When the clutch is faulty, full use of the VAZ 2106 becomes impossible. This mechanism, by disconnecting and connecting the engine to the transmission through the driven disk, affects smooth and precise gear shifting, noiselessness and smooth starting of the car from a standstill. An important part of this transmission component is the master cylinder, mounted on top. Under the pressure of the clutch pedal, this part produces force pressure, which forces the working cylinder to move.

Signs of malfunctions in the operation of this device may include a crunching sound at the place of its attachment, leakage of fluid, or freezing of the pedal. Another sign: the driven disk and pressure disk do not disconnect. A clutch disc that is not fully depressed makes it impossible for the synchronizers to hit the hub accurately. The synchronizer ring wears out intensively, which leads to its unsuitability and the inability to engage the gear.

When should repairs and replacements be carried out? At the first violations in its operation, when you can simply repair the clutch master cylinder. You should immediately establish and eliminate the causes of the VAZ 2106 breakdown, avoiding unnecessary expenses for repairs in the future.

Installing the clutch master cylinder repair kit

It is not difficult to determine when it is necessary to repair the master cylinder; the main signs of its malfunction are:

- Insufficient clutch release (clutch drives)

- Any type of leakage, whether from under the nuts securing the hose and tubes, or from the end from under the rubber seals

- Master cylinder stuck in pressed position

In my situation, the main leak was due to a worn out sealing ring, in other words, fluid flowed down the clutch pedal into the passenger compartment.

I started the repair by dismantling the reservoir hose, unscrewed the clamp on the main cylinder and quickly removed it from the main cylinder, turned it up and pinched it behind the reservoir cap so that the liquid did not flow out of the reservoir. Next, I unscrewed the tube that goes to the working cylinder, I did this with a special key, it’s a pity there is no photo, but you can buy one without any problems at any auto store. All that remains is to unscrew the main one itself, it is secured with two 13 nuts and remove it from under the hood.

The boot was removed and it was noticeable that fluid was flowing from here.

Having picked up the boot with a screwdriver, I saw exactly where the liquid was flowing from; the assumption was absolutely correct.

Next, you need to wipe the cylinder, remove dirt and rust.

Attention. Do not use gasoline or similar liquids for washing, as they will very quickly ruin the new rubber bands. To flush the clutch and brake elements, use clean brake fluid.

After cleaning the dirt, you can begin disassembling. To do this you will need an awl or similar object.

Next, you need to carefully remove the insides, keeping in mind that the piston is under the action of a spring.

This is what it looks like

Next, you need to clean the master cylinder body, you cannot scrape the parts with a screwdriver, sandpaper, etc., this is just in case, I use a rag with brake fluid. In repair manuals, I often came across such expressions that if rips, scratches, etc. appeared on the parts, then it is unusable. But despite all this, practice shows that despite all the risks, provided that a high-quality repair kit is installed, the master cylinder works without problems. I used this kit:

Repair kit for clutch master cylinder VAZ

We remove the old rings, clean all the grooves and holes. There should be no dust or debris there.

The ring is removed, clean the piston, install a new one

Thanks for subscribing!

And by the way, here is the reason for the clutch cylinder leaking:

The ring is not worn evenly

After cleaning and replacing the rings, you can assemble the cylinder, below is a photo of what should be there and how:

Here is a photo not cleaned, I added it here to show the correct assembly

Having assembled the cylinder, install the corkscrew ring

Bleeding the clutch on a VAZ 2106

After the repair has been made, it is necessary to bleed the clutch. In all repair manuals you can find standard instructions for bleeding the clutch, but it may not always help.

- The first bleeding option is standard; it consists of filling the tank with liquid, unscrewing the bleeding fitting, putting a hose on the fitting, and lowering the other end into a container with clean liquid. Then, by pressing the pedal, we monitor when the air stops being released, and also do not forget to control the level in the tank.

- The second method is to use an assistant - one person presses the pedal 4-6 times and keeps it pressed to the floor. The second unscrews the bleeder fitting; air bubbles should come out of the fitting; as soon as they stop coming out, you need to screw the fitting in and then release the pedal. And so on until normal operation of the pedal is restored and air bubbles stop coming out.

- There is also the simplest method of pumping, but which does not always work - to implement it you just need to pour liquid into the reservoir and unscrew the fitting on the working cylinder. The liquid will flow by gravity through the entire system and when it begins to flow steadily out of the fitting, it can be closed and the pumping can be considered complete.

Bleeding the system

The design of the VAZ-2106 clutch master cylinder is approximately the same as on a similar element of the brake system. Pumping is done in the same way:

- The entire system is assembled, threaded connections are tightened.

- Liquid is poured into the expansion tank to an average level.

- A tube is put on the bleeder fitting and lowered into a small container with brake fluid.

- An assistant presses the clutch pedal several times and then locks it in the pressed position.

- At this time, unscrew the bleeder fitting a little so that the air comes out.

Repeat the last two steps several times until air stops escaping from the system. Be sure to monitor the brake fluid level. Otherwise, the mechanism will run dry, and it may be necessary to disassemble the VAZ-2106 clutch master cylinder for repair.

The clutch system performs the function of briefly disconnecting the internal combustion engine from the engine. As a result, the transmission of torque from the power unit to the drive shaft of the transmission stops. This system includes many components. One of them is the clutch master cylinder, which we will talk about today.

What is he?

This mechanism is a small casting made of cast iron steel with a flange for attachment to the body. On its top there is a plastic tank with a lid. It is attached to the body using a threaded fitting. Thanks to this mechanism, a special fluid enters the clutch master cylinder. Inside the cast iron part there is a piston with a cuff and an o-ring. There is also a spring resting on it. It compresses the piston to the extreme right position. When these parts heat up, expansion occurs, and accordingly, the liquid in the system must go somewhere. For these cases, there is a special compensation hole through which it enters the tank from the cylinder cavity.

How does 2107 work?

This mechanism is designed in such a way that each time you press the clutch pedal, it moves forward using a pusher. And when the piston closes the hole, the pressure in the cylinder increases. Thus, the fluid flows to the working cylinder and disengages the clutch. When the pedal is released, a similar action occurs, only in reverse order. The liquid flows back - the valves open, the spring compresses and it moves from the working cylinder to the main one. If the pressure level drops to a point below the spring compression force, the first part closes and more pressure is generated in the system. This is necessary to sample the gaps of the mechanical part of the drive.

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

Purpose of the device

Cars are equipped with clutch master and slave cylinders, without which the operation of the mechanism is impossible. The VAZ 2107 clutch master cylinder is designed to push out brake fluid. Below is a diagram from which you can visually find out the operating features of the unit.

When you press the clutch pedal, the piston moves in the device in question, thereby pushing out the brake fluid. This liquid enters the working cylinder through a tube, where the reverse process is observed (the liquid pushes out the piston). Brake fluid drives a piston, which is connected by a fork to the clutch disc. As a result, the clutch disc and flywheel are separated, allowing you to change gear. The GCS is also called the main one, since it is with its help that force is supplied from the pedal when it is pressed.

The need to replace the device: when required

Like all parts of any car, the GVC tends to wear out, resulting in the need for repair or replacement. The simplest breakdown of a product is wear of the boot, which can be determined by the characteristic signs of a fluid leak.

To identify a cylinder malfunction, an initial visual inspection is required. It is possible to repair a failed main circulation system on a VAZ 2107; for this you can look for repair kits, but this is not always rational due to the quality of modern spare parts, so it is easier and faster to replace it entirely. The malfunction can also be determined by the characteristic loss of pressure in the system, which is determined by pressing the pedal. Let’s take a closer look at how to change a faulty VAZ 2107 mechanism.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

We change the clutch with our own hands without removing the transmission

The operation is performed like this.

- Place the machine on a viewing hole or a lift and securely secure it to prevent it from rolling away.

- Disconnect the cardan and slave cylinder from the gearbox.

- Remove the protective cover of the mechanism and the traverse.

Unscrew the box cushion.

- Using your hands or using a lever, push the gearbox housing away from the power unit until it stops. For insurance, you can install a support under the box.

- Next, you will need to unscrew the 6 bolts securing the basket from the flywheel.

The box basket needs to be moved all the way and the clutch disc pulled out through the resulting gap.

Similarly, slide the basket back and remove it.

The last step is to dismantle the release fork and remove the bearing of the same name from the gearbox input shaft.

Installation of new parts is carried out in reverse order.

VAZ cars: repair, maintenance, tuning

Failures in the clutch operation of the classic VAZ 2107 - VAZ 2101 must be eliminated immediately. The clutch hydraulic drive system is not too complicated, maintenance work does not take much time, so removing, disassembling and repairing the VAZ clutch master cylinder will not be difficult even for novice drivers. Let’s find out how to deal with problems in the VAZ clutch right now.

Hydraulic clutch bleeding procedure

After replacing or repairing both the main and slave cylinders, the driver will have to bleed the clutch hydraulic drive, since air gets into the machine’s hydraulics. There is no way to avoid this. Therefore, you will have to call your partner for help and start pumping.

Sequence of work

To bleed, you will need the following things: an old plastic bottle, a piece of hose about 40 cm long, a 12 mm spanner.

- The car is installed on the pit and securely fixed. The clutch slave cylinder fitting is clearly visible from the inspection hole. A piece of rubber hose is placed on this fitting so that the fitting nut remains outside. The other end of the hose is placed in a plastic bottle.

So, the master cylinder is the most important element in the VAZ 2106 clutch system. But replacing it does not require special knowledge and skills, so even a novice driver can cope with this task. To successfully replace the cylinder, you just need to be a little patient and strictly follow the above recommendations.

Source

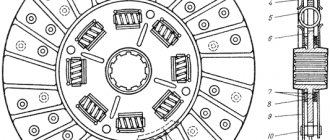

Clutch drive device VAZ 2107

We dealt with the clutch mechanism of the classic VAZ 2101-2107 not so long ago. There is nothing complicated there either and you can refresh your knowledge here. In all rear-wheel drive VAZ cars, the clutch release drive is hydraulic. The clutch master cylinder is installed in the engine compartment on the shield, the cylinder is located coaxially with the clutch pedal rod. A pusher is attached to the pedal itself through a hinge, which presses directly on the master cylinder piston. The VAZ clutch drive diagram is presented below.

Clutch drive diagram VAZ 2101-2107

Thus, the rod, through the pusher piston, acts on the incompressible brake fluid in the master cylinder, which transmits force to the piston of the working cylinder, already installed on the gearbox housing through the hydraulic hoses.

Malfunctions of the VAZ 2107 clutch master cylinder

Like any mechanism, the master cylinder is subject to wear, which reduces the efficiency of the system as a whole. The main malfunctions of the cylinder are fluid leaks or loss of nominal dimensions of the cylinder mirror, piston, wear of cuffs and seals. This is expressed in incomplete disengagement of the clutch, the pedal may fall through or be too tight. At the first suspicion of the clutch drive, we perform an initial diagnosis of the system:

- Check the fluid level in the clutch reservoir. A level that is too low indicates a brake fluid leak.

- Inspect the master cylinder for leaks. It should be taken into account that it can leak both in the area of the hydraulic drive fitting, the plug gasket, and in the area of the protective cap, which faces towards the pedal. In this case, the liquid will penetrate into the interior under the carpet and the leak may not be noticed immediately.

In this case, the leak was caused by wear of the piston cuff; fluid flowed into the passenger compartment. - If the clutch starts to engage only after a few presses of the pedal, then most likely air has entered the drive system. In this case, it is necessary to find out the cause of airing (loss of tightness, leak of the main or working cylinder), and only then perform bleeding and removal of air from the hydraulic system.

About choosing brake fluid

When starting to replace the cylinder, you should remember: any manipulations with this device are accompanied by leaks of brake fluid. And these leaks will then have to be replenished. Consequently, the question arises: what kind of fluid can be poured into the hydraulic clutch of the “six”? It is recommended to fill with DOT3 or DOT4 grade fluid. The best option both in price and quality would be the domestic liquid ROSA-DOT4.

Most drivers fill their 6s with DOT4 fluid.

Filling the liquid is extremely simple: unscrew the cap of the expansion tank, and fill the liquid to the upper horizontal mark on the tank. In addition, many car enthusiasts recommend slightly loosening the fitting on the clutch slave cylinder before adding fluid. This is done in case a small amount of air has entered the system. When filling in a new portion of liquid, this air will come out of the system, after which the fitting can be tightened again.

How to check the VAZ clutch cylinder, free play adjustment

In order not to do unnecessary work, it is better to spend half an hour and conduct independent diagnostics of the clutch drive. To do this, it is enough to place the car on a flat surface, it is advisable to have access to the gearbox housing from below (pit, overpass). Next, we check the operation of the system in this order:

- From inside, we check the free play of the clutch pedal. The nominal free play is from 0.4 to 2 mm. If adjustment is necessary, take a 10mm open-end wrench and loosen the lock nut of the limiter A in the photo below, setting the free play.

- We go down under the car and check the free play of the working cylinder pusher. Before doing this, it is advisable to apply WD-40 penetrating lubricant to it. To do this, press the pusher fork back with your fingers; the free play should be within 5 mm.

- To adjust the free stroke of the rod, use keys 13 and 17 to loosen the locknut.

- Using a 8mm wrench we hold the rod, and using a 17mm nut we achieve such a rod length that the free play is within 5mm.

- Tighten the locknut, go to the salon and check the free play of the pedal until the clutch disengages, which should be within 30 mm. If necessary, add brake fluid to the reservoir.

Features of the clutch mechanism

On cars of the classic series, a single-plate friction type clutch is installed. Unlike newer car models, the “classic” is equipped with a hydraulic drive, which includes the working and master cylinders. This design is more expensive, but more effective.

It’s just that there are many elements in it that can fail and immobilize the car. If problems occur, it is necessary to inspect and adjust the mechanism. You can complete all the work yourself in 20-30 minutes. Clutch adjustment can be done even without a lift or inspection hole; you only need a few keys.

How to remove the clutch master cylinder VAZ 2107 - 2101

During operation, rubber parts and the piston most often wear out, and after 200 thousand mileage it is necessary to carefully check the cylinder mirror.

VAZ master cylinder mirror with signs of wear

In order to remove the VAZ clutch master cylinder, you must first drain the brake fluid from the system. To do this, first of all, we put the hose on fitting 9 of the working cylinder (photo below), and lower the second end of the hose into a clean vessel.

Slave cylinder and clutch release fork: 1-clutch release bearing; 2-ball joint; 3-clutch release fork; 4-pusher; 5-adjusting nut; 6-lock nut; 7-tension spring; 8-body plug; 9-fitting for bleeding; 10-cylinder body; 11-o-ring; 12-wire cap; 13-piston; 14-seal; 15-plate; 16-spring; 17-support washer; 18 circlip

After this, unscrew fitting 9 half a turn and press the clutch pedal until all the liquid goes into the container. Screw in the fitting and remove the tube. If you need to remove the working cylinder (obvious leak, damage to the boot), remove spring 7, the cotter pin from the end of the pushers and unscrew the two mounting screws. To remove the master cylinder, simply disconnect it from the expansion tank and unscrew the two fastening nuts, as shown in the photo below. Remove the cylinder by unscrewing the hydraulic drive fitting.

How to repair the working cylinder of a classic “seven” clutch?

In certain cases, car enthusiasts prefer to independently purchase not only a clutch repair kit, but also spare parts for cylinder restoration on their own. This option allows you to save some money if you follow the following points:

- Clamp the part in a vice and unscrew the plug at the back.

- Remove the rubber cap.

- Remove the retaining ring from the plug side.

- Extract the internal elements of a node.

- Using a 10mm wrench, unscrew the bleeder fitting.

In order for the replacement of a repaired clutch slave cylinder on a VAZ 2107 to be of high quality, you need to:

- Inspect the condition of the spring and replace it if necessary.

- Replace all rubber seals.

- Inspect the node mirror.

- Clean the fitting.

Before assembly, all parts should be lubricated with brake fluid. You cannot use gasoline or diesel fuel, because the rubber will lose its quality. Change the gasket under the plug only if there are leaks. Having assembled and installed the unit, we finish the process by bleeding the system.

On cars, in addition to the master and slave brake cylinders, there are also clutch cylinders. Many do not even know the purpose of these devices, as a result of which the failure of one of the mechanisms forces the car owner to visit the nearest service station and pay decent money for minor repairs.

In this material we will pay attention to such a device as the VAZ 2107 clutch slave cylinder, what it is, where it is located and why it breaks

Repair of clutch master cylinder VAZ 2107

After dismantling the master cylinder, carefully wipe it from any remaining liquid and dirt and clamp it in a vice for disassembly.

First, let's estimate from the diagram which parts of the cylinder will need to be replaced.

Master cylinder parts: 1-body; 2-lock washer; 3-fitting; 4-gasket; 5-cap; 6-stop ring; 7-piston pusher; 8-o-ring; 9-piston of the main cylinder; 10-spring

First of all, after disassembly, we check the condition of the cylinder mirror. If the internal diameter is larger than the nominal 19.05 mm, there are obvious deep scratches and stepped wear on the mirror, repair does not make sense. You'll have to buy a new cylinder. If everything is fine with the mirror, we proceed to inspect the piston return spring. If it has lost its elasticity, we only change it. Next, using a standard repair kit, we replace all seals 8 and boot 5.

Complete repair kit for clutch master cylinder VAZ 2107

After replacing worn parts, we thoroughly rinse the entire cylinder and each part with fresh brake fluid, only then reassemble it according to the diagram.

Complete disassembly of the cylinder

To disassemble the master cylinder, you will need all of the above tools. In addition, a bench vise and rags will be needed.

- The cylinder removed from the car is thoroughly cleaned of dirt and brake fluid residues using a rag. After this, it is clamped in a vice so that the plug with the nut remains outside. This plug is unscrewed with a 24mm open-end wrench. Sometimes the plug sits in the socket so tightly that it is impossible to touch it with the wrench. In this case, it makes sense to put a piece of pipe on the key and use it as an additional lever.

Which clutch master cylinder is better to install on a VAZ 2107, articles and prices

To completely replace the VAZ 2107 - VAZ 2101 clutch master cylinder, analogues from other cars are not suitable. Fortunately, there are more than enough original cylinders and analogues on sale. As a rule, the public tries to choose a branded VAZ cylinder with catalog number 2101-1602610 . Other manufacturers also use this article, but when purchasing, it is better to start not so much from the price of the cylinder, but from the level of trust in the brand. A branded master cylinder will cost us 8-9 dollars and this is one of the most expensive options.

Next, you can choose from what is on the counter:

- The DK cylinder is half the price of the branded one, but often leaks due to poor-quality plug gaskets. As a temporary option, it will do.

- BAZALT , price about 200 hryvnia (about 7 dollars), Basalt and Phenox are highly not recommended due to the disgusting quality of mirror polishing.

- Excellent German Metelli , price approximately equal to the original one, factory article number 55-0014G .

- German ATE, HORT do not cause any complaints, the price is around 10 dollars.

- There are a lot of Chinese cylinders, like AT 2610-001H , the price is about 6 dollars, the quality is unstable.

Instability in China

Upon completion of the master cylinder repair work, fill in DOT4 brake fluid from any manufacturer and bleed the clutch drive in the same way as bleeding air from the brake system.