The procedure for bleeding the car's brakes serves to completely remove air from the system. During the operation of the car, we begin to notice that the brake pedal does not behave as usual when pressed. It becomes sluggish, that is, there is no clear emphasis on the pedal. It falls through, and sometimes even before it comes into contact with the policeman. And there is no braking. And in order to brake you have to press the pedal several times. There are several reasons for this behavior of the brake pedal.

How to remove air from the brake system

When repairing the brake system, the procedure for bleeding car brakes was followed. There is air left in the system. Typically, a sufficient number of rocking cycles have not been performed. And the air was not completely removed. Or the frequency of pumping the wheels has been disrupted. It is necessary to bleed the cylinders from the furthest one relative to the main brake cylinder. Each cylinder is pumped sequentially, gradually approaching the GTZ.

Perhaps the repair was not carried out efficiently and there is a brake fluid leak. At the point of leakage, air enters the system. The bleeder fitting is not tightened; the cuffs are damaged during assembly. One way or another, the system must be checked for leaks. There should be no brake fluid leakage. If everything is normal, then the system needs to be pumped again.

What needs to be done to maintain full functionality of the stopping system

A week later, or after completing a run of 500 km.

1. Checking tire pressure indicators.

2. Diagnostics of the level and condition of the working mixture in the brake system.

As you know, the mixture has an important role in the system. The use of low-quality or used fluid leads to premature wear of the components of the shutdown system.

3. Diagnosis of the sensitivity of the brake pedal and checking the smoothness of its movement.

4. Diagnostics of the performance of brake lights and warning lamps.

1. Diagnostics of front brake axle components.

2. Checking the tightness of the system conductors.

Every year or after completing 20,000 km.

1. Diagnostics of the rear brake axle.

2. Diagnostics of the brake pedal bracket and check of the working bushings.

3. Thorough diagnostics of the condition of the working fluid in the system. Replace brake fluid when used.

After two years or after completing a mileage of 50,000 km.

1. Forced replacement of the working mixture.

2. Diagnosis of GTZ. During the inspection, it is necessary to examine the system element for leaks and seal failures.

After five years or 120,000 km.

1. Repair of the GTZ, overhaul of calipers and wheel cylinders.

During the operation of the vehicle, it is also necessary to pay due attention to the condition of the discs and pads. Pads must be changed if the maximum permissible wear is exceeded

The level of permissible wear is indicated by the manufacturer of certain pads.

In this article we will take a closer look at one of the most important stages of brake system maintenance - replacing and bleeding the master cylinder. But, first, let’s get acquainted with the structure and operating principle of this element, as well as its purpose in a vehicle.

The main role of the GTZ in the vehicle system is the conversion of the energy placed by the motorist on the brake pedal.

Procedure for bleeding the brakes

The procedure for bleeding the brakes is based on: that the air is being forced out gradually. Starting from the circuit farthest from the GTZ. Press the brake pedal several times until it becomes elastic and press on it continuously. Then the assistant should unscrew the fitting on the working cylinder farthest from the GTZ. In this case, the liquid comes out of the fitting under pressure. The pedal should go all the way to the floor. It must be held pressed until an assistant tightens the bleeder fitting. It is most convenient to put a hose on the fitting, the other end of which is placed in a transparent container (glass) with brake fluid poured into it in order to see the air bubbles coming out of the hose. The cylinder must be pumped several times. Until air stops coming out.

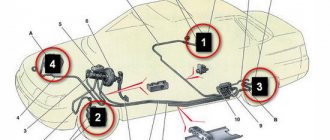

After which we tighten the fitting tightly and continue a similar procedure with the next cylinder located closer to the GTZ. As a rule, pumping begins from the rear right wheels (if the steering wheel is located on the left in the direction of travel of the car). Next we bleed the rear left wheel. Then the brake force regulator. It is located above the rear axle. Front right wheel then front left. If there are two brake cylinders on each side of the front axle. First, we bleed the farthest cylinder from the GTZ, usually the bottom one.

Components of GTZ.

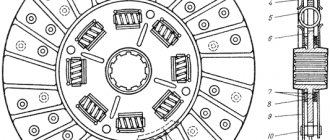

The main brake cylinder contains a cylindrical shell, inside of which there are two pistons. A specific piston is responsible for one functioning circuit. Each piston has a seal, which ensures correct interaction between the chambers and creates optimal pressure. Also, the separate piston is equipped with its own return spring. To install conductors, there is a special hole in the body of each cylinder. In addition, there is a special gap in the cylinder chamber that compensates for the pressure of the mixture.

How to bleed a brake system with ABS

Modern cars have an ABS system. The procedure for bleeding brakes with and without ABS is the same. The ABS hydraulic unit is sealed and air can also accumulate in it. And you can drive it out in the same way by pumping the working cylinders one by one. That is, the air in the hydraulic unit will escape through the fittings of the working cylinders. The ABS system is activated while the vehicle is moving. Depending on the signals received from the electromagnetic sensors, the electronic control unit controls the solenoid valves in the ABS hydraulic unit. The valves release the wheel blocking. If the wheel is blocked and starts to skid. When the ignition is turned off and the vehicle is not moving, the valves in the hydraulic unit are open and do not impede the passage of fluid.

How much does it cost to bleed the brakes?

The cost of bleeding brakes varies from service center to service station. For example, the average price for a VAZ 2109 is from 450 rubles. For approximately 900 - 1000 rubles, service engineers will replace the brake fluid and bleed the system. For other VAZ models the cost is approximately the same.

The price for foreign cars is slightly higher. You can find out exactly how much it costs to bleed the brakes on a car, for example a Skoda Octavia, only at a service center. On average, the service will cost from 800 to 1500 rubles. And if you have to use special equipment to pump the ABS unit, it will be even more expensive.

Violation of the tightness of the brake cylinders.

Air may enter the system through the O-rings or lip seal, depending on the design of the cylinders. The cuffs wear out through which the brake fluid begins to leak. In these places, air enters the system. As a rule, when the cylinder is worn out, simply replacing the rubber bands does not lead to anything. The entire cylinder needs to be replaced. In addition to the cuffs, pistons and cylinder liners wear out. And the fluid pressure that is generated by pressing the brake pedal, even if a new cuff is installed, passes by the piston due to the resulting ellipse, and the rubber cuff cannot cope with this pressure. Therefore, if fluid leaks from the cylinders, they must be completely replaced.

Basic faults

Failures in the master brake cylinder are practically excluded, and all malfunctions are associated with the passage of fluid through the seals:

- wear and aging of the sealing cuffs on the rod side, the liquid goes into the cavity of the vacuum booster or, in its absence, into the passenger compartment, onto the driver’s feet;

- similar malfunctions of the cuffs on the pistons, the cylinder begins to bypass one of the circuits, the pedal falls, braking worsens;

- jamming of the pistons due to corrosion of the pistons themselves and the cylinder bore, as well as loss of elasticity of the return springs;

- an increase in travel and a decrease in pedal stiffness when braking due to airing of the brake line.

For some cars, repair kits with pistons and cuffs are still preserved in spare parts catalogs. As well as recommendations for removing cylinder surface defects with sandpaper.

In practice, this activity does not make much sense; it is unlikely that it will be possible to noticeably extend the life of an exhausted turbocharger, and driving with an unreliable hydraulic brake cylinder, which is not for nothing called the main one, is unpleasant and dangerous. Therefore, in the vast majority of cases, the cylinder is replaced with a new assembly.

Problems when bleeding brakes

GTZ is not pumped

When pumping, some problems may arise, for example: You have completely removed the fluid from the system or replaced the GTZ with a new one. You start pumping, and the pedal moves without effort. And no matter how you try, the liquid from the tank does not flow into the cylinder. To avoid this, it is necessary to unscrew the tubes from the GTZ and allow the liquid to flow out of the cylinder randomly. But if the liquid does not flow out in this case, you need to screw the tubes back, press the pedal several times, unscrew at least one tube again, while keeping the brake pedal pressed. Tighten the tubes. This operation must be done several times in the same way as bleeding the brake wheel cylinders. To push through the air lock formed inside the GTZ. But this doesn’t always help. You can apply air pressure through the filler cap of the expansion tank using a compressor. At the same time, unscrew the fitting. After the liquid begins to flow out of the GTZ, you can begin the procedure for pumping the entire system as described above.

After bleeding the pedal from the second pumping.

Sometimes you have completely bled the system and are absolutely sure that there is no air in it. After a short period of time, you press the pedal and it falls through. The brakes appear after 2-3 pedal strokes. It's all about making brake discs or drums. Even if new pads are installed, the output is still large, and the cylinder stroke is greater than permissible. Therefore, replacement of discs and brake drums is already necessary here.

The same thing happens if the movement of the pistons in the working cylinders is difficult due to dirt and rust. Or some kind of pad jams for the same reason. That is, if at least one piston does not return from all working cylinders after releasing the brake pedal. The braking system will not work effectively. The pistons and pads should move easily. Therefore, when installing new working cylinders, you must check how the pistons move in it. And if movement is difficult, it means there is dirt or rust in the cylinders, despite the fact that the cylinders are new.

GTZ also presents a surprise. The liquid passes freely between the cuffs inside the cylinder. In this case, the cylinder works on its own and does not create pressure at the outlet. The reason for this may be either wear or damage to the cuffs or wear of the pistons and cylinder walls. GTZ has a higher cost in relation to working brake cylinders. Therefore, the problem can be solved by installing a repair kit. But as it turned out, it didn’t last long.

In general, the procedure for bleeding the brakes is the finishing work after what needs to be done when a malfunction occurs. If there is a need to bleed the brake system, you must definitely look for the reason why this or that malfunction of the brakes occurred.

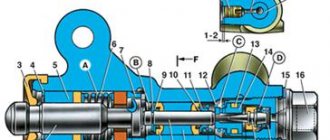

Procedure for replacing the GTZ.

On most modern cars, the master cylinder for the stopping system is located under the hood on the driver's side. The main cylinder is installed on the vacuum booster. If you own an earlier model of car, the master cylinder may be mounted directly on the car body, since the vacuum booster is simply missing. To a large extent, the process of replacing the brake master cylinder is similar. The main difference can only be noticeable in the method of fastening the various elements of the system.

1. For convenience of work, it is necessary to drive the car onto an inspection hole or overpass. After this, set the parking brake and open the hood. Next, you need to drain the entire working mixture from the system into a previously prepared container. If the working mixture has not become contaminated during the operation of the vehicle, it can be reused.

2. Unscrew the fasteners of the cylinder conductors. After this, it is necessary to release the remaining liquid from them.

3. The next step is to loosen the clamps of the hoses that come from the expansion tank with the working mixture. We remove the hoses and dismantle the tank.

4. Next, you can begin dismantling the cylinder itself. After this, the work surface must be thoroughly cleaned before installing the new brake cylinder. We install a working cylinder and reassemble the system in the reverse order.

5. After replacing the turbocharger, it is necessary to bleed it.

We pump up the GTZ with our own hands.

This procedure is extremely important when replacing the master cylinder of the system and will require a sufficient amount of effort and care. It is best to bleed the master brake cylinder with an assistant.

In addition to your partner, you need to stock up on the following set of tools and materials:

- 10mm wrench.

- Brake fluid.

At first glance, the procedure for bleeding the master cylinder may seem quite simple, but doing it yourself without the help of a trusted partner will be very problematic. Therefore, in order to successfully and efficiently complete the work, it is necessary to resort to the help of a partner who will benefit from experience in pumping the gas turbine engine.

Checking the wheels, handbrake and brakes while driving

Checking the wheels

When inspecting the wheels, know that they must be completely dry, both outside and inside. Inspect the inner surfaces of the wheels with special care using an inspection hole. The slightest presence of oily traces on the wheels will serve as an alarming signal that the working cylinder of the braking system is leaking.

Hand brake

When checking the brake system of a car, it would be unfair to forget about the handbrake, which is also part of this system and must be checked. A good, high-quality handbrake will not allow the car to roll back on a road slope of 23%. In this case, you need to count the number of clicks required during the process of raising the handbrake lever to lock the car in a stationary position. In the most ideal case, the handbrake operates in 3-4 clicks.

Brakes in motion

After visually checking the brakes, be sure to test the brakes while driving. To do this, accelerate the car on an open stretch of road to a speed of approximately 50-60 km/h and then sharply press the brake pedal

Important! Checking the brake system while driving can only be done after you have ensured that all its components are in good working order!

As for the size of the braking distance, it is different for each car and, as a rule, depends on the condition of the road surface, the tires, the weight of the car and many other reasons.

Note:

If the car has an ABS system, the braking process will be slightly different - when you press the pedal sharply, you will feel a feedback, which will manifest itself as a specific vibration. And if the car is equipped with an exchange rate stability system, then in this case, during sharp braking on the dashboard, an indicator will start working, informing about the operation of this system.

In conclusion, we note that the car’s braking system can be checked using a special diagnostic stand, which will provide objective information regarding the condition of the braking system.

Video about the operation of the car's braking system:

The braking system is necessary to quickly change speed or completely stop the car and hold it in place when parked. For this purpose, the car has such types of braking systems as - working, parking, spare and auxiliary systems (retarder).

If you have doubts about serviceability, you need to check them. After all, it will be regrettable if they really are faulty, and there will be a concrete slab in front or, worse, someone’s Lexus.

How to check disc brakes?

When checking disc brakes, as a rule, the thickness of the linings on the pads is measured first. If the steel base plate is visible, this tells us that it is necessary to replace the brake pads.

When checking disc brakes for serviceability, perform the following steps.

1)

. We jack up the car and remove the front wheel. In this case, you should also not forget about safety, that is, you should use wheel shoes.

2).

In front of you is a brake disc, also known as a rotor. We run our hands along both sides of the disk from the center to the edge. This way it will be possible to determine whether the brake disc is worn. If you feel uneven wear or the disc is heavily worn, you should contact a mechanic to determine whether the brake disc can be used further (after growth) or whether it will have to be replaced.

3)

. Next we check the brake caliper. Just remember, if the car has recently been driven, the caliper will be hot. But if not, then we wrap our hands around it and rock it from side to side, which will make sure that the mounting studs and eyes are in good working order.

4)

We also pay attention to the brake pads

In cases where the thickness of the brake pad linings is only 30 percent of the thickness of the linings on new ones, then we replace them with new ones.

5)

. Before replacing the pads with new ones, we recess the caliper pistons into the body so that the caliper can easily move from the brake disc. After this, unscrew one of the mounting bolts, move the caliper and replace the pads. We assemble in reverse order.

Brake fluid selection

In theory, even plain water will do - since, being a liquid, water cannot be compressed

However, it is important to remember that the main function of the braking system is to convert kinetic energy into thermal energy through friction. And the reality of this process is that some parts of the brake system will be exposed to very high temperatures

In fact, it is not uncommon for the rotor temperature to reach 600ºC while the vehicle is in motion, which can raise the temperature of the brake fluid to 150ºC. Since the boiling point of water is 100ºC, it is obvious that the water in the brake system can easily boil - and therefore release gases into the brake pipes - reducing the effectiveness of the system.

The "obvious" solution to this problem is to use a fluid that is less sensitive to extreme temperatures. Hence the development of “brake fluid”. However, unfortunately, there is no “ideal” brake fluid. And like most things in the world, adding certain useful features usually comes with trade-offs in other areas. With brake fluid, we typically must balance the fluid's sensitivity to temperature, its cost, and its effect on other components in the system.

Simply put, you can reduce the sensitivity of a liquid to temperature by varying its ingredients. However, certain combinations of ingredients can significantly increase the cost of the fluid and can react with original materials, damaging seals and causing corrosion of the entire brake system.