The ignition system is installed on gasoline engines. Its main task is to ignite the fuel-air mixture at the moment when the piston is in the upper position, compressing it as much as possible. The gasoline in the engine cylinder ignites with a spark that occurs in a special spark plug, which is the purpose of the ignition system in a car.

What is early or late ignition?

Among car enthusiasts, those who repair their cars themselves, expressions such as early or late ignition are used, what do they mean and how to correct the situation? Each gasoline internal combustion engine has an entire system that performs synchronized ignition of the fuel mixture in the cylinders. The peculiarity of its operation is that it is necessary to apply a pulse of a given duration in a narrow period of time so that gasoline in combination with air ignites correctly and fully. This value is also called the ignition angle. It can be changed very simply in engines with a carburetor. It is enough to turn the distributor in one direction or another, but this must be done as slowly as possible, since it is very easy to change the current setting.

It is necessary to achieve a position in which the spark will jump between the contacts strictly before top dead center. It is then that ignition occurs normally and the motor operates in the specified mode.

Late angle is a type of system malfunction in which ignition of the fuel mixture occurs later than a specified time interval. In this case, the piston is in a close position or directly at top dead center. This is an unacceptable mode, since the mixture does not burn completely. Some of the unburnt fuel is sent to the exhaust manifold with the ensuing consequences.

Early ignition angle - The fuel ignites earlier than expected, when the piston position is far from TDC. When operating this way, the engine literally consumes liters of gasoline and produces much less power. Plus, there is a counterforce on the piston, which moves upward.

Signs of early ignition

The most common breakdown or defect in the operation of gasoline-type internal combustion engines is early ignition. Due to its nature of origin, it occurs frequently, so it is important for all car owners to be aware of the signs of this condition. Symptoms of pre-ignition appear as follows:

- Dense black carbon deposits form on the electrodes of the spark plugs;

- shots are heard from the silencer;

- unstable operation in idle mode;

- poor driving dynamics;

- a lot of black soot is formed in the exhaust;

- problem with starting the engine;

- the sound of fingers is heard;

- there is an increase in fuel consumption.

Signs of late ignition

If the spark generation occurs after the specified time, then the following signs of late ignition are observed in the car:

- the engine does not start the first time;

- severe disruption and instability in his work, troit;

- shots occur in the intake tract and mixture preparation system;

- the engine responds sluggishly to the gas pedal;

- strong and rapid overheating of the internal combustion engine is felt;

- a white and gray coating appears on the spark plug electrodes;

- no detonation when pressing the gas pedal sharply;

- There is also an increase in fuel consumption.

Which ignition is better: early or late?

It is important that the engine operates correctly, and this indicates the correct settings for the ignition angle of the fuel mixture. But if for some reason the setting is lost, then which condition is less harmful to the car? The engine should not be allowed to operate in such modes, because the wear of parts increases, not to mention the increase in fuel costs in both situations. Therefore, if you choose which one is better, the answer will be no. Both are harmful to both the car and your wallet, but if you delve into the specifics of the work, there are differences in harm.

Late ignition, unlike early ignition, is more dangerous in that unburned fuel moves into the exhaust manifold with an open flame. This causes its excessive heating and early failure. There is also a risk of detonation occurring directly in the manifold, which is dangerous for the catalyst and other exhaust parts. You need to monitor this setting and adjust it in a timely manner.

Operating principle of the ignition system

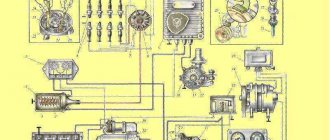

The fuel ignition system consists of several elements:

- spark plugs;

- distributor-breaker or distributor in carburetor cars;

- coils with capacitor.

When the driver turns the starting valve of the internal combustion engine, the starter begins to rotate the oilcloth shaft. The distributor, being meshed through a gear pair with the crankshaft, generates impulses transmitted to the primary winding. In the simplest implementation, the coil is shorted and energy is discharged to a capacitor connected in parallel by the breaker contact. It is generated by charging a capacitor and transforming a transformer (coil) to an amplitude of over 10 kW. The spark is transmitted through carbon contacts and resistance to the spark plugs, where it transfers its energy through ignition of the fuel mixture. The latter was injected in portions at the right moment and into the right cylinder.

On the injector

On cars with an injector there is no breaker, but electronic control is implemented and each spark plug has its own coil. The controller, in accordance with the position of the shaft position sensor, organizes the correct control of the operation of the coils through the ignition module, from which the spark is transmitted to the electrodes in the combustion chambers. On older cars with an injector, high-amplitude pulses are supplied in pairs and to 2 cylinders at once. Accordingly, in one the compression stroke has begun, and in the other - the exhaust gas exhaust stroke. The pairwise supply of pulses is called the “idle spark method”.

On the carburetor

The ignition system on a car with a carburetor consists of several components. There is a distributor or breaker, also known as a spark distributor, an ignition coil and spark plugs. When the driver turns the key, the starter begins to rotate the crankshaft of the internal combustion engine. There is a cam on the distributor shaft, which, when it hits the moving contact in the breaker, opens the power supply circuit of the coil. At this moment, the capacitor is charged through it to smooth out the current. An EMF with an amplitude of over 10 kW is generated in the secondary winding. Through the slider, the spark reaches the contact spark plugs.

Basic faults

The control unit constantly monitors the uniform rotation of the engine shaft. In case of ignition problems, it gives a signal about the presence of misfires in individual cylinders. In case of complete failure, the engine does not start at all or does not operate on all cylinders.

The reasons may be different:

- failure of spark plugs due to defects or untimely replacement, which not all drivers know about;

- breakdown of the insulation of the ignition coils, as a result of untimely replacement of spark plugs and an abnormal increase in their spark gap;

- burnout of power transistor switches in the control unit for various reasons, usually a manufacturing defect;

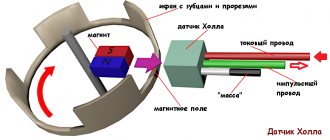

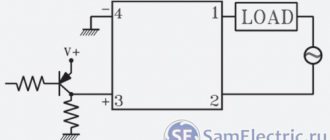

- failure of the main sensors, in modern systems this is the crankshaft position sensor, in outdated systems it is the Hall sensor in the distributor;

- in battery systems, burnt contacts and breakdown of the capacitor;

- in systems with an ignition distributor, the slider, the cover with contacts often breaks, or the interference resistor burns out;

- complete failure occurs when the contact group in the ignition switch burns out, the entire system is left without power.

Maintenance of the system comes down to the scheduled replacement of spark plugs. Conventional copper-nickel ones should be changed every 10-15 thousand kilometers, and those containing noble metals - after about 60 thousand. Otherwise, you will have to replace the ignition coils along with them, which is much more expensive.

How to determine early or late ignition

As stated earlier, incorrect ignition angle has certain symptoms. Actually, from them you can find out whether it is early. In normal operation of an internal combustion engine, the fuel ignites at the end of the compression stroke, that is, immediately before reaching TDC. When the explosion reaches maximum energy, the piston will begin to move downwards, which will lead to additional acceleration of the crankshaft. If the ignition is earlier or later, then the engine will in any case not gain its power, but with a late spark the dynamics are more pronounced, but there is a risk of overheating of the exhaust manifold, accompanied by explosions inside it.

On gasoline

If late ignition of the mixture occurs, then strong heating of the internal combustion engine and especially the exhaust manifold occurs, accompanied by explosions. When you press the gas pedal at a speed of about 40-50 km/h, there is no detonation characteristic of normal operation.

On diesel

On cars with a diesel power unit, there is no such thing as late or early ignition, because they do not have a spark. Ignition of the mixture occurs at the moment of its compression, that is, synchronous. In earlier modifications, this could still be somehow adjusted manually. This function is not implemented in modern cars.

On a car with HBO

Many owners install gas equipment on their cars because gas remains cheaper than gasoline. If it is present, it is also very important to correctly adjust the ignition angle of the combustible substance. Unlike liquid hydrocarbons, propane has a higher octane number (100-105, methane 120 octane). For this reason, angle adjustment is mandatory, since with a normal gasoline setting, the economic effect will be very small. For this purpose, HBO kits include a special unit called a variator. It switches the angle according to the mixture selection. For the most optimal operation, an increased advance angle is required, since gas burns longer than gasoline. They also resort to changing the compression ratio by lengthening the connecting rods, but such a motor will no longer be able to operate normally on liquid fuel. Accordingly, late ignition is dangerous for a gas internal combustion engine. If you install the HBO on classic, then you need to turn the distributor to “+” by 3-8 degrees.

Let's sum it up

Despite the significant priority aspects of the contactless ignition system, the cam mechanism has still not lost its relevance and has adherents among car owners. Democracy of details, simplicity and reliability of the design are the main advantages of KSZ. In turn, the BSZ is considered a modernized and improved design that corresponds to the times, allowing to minimize the likelihood of breakdowns and improve the performance of the vehicle. A description of the operating features of the systems and their significant differences presented in this article will help car owners make a choice, giving preference to one of the designs.

How to set the ignition

Setting the ignition angle is done differently on different cars. On carburetor engines, this is done using a distributor. This is a mechanical device, inside of which there is a shaft with a cam and a contact pair. When the shaft rotates, the contacts methodically close and open, which generates a spark. Accordingly, by rotating the distributor in a certain direction, you can achieve earlier or later ignition. It is usually marked with the designation “+” and “-”. Changing the position to “+” leads to early ignition or an increase in advance. Rotation to “-” leads to a reduction in advance, provided that it has already been set before TDC.

How to set the ignition using a strobe light

There is a technology for adjusting the ignition angle using a strobe light. Its use greatly simplifies the procedure. The principle of operation of the device is to illuminate a moving object in the dark at high speed with a short and very bright flash. As a result, the object illuminated by light will appear static and details will be clearly visible on it. Thanks to this effect, you can visually check the position of the marks on the crankshaft directly during its rotation without additional devices. The flash turns on at the moment a spark is generated and the observer should ideally notice two branches on the crankshaft pulley and on the housing, located opposite each other. If it is offset counterclockwise, then the ignition is too early, you need to turn the distributor to “-”. Accordingly, clockwise – in “+”.

We set the ignition according to the control light

You can also optimally adjust the ignition timing using a control light. The principle is the same, but now you need to rotate the crankshaft pulley by hand. The light bulb is connected to the ignition coil on the brown wire that goes to the breaker. As the crankshaft rotates, at some point the light will go out. This indicates that the contacts of the breaker have closed and the current flows to the ground, that is, the coil is charging. When the light bulb lights up, the circuit opens and the capacitor is discharged to the coil and the light bulb. It will light up. We need the moment when the lamp goes out. It is then that energy is released in the form of a high-voltage pulse. In this case, the marks on the pulley and the motor housing must match. Next, the adjustment is performed similarly to the previously described method.

Aurally

Over time, some experienced craftsmen have learned to adjust the lead angle by ear. This is a specific procedure and is not suitable for every car enthusiast. Let's look at its features:

- The first step is to loosen the nut that secures the distributor in one place.

- By slowly rotating it in one direction or the other while the engine is running, you find a position in which the internal combustion engine operates stably even after recharging.

- Rotate the breaker to “-” a few degrees to delay the ignition to save fuel and reduce noise, but a slight vibration will appear, which is considered normal.

There are situations when it is impossible to adjust the angle due to poor fuel quality.

By spark

Adjusting the ignition timing is similar to the method with a strobe and a light bulb. The spark on the spark plug should flash exactly at the moment the mark on the pulley passes the one on the engine body. To do this, usually remove the central high-voltage wire and place it at a distance of 3 mm from the ground. The crankshaft is rotated until its mark coincides with the first one on the body.

Where is it used?

Past and present owners of VAZ “classics”, who understand the design of such cars, are well aware of the weak points and operating principles of the contact-type ignition circuit.

Its peculiarity lies in the distribution of voltage to the combustion chambers of the engine through contact connections (hence the name).

Modern cars are equipped with more modern (electronic) ignition, which is controlled by a microprocessor.

The main systems operating on the contact principle include:

- KS3 (KSZ) is the most common type of circuit, the structure of which contains a distributor, a coil and a breaker.

- KTS3 (HKZ-2, JFU4, HKZk) - ignition system with a contact sensor and preliminary energy storage.

- KTC3 (TSZi) is another type of system that operates on the contact principle. It contains a transistor and contacts, as well as an inductive energy storage device.