Gap "B", between the edge of the throttle valve and the wall of the first chamber of the carburetor, appears when the choke handle is fully extended and the air damper is closed (the starter is cocked and ready for use).

Gap “A” appears when the engine starts and the diaphragm trigger mechanism is activated between the edge of the air damper and the wall of the first chamber.

If the starting device malfunctions or is incorrectly adjusted, it is quite possible that a cold car engine will not start or will start, but with difficulty, and will “flood” the spark plugs.

— slotted screwdriver (3mm)

— open-end wrench (7mm)

— open-end wrench (8mm)

— tachometer (multimeter, autotester operating in tachometer mode) To make adjustments without removing the carburetor from the engine.

If there is no tachometer, you can try to adjust by ear, but this is only if you have already dealt with adjusting and tuning carburetors and can distinguish between 3000 rpm of the engine and 3500 rpm. Such an adjustment is possible in principle, but will be very approximate. It is easier to adjust the starting device by removing the carburetor from the engine.

- a set of round probes or pieces of wire with a diameter of 0.85, 1.0, 1.1, 2.5, 2.7, 3.0 mm, depending on the carburetor model.

Before making adjustments, we check to see if the starting device is in order and we are wrongly blaming it.

Checking the operation of the carburetor starting device 2108, 21081, 21083 Solex

1. Remove the cover of the air filter housing.

2. Completely close the air damper by pulling out the choke.

3. The assistant starts the engine, and we look at the carburetor from above.

If the carburetor starting device is working properly, then during start-up (after the first flashes) it will open the air damper at a small angle (starting gap).

starting gap "A"

If you do not observe such a phenomenon, then there are only two conclusions - either the trigger device is not adjusted, or its diaphragm is leaky.

You can also take into account such versions - the screws securing the cover of the starting device are not fully tightened, the plane of the cover is deformed for some reason and does not fit tightly to the body of the device, which depressurizes the entire system.

We carry out the adjustment as indicated below, tighten the screws, change the diaphragm, grind the cover or replace it with a new one.

Preparatory work

We carry out the adjustment with the engine not warmed up.

— Remove the air filter housing.

Removing the air filter housing on the VAZ 2108 engine

Adjusting the starting device of the Solex carburetor without removing it from the engine

1. Connect the tachometer.

tachometer connection procedure

If there is a tachometer built into the instrument panel, then you can use it. 2. Pull out the carburetor air damper drive handle (“choke”) until it stops.

the air damper of the carburetor 2108, 21081, 21083 Solex is completely closed (top view of the carburetor)

The air damper completely covers the cross section of the first chamber of the carburetor.

3. Start the engine.

4. Press the edge of the carburetor air damper with a screwdriver and open it 1/3 (30 0 ).

open the air damper of the carburetor 2108, 21081, 21083 Solex approximately 30 degrees (1/3)

screw for opening the throttle valve of the first chamber of the carburetor 2108, 21081, 21083 Solex

6. Release the air damper .

7. Use a slotted screwdriver to turn the starter adjusting screw, loosen its lock nut with an 8 mm wrench and reduce the rotation speed to 2800 - 3000 rpm.

carburetor trigger adjusting screw 2108, 21081, 21083 Solex

8. Hold the screw with a screwdriver and tighten the locknut. The adjustment is complete.

Adjusting the starting device on a removed carburetor

Before making adjustments, it should be recalled that on the Solex carburetor 2108, 21081, 21083, with the air damper completely closed, the throttle valve of the first chamber should be slightly open, the second chamber should be completely closed.

1. Remove the air filter housing.

Removing the air filter housing on the VAZ 2108 engine

2. Remove the carburetor from the engine.

3. Turn the air damper control lever counterclockwise until it stops (the air damper is completely closed).

carburetor air damper 2108, 21081, 21083 Solex is completely closed

Setting up the float chamber

This type of work allows you to adjust the optimal amount of gasoline in the float chamber. An incorrect level causes a decrease in power, uneven engine operation, and excessive fuel consumption.

- set of wrenches;

- thin probe (diameter 1 mm);

- pliers.

1. Remove the air filter and unscrew the carburetor cover.

2. Carefully remove the float chamber cover.

3. Check the condition and position of the floats. They should be parallel to the imprints of the side walls of the float bath on the gasket.

4. If they are displaced, we align them by bringing them together or spreading them apart.

5. Next, lay the lid horizontally with the floats up and use a feeler gauge to measure the distance from the bottom of the float to the gasket. It should be equal to 1 mm. If it is higher or lower, we continue further adjustment after installing the carburetor on the engine.

6. When fuel is pumped into the float chamber, its level should coincide with the red lines, as shown in the photo.

7. If the floats are set incorrectly, this level will be lower or higher. Simple adjustment is carried out by bending or bending the tongue of the floats, then closing the carburetor cover and pumping fuel.

For details on setting up the float chamber, see here

What to do with increased consumption

Before you tightly grasp the carburetor, be sure to make sure that the other systems are in good working order - the spark plugs are in working order, the high-voltage wires do not break through to ground, and there is compression in the engine cylinders (the minimum value for the VAZ 2108 is 11 Bar). Unscrew the spark plugs and check the condition of the electrodes.

Important. The color of the electrodes reflects the picture of the operation of the power unit. A black coating indicates that the mixture is over-rich, the proportion of gasoline in it is too high. White color indicates a lean mixture, the norm is a light brown tint.

Light brown is the correct color for the electrodes on the spark plugs

The most unpleasant problem is an increase in fuel consumption, which occurs for the following reasons:

- the economizer diaphragm is worn out;

- the main air jet or channels inside the unit are clogged;

- the needle valve, which limits the flow of fuel into the float chamber, does not hold;

- jets of unknown origin from a repair kit were installed.

Location of the economizer cover

Note. Listed here are problems that you can solve on your own. If the recommended measures do not have an effect, then the malfunction is more complex and you will have to contact a carburetor repair specialist to fix it.

To check the diaphragm, remove the air filter housing (the cover is secured with 3 10 mm nuts, the housing with 4 8 mm nuts). On the left wall of the carburetor in the direction of travel of the car, find a triangular economizer cap screwed with 3 screws, unscrew them with a Phillips screwdriver. Underneath there is a spring-loaded membrane that needs to be checked and replaced if necessary.

Removing the filter on the figure eight

To eliminate other causes, you will have to remove the top cover of the Solex by disconnecting the starter cable and unscrewing the 5 fastening screws with a Phillips screwdriver. Then follow the instructions:

- Unscrew the air jets, remembering where each one should be. Fuel jets are hidden under them in the wells; unscrew them with a thin screwdriver and pull them out with a toothpick. Blow through the calibrated holes thoroughly.

- Using a blower, suck the gasoline out of the float chamber along with the dirt. Fill all channels and diffusers with the product from an aerosol can, wait for the time indicated on it and carefully blow out the carburetor without removing it from the car.

- Take the removed cover of the unit, turn it with the floats up and try to blow into the fuel supply pipe, plugging the pressure release fitting with your finger. If air passes through, replace the needle valve as it will also allow gasoline to pass through unhindered.

- If you replaced all the jets before increasing the flow rate, feel free to unscrew them and throw them away, and return the standard ones to their place.

- Before assembly, make sure that the floats do not touch the walls of the chamber; if necessary, carefully bend them.

- Reassemble the Solex in reverse order and begin adjusting.

To remove the top cover of the Solex you need to unscrew 5 screws

Reference. Oddly enough, with a lean mixture, gasoline consumption also increases. Since the car “does not pull” due to lack of fuel, you solve the problem by pressing the gas too hard, or even pulling the “choke”, half closing the air with the damper. Naturally, fuel is consumed beyond the norm.

Setting up the launcher

- open-end wrench 7;

- open-end wrench 8;

- flat screwdriver;

- electronic tachometer or multimeter with its function.

1. Remove the air filter from the carburetor. Pull the “suction” towards you as far as it will go. Next, you will need an assistant to start the engine. At this time, you are watching the starter flap, which should open slightly after starting.

2. If this does not happen, it means that the starter is not adjusted.

3. We begin the adjustment. Warm up the engine, turn it off and connect the tachometer as follows.

4. Pull out the choke and start the engine. The suction valve must be completely closed.

5. Next, use a screwdriver to press on the edge of the damper, opening it 30 0 .

6. Using a 7 key, rotate the throttle position adjustment bolt until the tachometer shows a speed of 3200-3400 rpm.

7. Now use a screwdriver to rotate the starter adjustment bolt, having previously loosened its locknut with an 8 key, until the speed drops to 2800-3000 rpm.

8. In this position, holding the bolt with a screwdriver, tighten the locknut.

The adjustment process can be seen in this video

Operating principle

Solex 21073 works as follows. Gasoline will enter the float chamber using the inlet fitting; the fuel also passes through the mesh filter, where it is cleaned, and goes through the needle valve. The chamber with the float is two-sectional, and the sections are connected to each other. They will contain the same amount of gasoline. This design makes it possible to significantly reduce the effect of body tilt on the fuel level in this chamber.

This ensures more stable engine operation. As the chamber fills, the float, pressing part of the needle valve, blocks the access of fuel to the chamber. This maintains a constant level of gasoline in the mechanism. Next, from the float chamber, gasoline flows through the jets into the mixing wells. Air enters these same wells through special holes in the emulsion tubes or air jets. Next, gasoline and air are mixed in them. As a result, a fuel mixture is formed. It will get into the small as well as large diffusers of the device. This is the main dosing chamber. Depending on the operating mode of the engine, certain mechanisms and systems can be started in the carburetor. When the owner tries to start the engine when cold to enrich the fuel mixture, the starting device comes into play. Its driver starts this choke from inside the cabin.

Svetlov dynamics carburetor economy 21073 Solex - 1 part

For long-term operation of the carburetor

, it is required to carry out competent preparation.

This video

is familiar.

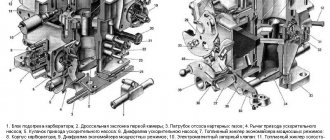

Solex carburetor design

The Solex carburetor has several models, namely:

The main modification of this brand of carburetors is SOLEX 21083. This model has the smallest diffuser cross-section. In terms of structure, all Solex models are the same, there are only some differences (different brands and models of cars have their own modification). Therefore, the Solex settings for all models are the same.

The Solex carburetor type is emulsion. It is installed only on cars with engines with contactless ignition.

Solex device:

- two chambers with throttle valves;

- chamber dosing system;

- transition systems for both chambers;

- idle speed system only for the first chamber.

Classification of Solex carburetors by configuration:

- Semi-automatic starting system.

- Carburetor accelerator pump.

- Power mode economizer.

Have you heard about a car device that can reduce fuel consumption, the FuelFree fuel saver?

Idle system

This unit is necessary in order to supply the combustion chambers with a combustible mixture at the lowest speeds. Thanks to this system, the power unit will not stall when there is no load. Fuel will enter the system through the main jet into the first chamber. Through the XX jet, where it is then mixed with oxygen, the fuel enters the system through the air valve. This mechanism allows you to ensure stable engine operation at idle speed without load.

See:

Next, the combustible mixture will enter the first chamber through a special channel located under the throttle valve. The fuel mechanism leading to the XX exhaust port is closed with a quality screw. This is an adjusting screw that can be used to adjust and change the characteristics of the carburetor. The operation of the engine in idle mode on the Solex 21073 is also adjusted with this element. Due to it, the gap value of the throttle valve of the first chamber in XX mode is determined.

How to set up a Solex carburetor

The best carburetor is SOLEKS. Therefore, many drivers replace their standard carburetors with devices of this type. Solex works clearly even if there was a strong overflow of fuel.

As it turns out, many people have difficulty setting up the SOLEKS carburetor correctly. It must be configured so that fuel consumption is minimal and power is maximum, so you need to look for the “golden mean”. Therefore, those who do not want to learn the subtleties and nuances of setting up give this job to a professional.

But, for those who want to learn how to adjust and configure a Solex carburetor, we will describe the correct procedure:

- It is necessary to set the level in the float chambers. The manual (instructions) states that the level can be set using a special template. This is difficult if there is no factory setting. If there is no factory setting, you need to do it yourself. How to do it? To do this, start the internal combustion engine and warm it up for about 10 minutes. Next, turn off the engine and disconnect the fuel supply hose. When the hose is disconnected, gasoline flows out normally, but fuel must not be poured into the chamber, otherwise the readings will be spoiled. Next, unscrew the carburetor cover bolts and remove the choke cable. After disconnecting the cable, you must very carefully and horizontally remove the Solex carburetor cover. If you do this carelessly, the floats may be damaged. Now you need to measure the distance from the Solex cap to the surface of the gasoline. It is necessary to measure in each chamber; the fuel level in them may be different. To determine whether the level is normal or not, you need to add the two resulting distances and divide by 2, that is (distance of camera 1 + distance of camera 2)/2. If the measured distance is between 25 and 35 mm, then everything is normal. If the level goes beyond the limits up or down, then you need to adjust the level. To do this, bend the float in the desired direction and drain some of the fuel.

- We adjust the idle speed of the internal combustion engine. It often happens that when you press the clutch pedal, the engine speed immediately drops - this indicates that the idle speed has disappeared. To do this, warm up the car engine to normal operating temperature. Next, turn off the engine. In the hole in the Solex sole we look for the mixture quality screw and turn it to the right until it stops. Now you need to start the internal combustion engine and push in (remove) the choke. This screw is used to set the permissible minimum speed. This number of revolutions should ensure stable, stable operation of the motor, while the vacuum should be minimal. A well-tuned Solex carburetor should allow the engine to idle at speeds from 500 to 1200 rpm. After the engine begins to operate stably, we continue to rotate the mixture quality screw until the internal combustion engine begins to operate unstably, after which we turn it back 1-2 turns. Next, we proceed to setting the engine speed to normal; we need to make sure that the speed is in the range from 800 to 900 rpm. Turn the screw until the engine starts running stably.

- When adjusting the idle speed, beginners often have difficulties. It happens when you turn the quality screw, the engine operation does not change, but the quality of the internal combustion engine must change. When the engine is unstable, the mixture quality screw can be adjusted. If the engine does not respond to changes in the adjustment of this screw, then fuel continues to flow into the idle channel, the screw cannot close it. This may be due to an enlarged nozzle (hole for metered fuel supply) or due to a poorly screwed plug, as well as a deformed nozzle. This can be done by carrying out a simple diagnostic procedure: with the engine running, you need to unscrew the valve - here the engine should stall. If the problem is in the enlarged nozzle, then the internal combustion engine will suddenly turn off, and if the internal combustion engine does not stall at all, then gasoline is not supplied through the nozzle. In this case, when the engine does not stall with the carburetor valve removed, then we check the stopper screw of the second chamber. The locking screw is used to smoothly open the throttle valve.

Adjusting the VAZ 2108 carburetor: troubleshooting it yourself

Russian passenger cars VAZ 2108, 2109 and even the first “tens” were equipped with carburetors produced by the Dimitrovgrad Plant (DAAZ) under license from the famous European brand Solex. The units are quite unpretentious and reliable in operation, but still require periodic maintenance and adjustment. Most G8 owners can perform this procedure on their own if they carefully read all its intricacies. It is unacceptable to mindlessly interfere with the operation of the carburetor.

How to check Solex

To ensure high-quality work on adjusting and tuning the carburetor, you should ensure that sand particles, etc. do not get on the throttle valves. If solid particles get into the carburetor, this can lead to an expensive overhaul of the internal combustion engine (due to some small thing).

After you have adjusted the carburetor correctly, you need to check the accelerator pump. When the throttle valve is opened slightly, the nozzle should spray gasoline. Here is the answer to the question: why does the car jerk when driving? If a stream of gasoline from the sprayer appears late, then this precisely leads to braking when you press on the gas and the car jerking.

To clean the carburetor, it must be disassembled. First, we unscrew the fuel and air jets, as well as the emulsion tubes. If it is difficult to remember what is where in the carburetor device, then it is most convenient to photograph each step.

To determine whether the diaphragm is intact, unscrew the cap of the power mode economizer.

Signs of a broken carburetor diaphragm:

- The internal combustion engine does not stall when the screw is tightened.

- If you turn off the ignition, the engine continues to run for some time, that is, self-ignition occurs.

- Unstable operation of the internal combustion engine.

- Increased gas mileage during normal, moderate driving.

ECTO or EURO? What brand of fuel is best to fill in? ECTO fuel is not recommended for use in cars with high mileage.

After checking the integrity of the diaphragm, we clean the SOLEKS. For cleaning we use air pressure (a compressor or pump is needed). If the dirt is hard and does not fly off with a stream of air, then carefully clean the stuck dirt with copper wire. I use air pressure cleaning without damaging the surfaces of carburetor parts. After this, close the lid and now you need to lubricate all the rubbing surfaces of the carburetor parts. It should be lubricated after washing the outer part.

When adjustment is needed

Before you take a screwdriver and start turning the screws of the fuel unit, you need to understand one important point. It is as follows: adjusting the Solex carburetor is not a separate operation, but the final stage of the troubleshooting procedure or its scheduled cleaning. The only exception is if the settings were accidentally or unknowingly changed by you or someone else.

Solex carburetor - general view

The following signs indicate interruptions in the supply of the air-fuel mixture to the engine associated with Solex problems:

- the car began to stall at idle;

- fuel consumption has risen above normal and is accompanied by unstable operation of the power unit;

- a cold engine starts and immediately stalls, you have to make several attempts by manipulating the choke lever and the accelerator pedal;

- when you press the gas, a “failure” occurs, accelerating dynamics are completely absent;

- The car stalls while driving when you release the accelerator pedal while coasting.

Note. Unfortunately, the cause of the listed malfunctions is not always the carburetor. Problems with cold starts also arise when there is no compression in the cylinders, and the “culprits” for failures are often faulty spark plugs.

Wear of spark plugs also leads to increased gasoline consumption and the appearance of failures.

Point two: fixing not every problem ends with adjusting the fuel supply. The issue will be covered in more detail below, along with methods for repairing common breakdowns of the G8 carburetor. But in some cases you can’t do without adjustment:

- after removing or disassembling the Solex for the purpose of repair;

- upon successful cleaning or purging of the unit’s channels;

- after replacing rings or the entire piston group in a car engine;

- as a result of reconfiguring the timing in the ignition system, replacing high-voltage wires or installing new spark plugs.

Advice. Considering the low quality of fuel sold at many gas stations in Russia, it is recommended to remove the entire carburetor once every 20-25 thousand kilometers, disassemble it and thoroughly clean it with a compressor. After which you need to make adjustments.

Solex carburetor tuning

Tuning, that is, improvement, modification of the carburetor is carried out to increase engine power and improve driving dynamics.

Important! In order to achieve maximum power, there must be a minimum of resistance at the carburetor inlet. With high resistance, the quality of the mixture is not always “at its best” (sometimes “poor”, sometimes “rich”).

If you sharply open the throttle valve with the Solex carburetor set at the factory, the air flow speed decreases, as a result of which less gasoline is supplied to the carburetor. Because of this, power drops significantly at low speeds.

The procedure for increasing engine power by tuning the Solex carburetor:

- We carefully disassemble the carburetor.

- We wash and blow, and divide into two halves.

- Pay attention to the air damper axis. There are protruding screws on this axis, which creates additional resistance while the car is moving. Any little things are important when tuning, so these protruding screws need to be smoothed out.

- Remove the axle and air damper from the top. The axle needs to be sharpened.

- From the lower part you need to pull out the throttle valves with their axles. At this stage, using a file we make the flaps larger. We hide the screw caps inside the axle. There are screws with conical heads, you can use them. The throttle valve needs to be assembled.

- Now we are tuning the diffusers. To improve the aerodynamics of the diffusers, it is necessary to make the legs in the shape of wings. We also check the protrusions of the factory casting; if there are any, they need to be ground off.

- The accelerator pump must have 2 tubes installed in one chamber. There is an opinion among some that when I use two tubes for each camera, “dips” may appear, that is, you press on the gas, but the car does not move.

In general, the basis of tuning is smoothing, erasing protrusions and irregularities. Any unevenness in the fuel and air mixing chamber creates resistance.

Operating principle of the main dosing chamber

During the combustion of the fuel-air mixture in the engine cylinders, air enters the chambers through the air filter. As the air flow increases, pressure is exerted on the nozzles. As a result, fuel rises from the wells into the atomizer. At the same time, air is fed through an air jet from above into the emulsion tube. In the chamber, the fuel is mixed with air and goes into the carburetor channels, where it is directed further into the engine under high pressure. This is the operating principle of almost all Solex carburetors.