05 February 2016 Lada.Online 77 564 10

How to quickly and accurately determine the condition of the engine? Check the compression in the cylinders! Is the engine running rough, you feel a loss of power, the consumption of engine oil or fuel has increased and the car has become difficult to start in cold weather? All of these problems may be caused by low compression in one or more cylinders.

To ensure that the compression test gives accurate results

Compression depends not only on the technical condition of the engine, but also on the conditions under which it is measured. Make sure that during the check:

- the compression gauge was working properly;

- the engine has been warmed up to operating temperature (up to 90 degrees);

- the throttle valve was fully open;

- spark plugs in all cylinders must be turned out;

- the starter was fully operational;

- the battery was fully charged;

- The engine air filter was clean.

Downward change

There are 2 types of deterioration in performance: a decrease in pressure in all 4 cylinders or only in one, less often in two. The limit at which immediate repair is required is considered to be 11 bar. When the compression is low at all 4 measurements, then you need to look for one of the following faults in the engine:

- The piston rings have expired. The pressure drops gradually as it wears out. It is considered a completely natural process.

- The same, the entire piston group. Due to the operation of the crankshaft, the cross-section of the cylinders becomes ellipsoidal rather than round. Gaps form between the walls and the pistons that even new rings cannot cover.

- The valves were covered with soot on the inside (in jargon: burnt) and lost their tightness. Carbon deposits prevent the valve from completely seating and closing.

- The rules for adjusting the thermal clearances of the valves were grossly violated. When there are no gaps, after the engine warms up, the valves are constantly slightly open. This most harmless malfunction can be eliminated by adjustment, after which the compression must be re-measured.

The first 3 malfunctions, as a rule, come together and definitely lead to disassembly of the power unit. It rarely happens that after removing the cylinder head, only ring wear is discovered. Typically, valves and seats also need to be cleaned and wiped, and there is an ellipse-shaped development inside.

Another option is when compression has disappeared in one place: just yesterday it was there, but today the car is already “sneezing” on 3 cylinders. The reasons are as follows:

- became covered with soot and 1 valve or 2 adjacent ones stopped closing;

- due to overheating, one piston expanded more than the others and stripped the cylinder walls;

- error when adjusting the valves, one of them is very “clamped”.

As in the previous case, the final diagnosis is made after disassembling the motor, examining and measuring the size of the ellipse. Scratches on the inner walls will be immediately visible and will lead to the replacement of all pistons along with rings and repair of the cylinders.

What are the cylinder compression standards for VAZ engines?

Engine specifications must indicate “minimum cylinder compression values.” If you cannot find such data, determine the compression standards yourself using the formula:

| Compression (kgf/cm2) = compression ratio (see technical specifications of internal combustion engine) * coefficient (for VAZ min 1.2, max 1.3) |

A few examples:

- The compression ratio of modern VAZ 21126 and VAZ 21127 engines installed on Granta, Kalina and Priora is 11. We multiply the values using the formula and get the compression standards: 13,2..14,3.

- For the Vesta engine (VAZ-21129) the compression ratio is 10.45, the compression standards will be: 12,5..13,6.

- For Niva (VAZ 21213, 21314) - 11,3..12,2.

If the compression gauge values in all cylinders are within the normal range, this does not mean that everything is fine. Different compression in the cylinders is also bad. It is important that the difference between all readings is minimal. Compare the minimum and maximum compression values in the cylinders. According to technical standards, the difference should be no more than 1 kgf/cm2 or 10% .

Comments and reviews

Ivan Ivanovich Baranov

Experience working at a service station:

View all answers

Avtozam.com - your assistant in car repair and maintenance

Your use of this website constitutes your agreement that your use is at your own risk.

Engine compression indicates the condition of the engine, its service life, power, and torque. This procedure must be performed every 20-30 thousand kilometers, as well as before purchasing a car. Even when checking at a service center, YOU will need knowledge on how to correctly measure compression, because service people love to deceive and make money from you.

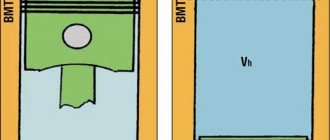

Compression is the pressure created in the cylinder at the end of the compression stroke. Another term is appropriate here: Engine compression ratio. Engine compression ratio What compression should be in the cylinders of a VAZ engine? Normal engine compression is at least 10 bar (1.0 MPa), and the difference between the cylinders should not exceed 1 bar (0.1 MPa).

If your compression is 11-12-11-12 from cylinders 1 to 4, then the engine is fine, but do not forget to adjust the valves every 2500 km. If you have 11-9-12-11, then you need to look for the cause and make repairs, because driving in such conditions will only kill the engine. How much should the ideal compression be? The ideal compression should be 14 bar for an 8-valve engine in each cylinder with minimal variation (14-14-14-14). How to measure compression? There is a special device for measuring compression, it is called a compression meter.

These devices come in two types: clamping, universal, flexible and threaded. How to measure engine compression? To check the compression we need a spark plug wrench, a charged battery and a compression gauge. You also can’t do without an assistant. 4) PPPPP The assistant presses the gas all the way and starts the car within 6-10 seconds.

5) PPPPP We remember the compression gauge readings and carry out similar operations on the remaining cylinders. Low and different compression in the engine, what to do? If, after checking the compression, the compression meter shows below 10 bar in at least one cylinder, then you urgently need to find out the cause and fix the problem, otherwise you risk losing compression in the remaining cylinders. If for example you don't have enough compression in the 1.4P and any other cylinder,

2) Spray oil into the hole that appears. 3) We measure the compression again.

If, after re-measuring, the compression has increased, it means

rings are worn out. If the result remains the same then

valves are burnt out or jammed. Stiff valves can be adjusted, and burnt valves can be replaced. High compression in the engine.

Main reasons. Don't be too happy if your compression readings are off the charts, this is in no way indicative of how cool your engine is. As stated above, the ideal compression for an 8-valve engine is 14-14-14-14. If your compression is higher than these numbers, then it’s time to think about malfunctions. High compression can damage the partitions of the pistons and tear the cylinders. The following are the main causes of increased/high compression:

Greater compression is created due to excess oil in the cylinder, which is why it is sometimes also called oil compression

2) PPPPP The oil scraper rings are worn out or stuck.

(In such cases, oil consumption is inevitable. Check the oil level:

Also pay attention to starting the engine after a long period of parking, for example, in the morning. When oil is consumed in the engine, the exhaust will be black). 3) PPPPP There may be carbon deposits in the cylinders.

Try to get rid of it by decoking. If you encounter the problems outlined below, it is possible, BUT NOT FAR A FACT, that your engine has insufficient compression. Therefore, you don’t need to pay attention to the signs, but you just need to measure the compression. 2) PPPPP PHigh fuel consumption (How to increase engine compression in other ways? There are several options for increasing compression without repair. These operations do not guarantee an increase in compression, but you can try.

But it is still recommended to eliminate the malfunction by mechanical action to eliminate the malfunction: re-install the rings or replace the valve. I tried it myself, it really works. The valve could be jammed and therefore not close, resulting in a compression leak. 2) PPPPP Roskoksovka removes carbon deposits and excess oil in the cylinder.

Reasons why there is no compression in the cylinder

Poor (small) compression in one or all cylinders indicates engine wear. There is an old and simple way to determine why compression has disappeared. You need to pour a tablespoon of engine oil into the spark plug hole and repeat the measurements:

- if the pressure has increased noticeably, it means the piston rings have poor sealing;

- if the pressure has not changed, then there may be several reasons (for example, leaking valves, broken gaskets under the cylinder head, there is a crack or burnout in the walls of the combustion chamber, in the piston bottom).

There is another, more accurate way to find out why compression has disappeared. To do this, you will need to modify the spark plug. We remove the insulator from it, and weld the valve of the car camera to the metal body. Next, set the cylinder piston to the ignition timing position, remove the radiator caps and oil filler neck, screw in the manufactured adapter and pump air into the cylinder using a pump (create pressure in it):

- if air enters the exhaust pipe, it means the exhaust valve is poorly sealed;

- If air goes into the intake manifold, there is a problem with the intake valve.

- if bubbles appear in the expansion tank, then check the cylinder head gasket;

- If there is a hissing sound in the oil filler neck, it means that the piston rings are not properly sealed.

Engine diagnostics using compression measurements in the cylinders allows you to quickly and accurately determine its condition without disassembling, and in some cases will help avoid major repairs of the power unit. Have you ever experienced a lack of pressure in the cylinders? What was the cause of the malfunction? If engine problems persist, check the fuel rail pressure.

Keywords: Lada Granta engine | Lada Kalina engine | Lada Priora engine | Lada Largus engine | 4x4 engine | Lada Vesta engine | lada xray engine | Niva engine | universal article

0 0 0 0 0 0

Share on social networks:

Why is verification needed?

The compression of the VAZ 2114 8 valve engine indicates the working condition of the engine. This indicator determines the engine power and its service life. The process of measuring the compression of a VAZ 2114 8-valve engine should be carried out at least every 20-30 thousand kilometers. In addition, this should be done before purchasing a car.

VAZ 2114 car with 8 valve engine

Compression itself is the level of pressure that is generated at the end of the compression stroke in the cylinder. That is, if you notice that the engine of your VAZ 2114 8 valves has become worse, namely, the consumption of gasoline and motor fluid has increased, and the power has decreased, then you need to check it. Engine diagnostics first of all includes checking the compression level. This is one of the few procedures that will reveal the condition of the power unit without disassembling it. But what should be the compression in a VAZ 2114 8-valve engine?

This question came to every car enthusiast. If its level is too high, then less gases will enter the engine crankcase. Accordingly, a more saturated gas flow will perform useful work. But if the level is excessively low, then this will affect the power of the car and the maximum possible speed that the car can reach. In addition, the acceleration dynamics will decrease by an order of magnitude. So what should the compression of the VAZ 2114 8 valves be?

The normal level should be at least 10 bar.

This is how engine compression is measured.

In this case, the difference between the cylinders should not be more than 1 bar. If, as a result of the measurement, you find that from the first to the fourth cylinder the pressure level is 11, 12, 11, 12 bar, then the engine is operating normally. But if the indicators differ significantly, for example, 11, 8, 13, 10, then it is necessary to repair the car. Ideally, the compression for a VAZ 2114 8-valve engine should be 14 bar in each cylinder.

What influences this indicator?

These proportions are influenced by many factors:

- Volume of incoming gas. In particular, to ensure normal pressure levels, the air filter should be changed on time.

- Setting the valve timing.

- Incorrect level of clearance adjustment in the drive of one of the eight valves.

- Motor operating temperature. If it is significantly lower, then the pressure level, accordingly, will be an order of magnitude lower.

- Defects in oil scraper rings, as well as burnout of valves.

- Gasoline, which for some reason enters one of the cylinders.

This is what a threaded pressure measuring device looks like

Possible solutions to the problem

To adjust the engine compression ratio yourself, you can try the following steps: 1. If the problem is faulty oil rings or valves, try replacing the valves or swapping the rings. 2. If the fault is a jammed valve, you need to adjust it. It is likely that it cannot close, which is why the pressure leaks. 3. If excess oil has accumulated in the cylinder or carbon deposits have formed, decoking is required. It will help with stuck valves, however, if they are burnt out, cleaning will not help.

Deviations from the norm: reasons

If after the measurements it turns out that the compression of the VAZ 2114 engine is lower or higher than 10 bar in at least one of the cylinders, it is necessary to establish the cause and make repairs. To determine the cause of low compression, you will need a 10 cc medical syringe filled with motor oil. Use it to spray oil into the cylinder bore and measure the pressure again. If after repeated measurements the pressure rises, we can conclude that the problem lies in the wear of the rings. If the result does not change, the problem is in the valves: they could burn out or become jammed. A high compression rate threatens to damage the engine pistons and rupture the cylinders. The cause of this malfunction may be the following: 1. The valve stem seals or oil scraper rings are over-wear. These problems inevitably lead to increased oil consumption; pay attention to its consumption. If it turns out that the oil consumption is increased, then, together with the pressure readings, this will clearly indicate over-wear of the caps or rings. 2. Formation of carbon deposits in the cylinders. You can get rid of it by decoking.

Increase compression

Yes, in some situations the compression can rise to 15 bar, which is not the norm. There is an explanation for this: all possible gaps are sealed with oil, there is no other liquid nearby. When engine oil splashes onto the piston group from below, the excess is removed from the walls by oil scraper rings. But when it comes from above, from the side of the combustion chamber, and even in large quantities, then it has nowhere to go. Part burns along with the fuel, causing white or bluish smoke to come out of the exhaust pipe, and the other part seals the cracks.

Oil enters the combustion chamber for the following reasons:

- valve oil deflectors (caps) have become unusable;

- After long-term use, the bushings inside which the valve stems move broke.

A good technician will eliminate the first reason without removing the engine head from the block by replacing the caps. The second will again require disassembly and pressing of new bushings.

How to analyze the obtained compression meter readings

The analysis of the obtained data is carried out based on 3 parameters at once:

- Maximum pressure value. Excellent pressure, which should ideally be in the VAZ-2109, is from 12 to 13 kg/cm2, which is approximately 1.2 to 1.3 MPa.

- Normal pressure is considered to be from 10 to 11 kg/cm2. (1-1.1 MPa).

- You cannot do without repairs if the compression gauge shows values from 8 to 9 kg/cm2, which is from 0.8 to 0.9 MPa.

Step by step instructions

The first thing you will need to measure the pressure level in the engine is a device with which you will do this. How can we measure this coefficient? The device for this is called a “compressometer”. Such a device can be of several types:

- universal device;

- threaded;

- flexible;

- clamping

This is what the pressure measuring device looks like disassembled

You will need to find such a device. Also, in this matter you will need the help of a friend, since you will have to simultaneously perform some actions both inside the cabin and in the engine compartment. In addition to the compression gauge, prepare a wrench for removing the spark plugs. Please note that it is better not to perform any work if the battery is not working. Therefore, fully charge your battery. So, let's start checking:

- First, get behind the wheel and start the engine. Let it idle and warm up to 90 degrees, that is, to operating temperature.

- After this, open the hood and take the key to remove the spark plugs. You need to remove the high-voltage wires, and then dismantle all the spark plugs. The wires fit to the spark plugs, you just need to pull them out.

- Now remove the ECU fuse to avoid possible damage to the device.

- When the spark plug is dismantled, you need to install your device in its hole to check the pressure level. Do this carefully so as not to damage the threads.

- Now you will need a friend's help. Ask him to sit in the driver's seat. The assistant must press the gas pedal all the way so that the throttle valve can open completely.

- Then turn on the starter and turn the crank pulley with it. This is done until the readings on the compression gauge stop increasing. As a rule, this takes no more than 10 seconds. In this case, the crank pulley must rotate, and its rotation speed should not exceed 100 rpm.

- Now you can read the received readings. Better write them down. Remember what the compression and compare these readings with the received ones. Once the readings are recorded, the device's needle can be set to zero.

- This procedure should be repeated for each cylinder of the VAZ 2114 8 valve engine.

As you understand, there is nothing particularly difficult in this procedure. You just need to carry out all the measuring steps correctly and you will get the most accurate results.

Why check

It is recommended to check the compression on the VAZ 2110 regularly to prevent possible malfunctions and problems with the engine. Measurements are taken with the throttle valve open and closed. Each test option gives its own results and data on the condition of the engine.

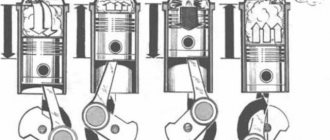

Checking with the valve open allows you to determine:

- Problems and damage on cylinder surfaces;

- Deformation, burnout of valves;

- Sticking or coking of piston rings.

If you check the compression with the throttle closed, you can find out:

- Are the valves stuck?

- Is there a tight fit to the valve seat?

- If a hydraulic tappet is present, the presence of defects in the camshaft cam profile is determined.

Measuring compression in a diesel engine

- In order to turn off the flow of diesel into the engine, you need to disconnect the fuel supply valve from the power supply. This can also be done by clamping the shut-off lever on the high pressure pump.

- Measurements on a diesel engine are made with a special compression meter, which has its own characteristics.

- When checking, you do not need to press the gas pedal, since such internal combustion engines do not have a throttle. If there is one, it must be cleaned before checking.

- Each type of engine is supplied with special instructions on how to measure compression on it.

Compression test on a diesel engine.

Compression measurement on an injection car

It is worth remembering that compression measurements can be inaccurate. For the most part, measurements need to take into account the pressure difference between the cylinders, and not the average compression value.

You should definitely take into account such parameters as oil, engine, air temperature, engine rotation speed, etc. Only taking into account all the parameters can one draw a conclusion about the degree of wear of the pistons and other parts that affect compression. And as a result of all these malfunctions, give a conclusion about the need for a major overhaul of the engine.

Signs of low compression and how to measure it on a VAZ engine

Compression on a VAZ 2114 should be measured every 30 thousand kilometers. This is usually done in conjunction with adjusting the valves. However, signs of low compression may not only appear with a routine check. As you use your car, signs of poor compression are easy to spot; you just need to keep a close eye on your engine. These are phenomena such as:

- ICE strength drops sharply;

- the engine fires, this can happen when low compression occurs in one cylinder;

- significantly increases oil and gasoline consumption.

Compression measurement results

The results of compression measurements show the condition of the engine, in particular the pistons, piston rings, valves, camshafts, and allow decisions to be made about the need for repair or just replacement of the head gasket or valve stem seals.

On gasoline engines, normal compression is in the range of 12-15 bar. If we take a closer look, the trend will be as follows:

- front-wheel drive domestic cars and old foreign cars - 13.5-14 bar;

- rear-wheel drive carburetor – up to 11-12;

- new foreign cars are 13.7-16 bar, and turbocharged cars and with a large volume up to 18 bar.

- in the cylinders of a diesel car, the compression should be at least 25-40 atm.

The table below shows more accurate compression pressure values for different engines:

| engine's type | Value, bar | Wear limit, bar |

| 1.6, 2.0 l | 10,0 — 13,0 | 7,0 |

| 1.8 l | 9,0 — 14,0 | 7,5 |

| 3.0, 4.2 l | 10,0 — 14,0 | 9,0 |

| 1.9 L TDI | 25,0 — 31,0 | 19,0 |

| 2.5 l TDI | 24,0 — 33,0 | 24,0 |

PREPARATION FOR MEASUREMENTS

Engine compression is measured with a fully charged battery. After charging and installing the power source in place, check the starter. It should create any problems either. Then warm up the engine. Its temperature during measurements should be 70-90 O C.

It is necessary to unscrew all spark plugs from all holes. Also unscrew the fuel hose to stop the fuel supply. Prepare the compression gauge for use.

Compressometer

Sources:

https://kaemavto.ru/stati/kakaya-dolzhna-byt-kompressiya-na-vaz-2114.html https://rockymotion.ru/kakaja-kompressija-dolzhna-byt-v-dvigatele-vaz/ https:/ /avtotop.info/kakaja-kompressija-dolzhna-byt-na-vaz-2115/

Taking measurements

The pressure must be determined on a warm engine, using a special pressure gauge - a compression gauge. The devices are of clamping and threaded type. The first ones need to be pressed with your hands, the second ones are screwed alternately into each cylinder. Measurements are performed as follows:

- disconnect and remove the high voltage wires, unscrew the spark plugs;

- insert or screw the working part of the compression gauge into the spark plug socket;

- press the gas pedal and turn the crankshaft several times with the starter.

Repeat the operation on each cylinder in turn. If the device is of a clamping type, then the services of an assistant will be required for measurements. While you press the pressure gauge firmly against the hole, an assistant should press the accelerator pedal and start the starter. Having received the results, you can proceed to analysis.