Despite the fact that most modern motorists prefer to have their cars serviced and repaired in specialized centers, self-diagnosis of vehicles has not yet been canceled. In addition, a basic understanding of the machine’s structure will help to avoid deception on the part of unscrupulous craftsmen who diagnose a missing wiring as a breakdown of a serious component. And they “repair” this breakdown by simply tightening the contact.

One of the situations in which a car enthusiast must be observant is the moment when he starts the engine. In general, this is possible if the starter is working properly. The key role in whether the vehicle’s internal combustion engine starts is played by the solenoid or traction relay.

Purpose of the starter retractor relay

This part should not be confused with the starter relay, which is used by the ECU to activate the starting mechanism. The traction unit (this name is officially used by the vehicle manufacturer in the technical documentation) is installed directly on the starter housing and looks like a separate element, but on one side is firmly connected to the main device.

Solenoid relays in cars do the following:

- Provide a strong connection between the gear wheel and the flywheel crown;

- Hold the bendix in this position as long as the driver holds the key or start button in the extreme position;

- They ensure the closure of the electrical circuit contacts, which leads to activation of the starter motor;

- The bendix returns to its place when the driver releases the button or key.

General Tips

To make the solenoid relay last longer, you should:

- carefully tighten the bolts securing the current-carrying conductors to the starter relay;

- periodically clean the starter housing from dust and dirt;

- start the engine for no more than 15 seconds;

- If extraneous noise appears during startup or when the starter does not turn, dismantle the starter and perform routine maintenance.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

Design, types and features of solenoid relays

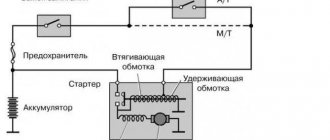

The solenoid has two windings. The most powerful is retractor. It is responsible for ensuring that the anchor overcomes the maximum resistance of all energized elements. The second winding of smaller wires simply holds the mechanism in this position.

To prevent the electric motor from being blown apart when the Bendix contacts the flywheel of an already running engine, the design of most modern starters has special overrunning clutches.

Also, solenoid relays differ in the type of housing. It can be collapsible or non-dismountable. Another difference between some modifications is in the control method. The system can activate only the starter drive or, together with it, also the circuit containing the ignition coil or other equipment.

Device repair

The first priority when replacing or repairing the solenoid relay is to dismantle the starter. It is secured with 2 or 3 bolts, unscrewing which is not a big problem. The main problem is that on modern foreign cars the starter is “hidden” far in the engine compartment, so to remove it it is necessary to additionally dismantle the interfering mechanisms. Some vehicles will even require engine support. If you are faced with such a situation, and getting to the starter and relay is problematic, contact a car service center. Having taken out the starter, you can pull out the relay directly. Solenoid relays come in two types: collapsible and non-dismountable. The latter cannot be repaired, so you will only need to buy a new component. Core replacement is generally performed according to the following scheme:

- disconnect the terminals from the battery;

- dismantle the mechanism and then clean it of oil and other contaminants;

- unscrew the brush system nut;

- remove the contact from the bolt;

- remove the coupling screws connected to the ground and the nuts from the end;

- replace the core;

- reassemble the structure in reverse order;

- check the functionality of the relay.

Removable components can be repaired. First prepare a screwdriver, a soldering iron with rosin and tin. Next, follow these steps:

- unscrew the mounting screws on the housing;

- if necessary, unsolder the ends of the winding;

- by removing the protective cover, you can replace the contacts or sand them if they are burnt;

- assemble the device and then place it in place above the starter;

- install the starter itself with the relay.

The procedure is not difficult, so try to do it yourself without spending money on car service services. Be sure to mark the terminals so that nothing gets mixed up during the assembly process. Additionally, degrease the contacts.

Operating principle of traction relay

The relay operates according to the following scheme:

- The traction winding receives voltage from the power source;

- A magnetic field of such strength is formed in it that it sets the armature in motion;

- The armature moves the starter fork so that it engages the bendix and moves it towards the flywheel;

- The teeth of the drive wheel engage with the teeth of the rim located at the end of the flywheel;

- At the same moment, from the other end, the anchor moves the rod on which the “penny” or contact plate is attached;

- The plate connects the contacts, which are connected to the car battery using a bolted connection via wires;

- Voltage is supplied to the starter motor;

- At this moment, the retractor coil is deactivated, and the holding coil is switched on to replace it (it is active while the driver is trying to start the engine);

- When the key (or the “Start” button) is released, the voltage in the winding disappears, the springs return the rod to its place, opening the contact group, the battery is disconnected from the starter, the electric motor is de-energized;

- This time the armature no longer holds the starter fork;

- With the help of a return spring, the bendix is disconnected from the crown, which by that time should already be rotating due to the autonomous operation of the internal combustion engine.

This is how a classic traction starter works. Depending on the functionality, the device can connect additional equipment to the circuit, for example, an additional relay or ignition coil.

A little theory

In general, modern starters are equipped with a pair of relays. The first is responsible for turning on the unit. It is located directly in the engine compartment, and in some car models the relay is also placed in a separate housing. The second relay, called traction ( retractor ), is installed directly on the starter. This device has several functions:

- Ensuring synchronous operation of automobile starter components when starting the internal combustion engine;

- Electrical distribution energy between the electromagnetic relay and the starter motor;

- Ensuring the joint operation of the overrunning clutch and the flywheel ring (supply of gears) and, conversely, withdrawal of gears at the right time.

Here's how it all works: when the contacts in the ignition switch are closed, the usual starter relay is immediately activated, which is responsible for supplying voltage from the battery to the so-called. pull-in winding. As a result, a magnetic field is induced, acting on the relay armature, due to which it gets inside the winding. Now 2 actions are carried out at once: the starter fork begins to move, helping the overrunning clutch, also called the bendix, to move, and the contacts of the installed retractor relay close. Simply put: the starter is now connected to the flywheel, after which it is connected to the battery and by passing current through the circuit, the engine can now start. Do not forget that the operation of combustion systems without proper operation of the electrical circuits of the car is impossible.

However, this is not all. Now, when the starter turns on, due to the operation of the so-called. holding coil, the armature is held in its extreme position - in this mode of operation, the solenoid relay does not consume much energy. And if the engine is already running, the starter circuit is broken and the relay is de-energized. Automotive relays have a spring - it is this spring that, trying to compress, returns the armature to its initial position. Then the contact disk and bendix change their position. The battery turns off. Then the relay is no longer involved in the operation of the car until the engine is started.

Signs and causes of relay failure

The very first symptom of a broken traction relay is the inability to start the engine. In this case, strange sounds may be heard coming from the trigger mechanism. You don't need to be a professional mechanic to identify a broken starter. When you turn the key, the car will either not start, or it will take several attempts. Sometimes it happens that the engine is already running, the key is released, but the Bendix wheel does not disconnect from the ring gear.

There are not so many reasons for traction failures. Two of them are mechanical - the Bendix return spring is broken or the overrunning clutch is jammed. In the first case, the gear will not engage well or will not detach from the ring gear. In the second, the pull-in winding does not have enough power to overcome such resistance. As a result, neither the motor turns nor the bendix extends.

The remaining faults are related to the electrical circuit, so to find out what exactly the problem is, you need to arm yourself with the appropriate tools.

Checking the starter retractor relay

The retractor may have several breakdowns. They can only be eliminated after the device is disconnected from the motor. But before you do this, you need to carry out a few simple procedures. They can eliminate a "symptom" very similar to starter failure.

So here are the simple steps:

- We check the battery charging - if the starter clicks, but the flywheel does not turn, it means there is simply not enough energy;

- Electricity may not flow to the terminals due to oxidation at the battery terminals or other wire connections. Oxidation is removed and clamps are more firmly secured;

- Check the starter relay to see if it is working properly.

If the malfunction has not been eliminated by these actions, the mechanism is removed from the machine.

Starter removal procedure

First, the car needs to be driven into a pit, lifted on a lift, or driven onto an overpass. This will make it easier to get to the starter mount, although in some cars the engine compartment is so large that access to the starter is possible even from above.

The starter itself can be removed quite easily. First, you should unscrew the contact wires (they must be marked so as not to confuse the polarity). Next, the mounting bolts are unscrewed, and the device is already in your hands.

How to check the starter solenoid relay

The functionality of the retractor is checked as follows:

- The positive contact of the device is connected to the “+” terminal on the battery;

- We fix the negative wire to the negative terminal of the battery, and connect the other end of this wire to the starter housing;

- A clear click from the device indicates proper operation of the traction relay. If the starter does not start the engine, then the problem must be looked for in other components, for example, in the electric motor of the starting device;

- If there is no response, a breakdown has occurred in the relay.

What else do you need to know about the starter?

The device with a gearbox is mounted on engines characterized by high power, as well as diesel internal combustion engines. The gearbox itself, which has several gears in its device, is installed directly in the housing and allows you to increase the voltage several times. Accordingly, this helps to increase torque.

We have already talked about the advantages of such mechanisms, but now we will consider them in more detail:

- Geared devices are more efficient, their efficiency is much higher.

- If the engine is started cold, the device will consume less current.

- The geared element, compared to the gearless element, is more compact.

- The gearbox allows you to maintain operating efficiency and operational features even when the starting current of the battery decreases.

As for gearless devices, they are simpler in design, but more resistant to increased loads.

Sorry, there are no surveys available at this time.

Repair of starter retractor relay

Most often, the traction relay is not repaired, since its elements are mainly enclosed in a non-separable housing. The only thing that can be done in this case is to carefully remove the folding of the lid with a grinder. Below it is a contact plate.

Often the malfunction consists of burning of the contact surface. In this case, the plate and contacts are cleaned with sandpaper. After repair work, the body is carefully sealed.

A similar procedure is performed with a collapsible modification. The only difference is the principle of disassembling and reassembling the structure.

If everything is in order with the contacts, but the traction does not work, then most likely there is a problem with the windings. In this case, the part is simply replaced with a new one. Repair of these elements is extremely rare, and then only by amateurs of handmade work.

Diagnostics without removing the starter using a multimeter

To do this, use a multimeter (tester) to first sequentially measure the voltage at the terminals of the battery, disconnected from the vehicle’s on-board network. It is approximately 12.7 V. If the device readings are less than 12 V, the battery is considered to be severely discharged and is not suitable for further testing.

Next, restore the normal connection of the wires and measure the voltage at the battery terminals and relay contacts. Compared to the previous case, it changes by no more than 0.1 V and will be equal at both control points. Turn the key to the start position. The voltage at the relay contacts should not fall below 12 V. Otherwise, the connecting wires are most likely faulty; it is possible that one or more contacts in the current flow circuit have burnt out.

Selecting a new solenoid relay

Finding a new retractor for an effective start of the power unit is not the most difficult task. The choice is made in accordance with the manufacturer's recommendations. In the store catalog, the company can offer different options for a specific starter.

You can also dismantle the starter and bring it to the store. There experts will help you choose the appropriate modification.

First of all, the choice should be made on the original spare part, even if it is not manufactured at the factory where the car was assembled. Basically, automakers only assemble vehicles, and spare parts for them are manufactured at other factories and, most often, by other companies.

It is worth considering that retractors for different starters are not interchangeable. They differ from each other not so much in design as in drive power and the principle of circuit connection. For this reason, you should be careful when choosing a new spare part.

Leading manufacturers

Among the products that are sold in retail outlets, you can often find the desired position on which there is a stamp of a certain company, but the fine print may indicate that this is a packaging company, and the manufacturer is completely different. An example of this is the products of the Cargo company. This is a Danish packaging company, but not a manufacturer.

Among the leading manufacturers of high-quality retractors are:

- European manufacturers - Bosch, Protech, Valeo;

- Japanese companies - Hitachi, Denso;

- And one American manufacturer - Prestolite.

By choosing products that have a high level of quality, the car enthusiast will make sure that the power unit of his car can start at any time. If the battery is charged, of course, but this is a topic for another review . In the meantime, watch a video on how to repair a traction starter yourself:

Solenoid Relay. Repair in 5 minutes. Traction Relay 2114. Clean the nickels