A classic of the genre, VAZ 2106 '97. This is the second time the timing chain has been replaced on this car in a month, since the first time the client brought an “original VAZ” chain produced in a nearby basement. A month later it stretched and hello again. But we have all been praising the quality of our spare parts for a long time, so we had to consult with experts in the car market and choose the chain that received the least number of complaints. Operation will show!

In addition to the timing chain, we will change the air filter, the alternator belt, the tensioner shoe, the damper and all the sprockets, so the song goes away.

The client went on foot to get the tensioner, damper and alternator belt, since he did not immediately take care of the purchase.

Design of the VAZ 2106, 2107 chain drive

To drive the VAZ 2106/2107 with a carburetor, a double-row roller chain is used. It transmits force from a sprocket mounted on the crankshaft to another sprocket mounted on the end of the camshaft. The chain is a structure that develops large inertia, so a chain drive requires vibration damping. Even if the chain is well tensioned, it retains the property of “playing” in those places where there are no sprockets or tensioners.

The chain has virtually zero ability to stretch and compress, and fairly limited flexibility. Therefore, in order to provide it with constant tension while working in its place at any speed, it has to be literally shackled, using a system of tensioners and dampers.

This problem on the VAZ 2106/2107 is solved by a damper - an additional spring-loaded clamping bar. It has a steel frame covered with a layer of durable rubber. Tensioners and dampers dampen vibration and noise quite effectively . The chain is prevented from falling off by a stop pin that is screwed into the block or cylinder head. During normal operation the chain does not touch it.

Design and purpose of the camshaft

With all the variety of elements and associated systems of a car engine, the power plant is a rationally coordinated single mechanism. The engine of the “six” is represented by a four-stroke type “engine”, and the alternation of strokes is strictly regulated. This determines the purpose of the VAZ 2106 camshaft, the price of which is relatively high and amounts to 1000-1200 rubles, depending on the manufacturer. The classic camshaft of the VAZ 2106 is responsible for the sequence (established order) of the operation of the valve elements to open and close the product for the removal of gas products of combustion of the air-gasoline mixture and the operation of the intake fuel line.

The main working body of the camshaft is the cams, which, through the influence of other elements of the product, including the camshaft chain, “open” the valves at a given frequency. The camshaft chain itself interacts between the gear and the camshaft sprocket of the “six” by means of a chain transmission.

Each valve corresponds to a separate cam, which, when operated by the action of a pusher on the protruding segment, presses on the valve element, which causes it to rise, which is why, depending on the position of the element, either a fuel-air mixture enters the cylinder or exhaust gases are discharged. When the pusher is released from contact with the protruding element, the spring “slams” the valve element with its tensile force.

The VAZ 2106 camshaft support neck is used for mounting the product in a retracted position. The mating parts are hardened using high-frequency current and are lubricated during operation.

Reasons for replacing the timing chain drive on a VAZ 2106, 2107

The performance and durability of the timing chain drive depends on the material and quality of heat treatment of the chain and sprockets themselves. Manufacturing accuracy and cleanliness of working surfaces are of great importance. A broken circuit is a rare occurrence. The deterioration of its condition can be monitored by increased noise when the engine is running.

For engines 2101 and 21011, where the block is lower, the number of chain links is 114, and for 2103/2106 the number of links is 116.

A method on how to replace the timing chain on a VAZ 2106 may be required when its critical wear has occurred, its resource has been exhausted, and tightening it with all sorts of “cunning” methods no longer gives results. These methods include:

- increasing the length of the working part of the tensioner by pressing on a piece of tube of a suitable diameter;

- “addition” of an additional bracket to the shoe and other “bullying” of the engine.

An extended timing chain no longer ensures accurate valve timing, which negatively affects engine performance. In addition, she wears out the shoe and constantly “beats the head off” the pacifier. In addition, engine noise increases, fuel consumption increases and engine starting becomes worse. It is also worth saying that the chain sometimes breaks with all that it entails.

To remove the timing chain, you do not need to remove the crankshaft sprocket!

For work we will need: keys “10”, “13”, “17”, a special wrench for the crankshaft pulley nut (or a head “36”), a screwdriver, a mounting blade, a hammer, and a bit.

After removing the sprocket, do not turn the drive shaft, because this may disrupt the initial ignition setting!

When to change the timing chain

The chain drive on VAZ family engines has a longer service life. The life of the chain ranges from 100 to 200 thousand kilometers .

If high-quality materials were used in the manufacture of components, and proper tension and abundant lubrication of the drive were ensured during operation, then the chain will last no less than the engine itself.

The optimal frequency for changing is every 200 thousand km.

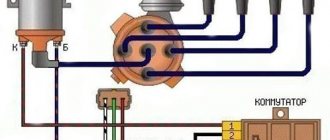

We set the ignition by ear

As mentioned above, the best way to set the ignition is only with the help of a strobe light. But you still need to somehow get to the service station.

For such cases, a quick method of setting the ignition “by ear” is perfect:

- First, loosen the ignition distributor mounting nut.

- After warming up the internal combustion engine and without turning it off, rotate the distributor housing alternately in both directions.

- The speed should be approximately 2000 rpm.

- Listen to the engine. The best position is when the maximum possible number of revolutions is produced with smooth operation of the power unit without failures.

- Once this position is found, you can tighten the fastener.

Which timing chain and tensioner should I install on the VAZ 2106, VAZ 2107?

timing chain number is 2103-1006040, the average price is 380 rubles.

Analogues:

- Fenox PC2103C3 — 519 rub.

- Kraft KT 017736 — 620 rub.

The original number of the timing chain tensioner is 2101-1006060, the average price is 364 rubles.

Analogues:

- TSN 671 — 254 rub.

- Riginal RG2101-1006060 — 230 rub.

- Trialli MT 151 — 407 rub.

Prices are current for 2022, although the cost has not changed much in three years.

Article: 2101-1006020-86, additional articles: 21010100602086, 2101-1006020

Order code: 000891

- Buy with this product

- show more

- Buy analogues

- Passenger cars / VAZ / VAZ-21012 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/privod_raspredelitelnogo_vala-82/#part1933″>Camshaft sprocketEngine / Camshaft drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/privod_raspredelitelnogo_vala-82/#part1934″>Crankshaft sprocketEngine / Camshaft drive

- Passenger cars / VAZ / VAZ-21032 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/privod_raspredelitelnogo_vala-57/#part10227″>Camshaft sprocketEngine / Camshaft drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/privod_raspredelitelnogo_vala-57/#part10226″>Crankshaft sprocketEngine / Camshaft drive

- Passenger cars / VAZ / VAZ-21052 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/privod_raspredelitelnogo_vala-62/#part16779″>Camshaft sprocketEngine / Camshaft drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/privod_raspredelitelnogo_vala-62/#part16778″>Crankshaft sprocketEngine / Camshaft drive

- Passenger cars / VAZ / VAZ-21072 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/privod_raspredelitelnogo_vala-70/#part23371″>Camshaft sprocketEngine / Camshaft drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/privod_raspredelitelnogo_vala-70/#part23370″>Crankshaft sprocketEngine / Camshaft drive

- Passenger cars / VAZ / VAZ-21213 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/privod_raspredelitelnogo_vala-50/#part10001118″>Camshaft sprocketEngine / Camshaft drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/karter_maslyanyiy_i_kryshki_bloka-47/#part58462″>Camshaft sprocket Engine / Oil crankcase and block covers

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/privod_raspredelitelnogo_vala-50/#part58539″>Crankshaft sprocketEngine / Camshaft drive

- Passenger cars / VAZ / VAZ-212132 drawings

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/privod_raspredelitelnogo_vala-58/#part2009057″>Crankshaft sprocketEngine / Camshaft drive

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/privod_raspredelitelnogo_vala-58/#part2009059″>Camshaft sprocketEngine / Camshaft drive

- Passenger cars / AZLK / Moskvich-21412 drawing

- » href=»/catalog/azlk-9/legkovye_avtomobili-30/moskvich_2141-53/kolenchatyiy_val__vkladyshi_korennyh_podshipnikov_i_mahovik-62/#part148679″>Shaft sprocketEngine mod. 2106 / Crankshaft, main bearing shells and flywheel

- » href=»/catalog/azlk-9/legkovye_avtomobili-30/moskvich_2141-53/privod_raspredelitelnogo_vala-63/#part148701″>Camshaft sprocketEngine mod. 2106 / Camshaft drive

- Passenger cars / IZH / IZH 2126 with VAZ3 engine drawing

- » href=»/catalog/ij-7/legkovye_avtomobili-30/ij_2126_s_dvigatelem_vaz-307/privod_raspredelitelnogo_vala-13/#part945909″>Crankshaft sprocketEngine / Camshaft drive

- » href=»/catalog/ij-7/legkovye_avtomobili-30/ij_2126_s_dvigatelem_vaz-307/privod_maslyanogo_nasosa-34/#part946279″>Camshaft sprocketEngine / Oil pump drive

- » href=»/catalog/ij-7/legkovye_avtomobili-30/ij_2126_s_dvigatelem_vaz-307/privod_raspredelitelnogo_vala-13/#part945910″>Camshaft sprocketEngine / Camshaft drive

- Passenger cars / IZH / IZH 27173 drawings

Replacing the VAZ 2106 timing chain without disassembling

Replacing the timing chain without disassembling

There is a simple way to replace the timing chain of a VAZ 2106 without removing the front cover. To do this, you only need to remove the valve covers and prepare a new chain.

The principle of how to change the timing chain on a VAZ 2106 is as follows: you need to disconnect one link of the old chain, as well as one link of the new one. After this, the edges of the old and new chains must be connected by making a corresponding mark at the junction with chalk or a corrector. Then you need to take the second end of the old chain and pull it out of the mechanism, while the new chain will gradually be put on the sprockets.

When the old chain comes out completely, it must be disconnected from the new one, and carefully rivet the links of the replaced chain.

How to change the timing chain on a VAZ 2107 with an injector

Replacing the timing chain on a VAZ 2107 injector is carried out according to the same principle as on a Zhiguli 2106. Moreover, you can install a new element either in the standard way by removing the front cover, or in a simpler way.

Checking the timing chain quality

Before changing the timing chain on a VAZ-2107, you should decide on the manufacturer and quality of the chain.

The reliability of a new product can be roughly checked by taking the chain by one end and lifting it horizontally. Holding the chain edge up, its second end will bend down slightly - the smoother this bend is, the stronger and more reliable the product!

Prepare the necessary keys and be sure to put proofreader or chalk somewhere nearby.

Briefly about the main thing

The technology for setting timing marks on a VAZ 2106 engine is performed with the chain removed. A sprocket mounted on the camshaft without a chain is fixed with a screwdriver and tightened with a wrench. After rotating the camshaft in the desired direction and combining the drilling with the boss on the bed, the gear is again immobilized with a suitable object and dismantled. Next, the new chain is installed.

Perfect alignment of the marks can only be achieved by using a split gear. However, this is not at all necessary to comply with. It is quite possible that the camshaft marks coincide and the crankshaft pulley moves a little forward.