into the engine when starting a cold engine and clogging the main filter element.

The drive of auxiliary units (water pump and generator) is carried out by a more reliable flat poly-V-belt.

The ZMZ-406 engine is equipped with a diaphragm clutch with so-called ellipsoid-wound driven disk linings, which have high durability.

The integrated control system also includes functions for controlling the ignition system and allows you to more accurately dose the fuel supply and adjust the ignition timing, including the detonation parameter, under changing engine operating conditions, which allows you to ensure the necessary power, economic and toxic indicators.

List of internal combustion engine modifications

The manufacturer ZMZ has 4 naturally aspirated modifications of the 405 series engine for buses, trucks and heavy executive Volgas, and one turbocharged version for special vehicles with armored linings, special equipment, and heavy frames.

The basic version 4052.10 has 214 Nm of torque, a compression ratio of 9.4, and a power of 152 hp. It is recommended for use both in the urban cycle and on the highway.

Motor 40522.10 has a lower torque of 211 Nm, the power remains the same, it is adapted for the gearboxes of Gazelle/Sobol trucks and buses. The compression ratio here is 9.3 for better responsiveness to domestic gasoline.

ZMZ 40522.10

Option 40524.10, on the contrary, is tailored to fit the box of the Fiat Ducato minibus, although it was actively used on Gazelles and Sobols. Meets the requirements of Euro-3 and Euro-4 in different configurations, has 214 Nm of torque and 140.5 hp. With. power. The compression ratio is 9.4, that is, the same as the base version.

ZMZ 40524.10

ICE 40525.10 has 213.5 Nm of torque and 143.8 hp. With. power, developed under Euro-3 regulations for GAZ Volga weighing up to 2.1 tons.

ZMZ 40525.10

Unlike previous naturally aspirated engines, modification 4024.10 is equipped with an air cooler and turbocharger, forged pistons and a steel crankshaft for increased loads. The diaphragm spring is strengthened here, and the exhaust valves are equipped with sodium cooling. In 2009, this turbo engine was equipped with Fiat Ducato buses. The compression ratio here is reduced to 7.4 units, the torque is increased to 343 Nm, and the power it develops is 195 hp. With.

ZMZ 4054.10 turbo

Engine Description

Previously, the engine was designed for newfangled power and ignition systems, which were controlled by a microprocessor.

This engine was the first to be equipped with four valves per cylinder, with hydraulic lifters and two camshafts with a double chain drive. An electronic fuel supply system and electronic ignition were also installed.

The four cylinders have an in-line arrangement, a water jacket and controlled fuel injection.

The ZMZ-406 injector runs on A-92 gasoline. Previously, a carburetor version of the 4061 engine was produced, which ran on seventy-sixth gasoline. It had limitations in terms of release.

The unit is unpretentious in maintenance. It has a high degree of reliability. Later, on its basis, ZMZ-405 and 409 units were developed, as well as a diesel version of the engine labeled ZMZ-514.

The disadvantages of the engine include the cumbersome nature of the gas distribution mechanism drive, which is explained by its low quality of workmanship and a number of technological shortcomings.

Maintenance and Prevention

The operating principle of an injection engine is based on controlling the fuel supply using electronics. Due to this, the engine requires preventive maintenance approximately every 12 thousand kilometers (according to the manufacturer’s recommendation). At the same time, the oil and filter are replaced.

If the Gazelle-405 (injector engine) operates in intensive mode, it is recommended to service the engine every 8-10 thousand kilometers, since under heavy loads the oil changes its chemical composition faster and loses its properties.

It is recommended to adjust the valves with the installation of appropriate washers every 15 thousand. In addition, it is necessary to check the gas distribution mechanism, since a broken belt can lead to deformation of the valves, which can lead to costly repairs or even replacement of the cylinder head.

Source

Carburetor engine

The ZMZ-406 carburetor (402nd engine) has been produced since 1996 and has managed to establish itself as a simple and reliable unit. This device develops a power of 110 horsepower. The fuel consumption of a car with this engine often depends on driving style and operating conditions. The power system of the carburetor unit is quite reliable. With timely maintenance and normal operation, using high-quality lubricants and gasoline, it can travel up to 500 thousand kilometers without serious breakdowns. Of course, with the exception of boring the crankshaft, which is necessary for this unit once every 250 thousand kilometers.

Reason #3

If, in the process of optimizing engine operation, increasing its power, reducing fuel consumption, etc., you are thinking about installing a non-standard camshaft, then you will certainly need to change the valve timing angle. A lightweight sports (stock) camshaft with a modified profile and increased cam lift should increase torque and “throttle response”, but without the correct phase setting, this can negatively affect the operation of the entire system. uazbuka.ru > technical > engine which engine is better, for example, 469 on warriors and 406-409 or. Which type of oil is better oil filter VAZ 2109. Engine VAZ 2109. Engine 405 received unwanted advertising or spam which engine is better on. For this. To solve this problem by establishing phase angle reference values, the easiest and most effective way is to use the “Ideal Phase” kit!

Ignition system

On ZMZ-406 engines, ignition is carried out by igniting the fuel mixture using a microprocessor system. For all engine operating modes, the electronics sets the required ignition timing. It also performs the function of adjusting the working process of the forced idle economizer. Due to the operation of this system, the engine is distinguished by its high economic performance, exhaust gas toxicity standards are monitored, the moment of detonation is eliminated and the power of the power unit is increased. On average, a GAZelle car consumes about 8-10 liters of gasoline per 100 kilometers under average loads. However, if you convert it to propane or methane, the “appetite” of the machine almost doubles.

Purpose and principle of operation of the ignition coil 406.3705

Ignition coil 406.3705

- is an element of the ignition system that serves to create a high voltage pulse with a power of 24 kV and supply it to the spark plug to ignite the fuel-air mixture in the engine cylinder.

While the cylinder piston is at top dead center, during the compression stroke of the fuel-air mixture in the engine cylinder, the engine electronic control unit (ECU) sends a low-voltage pulse through thin low-voltage wires to the primary winding of the ignition coil, which consists of a small number of turns. . An electrical pulse passing through the primary winding of the ignition coil creates an electromagnetic field around the metal core. This electromagnetic field creates a high voltage pulse in the secondary winding of the ignition coil, due to the large number of winding turns. This magnetic field generates a high voltage electrical pulse, 24 kV, in the secondary winding of the ignition coil. This high voltage pulse travels through insulated high voltage wires to the spark plug. From the resulting high voltage pulse, a spark is formed between the electrodes of the spark plug, from which the fuel-air mixture ignites during the compression stroke. The combustion of the fuel-air mixture creates an impulse for the vehicle to move.

Ignition diagnostic mode

When the car ignition is turned on, the ZMZ-406 engine diagnostic system automatically comes into operation (the ZMZ-405 carburetor is no exception). The fact that the electronics are working properly is indicated by a light sensor. It should go out when the engine starts.

If the diode continues to light, this indicates a malfunction of the elements and parts of the electronic ignition system. In this case, the breakdown should be repaired immediately.

Malfunctions and their elimination

Like any technical product, the Gazelle-Business motor is susceptible to breakdowns. Sometimes it needs repairs for various reasons. The most common problems that arise are:

- The motor does not start. Most likely there is no fuel supply to the injectors. It is necessary to use the appropriate fuel, rinse and clean the fuel intake.

- The tightness of the pipeline between the tank and the electric pump is broken. The connection points should be checked and the tightness restored.

- There are problems with the control electronics. It is necessary to replace faulty parts of the unit.

- Poor power delivery indicates problems in the electronic control system. After testing, it is necessary to replace the unusable element.

- The fine filter is clogged. In this case, the filter element must be replaced.

- Air appears in the fuel block. It is necessary to check and ensure the tightness of the system.

- If problems are detected in the fuel pump, the faulty injectors should be replaced.

Injection motor

In terms of technical characteristics and components, an engine with an injection power system is not very different from the carburetor analogue of the 405 model.

With proper operation, this unit is no less reliable and practical than with a carburetor, and in addition has its own advantages:

- Stable idle speed.

- Low level of harmful emissions into the atmosphere.

- The efficiency of the ZMZ-406 injector is much higher than its analogue with a carburetor, since the fuel mixture is supplied in a timely manner and in the right quantity. Accordingly, fuel savings are obvious.

- Improved fuel economy.

- Does not require prolonged engine warm-up in winter.

UAZ ignition order - how to set, order of spark plugs

The UAZ distributor is an important part in the ignition system of this vehicle. Its optimal adjustment guarantees efficient operation of the unit as a whole, increases its performance and efficiency, and allows the engine to be operated in any conditions and situations.

Setting up the ignition system so that it works correctly is not as difficult as it seems at first. But first of all, it’s worth understanding exactly how UAZ systems are structured as a whole and understanding their circuits. And if you do everything according to the recommendations, in the right order, then adjusting everything will not be difficult.

Block head

All engine modifications were equipped with one head, which complied with Euro 2 requirements. With the introduction of additional Euro 3 requirements, it was refined and improved. It is not interchangeable with the previous model.

The new head does not have idle system grooves; now their functions are assigned to an electronically controlled throttle. The front wall of the part is equipped with holes for attaching the protective chain cover, and on the left side there are ebbs for mounting the intake system receiver brackets. The part has pressed cast iron inserts and valve guides. The latter do not require periodic adjustment, since they are driven by cylindrical pushers with hydraulic compensators. The modernized ZMZ-406 head has decreased in weight by 1.3 kilograms. When installing it on the engine, use a metal multilayer head gasket.

Technical characteristics of ignition coil 406.3705

- The power supply voltage is 6-18 volts.

- Primary winding resistance: 0.35±0.02Ohm.

- Secondary winding resistance: 13±0.2 Ohm.

- Inductance of the primary winding at a frequency of 100Hz: 2.22±0.2mH.

- Output voltage: not less than 24 kV.

- Switching current in the primary circuit: no more than 7.5 A.

- Spark discharge energy: not less than 50 mJ.

- Discharge duration: not less than 2.2 ms.

- Current switching frequency in the primary circuit: 1…133Hz.

- Reel weight: 0.65 kg.

- Width: 0.08 m.

- Height: 0.06 m.

- Length: 0.08 m.

- To connect the ignition coil to the spark plugs, high-voltage wires with distributed noise suppression resistance must be used. The total resistance of the high-voltage wire, taking into account the noise suppression resistor in the tip, should be within 6 kOhm.

Camshaft

The ZMZ-406 camshaft is made by casting cast iron, followed by processing and hardening. The shafts are driven by a chain transmission. The engine has two shafts, the cam profiles of which are the same size.

The axial displacement of the cams is one millimeter relative to the hydraulic pushers. This factor promotes the rotation of hydraulic drive elements when the engine is running, which significantly affects the wear of the working surface of the pusher and makes it uniform.

The chain drive of the shafts has hydraulic tensioners that operate from oil pressure in the lubrication system. The parts act on the chain directly through plastic shoes that are attached to the axles. After modernization, on ZMZ-406 engines, sprockets were used instead of shoes to increase practicality and durability. The latter are fixed on rotary arms. The sprocket mounting axles are interchangeable with the shoe axles. Instead of an extension of the upper chain tension shoe axis, they began to use a spacer, which is fastened to the block with bolts.

The ZMZ-406 engine is equipped with camshaft drive chains. It is not possible to replace them with chains that were installed on earlier versions of motors.

List of car models in which it was installed

Initially, the ZMZ 405 motor was designed for several factories producing cars, so various modifications of this generation of ZMZ power drives were installed on the following vehicles:

- 10 – GAZ Volga, Gazelle;

- 10 – GAZ Gazelle 3302, 3221, 33023 Farmer, 32213, 32214, 2705, 2217 Sobol and Barguzin;

- 10 – Fiat Ducato GAZ Volga and Gazelle;

- 10 – GAZ Volga 3102, 3103, 3105, 3107, 3110, 3111, 3112, 3115;

- 10 – cash-in-transit and government armored vehicles, other special vehicles.

The improved characteristics of the engine made it possible to use it in the Volga Siber, but GAZ abandoned ZMZ engines in 2009 due to their high cost. The UAZ was equipped with a later version of the 409, created on the basis of the 405 engine.

Pistons

They are cast from aluminum alloy and have grooves for two compression rings and one oil scraper ring. During operation, the piston crown is cooled by oil through an oil nipple in the upper end of the connecting rod.

The spherical working surface of the upper compression ring has a layer of chrome coating, which facilitates better grinding of the ring. The second element is coated with a layer of tin. The oil scraper ring is of a combined type; it consists of an expander and two steel discs. The piston is attached to the connecting rod using a pin fixed to two corkscrew rings.

Crankshaft

Cast from cast iron with subsequent processing and hardening of the surface of the journals with high frequency currents. It is installed in the block on five main bearings.

The movement of the crankshaft according to the axis is limited by corkscrew half-rings, which are located in the flow grooves of the support and the cover of the third main bearing. There are eight counterweights on the shaft. A flywheel is attached to the rear of the shaft, in the hole of which a spacer sleeve and a rolling bearing of the gearbox input shaft are pressed.

Oil

The ZMZ-406 power plant is equipped with a combined lubrication system. Under the influence of pressure, the process of lubrication of the piston pins, connecting rod and main bearings of the crankshaft occurs, the support points of the camshafts, the hydraulic valve drive, the intermediate shaft and the driven gear of the oil pump are lubricated. All other parts and elements of the motor are lubricated by spraying oil.

Closed crankcase ventilation with forced exhaust of gases.

Characteristics

The injection engine in the Gazelle Business car has the following technical characteristics:

- Engine type is a four-stroke gasoline unit with 4 cylinders.

- The injection system is microprocessor controlled with ignition and air supply.

- Cylinder volume (cubic cm) - 2,464.

- Standard power at a rotation speed of 4.5 thousand revolutions is 214 Nm.

- The filter is an air dry replaceable element.

- The cooling system is closed type with forced circulation.

- Generator - with a built-in unit and voltage controller.

- Sensors for monitoring system overheating and oil pressure.

- The starter is a remote, electromagnetic version with a gearbox.

Technically, the 2.46-liter engine with a power of 140 horsepower allows the car to overtake or perform sharp maneuvers when fully loaded.