Normal PT adjustment ensures that the vehicle is held on a slope. This corresponds to 3-8 clicks of the handle on newer nines or 5-7 clicks on a VAZ 2110 released before 1995.

To carry out the test, follow a few simple steps:

- Find a slope that has about 25 degrees;

- Turn the handbrake to the required position;

- If the car starts to roll, the handbrake does not hold, adjustment is required;

- If there is no such slope nearby, the check is carried out in a garage;

- Place the car on a flat surface, raise the handbrake handle all the way;

- Approach from behind and try to push the car with maximum force;

- If the car begins to move, the RT requires adjustment;

- Check the operation of the handbrake at 2 clicks on newer versions of the VAZ 2109 and not reaching 5 clicks on versions before 1995. If the handbrake is working at full strength, the cable will be tightened. It will also need to be adjusted.

Operating a car with a tightened PT cable is also dangerous, as this leads to overheating and wear of the rear brake pads.

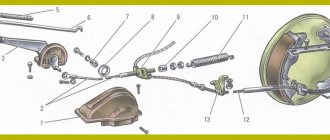

Bottom view

Adjustment

To adjust the PT cable you will need a pit, overpass or lift. Next we proceed according to the following algorithm.

- Raise the handbrake handle 2-3 clicks from the passenger compartment.

- Get under the car and loosen the locking nut of the parking brake cable equalizer. Before doing this, it is better to treat the nut with a wire brush to remove all dirt.

- Then act according to the circumstances. If the cable is overtightened, it must be loosened by appropriate manipulation of the nut. If the cable holds too weakly, the nut must be tightened more tightly.

- If tensioning the cable does not produce any result, then the element is already at the limit of its capabilities. Therefore, the only solution to this situation is replacement.

- When adjusting the degree of tension, be sure to evaluate the adjustment of the cable along the PT lever. As you remember, normally it is 3-8 clicks for more recent versions of the VAZ 2109, or 5-7 clicks for nines that were produced before 1995.

- Check the freedom of rotation of the rear wheels. If you overtighten the cable, the wheels will spin with difficulty and not as freely as they should.

- After making the adjustment, tighten the locking nut back and check the operation of the handbrake again by driving up a slope or pushing the machine with the PT on.

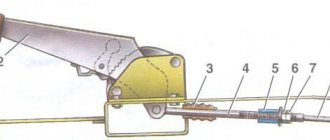

Adjustment process

We recommend: Reasons and process for replacing a Ford Focus fuel pump

If the adjustment did not give a positive result, the cable turned out to be worn out, overtightened and does not allow adjusting the operation of the RT, you will have to change it, thereby repairing the handbrake.

Replacement

In some cases, heavy movement of the cable in the sheath is due to lack of lubrication. To eliminate this defect, fill the shell with transmission or engine oil. Pour until grease flows out of the opposite end of the cable casing. Remember to move the cable while adding lubricant.

Cable replacement procedure

But lubrication is more of a temporary measure. If signs of cable wear are detected, it is better to replace it with a new one. This is done as follows.

- Loosen the tension on the PT cable locking nut.

- Unscrew the equalizer adjusting nut, which will loosen the handbrake drive cables.

- Raise the rear of your VAZ 2109 using a jack, then remove the brake drum and brake pad.

- Unscrew the drive cable end from the drive arm.

- Disconnect the fastening nut, and then remove the PT cable holder on the rear suspension beam of the vehicle.

- Remove the shell bushing from the hole in the brake shield.

- Pass the end of the PT cable through the hole in the brake shield.

- Remove the PT cable from all holders on the body of your car.

- Disconnect the end of the PT cable from the equalizer.

- Push the cable end out of the bracket to remove the cable.

- Install a new, tested cable, proceeding in the reverse order.

- Do not forget to adjust the cable tension and the performance of the restored RT at the final stage of assembling the unit.

Adjusting the travel of the handbrake cable on a VAZ-2110

The lever should tighten the cable tightly with 2-4 clicks.

- The pads are put in place and the wheels are put on. They should initially rotate freely when the lever is released.

- Then you should drive 1-2 kilometers by car. In this case, you need to brake several times.

- Then you should try the drum by hand. It shouldn't be hot. When it gets hotter, the cable needs to be released a little.

- Repeat the entire procedure until the drum stops heating.

It is much more convenient to twist the handbrake nut with a socket with an extension.

Slope check

You can also check the operation of the handbrake on a slope. To do this, you need to turn off the engine and put the car on the handbrake, turning on the neutral gear. It should not move on its own at a slope of 25%!. When it starts to roll, the cable should be tightened.

Important points

- It is best to use two people to disconnect the tip from the brake pads. One person should carefully press the brake rocker with a large screwdriver (or a thin pry bar), the second at this moment will be able to freely loosen the lock nut, after which the cable can be pulled out of the holder without risking injury to your hands.

- As soon as the cable is removed, its attachment points should be thoroughly cleaned of rust and dirt. The best way to do this is with a wire brush. Those places in the brake shield where the cable passes must be wiped with solvent.

- If too much rust has accumulated in the through passages of the cable, you should use concentrated acetic acid, as it corrodes rust well. You only need to work with it wearing gloves to avoid chemical burns.

- Before installing the brake drum, be sure to check the condition of the pads. If the spacers on the pads are very worn (and most likely this will be the case), they need to be replaced with new ones. A set of such strips can be purchased at any auto store.

Replacing the handbrake cable on VAZ 2109 and 2110. We can do without a service station

Rolling down a hill or replacing the handbrake cable on a VAZ 2109 and 2110 in a garage. The topic is quite relevant in view of the fact that the degree of fixation of the handbrake has always been of interest to every driver. Whatever one may say, this is an additional guarantee of safety both on the highway and in the parking lot. In some cases, emergency situations occur due to the fact that most drivers neglect the rules for using the handbrake, or deliberately bring it to a faulty state. Let's look at how to use it correctly and what is needed for this below.

Operating principle and replacement algorithm

Replacing the handbrake cable on a VAZ 2109 and 2110 can be done on your own within half an hour, unless of course you are lazy and go to a car service center for repairs. To do this we need the following equipment and tools:

Provided that we have all this ready, we can begin the repairs . So,

- It is necessary to have an overpass or inspection hole, since without them we will not be able to get under the bottom of the car;

For those who do not fully understand, the handbrake in all cars is located between the two front seats. It can be covered with various drawers - glove compartments, but this is not important. The main purpose is to fix the parking of a car without outside help, even when neutral is turned on and the road is downhill under the wheels, which is a ratio of no more than 1/4.

How to change

Tools and materials required for replacement

- New handbrake cable.

- Open-end wrenches for 10 and 13.

- Socket wrench 13.

- Flat blade screwdriver (large size).

- 2 mounts.

Step-by-step instruction

- The car is placed on an inspection hole, and wheel chocks are placed under the rear and front wheels.

- The handbrake lever is lowered to its lowest position (until the stopper clicks).

- The muffler and resonator are removed from the car. After this you can get to the cable equalizer.

Handbrake equalizer VAZ 2110

Nut and locknut of the brake cable VAZ 2110

Dismantling the brake pads of the VAZ 2110 and disconnecting the second cable tip

Less work - longer operation?

Many drivers believe that rare use of the handbrake ensures maximum performance of this unit. In fact, such an attempt to preserve the RT resource gives a completely opposite effect.

The less often you use the handbrake on your car, the less movement the cable makes in its sheath. This leads to loss of efficiency and performance of the cable. Loss of mobility leads to the appearance of breaks when the handbrake is rarely applied. As a result, at the most inopportune moment the car does not stand still as it should.

To prevent problems with the RT, periodically inspect the condition of the unit, and also do not forget to squeeze the parking brake handle when necessary and required by traffic rules.

Main causes of failure

The main reason why such an important device may break and need to be replaced is mechanical wear of the handbrake. As you know, the basis of the system is a small cable that transmits forces from the lever to the mechanism. It actually turns on this node.

The operating conditions of the cable are quite complex - the constant load from the force that the driver transmits through the handbrake lever to the system, sooner or later, can damage the device.

However, the cable breaks extremely rarely - most often, the cables simply jump off. Or the tips fixed in the drum are ground with very long wheel bolts. Needs renovation. Also, the parking brake may not work due to wear on the rear drum brakes (as well as abrasion of the pads, depending on the design).

As a result, the unit ceases to perform the functions assigned to it - the handbrake simply does not hold. The parking brake needs to be replaced and subsequently adjusted. But not everything is so simple - in some cases, the device can be damaged during emergency braking of the car - as a result, it will require repair or replacement.

Often the metal is not completely ground, but the steel fibers are stretched and moving in the shell is very difficult. But it doesn’t matter what the reason for the parking brake failure is, why it doesn’t hold. The purpose of our article is to figure out how to solve the problem.

Adjustment and checking

- The travel of a properly adjusted handbrake lever should not exceed 8 clicks. The optimal lever stroke is 6-7 clicks (this number varies depending on the car model; details for a specific VAZ model can be found in the operating instructions supplied with the car).

- After installing the new cable, the rear wheels of the car should be jacked up and try to spin them by hand. Rotation must be free.

- Now the brakes should be checked while driving. You need to drive 30-40 meters, then slow down using the parking brake. After braking, you need to get out of the car and touch the rear brake drum. It should not be hot, its temperature should not exceed the ambient temperature. If the drum gets so hot that it burns your hand, this means that the brake cable is too tight and should be loosened.

- To loosen the cable, you should put the car back on the inspection hole, unscrew the lock nut on the outer tip with a 13mm wrench, and then loosen the main fastening nut. After this, the locknut is tightened again.

- If the brake cable is too slack, it needs to be tightened. All steps are listed above, with one exception: the main nut on the tip should be tightened, not unscrewed.

- To independently check the reliability of the parking brake, you should find a slope with a ratio of 1:5 (that is, 1 meter high and 5 meters long), drive the car onto it, turn off the engine, put the car on the parking brake and squeeze the clutch. After these actions, the machine should remain in place and not roll downhill. If the car does roll, you should tighten the brake cable a little more.

As you can see from our article, there is nothing complicated about replacing a brake cable, and even a novice car enthusiast can do this task. The main thing you should pay attention to in this case is compliance with safety regulations. When changing a cable, it is very easy to get injured or get a chemical burn, so it is better not to carry out this operation alone, but to work together with an experienced auto mechanic.

Final Setup Steps

- continue rotating the adjusting nut until we are sure that the brake lever has a full stroke of approximately 3 clicks (this operation is convenient to perform with two people - one person rotates the nut, and the second checks the handbrake);

- after checking the working stroke, you need to tighten the locknut while holding the adjusting nut with a wrench;

- now you need to check whether the handbrake cable is not too tight: the parking brake lever goes down, the rear wheels are jacked up and turned by hand - they should rotate evenly, without delays;

- if the lever travel is still large, then we continue to tighten the adjusting nut (or unscrew it if the cable is too tight) and regularly check the handbrake travel until it reaches 3 clicks and the brake pads do not interfere with the rotation of the wheels.

After adjusting the system, you should check its operation. To do this, the driver needs to place his car on a section of the road with a slope of 23% and raise the parking brake lever. If the car is securely fixed on the road and does not move, this means that the work was carried out correctly.

Modernization

Many modern owners modernize their cars and install so-called hydraulic handbrake here. As a lyrical digression, we note that in this case it is necessary to replace the rear brakes with disc brakes without fail.

Very serious design changes are required - such as installing a hydraulic system in the parking brake. No cables are used here - the parking brake lever is connected to the master cylinder.

After the driver lifts the lever, the brake fluid in the system presses on the cylinders. Most often, hydraulic systems can be found on sports cars - after all, such a brake holds much better.

The main advantages that the hydro system gives:

- Full confidence that the hydraulic handbrake will work;

- There is no need to tighten the cable.

- It is quite difficult to bleed the brakes when replacing the standard cable system and installing a hydraulic handbrake;

- The hydraulic handbrake holds the car for several hours, after which the pressure in the system drops and the car can start moving.

Assembly occurs in reverse order.

After installing the brake drums, you need to adjust the travel of the parking brake lever.

You must have with you:

- socket wrench with ratchet 10;

- extension;

- 2 open-end wrench for 13;

- WD-40 – 1 bottle.

To begin with, the car is installed on the pit. Next, use a 10 key to disconnect the metal protection. Then, to get to the adjustment mechanism, you need to disconnect the rubber ring from the front muffler mount and slide the casing. Now, to raise the handbrake, use a 13 key to screw in the internal screw, while listening to the number of clicks. Upon completion of the adjustment, the position is fixed, and the second screw is tightened to 13.

We hope our article was useful to you!