Purpose of the VAZ 2106 timing chain tensioner shoe

The tension shoe is designed to reduce the amplitude of timing chain vibrations when starting the engine. If these vibrations are not suppressed in a timely manner, the crankshaft and timing shaft, connected by the timing chain, will rotate in different phases. As a result, the synchronous operation of the cylinders will be disrupted. This, in turn, will lead to failures in engine operation and its inadequate response to pressing the accelerator pedal, as well as to a sharp increase in fuel consumption.

The surface of the VAZ 2106 tension shoe is covered with a durable polymer layer

Timing chain tensioning system for VAZ 2106

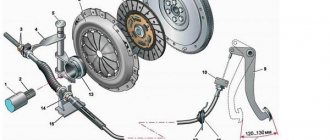

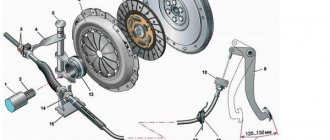

The timing chain tensioning system of the VAZ 2106 consists of three elements:

- timing chain tensioner shoe;

- tensioner oil fitting;

- timing chain damper.

The tensioner, fitting and chain guide are the main elements of the timing chain tensioning system.

Each of these elements has its own purpose.

- The timing chain tensioner shoe is a curved steel plate that periodically puts pressure on the timing chain and reduces the amplitude of its vibrations. The surface of the shoe in contact with the chain is coated with a particularly durable polymer material. This material is quite durable, but when it wears out, loud knocking noises from the chain beating against the cylinder block begin to be heard from under the hood.

- The tensioner oil fitting is the device that the shoe is attached to.

Because of this fitting, the shoe extends and puts pressure on the timing chain if it becomes loose, and retracts when the chain is tightened. A high pressure oil line with an oil pressure sensor is connected to the fitting. If the chain slackens when starting the engine, the sensor detects a decrease in pressure in the line. This reduction is compensated by the supply of an additional portion of oil, which puts pressure on the piston in the fitting. As a result, the shoe extends and dampens chain vibration. Oil tensioner shutters are reliable and durable: 1 - cap nut; 2 - body; 3 - rod; 4 — spring rings; 5 — plunger spring; 6 — washer; 7 - plunger; 8 — rod spring; 9 - cracker - The timing chain guide is a metal plate mounted in front of the tensioner shoe on the opposite side of the chain.

Its purpose is to dampen residual vibration of the timing chain after it is pressed by the tension shoe. It is due to the damper that the final stabilization of the chain and synchronous operation of the crankshaft and timing shaft are achieved. Without a damper it is impossible to completely dampen the vibration of the VAZ 2106 timing chain

Types of tension systems

- mechanical;

- hydraulic.

First, a mechanical system was developed in which the tension shoe was driven by the elastic force of a conventional spring. Since the springs with shoes pressed continuously on the chain, such a system quickly wore out.

The mechanical one has been replaced by a hydraulic calming system, which is used on the VAZ 2106. Here, the movement of the shoe is ensured by a special hydraulic fitting, into which oil is supplied as needed. Such a system lasts much longer, and the driver has noticeably fewer problems with its maintenance.

What do users recommend?

Car enthusiasts give different advice on how to improve or select a chain tensioner. Mercedes and other foreign cars from well-known manufacturers are often equipped with a timing chain drive. As a rule, the device for tensioning the chain in modern cars is designed to be automatically adjusted. This makes it easier to maintain and repair the unit, ensuring its reliable operation.

In addition, when replacing the tensioner, users recommend setting the rod of the new device to the minimum position. This makes it possible to pump the working chamber as much as possible, avoiding jamming and unnecessary noise. This, in turn, contributes to the correct adjustment of the degree of chain tension.

Characteristics of the VAZ 2106 chain drive

The function of the timing chain is based on the connection between the timing shaft and the crankshaft in the engine of the car. They are both equipped with sprockets with special teeth, due to which the chain is fixed. As soon as the engine starts, the above-mentioned shafts begin to rotate synchronously thanks to the presence of this chain. A violation of synchronicity against the background of any kind of circumstances provokes a malfunction in the functioning of the timing belt.

Malfunctions in the functioning of the cylinders are also possible, dips in engine power invariably form, fuel consumption increases significantly, and the vehicle itself does not respond well enough to activation of the gas pedal.

Classic VAZ cars are equipped with timing chains of the same length, the only difference is the number of links. As for model 2106, we are talking about a chain with 116 links with a length of 7.2 mm each. High quality alloy steel is used to make pins, which, thanks to this material, demonstrate increased wear resistance and strength.

Pros of the drive

Timing chain drive has been used for a very long time, but this does not mean that such a system is a relic of the past. Even today, due to its advantages, it is actively used by modern leaders in the automotive industry.

Among the advantages are:

- high resistance to any type of load;

- the ability to operate under conditions of noticeable temperature changes, as well as at extremely low or high temperatures;

- The operating life of the drive can reach 200 thousand km with proper operation.

Disadvantages of the drive

Along with the advantages, it is worth considering the disadvantages:

- the weight is significant, so the auxiliary elements of the mechanism must correspond to it in terms of quality;

- the noise during operation is quite noticeable, higher than that of other types of gears;

- replacing and tensioning a VAZ 2106 chain requires performing related procedures that inexperienced drivers may not be aware of;

- the forced use of compensating elements in the system significantly complicates the drive;

- the design is quite complex, which causes increased production costs; therefore, consumables and parts are relatively expensive.

The mentioned disadvantages cannot be called critical, since because of them there was no global refusal to use this mechanism. The classic VAZ auto industry to this day focuses on precisely this technology.

Wear level study

Visually, no driver will be able to distinguish an old chain from a new one, but there are two ways based on measurements and comparisons.

- Place a 20cm piece of old chain horizontally and turn it in your hand so that the pins are perpendicular to the floor. Examine the chain overhang angle. If the deviation of the hanging edge from the horizontal is 10-20 degrees, there is no cause for concern. If this parameter exceeds 45 degrees, replacing the chain is a mandatory measure.

- The second method can be considered more accurate, but its implementation requires a caliper. Select 18 pins or 8 links anywhere on the chain. Use a caliper to determine the length between the first and last element on the selected segment. Repeat the measurements two more times, but in other random areas. Exceeding the length by more than 122.6 mm in one of the areas you measured indicates that the chain needs to be replaced or tightened.

Is it possible to shorten a stretched chain?

Theoretically, such an operation is quite possible - it is enough to knock out the cotter pin of one or several links and reconnect the chain. Why such repairs are very rarely practiced:

- It is difficult to estimate the degree of elongation of the element and the number of links removed.

- There is a high probability that after the operation the marks will no longer align by 5-10 mm.

- A worn chain will definitely continue to stretch and will soon begin to rattle again.

- Worn gear teeth will allow the links to skip easily when the chain is pulled back out.

Economic feasibility plays an important role. A set of spare parts is not so expensive that you waste time and effort trying to repair the part by shortening it.

Replacing the timing chain drive will take an experienced technician approximately 2-3 hours. An ordinary car enthusiast will need twice as much time without taking into account unforeseen breakdowns. Set aside part of the weekend for repairs and do the work without rushing. Before starting the engine, do not forget to compare the marks and make sure that the mechanism is assembled correctly.

Required tools:

- keys from the standard set;

- universal pulley clamp;

- special key for “36”;

- empty, clean container for draining antifreeze.

Replacing the timing chain on a VAZ 2106 as well as a damper, tensioner shoe, and sprockets

- Remove the air filter housing from the carburetor.

How to replace the timing chain on a VAZ 2106 with your own hands

Unscrew 3 nuts with a 10 wrench, 4 nuts with an 8 wrench

All actions must be performed carefully so that nothing falls on the carburetor. If this is neglected, you will need to remove this unit, possibly the intake manifold

Do-it-yourself replacement of the timing chain on a VAZ 2106

- Remove the distributor cap and remove the pipe used to supply fuel.

- Using a “10” wrench, remove the 8 nuts securing the valve cover and remove the washers with plates.

- Disconnect the choke cable and throttle valve drive.

- Remove the valve cover with gasket (ideally it is better to replace it).

- Remove the protection from below, drain the antifreeze into the container that was prepared initially.

- Using a wrench set to “19”, loosen the generator mounting nut.

- Loosen the clamp of the lower water pump pipe and remove it.

How to replace the timing chain on a VAZ 2106, stabilizer, tensioner shoe, and sprockets on your own

- Turn off the power to the fan, as well as the power to the temperature sensor on the radiator.

- Remove the radiator with pipes and thermostat.

- Loosen the generator chain tensioner nut. Use a pry bar to move it forward.

Read more: Where is the cabin filter of the VAZ 2110 and how to change it: step-by-step instructions Replacing the timing chain on a VAZ 2106 with your own hands

- Disconnect the VAZ 2106 alternator belt.

- Using the “36” key, turn the crankshaft by the pulley until the marks of the cover and pulley, the sprocket and the casting in the camshaft bed coincide.

Timing chain VAZ 2106

Also check out

- Unscrew the “36” nut securing the crankshaft pulley. Use a special key to lock the pulley and unscrew it. If there is no special key, you need to engage fifth gear, depress the brake pedal, and unscrew it using the key.

Replacing the timing chain on a VAZ 2106, as well as a damper, tensioner shoe, and sprockets

- Remove the pulley. Unscrew 6 bolts and 3 nuts with a “10” wrench, then 3 more bolts of the camshaft drive cover, remove the cover.

We change the timing chain on a VAZ 2106 damper, tensioner shoe, and sprockets with our own hands

- Unscrew the 2 nuts securing the chain tensioner and remove it.

The photos show an automatic tensioner.

- Loosen the bolt that secures the camshaft sprocket, after which you can remove it. The position for centering is worth remembering, or better yet, marking.

In the photo you can see the result.

- A fuse to prevent the circuit from jumping.

- Fastening the timing chain tensioner shoe.

- Crankshaft sprocket.

- Using a “10” key, disconnect the fuse, the tensioner mount, and the bolt that secures the auxiliary drive sprocket.

- Remove the sprockets and old timing chain. The crankshaft key and the casting on the cylinder block must match.

- Install new sprockets, crankshaft and auxiliary units to the drive. Install a carefully lubricated new chain.

- To prevent the chain from falling down, you need to place some kind of tool under it. Changing the timing chain of a VAZ 2106 at home

- The sprocket is installed in the chain so that the descending branch of the chain is tensioned and all its marks coincide. Next you need to turn the camshaft from right to left and go back behind the crankshaft. Thanks to these actions, the chain is tensioned, and you can check the correct installation of the marks. If the marks do not match, you need to throw the chain over the tooth and then repeat the procedure.

- Return the tensioner to its place and activate it. Tighten all mounting bolts and secure them. Turn the crankshaft 2 turns, make sure that the marks match and that the valves and pistons do not collide.

- Lubricate the crankshaft cover gasket with sealant and install it in place.

- Place the pulley, make sure that the marks match, and tighten it.

- Unscrew the distributor nut to “13”, remove the distributor itself, turn the slider to the contact of the 4th cylinder.

- Return the distributor to its place.

- To complete the procedure for installing a new VAZ 2106 timing chain, be sure to turn on the ignition.

- Reassemble in reverse order and add antifreeze.

- At this point, the replacement of the timing chain on the VAZ 2106 can be considered complete.

Preparing to replace the drive chain

Before tensioning the chain on the VAZ-2106, it needs to be replaced. To carry out the work you will need the following tool:

- Open-end and ring wrenches for “10”, “13”, “17”.

- Ratchet key set to "38". With its help, the crankshaft rotates.

- Phillips and flathead screwdrivers.

- Mounting blade.

- Hammer.

- Ratchet and socket set.

Be sure to purchase a new chain and gasket for the cylinder head cover. But, as practice shows, reusing the gasket is possible; the tightness is broken only after it completely breaks.

Design and purpose of the camshaft

With all the variety of elements and associated systems of a car engine, the power plant is a rationally coordinated single mechanism. The engine of the “six” is represented by a four-stroke type “engine”, and the alternation of strokes is strictly regulated. This determines the purpose of the VAZ 2106 camshaft, the price of which is relatively high and amounts to 1000-1200 rubles, depending on the manufacturer. The classic camshaft of the VAZ 2106 is responsible for the sequence (established order) of the operation of the valve elements to open and close the product for the removal of gas products of combustion of the air-gasoline mixture and the operation of the intake fuel line.

The main working body of the camshaft is the cams, which, through the influence of other elements of the product, including the camshaft chain, “open” the valves at a given frequency. The camshaft chain itself interacts between the gear and the camshaft sprocket of the “six” by means of a chain transmission.

Each valve corresponds to a separate cam, which, when operated by the action of a pusher on the protruding segment, presses on the valve element, which causes it to rise, which is why, depending on the position of the element, either a fuel-air mixture enters the cylinder or exhaust gases are discharged. When the pusher is released from contact with the protruding element, the spring “slams” the valve element with its tensile force.

The VAZ 2106 camshaft support neck is used for mounting the product in a retracted position. The mating parts are hardened using high-frequency current and are lubricated during operation.

Symptoms of mechanism malfunction

The first signs that the engine chain tensioner or the chain itself is faulty are:

- A sudden stop in the vehicle's movement while the engine is running, and a significant increase in the speed of rotation of the crankshaft, with the same throttle position.

- Instant engine blocking (wedge), accompanied by a characteristic sound.

The causes of such breakdowns can also be factory defects, such as:

- A weak collet-type clamp that cannot lock the rod in one position, preventing the tensioner from working correctly.

- Deformed shape of one of the planes of the product.

- Damper spring faulty.

- Defective threaded connections of installation fasteners.

Video “Chain Knocking on a Classic”

This video examines the cause of engine knocking and demonstrates chain drive tension.

A VAZ 2107 timing chain tensioner is installed on the front right side of the car engine. The main purpose of such a mechanism is to tension the chain, which in turn is extended during operation.

Replacement work is not difficult and is completed within a short period of time. To replace the tensioner you must:

- Open the hood of the car and in the engine compartment, use a ten-point socket wrench to unscrew the two bolts securing the tensioner to the cylinder block and carefully remove it. A sealing gasket will be installed between the tensioner and the block. Check its condition and, if necessary, replace it with a new one.

- Having removed the tensioner body, we clamp it in a vice and use a thirteen key to unscrew the central cap nut, thereby checking the serviceability of the collet lock. If a crack is detected, it is necessary to replace the cap or the tensioner itself.

After checking the tensioner and if it needed to be replaced, you can begin installation. Before installing it, the tensioner must be charged; to do this, push the plunger all the way in and, holding it in this state, tighten the cap nut.

I tighten the cap nut, install the tensioner in its place and tighten the bolts that secure it. Then we turn the crankshaft one turn, thereby tightening the camshaft drive chain, after which we release the cap nut, releasing the tensioner, and tighten it again. At this point, the repair work to replace the timing chain tensioner of the VAZ 2107 is completed.

Sometimes a car enthusiast encounters extraneous sounds that come from the area of the front engine cover and resemble a kind of tapping. This may be a sign that the chain guide needs to be replaced. The damper on the VAZ 2107 model is necessary to soften the vibrations of the chain during its rotation. If you can clearly hear a clattering or metallic tapping sound, this means that the damper is very worn and needs to be urgently replaced. Another possible cause of the problem is that the chain tension is too loose. In this car model, the damper is located on the left, in front of the cylinder block. Use the diagram supplied with the machine to determine the exact location of the part to be replaced.

Replacing a chain guide on a VAZ 2107 is not a complicated procedure. Each driver will be able to carry out such an operation independently if he takes into account several important points. When replacing a part yourself, you need to proceed like this.

The long fastening bolt is installed at the top, and the short one at the bottom. If the bolts have a significant degree of wear, they need to be replaced, otherwise even after replacing the damper, the characteristic tapping sound may remain.

If the damper simply breaks into pieces while moving, you need to remove all its components. Sometimes this is quite difficult to do and you have to invent various devices to get the debris out. In such a situation, a magnet attached to the end of a long wire can help out. Place all the removed parts together to determine if there is anything left inside.

Replacing the tensioner

This element is necessary for tensioning the VAZ-2106 chain. Replacing it is very simple, just follow these steps:

- Remove the old tensioner; to do this, unscrew the two nuts that secure it.

- Unscrew the cap-type nut - this can be done conveniently using a vice.

- Clamp the tensioner in a vice and unscrew the nut. Inspect the collet located inside the nut.

- If this clamp has no defects, you can assemble the mechanism and “charge” it. To do this, you need to push the plunger inside the body, and then tighten the nut.

Let's consider a VAZ sprocket chain tensioner for a single-row chain

| On the left in the photo is a VAZ sprocket chain tensioner for a single-row chain. Installed instead of the factory one. Replacement is carried out independently or at any service station without modifications. Fits one to one instead of the original one |

| The VAZ sprocket chain tensioner for a single-row chain is shown in a top view. The tensioner sprocket is fixed in an all-metal housing. The case has high strength characteristics. Tests have shown high reliability and a high safety margin of the case |

| The VAZ sprocket chain tensioner for a single-row chain is shown on the bottom side. The location of the sprocket exactly corresponds to the center and any kind of inaccuracies are excluded. The Zvezda chain tensioner shoe has successfully passed a series of tests on dozens of cars. |

Let's consider a VAZ sprocket chain tensioner for a double-row chain

| On the left in the photo is a VAZ sprocket chain tensioner for a double-row chain. Installed instead of the factory one. Replacement is carried out independently or at any service station without modifications. Fits one to one instead of the original one |

| VAZ star chain tensioner for a double-row chain, top view shown. The tensioner sprocket is fixed in an all-metal housing. The case has high strength characteristics. |

| The VAZ sprocket chain tensioner for a double-row chain is shown on the bottom side. The location of the sprocket exactly corresponds to the center and any kind of inaccuracies are excluded. |

How much does the Zvezda chain tensioner shoe cost?

To provide a 1 year unlimited mileage warranty on the part, only high quality parts are used. In terms of price-quality ratio, there is a clear loss in the price of the product. The price of the Zvezda tensioner is lower than its quality. You are buying a quality part with a guarantee!

| Price 810 UAH. ONLY TO ORDER!!! The cost in other currencies will be shown when you click the “PLACE ORDER” button | Price 700 UAH. The cost in other currencies will be shown when you click the “PLACE ORDER” button |

| We provide a 12 month guarantee!!! If within 12 months any problem arises with the chain tensioner shoe, then under the terms of the warranty we undertake to replace the tensioner with a new one, and you send yours back to us. The warranty is valid without mileage limitation! If within 15 days from the moment you receive the goods in your hands, for any reason you remain dissatisfied with them and want to return your money for the goods back, then you can send the goods back to the warehouse in our city, and we We will return the money you paid for the product, minus the cost of delivery. In this case, it is necessary that the goods remain undamaged and then we are ready to accept the goods back and return you the paid price for the goods (minus delivery costs) |

Chain tensioner shoe “Zvezda”, payment - delivery!

You can order the “Star chain tensioner shoe” directly on our website. To do this, click on the button

order - and in a short time you will be able to receive a chain tensioner shoe.

Delivery throughout Ukraine is carried out from our warehouse using fast delivery services: “Novaya Poshta”, “Intime”, “Ukrposhta” - at your choice. We will send to the warehouse

selected delivery service - in your city.

Delivery to other countries is carried out using the state postal service “Ukrposhta”. Your order will arrive at the nearest government post office in your city.

Shipping on all days of the week, except weekends and holidays!

Delivery time in Ukraine

– usually ranges from 1 to 3 days

from the moment of dispatch, depends on the city/warehouse.

Delivery time to other countries

averages from 12 to 20 days, depending on the distance.

You can pay for the goods either in advance (before shipping) using one of the methods, or place an order by cash on delivery

(payment upon receipt). (Cash on delivery only in Ukraine.) Shipping to other countries is made upon prepayment!

If you choose cash on delivery, then you can place an order without paying anything and we will send you the goods. At the delivery service warehouse you will be able to pre -inspect the goods

- and if everything suits you, you transfer the amount to send to us and pick up the goods. If the product does not suit you, you are not obliged to pay for it, the product will be returned to us.

For all questions of delivery and payment, we are always ready to advise you by phone and Skype during business hours.

*"Delivery is carried out at postal service rates and is paid upon receipt of the goods. In most cases, this amount is from 20 to 40 UAH.”

Please tell your friends on social networks

Symptoms of loose chain tension

In principle, the symptoms are quite specific, and it is very, very difficult to confuse them with something else.

- Increased engine noise, even at idle speed;

- Instant increase in noise during a sharp increase in speed;

- The roar increases proportionally with a smooth increase in speed, and decreases gradually with a sharp release of the gas pedal;

- Most often, a loose VAZ 2107 chain rattles because the damper has broken and needs to be replaced.

However, let’s say that this is not the case, and we just need some tension. To work, we will need a special key to turn the crankshaft; on carburetor cars, you can turn it using a ratchet.

Briefly about the main thing

The technology for setting timing marks on a VAZ 2106 engine is performed with the chain removed. A sprocket mounted on the camshaft without a chain is fixed with a screwdriver and tightened with a wrench. After rotating the camshaft in the desired direction and combining the drilling with the boss on the bed, the gear is again immobilized with a suitable object and dismantled. Next, the new chain is installed.

Perfect alignment of the marks can only be achieved by using a split gear. However, this is not at all necessary to comply with. It is quite possible that the camshaft marks coincide and the crankshaft pulley moves a little forward.

We set the ignition by ear

As mentioned above, the best way to set the ignition is only with the help of a strobe light. But you still need to somehow get to the service station.

For such cases, a quick method of setting the ignition “by ear” is perfect:

- First, loosen the ignition distributor mounting nut.

- After warming up the internal combustion engine and without turning it off, rotate the distributor housing alternately in both directions.

- The speed should be approximately 2000 rpm.

- Listen to the engine. The best position is when the maximum possible number of revolutions is produced with smooth operation of the power unit without failures.

- Once this position is found, you can tighten the fastener.