- home

- Suspension

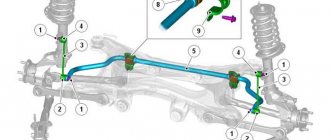

- Replacing the anti-roll bar and its bushings

06.10.2021

Today I will show you how easy it is to replace the anti-roll bar on a VAZ 2110 and why I decided to do it. At the same time, we will change the rubber bushings, since cracks have appeared on them. How easily any car owner can do this out of a hole on their own, I will tell you every step.

Advertising:

Purpose, design and principles of operation of the VAZ 2107 stabilizer

It has already been written above that the SPU is one of the important parts of the car. But why? The answer is simple - thanks to it, driving improves significantly, becoming more comfortable. This device makes it possible to keep the chassis tilt under control without increasing the pressure on the camber of the rear wheels.

The increased control over the vehicle on sharp turns is especially noticeable.

Thanks to the stabilizer, it will be possible to enter such turns at higher speeds without the risk of capsizing.

The roll bar SPU looks like a C-shaped hose that is installed next to the axle. The stabilizer is mounted on brackets with rubber bushings inside.

It is worth noting that the VAZ 2107 stabilizer bushing is the weakest point in the design and breaks most often.

The stabilizer works on the principle of distributing the load between two suspensions.

It works relatively simply - when making a sharp turn, the car can roll. Stabilizer, since one wheel lowers and the other, accordingly, rises. The stabilizer prevents this from happening by twisting the rod and raising the lowered wheel and lowering the raised one. Thanks to this, the car is leveled.

Why did I decide to replace the stabilizer?

When diagnosing the suspension of my car, it was discovered that the stabilizer struts had a lot of play on the stabilizer. Perhaps there is wear on the metal, we'll see after it's removed from the car.

In addition, cracks appeared on the rubber bushings, although they did not start to loosen, and there were no suspicious knocking noises. But since it got under the car, we’ll change them for prevention.

To Contents...

Advertising:

Diagnostics

A breakdown can occur for a variety of reasons, so it is impossible to determine the exact time of full operation without breakdowns. Basically it all depends on the operating conditions. For example, if you often drive off-road, the stabilizer will break down often.

Basically, the SPU is checked during annual maintenance, but no one bothers you to do it yourself at any time.

First you need to remove the wheel. After this, use the steering wheel to make a maximum turn in any direction and shake the “bare” stand from side to side with your hand, grasping the middle third. If there are faults, looseness will be noticeable.

Signs of a broken rear stabilizer

The most common signs of failure are:

- Vehicle roll during sharp maneuvers, instability;

- The car begins to sway, as soon as you turn the steering wheel a little to the side;

- If you drive on an uneven road, you will hear a sound from the suspension;

- The car begins to “yaw” when braking;

- If you lower the steering wheel, the car will start to swerve.

How should the stabilizer be positioned?

A correctly installed SPU should twist when the wheels turn.

Therefore, on passenger cars it is strictly forbidden to weld to the frame, since there must always be an intermediate link between it and the wheel. For example, in the VAZ 2107 bushings act as such a link. It is not recommended to use a stabilizer without them.

Causes of creaking stabilizer bushings

Drivers most often complain about bushings creaking either in cold or dry weather. But these are not the main factors and each driver may have his own reasons for this problem. They are individual for everyone. Main reasons:

- The material from which the bushings were made is of poor quality;

- When it freezes, the rubber from which the bushings are made becomes harder and loses its elasticity, which is why squeaks are heard;

- The bushing has simply worn out and can no longer fulfill its direct duties;

- Due to the design features of the car.

Before replacing the anti-roll bar, you need to figure out what the problem is. Most often you just need to replace the rubber bands.

Why does the stabilizer bushing squeeze out?

In fact, the bushing is quite gentle to use. It can wear out pretty quickly. This mainly happens in winter. In cold weather, the bushing freezes, which can cause cracks to appear on it. Various reagents that are used to sprinkle roads during icy conditions can also play a role in this.

If the driver did not notice the problem in time, the cracks continue to grow. Because of this, the bushing begins to lose its elasticity. And so, at the next turn, it can simply be squeezed out of the eyelet. It is no longer possible to return it back - it is too worn out and will not be able to perform its direct functions.

After this, when entering a turn, the motorist may hear a creaking and grinding sound. The vehicle's handling will also decrease.

About double stabilizers

As the name suggests, there are two rods in this stabilizer. But such a device is installed only on the front wheels. Basically there are no fundamental differences.

Thanks to this SPU device, the stiffness of the suspension will increase significantly, which on the one hand is good, but on the other hand, some problems may arise. The fact is that on the classic VAZ 2107 the two front wheels operate independently of each other - that is, if the left front wheel lifts, the right one does not. But due to the installation of a double stabilizer, everything will change - the suspension will become semi-independent and the steering will become much stiffer, and the traction will become worse.

Therefore, before purchasing and installing a double SPU, you need to think carefully - either comfortable driving and good cross-country ability, or no roll.

The process of removing the starter and installing a new element

Starter removal process:

- Place the car on the inspection pit. If this is not possible, use an overpass or just a good jack.

- Lift one side, remove the wheel, remove the boot or crankcase guard (if equipped).

- The next step is to unscrew the top nut that secures the starter. This can be done both from the engine compartment and from under the car - whatever is convenient. Additionally, unscrew the nut that secures the terminal to the solenoid relay. Remove it so it doesn't interfere.

- Disconnect the nearby wire going to the starter.

- The final step is to unscrew the nut, which secures the part from below.

- Now you can pull the element out of the clutch housing.

Checking starter malfunction:

- Take a flathead screwdriver and try to move the coupling forward/backward along the shaft. It should spin easily and not hit anything.

- Use a screwdriver to turn the gear. If everything is spinning in the same direction, everything is fine. If the scrolling goes in the opposite direction, the part will need repair.

- Checking the retractor relay is carried out using two wires with “crocodiles” for convenience. Place the red one on the positive terminal of the battery, and place the other end on the control terminal of the relay. Use the negative conductor to connect the negative battery and the starter housing. After such actions, a click will appear and the clutch will come forward. After disconnecting the wires, the coupling will return.

- The final stage of the test is to disconnect the wire from the control terminal of the traction relay. Connect the crocodile clips in exactly the same way. When voltage is applied, the starter armature should spin at a frequency of more than 5 thousand revolutions per minute. If everything is so, the element is working.

Installing a new starter is carried out in the reverse order of removal. If you do not want to completely change the part in question, but want to repair it, then we recommend that you familiarize yourself with the relevant information. We do not recommend that you do everything yourself without knowledge of the entire process. In this case, it is better to contact a service station.

To summarize, we note that the starter on the VAZ-2110, as on other cars, is a very important unit, the failure of which is a rather unpleasant situation. In the article we examined the main points for dismantling the old part and installing a new element. Carrying out the work should not cause any difficulties. It is enough to use the recommendations from the article to successfully repair your car.

Benefits of timely replacement

Replacing bushings is a simple process that any driver can handle. As they say - “if there is a desire.” If it is not there, it is better to contact a car service center, where you will be provided with professional assistance.

Thanks to the timely replacement of worn bushings, the anti-roll bar of the VAZ 2107 can last longer.

Thanks to the new bushings, driving on roads, regardless of whether they are of high quality or not, will become much more comfortable and safer.

Solution

Many beginners may experience problems or difficulties when replacing bushings. This section of the article will help you solve them.

When to replace transverse stabilizer bushings

SPU bushings are replaced immediately after wear is detected. If this is not done and you continue to drive with worn bushings, then irreparable problems may soon appear and then you will have to replace the stabilizer completely.

Installation materials and tools

In order to successfully change rubber bands you will need:

- A set of new bushings for the rear stabilizer;

- Set of open-end wrenches;

- Flathead screwdriver and hammer;

- Composition WD40;

- Mounting blade.

Sequence of operations for replacing rear stabilizer bushings on a VAZ 2107

Having prepared everything you need, you can begin the repair:

- After the car is placed in the pit, you need to inspect the fastenings. Usually, due to long-term use, a layer of dirt and rust could appear on them. To eliminate these unpleasant consequences, you need to treat the compounds with WD 40. After that, all you have to do is wait about fifteen minutes. During this time, dirt and rust should dissolve and work can continue.

- The nuts must be unscrewed with a 17mm open-end wrench.

- In order to loosen the stabilizer bar with the clamp, you will have to use a mounting blade. Having inserted it into a narrow hole, you need to use the lever principle and bend the clamp.

- After this you need to get rid of the old gum. This can be done with a knife.

- The place where the new bushing will be installed must be cleaned of dirt and rust. After this, you can install a new rubber band, having first lubricated its inside with grease (it should be sold with the kit). Now you need to put it on the rod and move it along it to the installation site.

- After the fifth step is completed, you need to tighten the nut on the clamp.

- Then all that remains is to replace all the other bushings according to the instructions above. Afterwards, you need to evaluate the quality of the work performed - if the stabilizer is not warped and no play is detected, then the replacement was carried out correctly. You can drive.

Chassis features

The rear axle of Renault Logan does not provide for the presence of struts, since the design is based on a continuous beam. Initially, this node is able to do without the presence of the elements in question. Vibrations in the vertical plane are very insignificant, and the body is protected from lateral rolls by a horizontal rod fixed on the axis.

If you touch the front chassis, its design includes a transverse stabilizer bar. The manufacturer states that the absence of this element cannot have a negative impact on reducing the level of safety while driving. But practice shows: the presence of this part will not interfere with the confident behavior of the Renault Logan car.

Video of replacing stabilizer bushings on a VAZ 2107. Useful video:

Let's summarize - the stabilizer for the classic VAZ 2107 is an extremely controversial tuning element. On the one hand, it increases the stability of the car, but on the other hand, it reduces cross-country ability and driving comfort. However, it has one undoubted advantage - ease of maintenance. Even a novice car enthusiast can cope with this. After all, the only part of the SPU that is subject to rapid wear is the bushings, replacing which will not be a problem for a person who has at least once held a wrench with a mounting blade in his hands.