Consequences of ignoring a fault

Ignoring the lubrication of crosspieces can lead to the most disastrous consequences, including complete failure of the spare part and breakdown of your car. In this case, you risk not only your life, but also the lives of passengers.

If you do not carry out the procedure, you risk facing the following consequences:

Vehicle vibrations. Worn seals or bushings can cause the driveshaft to vibrate. Failure to properly lubricate spiders, joints, or bushings may result in further damage to other transmission components.

Note that tire problems can also cause vibration problems, but they are easy to tell apart. Vibrations caused by tire balance problems are speed sensitive, but driveshaft vibrations are not. Difficulty turning

If you are having trouble turning, it may be due to a problem with the driveshaft. A faulty driveshaft can prevent your wheels from turning correctly, making your vehicle difficult to control. Loud noise. If you hear a loud noise when your car shifts gears, this is another sign of driveshaft damage. The likely culprit is worn crosspieces. The car shudders when accelerating. If you experience a shudder when accelerating from a stop or at low speeds, a loose weld or a bad center bearing may be to blame. Creaking noise. An annoying squeaking sound at low speeds can be caused by a lack of lubrication on the spiders. The lubrication procedure will get rid of it. Clicking or knocking sound. May indicate a worn or faulty driveshaft. Contact your mechanic.

Symptoms of a problem

Wear on the crosspiece manifests itself in the form of knocking when the car starts and vibration when driving. However, such signs are also typical for some other transmission malfunctions. To check the condition of a part, you must:

If there is play in the needle bearings, the cross joint must be replaced. You can do this yourself.

Important: untimely replacement of the cross joint can lead to accelerated wear of bridge parts due to vibration.

Necessary tool

So, you have established that it is necessary to lubricate the cardan cross once again. It is worth considering that this work cannot be done without a special tool, so you will have to prepare for the process in advance.

First of all, purchase a special syringe for lubricating cardan shafts; it is inexpensive and will last quite a long time. For this work, a lever-plunger type syringe is used. Please note that different models have different holes for lubricant supply, oil seals or nipples may be used, so check this nuance and purchase the appropriate nozzle.

Another point is the choice of lubricant

. Here it is worth familiarizing yourself with the manufacturer's recommendations. In many cases, modern cars use a specialized lubricant that is designed for a specific brand. The result of mixing it with other types of lubricant is quite difficult to predict. Therefore, if the manufacturer accurately indicated a specific brand of grease, it is better to use that particular one. If there are no clarifications on this matter, then you can use any option designed for such an application.

How and when to inject the driveshaft crosspiece: instructions

Grouting the driveshaft spider is a fairly simple job that must be performed regularly to maintain the transmission in working condition. However, many drivers decide to seek such work at a service station, when it is quite possible to do it themselves. The main thing that is required to perform this kind of work is to have the necessary tools and choose the right way to inject the cardan crosspieces with it. In this article we will consider this issue.

1. What is a cardan shaft 2. When to inject a cardan shaft crosspiece 3. How to inject a cardan shaft crosspiece 4. How to inject a cardan shaft crosspiece

The job of the driveshaft is to transfer force from the vehicle's gearbox to the axle. Most often it consists of two or three elements interconnected by a cross. The crosspiece is a hinge joint that provides reliable fastening between units with minimal wear during operation of the mating elements.

In order for the crosspiece to fully cope with its functions and not lose efficiency, it needs constant lubrication. When the car leaves the factory, the crosspiece is tightly packed with lubricant, which should be enough for a long time of operation of the mechanism, but at a certain time it runs out and needs to be replenished.

Adding lubricant to the crosspiece is quite simple, and this can be done without removing the driveshaft through the technological hole. Depending on the car model, its location may differ.

Important: The driveshaft crosspiece is almost always exposed to sand, dirt and other harmful factors. If it is used in such conditions without lubrication, it will quickly become unusable, so you need to correct the situation immediately after identifying the problem of lack or a small amount of lubrication

When to inject a universal joint on a driveshaft

The list of scheduled vehicle maintenance work should indicate the frequency of injection of the driveshaft crosspiece as recommended by the vehicle manufacturer. On average, the lubricant component must be updated every 10-15 thousand kilometers of the vehicle.

Important: When operating a vehicle in difficult conditions, the service life of 10-15 thousand kilometers is significantly reduced. For example, if we are talking about constant off-road driving, you need to take care of lubricating the crosspiece much more often

There are several symptoms that indicate that the driveshaft crosspiece needs to be injected:

- When the car moves from a standstill, a noise similar to crunching or tapping is heard in the area of the driveshaft;

- At high speeds (above 60 kilometers per hour), the vibration of the car and the “shaking” of the cardan are clearly noticeable.

If the above symptoms are observed on the car, you need to inject the driveshaft crosspiece as soon as possible.

How to inject the cardan shaft crosspiece

To carry out the work of injecting the cardan crosspiece, you will need to purchase a special tool - a syringe for lubricating cardan shafts. It can be purchased at almost any specialized automotive store. Such a syringe has a lever-plunger design and can last for many years.

Please note: Depending on the car model, the technological hole through which the lubricant is “poured” differs. It is necessary to determine before purchasing a syringe whether seals or nipples are used, since an appropriate nozzle will be required

You need to choose the lubricant that will be used for injection based on the recommendations of the car manufacturer. Most often, a lubricant specialized for a specific car model is used, and it is better to purchase it. If you pump a lubricant into the crosspiece that is different from what is already present there, there is a high risk of their “incompatibility,” which can lead to various kinds of problems.

Please note: If the vehicle's technical operating instructions do not indicate which specific lubricant to use for injecting the driveshaft crosspiece, this means that any universal grease will do.

How to replace the crosspiece on a Niva SUV yourself

The Niva car is equipped with two driveshafts that are part of the all-wheel drive system. They transmit energy to the front and rear axles and are a prefabricated structure with crosspieces as their central link. If the crosspiece fails, it must be replaced immediately. This will prevent damage to the driveshaft and failure of the car’s drive system.

Causes and signs of part malfunction: how to detect

The crosspiece is the key link of the driveshaft. Thanks to it, torque is transmitted from the gearbox, causing the shafts to rotate. Usually one of the crosspieces fails, of which there are four in Lada 21213. If it is not replaced in time, the steam room will quickly become unusable. The crosspieces allow the driveshaft to rotate evenly; if they break, play appears and the car loses power.

To avoid any unpleasant surprises on the road, you need to monitor the condition of the crosses. Carry out a thorough inspection of them regularly, clean and apply lubricant at least every 10 thousand km. If a part has become unusable, it must be replaced in a timely manner.

Parts in the drive system become unusable due to play in the units, which is caused by increased loads and mechanical stress. The wear of the crosspiece is facilitated by its unfavorable location. It is located close to the road surface, so it often gets sand, dirt, water and dust. Wear depends on the following factors:

The main signs of a faulty crosspiece:

The crosspiece is one of the parts that have a high margin of safety, but when exposed to a large number of mechanical influences and operation in an unfavorable environment, it quickly wears out.

Inspection and replacement of the crosspiece on the VAZ 2121

To carry out a correct diagnosis, you must perform the following steps:

If the decision is made to replace, we purchase the necessary consumables. To carry out the work, we prepare the tools:

Repair work on joints can only be carried out on a removed cardan shaft. We place the car on a viewing hole or lift it using a lift. We fix the wheels with supports, turn on neutral and the handbrake.

First of all, you need to dismantle the driveshaft. We clean the removed structure from dirt and begin disassembling and replacing parts:

When is work required?

It is important to correctly determine when to add lubricant, this will significantly increase the life of the spider. According to the manufacturers' recommendations, this element should be lubricated about once every 10-15 thousand kilometers; more precisely, you need to look at the list of scheduled maintenance work

But it is not always the case that crosspieces can be used freely for the entire time allotted for this by the manufacturer without lubrication. The reasons for this are very different, most often due to rather harsh operating conditions. Often, SUVs that are operated in harsh conditions require increased attention to the driveshaft. This is due to constant contamination of the joint, which leads to the production of lubricant at an accelerated rate.

Signs of a malfunction of the Niva VAZ 2121 crosspiece

Naturally, the behavior of a car with worn crosspieces changes. Practice shows that the service life of the cross varies depending on operating conditions from 40 to 50 thousand km .

If you take care of the crosspieces and inject them in time, they can easily last at least 80,000 km .

After this run, if nothing happens to the cardan before, we carefully listen to the operation of the transmission. These symptoms will indicate the need to revise the crosspieces:

The second way to determine a malfunction is in the pit. It is necessary to grasp the cardan pipe and the flange fork, then rotate them relative to each other. If play, knocking or noticeable movement is felt, the crosspieces must be replaced.

Driving with a vibrating driveshaft is dangerous for the transmission. Vibration breaks the seals of the transfer case and axle gearbox and reduces their service life . If neglected, the problem can break the lugs and render the driveshaft unusable.

The final stage of replacing the driveshaft crosspiece on the Niva family: installation of a new product

Before carrying out installation work, it is necessary to clean the seating surfaces under the bearing cups. The newly purchased part should be prepared for subsequent installation:

- remove the bearing housings from the crosspiece;

- check the presence of grease in the bearings (if it is absent, 0.8-1.2 g of Fiol-2U should be placed in each cup);

- Lubricate the outside of the cups with any composition (necessary to facilitate installation).

The installation stage in the technology for replacing a defective driveshaft cross on a Niva includes the following transitions:

insert two cups of the rolling bearings into the corresponding holes on the “cardan” fork; mount the crosspiece; press the bearing housings in a vice so that the end of the part is below the groove for the retaining ring (at the final stage it is necessary to use a spacer of suitable diameter); repeat the described steps for a plug with a flange, paying attention to the location of the previously placed marks; install 1 retaining ring; Using the tool, push the opposite cup until it stops and insert the 2nd locking ring, then repeat the action for the second pair of cups. Key points:

Key points:

- when pressing new cups with bearings, it is necessary to control the ease of rotation of the cross;

- if, when pressing the bearing housings, the crosspiece “rests”, it is necessary to check the location of the swinging elements of the device - the needles;

- after assembling the crosspiece, strike the fork and flange with a hammer through the plastic lining to select the gaps between the cups and retaining rings;

- Before installing the shaft, you should move the hinge in different directions in order to select the gaps and align the marks on the flanges;

- When working with the sliding fork hinge, it is recommended to disconnect it from the shaft by sliding the oil seal and noting the relative positions of the elements.

Design and principle of operation

The part is a cross-shaped joint, which is responsible for the alignment of the rotating parts of the cardan. Two propeller shaft forks are attached to its four ends.

The movable connection is ensured by needle bearings inserted into cups placed on the crosspiece.

Fixation of parts is ensured by locking rings, which determine the size of the gap and backlash. On some vehicles, driveshaft vibration can be eliminated without replacing the U-joint.

To do this, you just need to install larger width retaining rings. However, on the Chevrolet Niva, as on most passenger cars, the problem is solved by replacing the crosspiece.

Tool for injecting crosses

To lubricate the cardan crosspieces on a Toyota Prado 120, 150 or other model, purchase special tools - syringes. They come in several types:

- Mechanical - easy to use devices. Liquid is poured into the body, and by pressing the handle it is squeezed out to the injection point.

- Pneumatic - tools with an air compressor that uses compressed air.

It is worth noting that pneumatics are more convenient to use, since the driver does not need to expend a lot of effort and energy to tighten the cardan or crosspieces of the Prado 120/150 (both diesel and gasoline).

Based on the method of supplying consumables, the following types of tools are distinguished:

- plunger - a syringe with a movable body, a fixed piston and a suction element;

- electric - a syringe with a medium-power battery (18 W);

- screw - a mechanism with a fitting, the pressure inside of which is created by a bolt with a piston screwed into the body;

- pneumatic - a tool with a gun, when the trigger is pressed, lubricant is squeezed out.

When choosing a syringe, you should pay attention to both the technical characteristics of the mechanism itself and its compatibility with the car. Price should not be the deciding factor when purchasing

For Prado Kruzaks, drivers often use plunger and pneumatic tools.

Replacing cardan crosspieces in the field

Welcome! Cardan shaft crosspieces - firstly, let's say right away about cardan shafts, you most likely already know that the Niva car is equipped with two cardan shafts, unlike other cars, for example, unlike cars of the Classic family on which only one cardan shaft is present, due to with this, on Nivas there will be more crosspieces (two crosspieces per driveshaft), so there will be a little more work, but as a rule, one of the four crosspieces fails out of all four, and not all at once, but if you don’t change it in time the crosspieces will break very quickly, the crosspieces need to be twisted only in order to connect the joints of the cardan shafts (Simply if you connect the shafts directly, they can deform over time and bend, but this will not happen with the crosspieces since the crosspieces can move) and therefore If one crosspiece fails, then the shaft develops play and it begins to rotate unevenly, which leads to the failure of the other crosspiece and a loss of power in the car.

Note! To replace the driveshaft crosspiece, you will need to stock up on: Screwdrivers, and also if you have thin pliers, then take them too, in addition to this, you will definitely need a set of all kinds of keys, and in general, no repairs can be done without keys, and a hammer with You will need a hammer made of mild steel (this type of steel includes: Aluminum, copper, brass) and a vice (You can also use a press instead)!

Where are all the crosspieces on the driveshafts? They are located at the bottom of the car, so you will have to crawl under the car in order to replace the crosspieces themselves or to see them at all. For clarity, just below is a photo that was taken from under the bottom of the car; two cardan shafts are visible on it (Indicated by red arrows ) and the places where all four crosspieces are located, these places are indicated by blue arrows, but unfortunately one crosspiece is not visible in the photo (It was not included in the frame), but as soon as you climb under the car you will immediately find it.

When do you need to change the crosspieces of cardan shafts? As soon as they become loose and play appears at one of the driveshafts of the car, it is very easy to check this play, just crawl under the car and exactly in the place where the crosspiece you are interested in is located, take your hand and pull the driveshaft (don’t forget to lock it with a screwdriver , otherwise it will turn, or just hold the shaft itself with your first hand, and with the second pull it from side to side in the place where, in your opinion, the crosspiece is worn out, if there is play, then in this case the crosspiece needs to be replaced), but These are all checks, and the symptoms that the crosspiece has worn out will be as follows: Firstly, when starting from a stop, as well as during sharp braking, when you also press the gas sharply and when switching gears, a knock may occur in the lower part (Where the driveshafts are located ), if you constantly hear this knock, then it only means that one of the crosses has become unusable and also needs to be replaced.

Note! As for the play at the crosspiece, we would like to tell you that if the bearings at the crosspiece become unusable (they break and the like), then this play will not even exist, so when you crawl under the car, also inspect the crosspieces for the presence of deformations on them, or even better You can inspect them by separating the flanges from each other (To do this, you just need to unscrew the nuts, as you read the article you will understand what we are talking about)!

Replacing the outboard bearing

Motorists who want to learn how to do most of the repairs to their car with their own hands most often encounter a problem when it is necessary to replace the crosspiece and outboard VAZ.

General view of the bearing and crosspiece of the propeller shaft

Work order:

- When the work on replacing the cross has been completed, you can begin replacing the outboard bearing.

- After removing the crosspiece, the driveshaft is inserted into the flange of the elastic coupling that was there before, with the end on which the splines are located. Using a “27” wrench, unscrew the nut securing the universal joint fork to the front shaft.

- Using a puller, the hinge fork is removed. After this, the outboard bearing is removed from the shaft. You can do this in one of the following ways:

- the outer ring of the bearing is cut off and, using a puller, the entire bearing is removed;

- knock it off the driveshaft.

- Bearing assembly is performed in reverse order.

How to replace a VAZ crosspiece can be clearly seen in the video.

Replacing the steering column cross

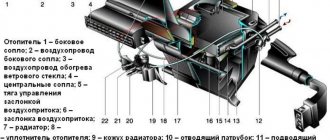

VAZ steering design

The crosspiece on the steering column often needs to be replaced. The design of the steering column itself is not complicated. The steering column shaft is directly connected to the worm, and there are no other complex components here. The steering crosspiece is sometimes needed to transmit torque to the parts of the rack and pinion mechanism from the shaft in the cabin. Some car models even have two crosspieces on the steering wheel. The steering crosspiece is replaced after the following signs are detected:

- you have to make great efforts to turn the steering wheel;

- wheel response is delayed, especially when turning;

- the angle of free play of the steering wheel (play) increases;

- the steering wheel rotates unevenly and jerkily;

- Uncharacteristic knocking, noise and grinding noises are heard when the driver tries to maneuver when driving on uneven sections of the road.

The universal joint, located in the engine compartment, is constantly exposed to various mechanical influences. It could also be a change in temperature affecting operation, increased humidity, and much more. All this taken together puts a very strong load on the part, as a result of which it fails. The elasticity of the rubber seals is lost, the lubricant leaks out and corrosion, dust and dirt begin their destructive work. First of all, the bearing needles fail. Replacing the crosspiece on all VAZ models is carried out as follows: a new part is purchased along with all the bearings and the replacement is carried out. The process is carried out according to the following basic principles:

- the steering shaft must be installed in such a way that full and free access to the fasteners that compress the casings of the forks of the cross is provided;

- the bolts on the forks are completely unscrewed and removed;

- the crosspiece block moves along the splines and is removed (in this case, you need to do this first from one end of the shaft, and then from the other, and often you have to remove the entire steering column).

The procedure for dismantling the cross

The part in question is installed in the forks with tension and is also secured with retaining rings. When replacing the driveshaft crosspiece on a Lada Niva, it is recommended to use “original” retaining rings - in this case, it will be possible to avoid balancing the shaft.

The process of removing the cross is carried out according to the following scenario:

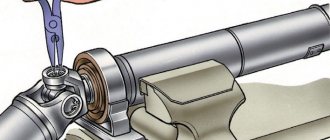

- remove the four retaining rings using pliers;

- use paint or a chisel to mark marks indicating the relative orientation of the flange yoke and the propeller shaft yoke;

- press the bearing housing out of the fork seat (it is preferable to work with the flange part first) using a puller;

- secure the free bearing cup in a vice (it is recommended to first make a flat on the cup using a grinder);

- remove the bearing housing from the seat;

- press out the opposite cup;

- remove the flange part from the cross, slightly warping the fork;

- knock out/press out the bearing housing remaining in the fork of the flange part;

- similarly remove two more bearing cups pressed into the cardan fork.

cardan If there is no puller, the bearing housings can be dislodged by hammer blows through a drift of suitable diameter. An alternative method for dismantling the crosspiece is based on similar principles: having moved the bearing housing outward, it is proposed to cut the opposite one with a grinder, then vice versa. Having disconnected the flange, you should repeat similar steps for the “cardan”.

Replacing the steering column cross

VAZ steering design

The crosspiece on the steering column often needs to be replaced. The design of the steering column itself is not complicated. The steering column shaft is directly connected to the worm, and there are no other complex components here. The steering crosspiece is sometimes needed to transmit torque to the parts of the rack and pinion mechanism from the shaft in the cabin. Some car models even have two crosspieces on the steering wheel. The steering crosspiece is replaced after the following signs are detected:

- you have to make great efforts to turn the steering wheel;

- wheel response is delayed, especially when turning;

- the angle of free play of the steering wheel (play) increases;

- the steering wheel rotates unevenly and jerkily;

- Uncharacteristic knocking, noise and grinding noises are heard when the driver tries to maneuver when driving on uneven sections of the road.

The universal joint, located in the engine compartment, is constantly exposed to various mechanical influences. It could also be a change in temperature affecting operation, increased humidity, and much more. All this taken together puts a very strong load on the part, as a result of which it fails. The elasticity of the rubber seals is lost, the lubricant leaks out and corrosion, dust and dirt begin their destructive work. First of all, the bearing needles fail. Replacing the crosspiece on all VAZ models is carried out as follows: a new part is purchased along with all the bearings and the replacement is carried out. The process is carried out according to the following basic principles:

- the steering shaft must be installed in such a way that full and free access to the fasteners that compress the casings of the forks of the cross is provided;

- the bolts on the forks are completely unscrewed and removed;

- the crosspiece block moves along the splines and is removed (in this case, you need to do this first from one end of the shaft, and then from the other, and often you have to remove the entire steering column).

As for the bearing races, they are fixed by punching, which can be easily removed using a chisel or drill. In a vice, the clips are pressed out one by one. Reassemble everything in reverse order. In this case, you need to remember that the bearing races are threaded into the forks until they are completely immersed. After which you should not forget to apply a new type of core that secures the bearings.

Replacement

Before starting work, you need to provide access to the bottom of the car by placing it on a pit or overpass.

To replace the cross joint you will need:

Keep in mind that the chisel is only needed to mark the relative positions of the transfer case and cardan flanges.

Tip: parts can be knocked out of the holes in the cardan forks using a socket head of a suitable diameter as a stop.

After this, all that remains is to tighten the nuts securing the propeller shaft flange.

What kind of lubricant should be used for crosspieces?

Manufacturers of oils and lubricants sell a fairly large assortment of materials intended directly for both cardan crosspieces and having general positive characteristics for various parts of a car or other equipment

To make the best choice, you need to pay attention not only to the cost of the lubricant and the manufacturer, but also to its main performance characteristics. You can get all the necessary information from your car's owner's manual or from your mechanic.

If we talk directly about the cardan, then a suitable mixture for it should have the following properties:

- high anti-corrosion and water-repellent properties;

- the lubricant must be designed for use over a wide range of temperatures and pressures (resistance to high temperature and pressure is required);

- should be thick and sticky; this way it can remain in place even with high vibration or intense rotation of parts;

- must be safe for human health;

- mineral lithium compounds are used to lubricate components and parts of the suspension and transmission, so the lubricant for the cross must be combined with them;

- the characteristics of the composition should extend the service life of the driveshaft components, increasing the range of its replacement;

- the density of the composition should not increase with decreasing temperature;

In a word, the mixture must have high mechanical and chemical properties, maintain density and composition under different extrusion conditions, and also withstand the effects of external aggressive factors.

Results of technological work

The route of the operation to replace the crosspiece of any driveshaft on the Niva is formed by the following activities:

- remove the “cardan”;

- remove the retaining rings;

- dismantle the defective assembly using a puller and a vice or hammer, a suitable drift and a grinder;

- install a new crosspiece;

- press in the bearings;

- install retaining rings;

- select gaps in connections.

Sources:

https://niva-remont.com/zamena-krestoviny-kardana/ https://masteravaza.ru/hodovka/kardanyj-val/zamena-krestoviny-vaz-2121-vaz-2123-i-vaz-2131-106 https ://labavto.com/vaz/kak-samostoyatelno-zamenit-krestovinu-na-vnedorozhnike-niva/ https://vaz-russia.com/remont-vaz-21213-niva-trehdvernaya/zamena-krestovin-kardana-na -nive.html https://mashinapro.ru/1246-krestavina-niva.html

Replacement of cardan crosspieces for Chevrolet Niva (VAZ 2123)

We've been driving around with a rattling rear driveshaft for almost a month now. Due to a change of job and the need to pass exams, there was no time to work on the car, but the exams were passed and permits were obtained.

0:332

A couple of days ago my wife went to a neighboring town for work, 140 km along the highway doesn’t seem like much, but it finished off the cross. Since the crankshaft was inspected and I didn’t find the retaining rings in their rightful places, I went to the Internet, and on the drive they suggested that they could be from 412 Muscovite, if the cardan was made in Belarus, so it turned out, but again this is not a problem, in the city stores there were no crosses, having driven through all the shops, only in the last one did we find the last pair for the whole city. I bought them, and also took 4 spare retaining rings, as it turned out it was not in vain, one broke and was lost in the depths of the garage.

0:1420

We unscrew the cardan, clean it from dirt and see that on the bottoms of the cups of the crosses the paint is the same as on the cardan, which means it was not rebuilt from the factory. We take out the retaining rings, and, using 32 and 17 mm sockets, remove 1 cup of crosspieces in a yew. Then we grab the bottoms of the cup with a gas wrench No. 2 and unscrew them from their seats. After disassembling I saw this picture.

0:2111

1:504

On one cup there is completely no needle lubrication in rusty powder

1:639

2:1144

It’s not surprising that there are grease traps, but they are in such a place that there is no way to get into them. There are new crosspieces without them at all, but I didn’t have to choose. We put the cardan in place. And since we are in the hole, we need to tighten the handbrake. But that was not the case. Two M8 nuts on the cable adjustment, they didn’t want to give up for about 2 hours. The bolt was rubbed to a shine with a wire brush, lubricated with WD-40 and nothing. After 2 hours of torment with the handles up, I already regretted that I even stuck to the handbrake, it was 23.50 at 6.30 to get up for work, and the car was working without brakes. But by 0.30 I finally finished her off.

2:2143

When driving the next day, it was noted that the squeaks, knocking and vibration from the rear were gone. It was not in vain that I struggled with the brakes, the handbrake holds at 5 clicks, and the Nyvka now responds to the brake pedal better.

2:341

The old owner also threw in a surprise in the form of loose clamps on the cooling system pipes. Of course, I understand that it’s not the most convenient place to tighten them on the pump fitting, and the bottom one near the thermostat, but still. And because of this, I poured out 2 liters of antifreeze somewhere. It was decreasing little by little, but it was unclear where. I already thought that I would have to open the engine, but with a UV lamp I found a huge spot on the block near the pump. Apparently, it leaked little by little and had time to dry out.

2:1176

https://www.drive2.ru/l/6598834/

2:1212 next article:

How to replace crosspieces on a VAZ 2121 Niva

Place the machine on a pit or overpass and lock the wheels to prevent spontaneous movement.

The driveshaft is removed from the vehicle and placed on a workbench. Using a drift, you need to tap the retaining rings, since during operation they can become stuck and will be difficult to come out.

Using a circlip puller, the ring must be compressed and pulled out of the fork eye. If it does not budge, you should tap the ring again and try to turn it with a flat-head screwdriver.

Lubrication (injection) of the cardan shaft

Are you looking for a place to repair a driveshaft in Perm? — Contact us, our competent specialists will help eliminate any malfunction of your driveshaft and return it to its original factory condition.

Our specialists carry out repairs of universal joints in Perm of any complexity:

- Diagnostics - free!

- Comprehensive repair of cardans;

- Replacement of the cross, support, spline, pipe, fork;

- Syringing;

- Manufacturing of new cardans in Perm;

The driveshaft is one of the most important devices in a car. And periodically it needs maintenance. So from time to time it is recommended to spray or lubricate the cardan shafts, in particular the cardan crosspieces (needle bearings). This procedure is one of the main specializations of employees.

We offer you timely, high-quality lubrication, which is guaranteed to provide shaft parts with high wear resistance and extend their service life.

Lubrication of universal joints (cardan shafts) may vary. As a rule, a special lubricant is used for crosspieces. If the shaft design includes CV joints (constant velocity joints), special lubricants designed specifically for them are used.

At the same time, the lubrication of the cardan (cardan shafts) differs in a number of features. The car mechanism requires this procedure after a certain mileage. The frequency of this may vary depending on the model of the machine. But on average, it is recommended to carry it out after every 10,000 km.

Preparatory process: fault identification, purchase of components and necessary tools

It is important to replace the driveshaft crosspiece on a Niva if there are extraneous creaks, knocks and crackles in the transmission, regardless of the speed of movement. Before purchasing new parts, consider the following facts:

- on cars manufactured since 1988, modified parts with increased diameter and stamped bearings are used (however, on models before 1988, new shaft assemblies can be installed);

- models released in May 2010 and later are equipped with shafts with constant velocity joints;

- The retail chain sells parts with a convenient injection hole location: at the end of the bearing cup.

From the set of tools and accessories you will need:

Comparing lubricants for servicing kingpins

EFELE MG-212

1

place

EFELE MG-212

/100

RATING

100

EFELE MG-212 is the best grease for king pins. It contains high-quality mineral oil thickened with lithium soap, as well as extreme pressure additives and molybdenum disulfide. Operating temperature range from -30 to +120 °C.

In addition to kingpins, the material is used in chassis components of transport equipment operating in harsh conditions.

Suitable for equipment components in the woodworking, polymer industry, metallurgy and other industries, as well as heavily loaded bearings of general industrial machines, bearings of electric motors and fans.

EFELE MG-212 is resistant to water washout, provides excellent protection against wear and corrosion, and can withstand impact loads. It has proven itself positively when working in damp and dusty environments, and also serves as an anti-emergency lubricant.

This lubricant has the highest performance characteristics among all presented materials and an affordable price.

Molykote BR2 Plus

2

place

Molykote BR2 Plus

/100

RATING

100

Molykote BR2 Plus is a lithium mineral oil based grease. Provides long-term lubrication of components of various machinery and industrial equipment Operating temperature range from -30 to +130 °C.

In addition to pins, it can be used in other elements of the chassis of lifting and transport machines and friction units of industrial equipment.

The material is characterized by high load-bearing capacity, high anti-wear and anti-corrosion characteristics, works in conditions of moisture and dust, and has the properties of an anti-emergency lubricant. It is not washed out by water, prevents stick-slip, fretting corrosion and has a long service life.

Mobilgrease XHP222

3

place

Mobilgrease XHP222

/100

RATING

100

Mobilgrease XHP 222 is an extended life blue grease. Made from mineral oil thickened with lithium soap. Operates at temperatures up to +150 °C, lower limit not specified.

It has proven itself well for servicing kingpins, as well as other components of industrial equipment and various equipment: construction, marine, agricultural, etc.

The material can withstand exposure to water and high temperatures, has high extreme pressure and anti-wear properties, protects against corrosion, and has high adhesion to surfaces

According to the characteristics of Mobilgrease XHP 222, it is not inferior to previous materials only in terms of heat resistance. Otherwise, it is inferior to the first two materials in terms of characteristics.

Litol-24

4

place

Litol-24

/100

RATING

100

Gazpromneft Litol-24 is an anti-friction lithium lubricant based on mineral oil. Operates at temperatures from -40 to +120 °C.

Used for servicing various rolling and sliding bearings, hinges, gears, etc. in industrial equipment, wheeled and tracked vehicles, electrical machines, etc.

The material withstands exposure to water, protects against wear and corrosion, and is mechanically, chemically and colloidally stable. It adheres well to surfaces and ensures performance even in heavily worn mechanisms.

Litol-24 is one of the most popular lubricants in Russia and the CIS countries. It can be used in kingpins, which is what many car owners do, but the characteristics of this material do not entirely satisfy the requirements of this unit. The quality of the lubricant is much inferior to previous materials.

TAD-17

5

place