Almost all cars have tachometers. Previously, all these devices were analog. Then digital models appeared. And today you may not find them at all. They were replaced by indicators or light bulbs.

Although they continue to do the work that the tachometer did, they just do not display the number of revolutions, but signal their critical values. Why the arrow jumps on some devices and what to do about it will be discussed in this article.

General information about the device

A car tachometer is a device for measuring the speed of a car's engine. It shows how many revolutions the shaft makes in 1 minute. The driver needs speed control to ensure normal engine operation.

The design of a traditional tachometer includes the following parts:

- a sensor that records the number of crankshaft rotations, usually measured in tens of thousands per minute;

- cable transmitting information from the sensor to the device;

- the tachometer itself, in a housing with a graduated scale and arrow.

The main function of the device is to help in choosing the optimal gear on a car's manual transmission. As soon as the needle approaches the red zone, you need to prepare to switch to the next higher gear.

It should be noted that the normal operating zone for a carburetor engine of a passenger car is considered to be speeds from 2 to 5 thousand revolutions per minute. When the upper limit is reached, or a little in advance, a shift should be made up one gear. Automatic cars do this on their own. Operation at high speeds leads to increased fuel consumption, overheating and severe wear of the power plant.

Unlike gasoline engines, diesel engines are not as revvy. Their optimal operation is considered to be 1.5–4 thousand rpm. For large trucks, the normal crankshaft speed ranges between 1.5 and 2 thousand rpm.

The tachometer readings are also used in some other cases, not just when driving. For example, when making adjustments or when starting a cold engine. By the way, in a warm state, the engine of a stationary car should not rotate at a speed exceeding 800–900 rpm.

When starting a cold unit, this figure rises to 1500. As the engine warms up, the speed gradually decreases until it stabilizes. If they do not drop and continue to exceed 1000 rpm, then there is some kind of problem. But this is a topic for another review.

In addition to the fact that in a working tachometer the readings are stably at a certain level, they should not change just like that, and the needle should not fall and rise for no reason.

Why do the instrument panel arrows swing back and forth when starting the engine?

I think many people have noticed that when you turn on the ignition, the arrows on the speedometer and tachometer shudder, rising to the maximum value and returning back. This phenomenon occurs on most famous cars. At first glance, this is just a side effect that does not have any significance, but in practice it is allowed for a specific purpose.

On modern models, this function can be disabled, but to do this you will have to contact a dealership or service station that specializes in diagnosing and restoring on-board equipment. Interestingly, this is far from the only feature that manufacturers hide in the car’s control unit. Most car enthusiasts simply have no idea about the available functions, because basic knowledge is enough to drive their car.

Practical purpose

There is an opinion that the movement of the arrows when starting the engine serves only for an aesthetic effect

It does look nice and attract attention, but nothing in a good car just works. When the ignition is started, the arrows go through a full circle, which allows you to understand whether the device is working properly and whether the displayed indicators are correct

If the arrow moves smoothly, easily covering the distance from 0 to maximum and back, then the indicator is capable of working across the entire range. If you detect a deviation from the normal operation of the speedometer and tachometer, you should contact a service station or service center of your manufacturer. The reason for this may be a malfunction of the instrument panel element itself, or the problem is hidden in the engine itself and other on-board systems.

In this unobtrusive way, manufacturers offer their customers the opportunity to monitor the accurate display of indicators on the instrument panel.

For lovers of new products and innovations, I have a great offer!

The latest Linza DVR with a voice assistant and other various useful features will help you always be in trend and with the latest car gadgets.

And it's quite inexpensive. You can read more about all the functions and features of this DVR and buy it on their website by simply clicking here :)

Source

Principle of operation

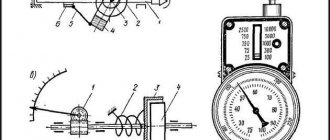

The principle of operation of an autotachometer is to record and count impulses transmitted by sensors, which are then converted into instrument readings. The device error is up to 500 rpm. The best digital samples brought it down to 100.

Tachometers may vary:

- installation location;

- way of displaying readings.

There are remote and standard devices. External ones are typical for sports cars. They are additionally equipped with light indicators so that the pilot, in a rapidly changing environment, is not distracted by looking at the numbers, but switches gears at the level of practiced reflexes. Standard devices are installed on production cars.

Depending on the method of displaying readings, tachometers are either analog or digital. In digital instruments, readings are displayed on an electronic display or screen in the form of numbers. They are convenient to use when adjusting the engine and during ignition settings.

Analog instruments display information on a dial with an arrow. The movement of the arrow is determined by a special chip that receives information from sensors. Currently, most cars are equipped with such tachometers.

An analog device is more convenient for ordinary drivers who do not need accurate digital indicators. And raising and lowering the arrow within the “green” zone provides all the necessary and understandable information.

But sometimes this arrow behaves strangely. It either rises for no particular reason, or twitches, or is at zero when the machine is running. Let's look at why this happens below.

Types of tachometers

There are two types of tachometers: analog and digital.

Analog instruments use an induction magnetic coil, thanks to which the number of crankshaft revolutions is shown by an arrow moving along the scale. This device is installed as standard on most machines. It is almost the same size as the speedometer and is located next to it on the dashboard. This arrangement of the device is convenient for the driver, since it is always in front of the eyes and makes it possible not to be distracted from the situation on the road.

In digital devices, information is reflected on a liquid crystal or diode display. The number of revolutions is transmitted either by a magnetic sensor that records the passage of a specific point on the crankshaft near the measuring device. An electronic sensor – optocoupler – can be installed. It generates a beam of light and determines the rotation frequency by its reflection from nearby objects. The digital device is useful when tuning engines and operations with electronic ignition units.

Photo gallery

1. Analog meter

2. Digital measuring device

Devices differ in their installation location. They can be regular or remote. The default mode is usually set to analog. If there is no standard device, you can install an external one yourself. It is often installed on racing cars to provide more accurate RPM readings, as speeds must be changed at a certain number of shaft revolutions. To achieve this goal, they are equipped with indicators that indicate when a certain speed is reached.

Information on pointer devices is better perceived by humans than on digital ones.

True, if the tachometer needle twitches, then the information may be unreliable. The advantage of digital analogues is accuracy, although under normal conditions this is not of great importance.

Why does the arrow start jumping?

When the tachometer jumps, that is, the needle jumps at constant speed, or it drops down after pressing the accelerator pedal, there is no need to talk about the reliability of the readings.

Possible reasons for the hand falling to zero or for it to “float” across the dial for no reason are as follows:

- Lack of contact and damage to wires. Because of this, the electrical impulse does not reach or arrives intermittently.

- Insufficient voltage in the vehicle network. Therefore, the arrow “lies at zero”;

- Another reason is a malfunction of the sensor that records engine speed;

- Problematic distributor contacts, which causes the tachometer needle to jump at idle speed. The distributor capacitor may also be faulty.

- The next reason why the tachometer jumps is damage to the ignition circuit.

- Sometimes it is not clear why the arrow is jumping. Most likely, the device was replaced, but installed incorrectly and not reset.

- When the tachometer jumps at high speeds, it means something is wrong with the switch. Although there may be other reasons related to engine malfunction.

- There is another reason - poor connection of high-voltage wires, their wear or damage.

- If the coil impulse does not match the cable resistance, the needle twitches slightly, bouncing slightly and falling down.

So what to do in one case or another when the tachometer needle does not behave adequately: jumps, floats or shakes?

What's the result?

If the driver notices malfunctions in the tachometer, it is important to immediately determine the cause of the malfunction. It should be borne in mind that problems with the device itself are not critical for the car.

However, if the tachometer jumps due to problems with the engine, this symptom indicates the need for diagnostics. Ignoring this recommendation and further operating the vehicle may cause serious internal combustion engine malfunctions.

We also recommend reading the article about why the speed sensor in the car does not work. From this article you will learn why the speed sensor does not work, as well as how to check the specified sensor.

For example, breakdowns that can be caused by misfires and other failures can quickly destroy the engine. For this reason, it is important to monitor the tachometer while operating the car. If it is noticeable that the engine speed is floating or jumping, it is necessary to accurately determine and properly eliminate the malfunction.

Trouble-shooting

The repair method depends on the cause of a particular malfunction:

- First you need to check the integrity of the wires and their damage. If a break or other defect is detected, the wires are replaced. It is possible that the lack of contact was a consequence of oxidation. To restore the functionality of the electrical network, you need to clean the oxidized contacts.

- Insufficient voltage occurs due to poor contacts, damaged wires or a faulty alternator. The work schedule depends on this. You can easily figure out the wires and contacts yourself, but in the case of a generator, it is better to contact specialists.

- If the sensor is faulty, it is replaced with a new one.

- When the needle jumps at idle, first check the contacts of the distributor, and if they are of proper quality, change the capacitor.

- If the integrity of the ignition electrical network is violated, you need to “ring” it and, if a specific location is identified, eliminate the malfunction.

- When installing a new tachometer, you need to ensure that it is connected correctly, and upon completion of work, “bring it to zero” using the toggle switch, which is located at the back of the device.

- If it is determined that the arrow is jumping due to a faulty switch, the latter must be replaced. But when replacing this spare part does not help, you should contact a service station.

- Problems with high-voltage wires are eliminated after checking their connections, serviceability and degree of wear. They are either replaced or repaired.

- The discrepancy between the tachometer coil pulse and the cable resistance is corrected by replacing the microboard resistor with an element with a different rating.

You can figure out some reasons for a tachometer malfunction on your own, while others require the help of specialists. But, still, it is better to contact a specialized organization that has the necessary equipment to repair all automotive mechanisms and systems.

In any case, you cannot leave the problem unresolved and continue to drive a car with a faulty control device.

What does the tachometer jump at high speeds indicate?

If the tachometer needle jumps during a trip or at high speeds, then the problem is also associated, as a rule, with the car’s engine. But before contacting a car mechanic, you can independently check the presence of fuel in the tank, inspect the camshaft drive chain, the timing belt that connects the crankshaft and the camshaft; perhaps it is loose and needs to be tightened. These are the main and frivolous reasons that can cause interruptions in engines and jumps in its speed.

If no visible problems are found with these elements, then you should go to an auto mechanic. Delay and failure to respond to a signal such as unstable tachograph operation can lead to serious damage to the vehicle’s cylinder-piston system and costly repairs.

It is better not to engage in diagnostics and independent repairs if the tachometer needle is floating. You should trust specialists who, using special equipment, will identify and eliminate the causes of the failure.

Why does the engine jerk at low and idle speeds?

So, if the car jerks at idle, there may be several reasons for such a malfunction. Most often, problems affect the ignition system and power supply system; less often, elements of the engine control system or parts inside the internal combustion engine fail.

- First of all, damage to the engine mounts should be excluded, since increased vibrations from the internal combustion engine in this case often occur precisely at idle. If everything is normal with the airbags, then twitching of the power unit may occur due to malfunctions of one cylinder.

- The most common cause is spark plugs, as well as high-voltage armored wires. Often, the spark plug may be damaged, dirty from carbon deposits, etc., as a result of which there is a spark on it, but it is very weak or unstable, and is supplied at the wrong angle.

Damage to the insulation of high-voltage wires when a spark “breaks through” also leads to similar symptoms in the form of motor twitching. The ignition coil, switch, ignition module, and distributor also deserve additional attention. Depending on which ignition system is installed on a particular engine, all its elements must be checked one by one.

After diagnosing the ignition system, you need to move on to the fuel and air supply systems. As a rule, injection nozzles may be faulty or dirty. Fuel filters are also checked, and fuel lines should be inspected for leaks.

Let us also add that in cases where the engine jerks at idle, you need to make sure that not only the fuel filter, but also the air filter is in good condition.

The fact is that if the air filter is dirty, the engine may not have enough oxygen to prepare the correct fuel-air mixture. The same is true in cases where airing occurs in the power system or excess air is sucked in at the inlet.

In any case, the mixture may turn out to be too rich or lean, and the normal and timely combustion of such a charge in the cylinder does not occur. At the same time, in such a situation, the spark plugs become even more covered with soot, and sparking further deteriorates.

On injection engines, the cause of twitching at idle in some cases is the electronic engine control system (ECM). In such a situation, it should be taken into account that this system includes a whole group of various electronic sensors and actuators that exchange data with the controller (ECU).

Another possible cause of engine jerking at idle is problems with the throttle valve and problems with the IAC (idle air control). The idle air control itself is a stepper motor that closes the channel for supplying air bypassing the throttle valve.

In case of incorrect operation and malfunction of the regulator, as well as in the accumulation of a large amount of dirt and carbon deposits on the damper, the idle speed becomes unstable. In this case, the engine not only jerks, but the idle speed often fluctuates greatly.

Such “floating” of revolutions can appear on a cold engine and disappear as it warms up. Also, in some cases, the speed jumps and floats both cold and hot. To solve the problem you need to clean the throttle and also check the IAC

It is also important to consider that on many cars, after cleaning, it is also necessary to train the throttle

Ignition system

As mentioned earlier, the ignition system of the VAZ 2107 car and the tachometer needle are interconnected; they cannot exist without each other

And if the arrow twitches, and all the above tips did not help, you should pay attention to the condition of the ignition elements. First of all, inspect the wires for damage or lack of contacts.

It is quite possible that there is a break inside the device itself. The photo shows a wiring diagram, study it to get an idea of where the wires go and where they come from. If the power system has a carburetor and a classic ignition system is installed, then it is possible that a breakdown of the capacitor installed in the lower part of the distributor has occurred.

In most cases, the needle jumps if there is a malfunction in the ignition system. It is quite possible that the Hall sensor is malfunctioning. But in this case, unstable engine operation will be felt. If you have an injector, then you should check the condition of the engine speed sensor and all connecting wires.

The tachometer needle jerks and the engine runs smoothly.

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Greetings to everyone! Prize, help. parents, and their six children have such a problem: When I was driving their car from Barnaul to Biysk (150 km), halfway through the journey the car suddenly stalled right on the move. Then the engine idles smoothly, but as soon as I increase the speed to more than 2 thousand, the tachometer needle begins to wobble. When driving, the car also drives normally, only up to 2 thousand revolutions it jerks further, and the more revolutions, the more it wobbles. It is impossible to accelerate more than 40 km/h. I came and took it to the service station, the guys said that the fuel pump had failed - they replaced it. At the service station they said that the contact group is fine. Three thousand before that, the valves were adjusted and the carburetor was cleaned. The carburetor was looked at again and everything is fine. There are no problems for half a day, then everything starts again. I didn’t go to the service station anymore. I replaced the spark plugs (the old ones were all black; they drove more than 20 thousand). Replaced the slider. Does not help. The car starts up without problems when cold, if you drive about 10-15 km after that, everything starts all over again. Tomorrow I’m returning to Barnaul, so if anyone knows anything, please help me today.

It looks like the ignition coil is going bad. Try it with another car, a reliable one. And try removing the wire from the coil that goes to the tachometer.

Does the tachometer fluctuate sharply or evenly as engine speed drops?

It is easier to eliminate the capacitor by simply replacing it.

So, let's diagnose the contact group. We take a control light, one wire goes to ground, the other goes to the reel, where the wire from the contact and tachometer goes. The light should light up when the contacts are open and go out when they are closed. This is with the engine off. With the engine running, it should burn at full intensity - blinking will no longer be noticeable. But in those moments when the arrow pulls, the lamp will either burn at full brightness or go out. If it goes out, it means either the contact does not open, or there is a short circuit to ground somewhere besides the contact group. If it lights up brighter, the wire is broken or the gap is large and does not always close.

After we have decided whether it is on or off, we turn off the engine and try to reproduce it with it turned off. For example, we close the contact (set the speed to 4 and, moving the car back and forth, turn the HF so that it closes) and try to move and pull the wires, and see when the lamp lights up. It is very likely that the wire inside the insulation of the wire that goes to the contact group will break. Closer to the terminal. If it goes out, we open the contacts and see where it can close. Maybe the wire is not lying well and has become chafed by the shaft.

Source