April 30, 2021 Lada.Online 24 475 13

We have written about the howl and hum of VAZ gearboxes (manual and AMT) more than once. The reason is gear vibrations. The problem can be radically solved only by updating the factory equipment, which is not planned in the near future. Is it possible to reduce increased gearbox noise using transmission oil additives?

We have identified three of the most popular gear oil additives. Here's what LADA car owners write about them.

Description of transmission

Below we will consider the most important indicators that affect the operation of the car:

- the gear ratio for the VAZ 21807 shows figures of 3.94, for the French analogue this figure is slightly lower - 3.87;

- with this transmission, the Lada Vesta accelerates to one hundred in 10.2 seconds, which is a second faster than the JH3 - 11.2;

- the maximum speed for the VAZ 21807 is 188 km/h, for the JH3 the figure is 178;

- The fuel consumption of Lada Vesta with a domestic gearbox is 7.5 liters, the French gearbox consumes 7 liters.

Manual transmission

The most important thing the engineers worked on was modifying the transmission tooth profile. They took an example from European models, where the noise of the gearbox should merge during downshifts with the roar of the engine. Lada Vesta designers applied new developments, improving the entire system and adjusting its balance.

Characteristics of all types of Lada Granta gearboxes

The first manual transmission of this sedan and liftback class model received the index 2180. It was soon replaced by a modernized cable-driven gearbox, which is indexed as 2181. It is installed starting with the “standard” configuration.

Traction and cable gearbox Lada Granta

The difference between these two checkpoints is obvious. The first and most important thing is to use, instead of rigid rods that increase vibration on the body and rocker, more flexible cables from the Japanese manufacturer Atsumitec. In addition, gearbox 2180 differed from 2181 in other parameters.

- The 2181 has cone-shaped synchronizers, which reduces the impact on the gear lever when setting 1st or 2nd speed.

- The clutch disc has become larger in diameter (215 mm). Because of this, the clutch housing increased in size, and the starter began to be located along the internal combustion engine.

- The synchronizers received teeth with a reduced angle bevel (100 degrees), and the initial preload force was reduced to 70 Nm.

- A different mechanism for selecting speeds was developed by Schaeffler. In addition, it was moved upward, which made it possible to reduce the effort when switching in cold weather and eliminate oil smudges.

- The clarity of gear shifting is made possible, among other things, thanks to the selector plate.

- Instead of mineral gear oil, semi-synthetic oil was used from the factory, and the oil volume was reduced to 2.2 liters.

Structurally, the gearbox has become not only more reliable, but also more comfortable for the driver. Vibrations to the gearshift lever and the body as a whole have decreased significantly. The speeds began to turn on clearly and without delay. At the same time, the modernization of the gearbox on the Lada Granta and Kalina 2 entailed an average increase in price by 5,000 rubles. According to experts, the main difference between the updated transmission is not so much in reliability, but in the quality of gear selection.

What is characteristic is that the new editions of the Lada Priora did not receive a cable gearbox; this car is still equipped with an outdated VAZ 2180 with rigid rods.

Features of a robotic gearbox

In addition to the updated mechanics, the Lada Granta since 2015, starting with the “luxury” configuration, can be equipped with a robotic gearbox. The new transmission will be available in “standard” and “luxury” variations. According to the engineers, this device should completely eliminate the negative impact of the human factor, in which various errors are made.

Granta became the first car of the VAZ family to receive a robotic transmission option. The main manufacturer was the Japanese company Jatco, known in its field for the development and production of robotic, automatic transmissions and CVTs. They began installing a 4-speed gearbox, proven over the years, on the Grant. Not the most modern, but reliable.

Features of automatic transmission

The period of adaptation of the robot and the release of the first pilot versions of Granta on the machine lasted quite a long time. During this time, the symbiosis of domestic and Japanese developments was subjected to numerous calibrations. The modernization included about 30 modifications, and engineers from Austria were involved in the process. Only after this did the automatic transmission go into production.

Experts even took into account ergonomic issues: the hand fits comfortably on the gear shift lever. The selection of the appropriate modes is indicated on the selector; the specified mode is also duplicated on the BC screen. The only drawback revealed during operation is the unreliable fixation of the lever in the selected mode.

The gearbox operates in several modes. First and second gears are fixed. There is an overdrive button, thanks to which the automatic transmission will not switch to fourth speed. This mode is relevant when overtaking on the highway. Fixed first two gears are used for off-road driving or long uphill climbs. In winter, the transmission will not engage in higher 3rd and 4th gears until the oil warms up to 15 and 60 degrees, respectively.

Unlike the manual transmission of the Lada Grant, the automatic transmission does not have a flywheel. A drive disk is used instead.

Features of the automatic transmission scheme led to a decrease in the vehicle's ground clearance. The electronics that control the device are located behind, on the left side below the headlight. Many believe that such a location will lead to uncontrollability of the car in an accident. But engineers think differently. Automation will reliably control the work. Judging by the reviews, the system really functions flawlessly, and this is good news.

Problems with manual transmission VAZ 21807

Knowing about the shortcomings and errors of the transmission on the basis of which the 21807 was designed, buyers are subconsciously wary of investing money in a car with such a transmission. Statistics show that almost half of consumers want to buy a Lada Vesta with a French gearbox.

The howl may be mistakenly attributed to the VAZ 21807. If the manual transmission hums in neutral gear when the speed decreases from 3000 rpm, the reason may well be a defect in the muffler vibration compensator.

Should I change the box?

Replacing a box with a Lada Granta, Kalina and Vesta is a lottery. The transmission has undergone several modifications, so manual transmissions produced at different times may sound differently. But it’s not a fact that you’ll be lucky: the new box may be even noisier. It’s good if they replaced it for free under warranty, but it definitely doesn’t make sense to buy a unit with your own money.

You need to understand that the howling of a VAZ cable-driven gearbox is not a problem with a specific instance, but a design feature.

New gearbox 21807 in Lada Vesta - owner reviews

My car has a VAZ manual transmission. As long as you're happy with the work, manufacturers don't lie. You have to wait for something to break in order to identify errors or hope for the best and the absence of a breakdown. The howl of the box was not noticed, and I also did not hear any hum or extra noise. There are no sudden jerks when changing gears, reverse speed does not cause headaches. I don’t notice much difference compared to foreign manual transmissions.

People are doing the right thing by not completely trusting their compatriots. Lada Vesta is almost a foreign car anyway. When you hear that a reliable French box is being replaced with something of their own that is not particularly trustworthy, interest in the product disappears. Consumption increased by half a liter. This is a lot for a long journey. Acceleration to one hundred and maximum speed are, after all, not the most important things for the reliability and durability of the box.

My Vesta with a VAZ manual transmission began to hum after 500 km. This upset me very much, because at first I didn’t feel any problems, but now I have to contact a repair center. At first I heard a rattling noise, which went away after the engine warmed up. It's very annoying when the box buzzes. Unpleasant howls are heard in three gears. I hope the technicians will fix everything and this problem will no longer arise on my Lada Vesta.

As a rule, when buying a new car, those who are primarily concerned about reliability opt for models equipped with a manual transmission. And this is not surprising, because in general the “handle” is more reliable compared to an automatic machine.

The same applies to potential buyers of LADA Vesta. Many people prefer the “handle”, not only for the reason stated, but also because the Russian sedan does not have a classic automatic transmission. There is only a robotic transmission - AMT - however, this option, although it has certain advantages, still does not suit everyone.

Characteristics of all types of Lada Granta gearboxes

The first manual transmission of this sedan and liftback class model received the index 2180. It was soon replaced by a modernized cable-driven gearbox, which is indexed as 2181. It is installed starting with the “standard” configuration.

Traction and cable gearbox Lada Granta

The difference between these two checkpoints is obvious. The first and most important thing is to use, instead of rigid rods that increase vibration on the body and rocker, more flexible cables from the Japanese manufacturer Atsumitec. In addition, gearbox 2180 differed from 2181 in other parameters.

- The 2181 has cone-shaped synchronizers, which reduces the impact on the gear lever when setting 1st or 2nd speed.

- The clutch disc has become larger in diameter (215 mm). Because of this, the clutch housing increased in size, and the starter began to be located along the internal combustion engine.

- The synchronizers received teeth with a reduced angle bevel (100 degrees), and the initial preload force was reduced to 70 Nm.

- A different mechanism for selecting speeds was developed by Schaeffler. In addition, it was moved upward, which made it possible to reduce the effort when switching in cold weather and eliminate oil smudges.

- The clarity of gear shifting is made possible, among other things, thanks to the selector plate.

- Instead of mineral gear oil, semi-synthetic oil was used from the factory, and the oil volume was reduced to 2.2 liters.

Structurally, the gearbox has become not only more reliable, but also more comfortable for the driver. Vibrations to the gearshift lever and the body as a whole have decreased significantly. The speeds began to turn on clearly and without delay. At the same time, the modernization of the gearbox on the Lada Granta and Kalina 2 entailed an average increase in price by 5,000 rubles. According to experts, the main difference between the updated transmission is not so much in reliability, but in the quality of gear selection.

What is characteristic is that the new editions of the Lada Priora did not receive a cable gearbox; this car is still equipped with an outdated VAZ 2180 with rigid rods.

Features of a robotic gearbox

In addition to the updated mechanics, the Lada Granta since 2015, starting with the “luxury” configuration, can be equipped with a robotic gearbox. The new transmission will be available in “standard” and “luxury” variations. According to the engineers, this device should completely eliminate the negative impact of the human factor, in which various errors are made.

Granta became the first car of the VAZ family to receive a robotic transmission option. The main manufacturer was the Japanese company Jatco, known in its field for the development and production of robotic, automatic transmissions and CVTs. They began installing a 4-speed gearbox, proven over the years, on the Grant. Not the most modern, but reliable.

Features of automatic transmission

The period of adaptation of the robot and the release of the first pilot versions of Granta on the machine lasted quite a long time. During this time, the symbiosis of domestic and Japanese developments was subjected to numerous calibrations. The modernization included about 30 modifications, and engineers from Austria were involved in the process. Only after this did the automatic transmission go into production.

Experts even took into account ergonomic issues: the hand fits comfortably on the gear shift lever. The selection of the appropriate modes is indicated on the selector; the specified mode is also duplicated on the BC screen. The only drawback revealed during operation is the unreliable fixation of the lever in the selected mode.

The gearbox operates in several modes. First and second gears are fixed. There is an overdrive button, thanks to which the automatic transmission will not switch to fourth speed. This mode is relevant when overtaking on the highway. Fixed first two gears are used for off-road driving or long uphill climbs. In winter, the transmission will not engage in higher 3rd and 4th gears until the oil warms up to 15 and 60 degrees, respectively.

Unlike the manual transmission of the Lada Grant, the automatic transmission does not have a flywheel. A drive disk is used instead.

Features of the automatic transmission scheme led to a decrease in the vehicle's ground clearance. The electronics that control the device are located behind, on the left side below the headlight. Many believe that such a location will lead to uncontrollability of the car in an accident. But engineers think differently. Automation will reliably control the work. Judging by the reviews, the system really functions flawlessly, and this is good news.

Problem

However, as experience in operating the model has shown, the manual transmission is also not without some drawbacks. Sometimes owners begin to clearly hear extraneous sounds, similar to crackling and clicking noises in the manual transmission of the Lada Vesta. Moreover, for some they appeared on completely new cars that had not driven even 15,000 km.

In most cases, noises are heard while driving in third gear, however, over time, the situation worsens and a similar sound, only even more pronounced, begins to appear in fourth gear. But only in cases when the accelerator pedal is released.

This is clearly demonstrated in a video made by one of the members of the DRIVE2 community, known there under the nickname Zheka700.

The fact that this is a crackling and clicking sound in the manual transmission of the Lada Vesta is also confirmed by the fact that it is enough to press the lever handle a little and the sound disappears. This means that the problem is directly in the transmission, and not in the lining.

What is the moral of this fable?

One gets the feeling that among all the shortcomings of Vesta, the main one is the low level of production culture (in simple terms, the crookedness of the hands of those who assemble it). And also the need to forcefully kick official dealers so that they do their job.

Timing roller. It seems like a cheap part, but if adjusted incorrectly it can become a source of much bigger problems. An overtightened belt wears out faster, and the load on the shaft bearings and their wear also increases. Regular replacement of the belt on Vesta is provided every 180 thousand kilometers. What will tightened belt turn into after such a mileage?

During a conversation with the master, he casually said that they had another Vesta in service and was waiting for an engine replacement. The reason is a jammed timing belt tension roller, which results in a belt break and the valves meeting the pistons. Mileage - 30 thousand kilometers. Draw your own conclusions.

AvtoVAZ reaction

It is worth noting that not all sedans are susceptible to this problem, but only the first batch cars.

In September 2016, the issue was resolved - all Vestas began to be equipped with new manual transmission cables. So the Russian automobile concern acted quite quickly.

As for the instructions, if such a defect exists, AvtoVAZ recommends contacting the dealership and having the cables replaced.

However, not all owners are ready to do this. The fact is that such a procedure is quite lengthy, since to replace it it is necessary to dismantle the entire dashboard, then remove the steering column, including the electric power steering, and also the heater. Also, such a replacement involves draining antifreeze and freon.

Naturally, this is quite a long time and not every Vesta owner is ready to give the sedan for service for such a long period of time.

If such a situation arises, but you want to do without replacing the cables, and the car is under warranty, it is strongly recommended that you make an appointment for diagnostics at a dealership. And in order to narrow down the search and help those who decide to fix the defect themselves, we will give recommendations on where to look first.

Will disassembling the manual transmission help eliminate the whining?

Most Lada car owners, having tried the methods listed above, calm down, manage to get used to the noise and continue driving their car. But some are ready to go all the way, so they decide to disassemble the box themselves or contact a service center for this service. Is it possible to achieve the desired result using this complex procedure?

Sometimes when opening the box, significant defects in individual gears are revealed. In this case, the transmission usually makes a loud noise when engaging a particular gear. There may also be problems with the clutch and release bearing. Sometimes replacing these parts solves the problem.

In most cases, installing new parts does not make the gearbox quiet, because all gears are made on the same equipment, which, as already mentioned, does not allow for an ideal configuration.

The procedure for removing and disassembling the gearbox is lengthy and expensive, but may not yield results, so it is hardly worth going through the gearbox if howling is the only problem.

Dismantling

Before you begin work on eliminating crackling and clicking noises in the manual transmission of the Lada Vesta, you will need to remove the central tunnel. It consists of 2 sections - front and rear, with the rear being noticeably smaller.

To remove the rear section, you need to arm yourself with a ratchet with a Torx 20 bit (asterisk), use it to unscrew the 2 mounting screws, and then remove the plug. The trim itself is carefully pulled out - to do this you will need to remove the handbrake from it.

As for the front part, the tunnel is covered with plastic shields on both sides. They are secured with screws (1 per side), which need to be unscrewed and the plastic removed.

The screws need to be unscrewed

Then, carefully prying up the frame with a knife or screwdriver, the cover of the manual transmission lever is removed, after which the plug is disconnected and the lining is removed.

In the end, all that remains is to unscrew the 4 mounting screws and remove the remaining cladding.

Everything is clearly shown in the plot.

Let's look at the instructions for identifying AMT faults

The check procedure is described in the book on operation, repair and maintenance of the Lada Vesta car:

1. We make sure that the AMT control system is working, to do this, turn on the ignition. Then, pressing the brake pedal, move the selector lever in turn to all positions, and the corresponding symbols should be displayed on the instrument panel. After that, return the selector lever to position N (“neutral”).

2. Start the engine. If you hear a whining sound , the clutch release bearing is likely worn out. A similar sound may be caused by worn transmission bearings.

3. Keeping the brake pedal pressed, we switch the selector in turn to all positions, while making sure that the gear shift mechanism is working. Turning on should be easy, without crackling or crunching.

- If the whining sound intensifies , the clutch release bearing is worn out. If the sound disappears, then the gearbox bearings are worn out.

- If you hear a cracking sound and the car jerks , it means that the clutch is not disengaging completely. The cause may be a malfunction of the gear shift mechanism, wear or loss of elasticity of the clutch diaphragm spring, as well as a malfunction of the electric clutch release drive. To check the gear shift mechanism and the electric clutch release drive, it is necessary to check the fault codes stored in the transmission control unit, so this work should be performed at a specialized service station with the necessary equipment.

4. Set the selector lever to position N (“neutral”). We lower the brake pedal, but the car should not start moving.

We also recommend that you read

5. Check the operation of the Lada Xray gearbox in motion. To do this, turn on mode A (forward movement in automatic mode) and slowly press the gas pedal. In this case, the clutch should engage smoothly. We move first with acceleration and then with deceleration, making sure that the clutch is engaged smoothly, that gear shifts smoothly (both up and down), and that there is no crunching, knocking or other extraneous sounds from the gearbox.

6. Turn on M mode and repeat the test, shifting gears manually. To do this, move the selector lever first towards the “+” symbol and then “─”. The box should work smoothly, changing gears in the selected direction.

7. Stop the car and move the selector lever to position R. After releasing the brake pedal, the car should start moving backwards.

- Jerking and rattling when the clutch is engaged can be caused by oiling or warping of the clutch discs or destruction of the torsional vibration damper.

- Untimely gear shifting , or engaging a gear that does not correspond to the driving speed, is caused by a malfunction of the transmission control unit.

- Jerks and delays when changing gears while the car is moving, or shifting into gears with an impact may indicate a malfunction of the gear shift mechanism or the electric clutch release drive. Troubleshooting such problems requires reading fault codes stored in the transmission control unit, so such work should be performed at a specialized service station with the necessary equipment. In addition, when replacing a faulty electric drive mechanism, it is necessary to configure the transmission control system. Otherwise, correct operation will not be possible.

Work in the salon

Retainer

It is the plastic clamp, to which the drive cable is connected on one side, while the transmission lever is attached on the other, that is one of the possible reasons.

To get rid of sounds, it is recommended to place elastic material under the cable. This will cause the cable entering the clamp to rest against the lining. As a rule, simple electrical tape is used.

To do this, the tape is first glued in half (with the adhesive side inward), after which the cable is pulled out a little and the tape is installed. The cable is put back and it will push the tape into the lock itself.

It is recommended to carry out similar modifications for both clamps.

Ties and lining

The cables themselves are attached using plastic brackets, and a slight play is visible, which can also become a source of background noise.

What will be needed

Now let's take a closer look at what may be required to carry out the oil change process. The current state of affairs shows that almost every Kalina owner is very smart and handy, and rarely goes to repair shops. This behavior of car enthusiasts is quite justified, because in cars of the domestic automobile industry, all work on changing the oil is quite easy to do with your own hands. In order for the process to go quickly and to save time, it is better to prepare in advance:

- wrench for 17, or even better, the so-called “scapular” one;

- a funnel and a tube (about 50, but no more than centimeters), which can be bought at any store;

- directly the oil to be filled;

- deep and voluminous container for “working off” (i.e. used oil);

- special flushing compounds for cases where flushing is planned;

- a jack or lifting device, which will be useful when flushing.

Of course, and there is no need to remind you about this, you will need to drive your car onto an overpass or inspection hole. So, let's move on to the process itself.

Engine compartment

Near the manual transmission

If modifications in the interior do not produce results, it is recommended to look for the reason under the hood.

To begin with, you can better secure the cable directly in front of the transmission using plastic clamps.

Screed in front of manual transmission

Near the engine shield

The fourth option for independently eliminating crackling and clicking noises in a Lada Vesta manual transmission also involves the use of plastic clamps, but they must be placed not near the place of fixation, but as far as possible from it.

Screed near the engine shield

In this case, you just need to tighten the cables together with a clamp.

The engine air filter should not interfere

The air filter box in Granta and Kalina-2 cars is secured with three rubber stops. It will not be difficult to dismantle them, but first you will need to disconnect all the connectors attached to the box from the outside. You will also need to remove the adsorber valve.

And only then, without fear of damaging anything, the plastic box is taken to the side.

The result of all the work done looks like this:

The filter box is simply folded back

The steps mentioned above are listed here in order:

- Disconnect the negative terminal of the battery;

- Disconnect the clip “1” that holds the power wire and disconnect the connector “2” of the mass air flow sensor (Fig. 1);

- Dismantle the canister purge valve.

Disconnect the connector with the wires, then use a flat screwdriver to press the spring on the side and remove the module itself from the grooves (Fig. 2); - All stops holding the box can be easily removed from the slots (Fig. 3).

The connector that needs to be disconnected in “step 2” will not be available in configurations with motor 21127.

We wish you success.

Couplers and spring

In this case, there is no need to go into the engine compartment. This troubleshooting option was proposed by another member of the DRIVE2 community named Roman, who is known there under the nickname Roy04.

First, he dismantled the lining of the central tunnel to gain access to the mechanisms. After examination, it was determined that the sounds were coming from 3 points.

Further, after a test drive with the tunnel removed, it turned out that this was not the cause, but only its consequence. It's all about the design of the Lada Vesta transmission. Due to the design features, when driving at speed III, vibration occurs in the gearshift mechanism, which is directly on the transmission (under the hood). And from behind the scenes the cable vibrates and moves longitudinally.

There are no devices for damping these vibrations, but you can make your own “counterweight”, from scrap materials. To do this, you can use plastic clamps and a spring, for example, from a figure eight carburetor.

With the help of clamps, the rigidity of the components that make sounds is increased, and the spring guarantees tension on the manual transmission handle itself.

As a rule, after such modifications, crackling and clicking noises in the manual transmission of the Lada Vesta disappear.

In mid-2016, AvtoVAZ officially abandoned the use of manual transmissions from the French manufacturer Renault. The reason is the high cost of the “product” and the lack of a base for maintenance.

If domestic gearboxes cost 20–25 thousand rubles, then imported ones reached 45–50 thousand. Obviously, such a rise in price automatically increased the cost of the car as a whole. Perhaps because of this factor, many car enthusiasts preferred a model with a classic automatic or robotic option.

However, there are those who claim that the quality of production of domestic new mechanics (21087) is inadequate. They are ready to pay an additional 30,000 rubles for the French version. Let's compare the Renault JH3 (JR5) manual transmission and the VAZ 21087 manual transmission.

Reviews of XADO additive

The manufacturer writes that the additive is intended for the restoration of gears, bearings and other gearbox and gearbox components and their protection from wear. Forms a new metal-ceramic coating with unique characteristics on the surfaces of friction pairs and completely restores the geometry of the parts.

- restores and protects friction parts of the transmission from wear;

- eliminates sinkholes and scratches on work surfaces;

- restores the geometry of parts;

- optimizes contact patches in gear meshing;

- reduces noise and vibration of components by 10 times;

- increases the clarity of gear shifting;

- improves the performance of synchronizers;

- provides significant fuel savings (especially on all-wheel drive vehicles);

- etc.

Review from the owner of Lada Kalina (beijo2908)

:

In general, I drove 100 - 150 km... The gearbox noise decreased subjectively by 20%. It didn't get any worse. The rustling still remains, but a little quieter.

Review from the owner of Lada Kalina (nixx56)

:

It really works) The noise of the gearbox has decreased significantly, the humming noise when cold has practically disappeared and the gears began to engage better (especially noticeable when changing from 2 to 1 in a traffic jam while driving). In general, the topic is normal)

There is no clear opinion. Each additive has positive and negative reviews.

Review from the owner of VAZ 2112 (seromy)

:

Having poured two tubes into the box according to the instructions, I can say that the box has really become quieter and smoother, the jerking when downshifting has disappeared. I didn't expect such an effect. Miracles indeed. I don't know what will happen next, I hope it won't get worse.

Review from the owner of Lada Kalina (gribanovmaks)

:

Now I have driven 2000 km, after filling, the result is positive, but the sound has not completely disappeared. So it's something like this.

Car enthusiast (somebody)

:

After rebuilding my gearbox, I bought two of these tubes, and even first dissolved them in a liter of oil - there was almost no effect. Wait, I just filled up the g-ff half-blue zik and I don’t plan to spend any more on all this nonsense. It’s better not to spend money on miracle remedies, but to spend it on shvi and good music in our cars.

Conclusion

: There are two opinions about gearbox additives:

- They really work.

- There's no point in them. Not a single additive will restore the incorrectly milled metal surface of gears or create a layer between the contacting parts, so that the gasket makes it quieter.

Have you managed to eliminate gearbox whine using additives? Take the survey!

Specifications

| Name | Renault JH3 (JR5) | Manual transmission - 21087 |

| type of drive | Wire rope | |

| Number of speeds | 5 | |

| Main couple | 3,9 | |

| Gear ratio | 3,87 | 3,94 |

| Acceleration to “hundreds” | 11,2 | 10,2 |

| Maximum speed (km/h) | 175 | 188 |

| Fuel consumption (l/100 km) | 6,9 | 7,5 |

| Gear ratios for each gear | 3,636; 1,950; 1,357; 0,941; 0,784 | 3,727; 2,048; 1,393; 1,029; 0,795 |

Installing a shorter main pair increased the dynamics of acceleration, taking one second from the French “brand”. Adjusting the gear ratios for each gear made the transitions to higher gears smoother, without jerking, and dynamic.

Manual transmission volume

Lada Vesta uses 2 types of manual transmissions:

- Renault JH3 unit, installed from the start of production until October 2022. To designate the device, the number 3 is used, located in the 8th place in the factory VIN number of the car. The transmission features an increased crankcase volume designed to hold 2.34 liters of oil.

- The Russian analogue of the VAZ-21807, supplied to the assembly line since October 2020. The gearbox is built on the basis of the transmission from the Lada Granta/Kalina/Priora, the crankcase volume is 2.25 liters, the gear ratios and installation dimensions are identical to the French analogue. The unit is recognized by the number 1, located in the 8th position in the VIN number.

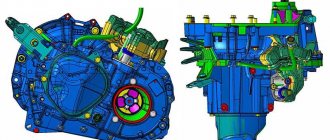

Design and diagram of manual transmission on Lada Vesta

with engine capacity

1.6 / 106 hp., 1.8 / 122 hp.

| Name | Data |

| Type | Mechanics |

| Factory index (article) | 21087 |

| Drive unit | Front |

| Engine capacity | 1,8 |

| Torque | 170 Nm |

| Default oil type | ZIC GFT 75W-85 |

| Oil volume | 2,2 |

| Lubricant replacement | Every 75,000 km |

| Filter update | Likewise |

| Average service life before major overhaul | 180000 km |

Checkpoint operation diagram

To find out the transmission type of your car, look at the VIN code:

- GFL11: mechanics;

- GFL12 - AMT box;

- GFL13 ─ mechanics from Renault.

Changing the fluid in the manual transmission of Lada Vesta

On a warm Lada Vesta we drive onto a pit or lift. The used liquid must be drained immediately, because when it cools down it becomes more viscous and leaks worse.

- First, we de-energize the Lada by removing the terminal from the battery;

- We remove attachments that obstruct the path to the filler hole: air filter, pipes;

- We unscrew either the control plug with a size 17 wrench, or the reverse switch, having first removed the wires from it (wrench 22). The location of the switch is more convenient for filling oil.

- We go down, dismantle the technological hole for draining the oil from the gearbox or completely remove the engine protection (key 14 or 17);

- We substitute a container for “working off” with a volume of 2.5 liters (2.2 to be precise);

- Using a 17 wrench, unscrew the drain plug in the crankcase;

- We wait for some time, let the liquid drain completely;

- Screw the plug into place;

- We insert a hose with a clean funnel into the switch or control hole, change the oil to the lower edge of the control plug or, more simply, until lubricant flows out of it;

- After all the manipulations, close all the holes and check them for leaks. Then we install the protection in place. We remount the VF Frets, the removed pipes and terminals.

“Pros” and “cons” in comparison with an automatic machine (robot)

| Advantages | Flaws |

| Acceleration dynamics have become better, the car picks up speed faster | Increased fuel consumption in the combined cycle |

| The car is 30 - 35 thousand cheaper when purchased with a manual transmission | Crunching, creaking when driving at low speeds |

| Long service life | |

| Cheapness of spare parts and components | |

| The car is more expensive on the secondary market compared to the robotic version |

Oil change procedure

Stages of changing the oil in the box in the Lada Granta (liftback):

- The vehicle warms up to ensure optimal fluidity.

- The Lada is started into the inspection hole.

- It is necessary to remove the protection from the crankcase to gain access to the drain hole.

- The plug is unscrewed and the fuel is drained into a previously prepared container.

- The control plug is unscrewed using a special key.

- Oil should be added to the gearbox through the inspection hole. The battery terminal should be disconnected.

- To gain access to the switch, the filter must be removed.

- Transmission fluid should be poured through a special funnel, which must be supplemented with a special hose.

The volume of fuel that needs to be filled directly depends on the type of gearbox available. It is better to carry out this procedure with gloves, as you can get burned by the transmission fluid.

When to change the oil in the box? It is worth contacting a service station if there is a suspicious noise while driving. When the transmission overheats, a burning smell will appear.

Thus, the quality of the fuel poured into the box directly affects the service life of the automotive system. The driver can check the oil level in the box with a dipstick, which is pulled out of the gearbox hole. The Lada Granta manual transmission should be filled with approximately 2.3 liters of fuel. Changing the transmission fluid begins with removing the old lubricant. If the drained oil has changed color or acquired an unpleasant odor, it is advisable to flush the gearbox. The replacement process is not difficult.

Malfunctions and ways to eliminate them

| Malfunctions | Troubleshooting Methods |

| Transmission howl at 2000 – 3000 rpm | Insulation lining for gearbox control cables |

| Knock at idle | Replacing the pressure bearing |

| Critical wear of gears and teeth | Replacement with new ones, cannot be restored |

| Oil leaks from seals are less common. | Replacement of sealing seals with new ones. Overhaul of gearbox |

Service life - from the factory and actual

The manufacturer in the operating instructions indicates an average interval of 180,000 km before major repairs. In fact, the mechanics last up to 200,000 km, provided that the manufacturer’s recommendations for care and maintenance are followed.

At the stage of using mechanics, breakdowns associated with depressurization of the system, oil leakage, and wear of the pressure bearing are most often recorded. Malfunctions are insignificant, not critical, and can be eliminated in a few hours of work by technicians at a service station.

Conclusion

The manual transmission under the factory code 21087 is a real technological breakthrough of domestic engineers. The transmission turned out to be not only more powerful, but also faster. At the same time, fuel consumption increased by 0.5 liters.

“Mechanics” has its advantages and disadvantages compared to the robotic version. Therefore, before purchasing, carefully analyze the technical characteristics of each type of gearbox.

From personal experience I will say the following:

- The mechanics are most adapted for active use on rough terrain.

- The robotic version, “automatic”, is mainly used for high-speed modes.

Tools and materials

In order for the oil change in the 2nd and 1st generation Kalina gearbox to be successful, we need to prepare:

Open-end wrench 17 (or ratchet with a head). Jack. An empty canister or any other container for draining waste

It is important that it is wide and flat, otherwise it will not fit under the bottom. You can cut the side of a motor oil can and place it under the drain hole

The Kalina's clearance allows this to be done. Watering can. It is advisable to lengthen it, since the box with the filler hole is very deep. For convenient filling, use a hose of the appropriate diameter. It is important that its length is at least 30 centimeters.

Reviews

| № | Positive |

| 1. | Dmitry , 33 years old (drive2.ru): they can’t say anything bad about the mechanics, the gearbox works properly. The car is only a year old, I regularly undergo maintenance, I don’t drive, I drive carefully. |

| 2. | Vyacheslav Petrovich , 47 years old (prom.ua): in a year and a half I drove about 20,000 km, mileage is above average. Impressions of the new mechanics are only positive. There is something to compare with; before this there was the Lada Granta. Grantmakers understand what I'm talking about. |

| 3. | Alexander Alekseevich , 43 years old (drom.ru): after buying the car, I changed the transmission oil for the first time at the 7000 km mark. I didn’t wait for 75,000 km, as the manufacturer recommends. The waste was of a natural color, metal shavings were present, but their quantity was insignificant. I did the same. |

| 4. | Alexey Petrovich , 48 years old (rozetka.ua): I’ve heard numerous negative reviews about the mechanics, I can’t confirm. I believe that the technical condition and performance of the unit depends on the driver. I don’t have any problems with this, I take care of my equipment. |

| 5. | Semyon Vyacheslavovich , 40 years old (Auto.ru): This is the second year since I bought and actively use a Lada Vesta on the mechanics. The review is positive, there are no comments about the work. |

| 6. | Vasily Timofeevich , 43 years old (Auto.Mail.Ru): for a year and a half of using a car with mechanics, he once made an unscheduled visit to a service station for diagnostics. I was at fault for the hum in the manual transmission, but it was the suspension. I hope that the device reaches the 180,000 km specified by the manufacturer. |

| 7. | Dmitry Gennadievich , 41 years old (drive2.ru): I like the mechanics more than the robot, I drove the AMT for three months, I can compare. Both robot and automatic are not adapted for domestic roads. The units do not last long, so it is better to buy a manual transmission. |

| 8. | Sergey , 35 years old (drive2.ru): on the mechanics, as soon as I pressed the pedal, I pressed it. And overtaking, and maneuverability, without kickdowns, delays in switching. Choice: definitely mechanics. |

| Negative | |

| 9. | Dmitry Semenovich , 52 years old (prom.ua): no matter how hard we tried, a miracle did not work. We decided to save several tens of thousands, but for the wrong reasons. It would be better to make the plastic cheaper than to install a Russian gearbox instead of a French one. Knocking and noise in the manual transmission was detected at 40,000 km. With such a low mileage there are such significant defects. |

| 10. | Gennady , 46 years old (Bibika.ru): after 30,000 km, cases of clutch slipping, delays when changing to higher gears, and howling of the gearbox became more frequent. You need to go to a workshop and order diagnostics. Couldn’t it have been done better from the start? |

| 11. | Boris , 38 years old (drive2.ru): at 25,000 km a gearbox whine appeared on a Lada Vesta. The officials said that the pressure bearing needs to be changed, but this is not certain. The final diagnosis will be announced after a comprehensive diagnosis. |

| 12. | Sergey Gennadievich , 45 years old (Avtodispatcher.ru): a knock in the gearbox was detected already at 31,000 km. Initially the fault was with the suspension, but after diagnostics the technician assured me otherwise. |

Reviews of the additive RESURS-T

The manufacturer claims that the additive eliminates noise caused by wear of gear teeth, synchronizers and bearings. Makes gear shifting easier. Compatible with all types of gear oils! Increases the service life of transmission oil up to 5 times!

Review from the owner of Lada 4×4 ( drpsychosocial)

:

After 500 kilometers, listening to the squeal of the box, I remembered about the flooded slurry, I even wanted to write a negative review, but I decided to ride until two thousand, and then think about it. At about one and a half thousand I stopped paying attention to the checkpoint, I even forgot about it. But at two thousand, remembering the miracle remedy, I noticed the silence. This “bastard” really worked. In fact, I never expected that some kind of additive would cause the input shaft bearing to shut up, because... far from it. As a result, I have driven about five thousand and the box is silent - I don’t believe it, but I have to.

For the life of me, I don’t know if it will work for you, because... I didn’t believe in anything, but it worked for me.

Review from Lada Priora owner (insaid)

:

I didn’t notice the departure coming. but the switching is unrecognizable. No twitching or retaliatory blows to the lever. clear inclusion, etc.

Review from the owner of Lada Kalina ( paulys003)

:

The first additive to be poured was RESURS T - for manual gearboxes 50g in the amount of 2 pieces (recommended by a local master). After driving about 3,000 km, I didn’t notice any particular reduction in noise; the gears just seemed to shift better, but more at the placebo level.

Review from the owner of VAZ 2112 (duckattack)

:

So far, when I arrived, I noticed two things: 1) it seemed to me that it became more difficult to engage in speeds 1 and 2 sometimes; 2) the noise of the bearings and shafts has not gone away. More precisely, as soon as the bearing arrived, it began to make even more noise.