Modern youth no longer begins their automotive experience with the “classic penny”, because they want more modern and reliable cars. But the financial capabilities of most young people are not so great that they can immediately get behind the wheel of a foreign car, and therefore most novice car enthusiasts buy themselves a “ninety-nine”. And if it is injection, then we can consider ourselves lucky.

What is an injector?

Essentially, an injector is a worthy alternative to a carburetor, which includes fuel rails and injectors. At the same time, the injector is a fairly sensitive device, which is regulated using the so-called on-board computer. Without it, the car would become completely capricious, because it is very problematic for the mechanical system to detect minor changes. It is thanks to him that diagnostics of cars in the relevant centers has become much easier and faster. After all, all the technician needs to do is simply connect the appropriate equipment and scan the on-board computer data.

However, this does not mean that the car will not undergo an initial inspection. Thanks to the on-board computer, it will be several times easier to understand the problems.

In the VAZ-21099 car, the injector has a distinctive feature - the presence of front-wheel drive, which allows the car to feel several times more stable on the road than similar vehicles. The working volume of the 4-valve engine is 1.5 liters. Thanks to this, the vehicle can reach speeds of up to 180 km/h. However, according to the manufacturer's recommendations, it is strongly recommended not to accelerate the vehicle to speeds exceeding 160 km/h. Operating at the limit is not the best solution for those who want to keep their car running for as long as possible.

Another advantage of this car is a significant reduction in fuel consumption compared to carburetor models. On average, this figure reaches 7 liters per 100 km, provided that the car reaches a speed of up to 120 km/h.

To the great joy of the owners, the car is completely unpretentious to the octane number of fuel, so it works equally well on both A-92 and A-95 gasoline.

Choosing an auto electrician - main features

Most problems with increased speed, increased fuel consumption, and unstable idling are solved by an electrician. This specialist finds problems in the electrical part of the car, diagnoses all components, and carries out repair work in the electrical part. You are unlikely to figure this out on your own; you will have to try hard to study the wiring diagram for all the parts of your car. And finding the location of all the sensors is often difficult, especially in a technologically complex modern car. So you need to entrust the work to an experienced craftsman.

When choosing an auto electrician, consider the following features:

official service - in most cases this will be the best solution, since here specialists work only with one specific brand of car and provide a guarantee of quality; the equipment of the service station plays an important role in identifying potential problems in your car; you just need to make sure that the station is well equipped and has normal equipment; experience of a specialist - pay attention to who exactly will service your car, the technician must be quite experienced, it is better to check reviews about him from different sources; a good option is to choose an electrician by recommendation; if you do not use the services of an official station, the recommendations of your friends will help you find the optimal service; It’s worth starting cooperation with diagnostic services; diagnostics will show how competent the specialist is, and whether it makes sense to cooperate with these specialists in the future

As you can see, there are several ways to check a person’s competence and make sure of his professionalism. If you decide to have your car serviced at an unverified station, be sure to be present during the repair and monitor every step of the technician. This is your right, it is quite possible to be present during repairs even in a garage station, where not a single master will like it. You can leave your car unattended either with the officials or with a trusted service that you have been working with for quite a long time. Keep this in mind the next time you need to go get your car repaired.

We also suggest watching a video about car diagnostics:

Trouble-shooting

Regardless of its own condition and the weather outside, the VAZ 21099 car may suddenly stop starting, practically not respond to the gas pedal, etc. In this case, the on-board computer behaves as usual and does not show any errors. Of course, you can continue to ignore the situation, but this is unlikely to lead to good things. It is imperative to look for a breakdown in the injector, because the road almost never forgives such carelessness. An unpredictable mechanism can stall at the most inopportune moment.

Most often, the breakdown affects injectors that become clogged from constant use.

As a result, the car may begin to consume several times more fuel, and its traction will decrease significantly.

It is quite possible to clean the injectors yourself, but only if the car owner is confident in his own abilities. Otherwise, you can make the situation even worse.

If problems arise, you should also pay attention to the throttle valve, which over time becomes overgrown with black soot. As a result, it begins to significantly inhibit the penetration of air, but this problem can easily be eliminated with the help of a cloth and a special spray.

In order for your car to operate flawlessly for many years, it is important to fulfill the following requirements:

The VAZ engine is quite durable and can withstand significant loads. However, there is a limit to its performance.

Principle of operation

The basic principle of operation of the IAC is reduced to changing the cross-sectional area of the calibrated hole in the bypass channel based on the current position of the throttle valve. This change begins with the translational movement of a needle connected to the armature of a stepper motor through a worm gear. Completely closing the bypass channel with the throttle valve fully open does not affect the operation of the power unit. When the needle moves back, the amount of air increases in proportion to the closing angle of the throttle valve. Due to this, it is possible to smoothly regulate the crankshaft speed during the transition from the operating state of the car engine to the idle mode.

Content

The injector is controlled by electrical signals that come from a microprocessor

, and in order to issue them, he monitors signals from sensors installed on and in the engine.

The only work that can be done on an injection engine to adjust it and stabilize its operation is flushing the injector, or rather flushing the injectors.

Injection diagram for VAZ 21099

The system for supplying the fuel-air composition to the cylinder block consists of the following functional elements

:

- a filter for cleaning the air entering the engine system;

- air flow sensor;

- set of connecting hoses;

- injector control boards;

- gasoline filter;

- gas tank;

- pressure control devices in the system;

- injector mounting frame;

- nozzles;

- top cover of the cylinder block.

Lubricating parts

Combined engine lubrication device for the VAZ-2109 (2110). Oil is supplied to the main and connecting rod bearings, as well as to the camshaft supports under pressure; the cylinders, pistons, pins and rings, camshaft cams and pushers are lubricated by splashing; all other associated parts are lubricated by gravity.

A gear-type oil pump with a bypass valve is installed at the front of the block. The oil receiver is mounted using bolts on the cover of the second main bearing and the pump housing. The oil filter is non-separable and has bypass and anti-drainage valves. The design of the lubrication system and other engine systems is discussed in detail in separate articles. » alt=»»> Crankcase ventilation is forced, gases are removed through the oil separator.

Source

Injector flushing procedure

The contamination of injectors with tar deposits is primarily caused by the desire of companies that own gas stations to buy fuel cheaper and sell it at a higher price, and at the same time mix into it everything that increases the volume:

- benzene;

- sulfur;

- water;

- olefin;

- sometimes it's just dirt.

The whole process is discussed in detail in the article:

“How to flush an injection engine yourself.”

After consuming such a “cocktail”, a tarry coating forms

, which does not contribute to the normal operation of the engine.

The procedure for cleaning the nozzles and flushing the injector will consist of the following manipulations.

Before starting work, you need to stock up on special flushing liquid, new spark plugs and a syringe or powerful syringe. It is best to invite an assistant to perform this type of work. He does not need any qualifications in car mechanics; his task will be to maintain constant engine speed by pressing the gas pedal.

Algorithm

- Flushing liquid is mixed with gasoline in a volume of 1.5–2 liters;

-

connecting the intake manifold and the brake booster is disconnected - A mixture of gasoline and rinsing is introduced into the adapter using a syringe;

- For the flushing mixture to react and clean the surface of the nozzle, it is enough to pause for 20 minutes. After this, the engine starts and idles. The speed must be constantly maintained with the gas pedal;

- After injecting the flushing solution, white smoke will come out of the hose along with pieces of black dirt. It will be greater the less frequently the injector is washed;

It is best to inject the washing mixture In this case, the quality of washing will be higher. After injecting the entire volume of flushing, the engine can be turned off;- It is necessary to install new spark plugs only on a cooled engine, for which a certain time is allotted.

As a preventive measure, to reduce the degree of contamination of injectors, repair of the VAZ 21099 injector must be carried out every 5,000 km. mileage

, adding special additives with a cleaning effect to the gas tank as a preventive measure.

It is strictly not recommended to use solvent as a cleaning agent, as it will simply corrode the silicone on the injectors.

Front-wheel drive VAZ cars are very popular in Russia due to their high maintainability, relatively low cost of spare parts, and simple design. But due to the large number of modifications, it is not easy for the driver to understand even the instructions where this or that unit (part) is located, in particular, on the VAZ-21099 car the injector.

What is the reason for floating revolutions

Car owners often continue to operate their vehicle even if the engine is unstable while driving. However, such a malfunction can have a number of negative consequences. Firstly, floating speeds can easily lead to a traffic accident when, when coasting or changing gears, the engine stops working and the steering wheel jams. In addition, the driver must be constantly distracted in order to stabilize the speed by stepping on the gas or simply not allowing the engine to stall by keeping his foot on the gas. Secondly, fuel consumption increases significantly, and all engine operation systems operate in variable mode, which creates additional load on them. The malfunction is easily diagnosed, its elimination does not require significant investment of time and money.

Check the spark plugs first

If the coordinated operation of individual components of the power and ignition system is disrupted, various malfunctions occur that lead to engine failures. One of the first signs of a problem is high engine speeds if the injector stalls while driving. The most typical manifestation of a possible malfunction is a situation where the idle speed fluctuates. The speed can change from 500 to 2500-3000 per minute with an oscillation interval of about 1 second. In this case, the number of revolutions is periodically equalized. If the amplitude is larger, the engine will most likely stall.

Situations arise when the control unit receives incorrect information, which is why the electronics cannot make a timely decision about the command being given. If an excess amount of air enters, while the engine temperature is sufficient for normal operation, and the throttle is open in the desired mode, the control unit may not cope with the problem. When engine speeds fluctuate or are simply high, one of the possible reasons may be improper operation of the forced speed increase device. This will be the culprit for the intake of too much air.

Where is the fuel pump located on the VAZ-21099 injector

Removing and installing a gasoline pump (PG) is not a difficult job and does not require extensive plumbing experience or high qualifications. But if you don’t have to look for a fuel pump on carburetor cars for a long time (it is located on the engine, under the hood), then a beginner may not find it on the injector on the first try. Where is the fuel pump located on the VAZ-21099 sedan injector? Let's figure it out step by step:

- we move the front seats in the car forward as much as possible to free up space in the rear;

- open the rear left door of the car, find a small hinge on the rear sofa, which is located at the junction of the “seats” approximately in the middle of the cabin;

- pull the loop up, thereby raising the back of the lower seat;

- under the carpet we see the gas tank flap;

- unscrew the two fastening screws, remove the hatch and find the fuel pump underneath.

Block head and timing device

All front-wheel drive cars of the VAZ family, be it 2109, 2110 or 2114, have one cylinder head, common to all cylinders. They are mounted to the block using ten screws. During installation, a metal gasket is placed under it. This gasket is for single use and cannot be reused. There are five camshaft bearings at the top of the cylinder head.

The camshaft of the engine of the VAZ-2109 car has the index 21083. Some engines are equipped with 2110 or 2111 shafts; their design is slightly different from 21083, which allows for an increase in engine power. The shaft is cast from cast iron, there are five supports and eight cams on it that open the valves. It is driven by a toothed belt from the crankshaft pulley. The shafts can be correctly installed relative to each other using the alignment lug on the rear timing belt cover and the marks on the drive gears and flywheel.

Seats are pressed into the cylinder head, as well as valve guides. On the inside of the bushings there are grooves for supplying lubricant; the bushings are closed on top with oil deflector caps.

The valves are made of steel, and the intake head is made of heat-resistant steel. They are mounted obliquely in one row. The inlet valve has a larger diameter than the outlet valve. The gaps between the valves and camshaft cams are adjusted using shims that have increased wear resistance.

Where is the fan relay VAZ-21099 injector

Quite often a problem arises with the Ninety-Nine when the engine fan does not turn on and the coolant begins to boil. If such a malfunction occurs, first of all they check the functionality of the fan itself by applying voltage directly to it from the battery, but there may be other problems.

In order to check the entire circuit, it is important to find where the VAZ-21099 injector fan relay is located, since it is responsible for turning on the airflow. We find this part in the front of the car, on the passenger side, it is installed under the glove compartment, at the passenger’s feet.

The required relay in the picture is indicated by an orange circle, and here you will also find a fuse that blows when the cooling fan is short-circuited.

Examination

Today, VAZ 2109 car owners use two methods to check the condition of the coolant temperature sensor. Let's say right away that the second one is more reliable, but the first one is easier. Decide for yourself which of the methods presented below to use.

Verification method

Your actions

According to the table, check whether the resistance corresponds to that required at a particular temperature of coolant or boiling water.

Temperature (in degrees Celsius)

Resistance (Ohm)

If there are deviations from the norm, we conclude that the sensor no longer performs its functions properly and therefore requires mandatory replacement.

Replacement

Where is the mass of the VAZ-21099 injector (main)

If the starter turns weakly, or the engine does not start at all (clicks occur when starting), various electrical problems arise, it is likely that the car does not have normal weight. Fixing such a problem is generally not difficult, but to do this you still need to know where the mass of the VAZ-21099 injector is located.

The main mass (thick) wire goes from the negative terminal of the battery to the engine, the thinner wire is connected to the car body, all energy consumers in the car depend on this connection. If the contact is poor, the battery stops charging normally; in order for the starter to turn well, you should check the reliability of these contacts and clean the metal from oxidation. If, due to a heavy load (for example, when installing additional equipment), the ground wire heats up and there is clearly not enough of it, you can “lay” additional ground almost anywhere where good contact between the engine and the body is ensured. The main thing is that this wire has a sufficient cross-section.

Floating idle, carburetor 2109

Tell me, guys, why the idle speed on the carburetor nine floats?

The carburetor was flushed, blown, cleaned and tuned. The distributor slider was changed because... loosened. The engine runs perfectly, does not stall, does not smoke, the spark plugs are clean. All of the above procedures did not solve the problem.

The idle air valve is missing, instead there is a plug in the form of a bolt with a jet.

We thought it was bad gasoline, because... There are no more thoughts yet, I filled in another gas - the same result.

We thought about the explosive wires, but if they pierced, the engine would fail.

I look forward to advice and help from you.

It's amazing, not one answer in a week.

Check the integrity of the pipe that goes from the vacuum brake booster to the intake manifold. 95% it's his fault. 4% – air leaks in other connections where there shouldn’t be (all gaskets are installed tightly, including the air filter) and 1% – these are other basic things, like an old (sometimes leaky) air filter or others. Also, If all of the above is present, it would be a good idea to check how big the difference in the electrical circuit is during the “floating” speed - if the difference is insignificant, proportional to the speed, then it’s normal, but if it jumps like crazy, then maybe the insulation is broken somewhere (and instead of a fuse there is a “bug”) - there is more load on the generator. While this is a theory, this may not be the case in practice.

Which one is this 4?!

The filter is new and clean. The gaskets are all new, everything is installed tightly.

Yes, he is the one. I had this happen on my shokhe - the pipe became wooden over time (over 20 years) and cracked due to vibration (micro cracks). Cured with a replacement. Yours is, of course, younger, but its quality may be worse. In order not to spend money on a new one to check, remove this one from the manifold, and put a plug on the hole (there will be something like a Christmas tree there) (I wouldn’t recommend unscrewing the Christmas tree itself, it’s already settled in there, stuck, so it will be more airtight). Run the engine and see the result.

Good luck!

well, well, I'll try it, thanks!

Yes, and do not rule out that the leak may be through the vacuum booster itself. Judging by the photo, the machine is new (or is it not yours?), then the probability is minimal.

This is from the Internet, mine is in the profile, it’s not new))))

If there was a vacuum leak, would the brakes also suffer?

Not really. Much more force is needed on the pedal.

Nothing has changed with the brakes.

And it wouldn’t hurt to check the tube from the distributor (vacuum ignition timing corrector). The cross section there is small, it won’t have a significant effect, but still.

Post your results. Interesting

Today we were poking around. It hasn’t been cured yet, but it’s definitely not the hose or the tube. Now we are thinking about the ignition coil and possibly wiring. In general, today it was fun with the wiring - I took a bundle of wires, in which there were wires from the idle air control, switch, coil and hall sensor, raised this bundle a little and the car stalled. And so several times, maybe tomorrow we’ll get to the electrician and listen to what he says. You may have to replace this entire bundle; most likely the wire has broken or several have broken at once. By the way, I cleared out the entire mass from this bunch, and subjectively it seems that the idle has become a little smoother, but still floats.

Where is the starter relay located?

Just like the engine cooling fan, the starter is controlled by a relay, and its malfunction can cause problems:

- when you turn the ignition key, nothing happens, the engine does not show any signs of life;

- When I try to start the engine, clicks are heard, but the starter does not crank.

Finding out where the starter relay is located on a VAZ-21099i car is very simple; to do this, you just need to open the hood of the car and look behind the air pipe of the injection engine; the part you are looking for is shown below in the picture.

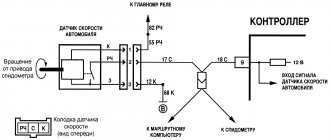

Where is the speed sensor located?

The speed sensor (DS) on front-wheel drive VAZ cars reads pulses depending on wheel speed and transmits the data to the electronic control unit (ECU). When braking the engine, the fuel supply is turned off with the help of the diesel engine and the computer, thus achieving more economical operation of the internal combustion engine. If the sensor is faulty, an error code is recorded, gasoline consumption increases slightly, and idle speed decreases, especially during heavy braking. It is difficult to immediately detect where the speed sensor is located, since it is hidden under the air filter housing (AFC).

We find the part we need as follows:

- open the hood of the car;

- Using a 10mm wrench, unscrew the two KVF fastening bolts;

- loosen the clamp of the air “corrugation”, disconnect the “chip” with the wires;

- we take out the KVF, now the sensor has already appeared in the field of view, it is located on the gearbox (gearbox) housing, wires are connected to it, connected using a connector.

The DS can be easily unscrewed by hand, and the plug with wires can be pulled out even after the sensor has been unscrewed (but carefully so as not to damage the wiring during rotation).

Repair

Repair of the power unit is carried out with your own hands. As practice shows, most car enthusiasts carry out this process in their garage. Elements such as the thermostat, water pump, spark plugs and high-voltage wires can be changed without problems. As for the injectors, to clean them you will need a special stand, which is available at car services.

To reduce fuel consumption, you can flash the engine control unit. This is what motorists do. This operation can only be performed independently, but it is recommended to contact professionals who understand the process and also carry out additional adjustments.

Carrying out a major overhaul will require some design knowledge and engine repair skills. So, to grind the plane of the block and head, you will need a surface grinding machine. Also, for boring cylinders, a boring and honing stand is required. All other operations are performed by hand.

Where is the fuel filter located?

The fuel filter (TF) on the VAZ-21099i is designed to clean gasoline from debris, dirt and various impurities; it is a monolithic structure with a rigid metal body and a filter element inside. The frequency of its replacement is every 20-30 thousand km of the distance traveled, also if the car begins to move jerkily, and diagnostics showed that the fuel pump is clogged.

It’s easy to find out where the fuel filter is located; to do this, you need to install the car on an inspection hole or a car lift. The TF is located on the bottom of the body, next to the rear beam and the gas tank, and is secured with a special clamp, which is tightened with a bolt and nut.

Before you start changing the filter, you need to relieve the fuel pressure, otherwise when you unscrew the fuel fittings, gasoline will splash under high pressure. You can relieve pressure in the line using a special nipple located at the rear of the fuel rail. Before starting such an operation, it is necessary to prepare a plastic container into which gasoline should be poured, then unscrew the safety cap.

To release the pressure, you can use a standard flat-head screwdriver; when you press the nipple valve, gasoline will come out of the system.

After removing fuel from the line, we proceed to replacing the fuel pump.

Related articles:

- The influence of the fuel vapor recovery system on the operation of the Lada Kalina engine. Modern technologies are developing, equipment is becoming more complex and sophisticated, and progress does not bypass motor vehicles. Carburetor cars were very simple, and understanding them [...]

- Front spar of the VAZ-2109 - replacement, repair, cost of work The VAZ-2109 is a car that does not have a strong body; iron corrodes quite quickly, and almost all body parts rust. Replacement of the front side member is required […]

- Features of replacing the VAZ-2114 oxygen sensor, signs and causes of malfunction In connection with tightened environmental standards, all cars began to be equipped with additional systems that reduce the toxicity of exhaust gases, and on almost every car with […]

Engine crank mechanism

The design of the cylinder block of the VAZ-2111 engine is identical to block 21083. It is cast from cast iron, the cylinder diameter is 82 mm, and if the piston group is replaced, it can be increased by:

- 0.4 for the first repair;

- 0.8 at the second.

Crankshaft

The crankshaft is located at the bottom of the block and rotates on five main bearings that have removable covers, which are secured to the block with bolts. The covers are not interchangeable and are marked with marks on the outside. The middle support of the main bearing has slots into which support half-rings are installed, eliminating axial displacement of the crankshaft. The front half-ring is made of an alloy of steel and aluminum, the rear half-ring is made of cermet. If play in the crankshaft appears, the half rings must be replaced.

The bearing shells - support and connecting rod - are thin-walled, made of steel-aluminum alloy. There are grooves on the inside of all the upper main bearings, with the exception of the third bearing bearing.

The design of the crank (engine crankshaft) is as follows: it is cast iron, has four connecting rods and five main journals. Eight counterweights are cast together with the shaft. Channels are drilled inside the shaft, closed with plugs and having a dual purpose:

- they supply oil to the connecting rod journals from the main ones;

- they clean the oil, since centrifugal force throws all mechanical impurities that are not retained by the filter towards the plugs.

The latter circumstance must be taken into account when overhauling the engine, and when removing the crankshaft, and especially when balancing, it is necessary to clean the channels from accumulated deposits. After cleaning, the plugs are replaced with new ones.

The camshaft drive pulley is attached to the front part of the crankshaft, and to it is the generator drive pulley, which also works as a damping device, thanks to the elastic element between the outer and inner parts of the pulley. A cast iron flywheel is attached to the rear end using six bolts. It has a ring gear designed to start the engine using a starter. In addition, there is a conical mark on its surface, designed to determine TDC after the engine is assembled.

Piston group

The connecting rods are made of steel and have an I-section. The covers are processed together with the connecting rods, and therefore are not interchangeable. The cylinder number is stamped on them and on the connecting rods.

Piston pins are steel tubes. They float freely in the piston bosses, in which they are fixed using retaining rings.

Piston design: the pistons are made of aluminum alloy and have three grooves in the upper part for piston rings. The set of rings for each piston consists of two compression rings and one oil scraper ring. Compression rings prevent gases from entering the crankcase, and the oil scraper removes oil from the cylinder walls and carries it to the bosses to lubricate the piston pin.

Slightly lower are the holes for the piston pin (boss). There is a recess in the bottom of the piston designed to prevent bending of the valves in the event of a break in the timing belt. In the VAZ-2109 with an engine capacity of 1.3 liters, it is flat, so a broken belt inevitably led to failure of the entire piston group and gas distribution mechanism, and as a result, to expensive repairs.