The CVT variator transmission is quite common today, although ten years ago in the CIS this type of automatic transmission was relatively rare. At the same time, as practice shows, many car owners do not even know that the car is equipped with a CVT, and not a “classic” hydromechanical automatic transmission.

Also, some owners of cars with a CVT believe that this gearbox is no different from a traditional automatic transmission, that is, when operating, drivers adhere to the same rules as when driving a regular automatic transmission. In fact, this is a common mistake. Moreover, it is partly for this reason that the CVT variator has gained fame as a problematic, expensive transmission with a short service life and prone to early breakdowns.

In this article, we will look at what a variator gearbox is, operation, features of a gearbox of this type, as well as how to drive a variator in order to preserve the intended resource, avoid premature breakdowns and increase the overall service life of the unit.

How to use the variator?

The continuously variable variator in automatic control mode smoothly changes the gear ratio depending on the position of the selector lever, vehicle speed and the position of the accelerator pedal. The operating mode scale bears the following symbols: “P” - parking. In this position, the variator is locked to prevent the parked vehicle from moving. If the selector lever is in this position, the engine can be started; "R" - reverse. In this position of the selector lever, the car moves backward. Move the lever to this position only when the vehicle is completely stopped;

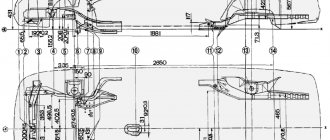

Stepless variator control selector lever:

1 - scale for controlling the automatic mode of operation of the variator; 2 — lever lock release button; 3 — lever safety button; 4 — lever handle; 5 — slot for controlling the automatic mode of operation of the variator; 6 — slot for controlling the manual mode of operation of the variator.

Warning Never move the selector lever to position P (parking) or R (reverse) while the vehicle is moving! This will lead to damage to the variator. "N" - neutral. In this position of the lever, the engine is disconnected from the drive wheels. This position is used during long stops, for example in traffic jams; Warning Never move the selector lever to the “N” (neutral) position while the vehicle is moving! In this case, you may accidentally move the lever to the P (park) or R (reverse) position, which will damage the transmission. In addition, engine braking will become impossible.

Helpful Hints To help prevent you from losing control of your vehicle, keep your foot on the brake pedal or lift the parking brake lever when the lever is in the N (neutral) position and when moving the lever to this position. If the car is on a slope, then when starting the engine, the selector lever must be set to position P (parking), and not N (neutral).

"D" - forward movement. This is the main position of the selector lever, in which it is located most of the time when driving. In this case, the variator control system selects the gear ratio that is optimal for a given vehicle speed and acceleration;

"L" - low range. This range allows for intense engine braking on steep descents. The range is used when driving in mountainous and hilly areas (both downhill and uphill). It is recommended to switch to L range before going through a series of tight turns. In manual mode, there are six forward gears and one reverse gear. Gears are switched by moving the CVT control selector lever either forward (for upshifting) or backward (for downshifting).

To turn on the “P”, “R” or “L” ranges, press safety button 3 (Fig. 1.16). The movements of the lever, which are performed only when the button is pressed, are shown in Fig. 1.17 with shaded arrows. All other ranges are activated without pressing the safety button (the corresponding lever movements are depicted by white open arrows).

Source: Nissan Primera P12 Operation, Maintenance and Repair Manual. Publishing house "Third Rome".

CVT gearbox: features of operation and maintenance

So, the absence of a clutch pedal in a car means that this type of vehicle is equipped with an automatic transmission. However, there are several “automatic machines”: hydromechanical automatic transmission, variator, and also a robot. Each of these types of transmissions is visually similar to each other in the interior, has similar modes (to simplify interaction), but the boxes themselves are fundamentally different in their design and operating principle.

It turns out that the variator is a separate type of gearbox. So, first of all, this transmission is continuously variable. This means that there are simply no physical steps (gears, speeds). As a result, the change in gear ratio occurs smoothly, softly, without jerks and jolts, as well as delays and failures.

The traction on the variator is constant, smooth, there is no interruption in the flow of power to the wheels. An engine with such a gearbox operates in an optimal speed mode; there is no usual “spin-up” of the engine, after which a gear increase occurs during acceleration. In fact, the driver simply does not notice how the variator works, the engine runs quietly, without reaching high speeds, there are no noticeable gear changes, the traction is constant, there is a minimum of noise from the gearbox and internal combustion engine when driving.

This operation of the transmission and power plant was made possible due to the fact that there are two disks (pulleys) in the box, one of which is driving (connected to the motor), and the other is driven (transmits the converted torque). In most cases, the pulleys are connected to each other by a belt (variator chain). This device is the most common, the design is called a V-belt variator. There are also torus variators, which we will not talk about in this article due to their low prevalence.

In a V-belt unit, both pulleys, under electronic control, have the ability to constantly change their diameter, thereby changing the gear ratio. This feature allows you to obtain high transmission efficiency, quickly and smoothly accelerate the car, while achieving high fuel efficiency, since the engine operating mode is always optimal.

- However, it is important to understand that even with all the advantages listed above, there are also significant disadvantages of the variator. Also, this design requires increased attention and compliance with a number of rules during operation and maintenance.

First of all, the variator is very demanding on the level and quality of gear oil. CVT oil is expensive and needs to be changed more often than in conventional automatic transmissions (every 30-40 thousand km in a CVT versus 60-80 in the case of an automatic transmission).

The fact is that quite high loads are created at the point of contact between the belt and pulleys. On the one hand, the lubricant should not interfere with the connection of the belt with the surface of the pulley (the belt should not slip on the pulleys), and on the other hand, effective and reliable protection against mechanical wear and damage to the contacting surfaces is also necessary.

Article on the topic: Repairing shock absorbers with your own hands: creaks, knocks, leaks?

It is for this reason that it is important to use only special oils for CVT variators (ATF lubricant is not suitable for conventional automatic transmissions). You also need to regularly monitor the level and condition of the oil in the variator gearbox during vehicle operation. It is also necessary to ensure that during maintenance the working volume of oil is always filled (either underfilling or overfilling of lubricant is not allowed).

Let's move on. Like any other automatic transmission, the variator has designations that correspond to the various operating modes of the box of this type. In this case, the designations are similar to those applied to automatic transmissions, manual transmissions, etc. In short, the variator has modes:

- “P” - parking, that is, the car is expected to be idle for a long time. At the same time, the shaft locking is activated, preventing the vehicle from spontaneously rolling forward or backward. Also, starting the engine after parking should be done in this mode;

- “D” - forward movement, the gear ratio changes automatically;

- "N" - neutral gear. The mode is necessary during service (rolling the car, spinning the wheels), as well as when the car is parked on a slope in the parking lot. In the latter case, it is possible to “unload” the lock that operates in the “P” mode. However, in “N” mode, it is important to secure the car using the parking brake and/or wheel chocks when parking on slopes.

Let us also add that when parking you need to adhere to the following algorithm:

- press the brake and stop the car completely;

- holding the brake, move the selector to “N” mode;

- pull up the handbrake, release the brake pedal, then press the brake again;

- move the selector to mode “P”, then release the brake pedal;

Such actions are necessary in order to avoid unwanted damage to the thin shaft of the locking system, which is activated when the “parking” mode is activated.

Also, the variator, in addition to the main modes, also has additional ones. Among them, we can highlight the “L” mode, which can be compared to engaging the first gear and driving in it, and higher gears will not be automatically engaged. This mode allows you to increase engine speed, as well as achieve a more pronounced engine and gearbox braking effect when driving downhill, off-road, when towing trailers, etc.

Manufacturers also often equip CVTs with “S” (sport) and “E” (economy) modes. In the first case, the electronics allow you to spin the engine to high “power” speeds in order to obtain active acceleration. This solution often makes it possible to simulate the operation of step transmissions, since many drivers of cars with a CVT cannot get used to the fact that the engine speed paired with a continuously variable transmission does not change during acceleration.

In the “economy” mode, the load on the internal combustion engine is minimal in order to reduce fuel consumption to minimum levels. Let’s also add that many CVTs also have a manual mode, which is semi-automatic (analogous to Tiptronic on an automatic transmission).

Maintenance or how to extend the life of a variator

There are a number of operating features and recommendations on how to protect a car with a front-wheel drive CVT, as well as an all-wheel drive or rear-wheel drive version.

Monitor the sensors

The peculiarity of CVT is depending on the operation of the sensors. Failure of any of them can lead to failure of the variator. That is why it is necessary to monitor their serviceability and replace them at a Jatco station if necessary. You can diagnose and fix problems of any complexity at the CVT Repair Center No. 1.

Get additional information by calling: Moscow - 8, St. Petersburg - 8. We accept calls from any region.

Timely replacement of transmission oil

The frequency of filling new oil in a car with a CVT is indicated in the operating instructions. On average, replacement needs to be done every 40,000 km. When using a car in difficult conditions, it is better to replace it after 30-35 thousand.

This especially needs to be taken into account when:

- abuse of towing;

- aggressive driving style;

- staying in traffic jams for a long time;

- frequent off-road trips.

If this is not done, there is a high risk of wear on the splines, cones and belt.