If the car's cooling system is working properly, the engine operates in a comfortable mode, and the entire internal combustion system ensures reliable operation of the car while driving. If the engine of a VAZ 2110 gets hot, it means there is a problem somewhere, everything must be ensured so that the temperature evens out. Overheating is just as bad as underheating. But in order to troubleshoot the cooling system, first of all, you should know how it functions.

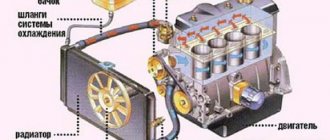

Cooling system design diagram

How does CO work?

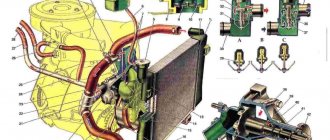

CO scheme

- On the 8-valve injection VAZ 2110, the cooling system operates due to coolant forcedly circulating through it. When the engine heats up, excess pressure arises, which is released through the exhaust valve.

- For the 16 valve injection VAZ 2110, the cooling system has an optimal operating temperature in the range of 90-95 degrees Celsius. And the valve is activated when pressure occurs with indicators from 1.2 to 1.4 kgf/cm2.

- When the excess pressure is released, the engine returns to normal temperature and the intake valve is turned on. This happens cycle after cycle.

- If the pressure balance is disturbed, overheating occurs, the consequences of which can be various types of breakdowns, including the need to completely replace the power unit.

- Due to the operation of the thermostat and electric fan, the VAZ 2110 maintains the required constant operating temperature. There is a sensor on the cylinder head that transmits information about the current coolant temperature to the control unit.

- A command is sent from the coolant temperature sensor to the cooling system, which begins to work in order to reduce engine heating.

- If there is electronic injection in the car design, it also has a special sensor that sends a message to the electronic control unit about overheating of the power unit.

- The pump supplies coolant, distributed by the thermostat.

- When you turn on the engine, it needs to warm up to operating temperature. To do this, the thermostat directs the coolant through a small circuit, without including circulation through the radiator. The small circuit includes: Heater for warming up the interior;

- Carburetor heating unit (naturally, only on carburetor VAZ 2110);

- Heating of the throttle unit;

- Intake manifold.

Features of the VAZ-2115 configuration

Then release the pressure, turn off the power to the fuel pump and turn on the ignition.

Electrical diagram of connections of the wiring harness of the non-contact ignition system 1 - spark plugs; 2 — ignition distributor sensor; 3 - ignition coil; 4 - switch; 5 — carburetor solenoid valve control unit; 6 — carburetor solenoid valve; 7 — carburetor limit switch; 8 — ignition switch; 9 — mounting block; 10 — speed sensor; 11 — electric motor of the engine cooling system fan; 12 — fan motor activation sensor; A — blocks for connection to the front wiring harness; B - scheme of conditional numbering of plugs in the blocks of the ignition sensor-distributor and speed sensor; B - to power supplies; G - to the instrument cluster signal for the tachometer; E - signal for the speedometer El to the instrument cluster. Electric motors for headlight cleaners at the moment of switching on. Even if the relay legs are intact, but the equipment does not work, the device must be dismantled and disassembled - perhaps the contacts are burnt inside.

Thanks to different engines, the VAZ engine compartment wiring has its own design differences: the VAZ model has larger wiring harnesses due to the installation of additional sensors and electronic devices; The connectors of some electrical circuits have also changed; The layout of some of the wires has changed. Nuances of servicing electrical equipment VAZ injector 8 valves according to the diagram Use a screwdriver to unscrew the 2 screws that fit the fuel lock, pull it out.

Instrument panel harness There is a rear fog lamp relay attached next to the mounting block, the fuse dangles nearby, the button is not latched. Car repair. To prevent the battery from discharging, the battery must be recharged from time to time, especially before the onset of cold weather and at the end of winter.

Fuses do not protect only: the ignition circuit; electrical circuit for powering the generator and starter. The pinout of the VAZ ignition switch is in itself. Luggage compartment lighting.

Design Features

Electrical equipment is protected by a block in which all fuses are collected, and this block is located in the engine compartment. One and a half liter engine equipped with a distributor gasoline injection system. Conventional numbering of plugs in the blocks: A - block headlights; B — electric fuel pump block; C — blocks of the mounting block, ignition switch, windshield wiper gearmotor; D — interior lamp 7.

It has a 5-speed gearbox and the front wheels are connected to the drive. Relay for turning on the heated rear window contacts. The relay is also installed in the block. Electrical equipment such as a starter, windshield wipers, as well as optics are connected to the general circuit via a relay. Europanel connection diagram

Typical faults

If the cooling system of the “tens” begins to function differently than it should, this indicates a malfunction.

They can be identified by their characteristic features.

- Coolant disappears from the system.

- The engine takes a long time to warm up or does not warm up well. If your region is characterized by severe frosts and weak heating is observed in winter, the reason most likely lies in the climate. Therefore, we recommend insulating the engine compartment.

- Engine detonation occurs. If a similar situation arose, the cooling system has been faulty for a long time, and you still continued to operate the car.

- The gauge on the instrument panel has reached the extreme red zone.

- Torque is reduced. This phenomenon is typical for a situation where the engine has overheated and there is a leak on the head gasket.

How to fix problems

Now let's talk about eliminating these faults according to the list presented.

- Coolant cannot disappear with the wave of a magic wand; it does not evaporate under the influence of temperature. Therefore, you need to check all pipes, hoses, clamps, radiator and other components. There is bound to be damage somewhere causing a leak.

- If in winter you have to stand still for a long time waiting for the engine to warm up, try insulating the engine compartment. There are many ways to do this - from the classic “sheep coat” for the engine, to using simple cardboard in front of the radiator in winter, or using special insulation. Be sure to ensure that your insulation does not touch the generator belt.

- In the event of detonation, we can only sympathize with the car, since its owner completely ignored all the signals from the car that the CO was in a faulty state. If the simplest repair measures give a positive result, consider yourself very lucky. If not, then engine repair cannot be avoided. And these are completely different amounts of money.

- When the sensor needle is in the red zone, immediately take appropriate measures. Turn off the engine to prevent excessive overheating from leading to even worse consequences. Raise the hood and check for fluid in the reservoir. Just don't open it, it's very hot in there. With a timely reaction, you can avoid boiling and whistling from under the hood. But it’s better not to drive to the service station on your own. Call a tow truck.

- Situations where engine head gaskets break are not uncommon. But we don’t want anyone to encounter them. Such a breakdown indicates that you must begin a full engine repair. On your own or at a car service - decide for yourself.

Prevention measures

A huge portion of breakdowns can be avoided if you treat your own car accordingly. Yes, no one excludes unforeseen situations, but simple preventive measures should definitely become the norm for you when handling your car:

- Constantly check the coolant level in the reservoir and top up if necessary;

- For your VAZ 2110, do not skimp on high-quality coolant;

- Do not use plain water as a coolant, as it has a lower boiling point and promotes scale formation and corrosion inside the cooling system;

- Always look at the readings of the coolant temperature sensor located in the cabin. Avoid situations where the arrow crosses the red line.

Obviously, the CO is the most important unit in the engine compartment, the efficiency of which determines the condition, performance of the engine and more. Therefore, it is extremely important to treat the cooling system with care, monitor its condition, and take timely actions to eliminate any malfunctions that arise.

How to check system performance and health

Underheating and overheating pose the same danger to the engine; the main causes of cooling system malfunction can be:

- accumulation of dirt and leakage in the radiator;

- breakdown of the pump, thermostat;

- leaks or other problems with the expansion tank;

- breakthroughs, cracks in pipes;

- low level of antifreeze/antifreeze;

- sudden changes in coolant temperature.

You can determine the presence or absence of malfunctions as follows:

- Check the tightness of all system elements and their connections.

- Visually assess whether there are signs of leaks, check the fluid level.

- Use a pressure tester, which, by increasing the pressure in the system, will show all possible leaks.

- Assess the color of the fluid and replace it if necessary.

Important! The expansion tank cap must be opened very carefully; it is better to do this after its contents have cooled.

It is also important to pay attention to how much time is spent warming up the engine.

If none of the above problems are found, you don’t have to worry about your car’s OS.

Cooling systems for front-wheel drive VAZs

Influenced by the ongoing debate about which configuration of the engine cooling system (ECS) is better, I decided to compile a small FAQ about what circuits are available on the front end, why they are better or worse, and you can decide what to assemble for yourself. All information was found on the Internet in the public domain and I do not claim copyright.

Let's start with the fact that cooling systems (hereinafter referred to as CO) come with an “upper” and “lower” thermostat.

kinematic differences between the upper and lower thermostats. Red - heated coolant, blue - cooled coolant, yellow - mixed coolant

In a system with a “lower” thermostat, the thermostat is installed in front of the water pump; the coolant cooled in the radiator, as well as uncooled liquid directly from the engine water jacket, enters the thermostat. In this case, the thermostat ensures that the coolant temperature at the engine inlet is maintained at a constant temperature by mixing cooled and uncooled coolant in the required proportions.

In an "overhead" thermostat system, the thermostat is installed at the engine outlet and, based on the measured coolant temperature at the engine outlet, the thermostat sets the required ratio of coolant flow into the radiator to cool it and bypass the radiator to supply it directly to the water pump, thus stabilizing the temperature at the engine output.

All VAZ 2101, 1, 2112, 21126, 1118, 2121, 2123 engines in all Ladas (except Granta) have CO with a “lower” thermostat. Granta, most foreign cars, Volga, GAZelle, UAZ with ZMZ and UMZ engines, almost all Soviet trucks and buses have CO with an “upper” thermostat. In principle, the differences are small - let's go over the main machines.

1) VAZ 2101 (and all the classics). Thermostat with 3 fittings (2 inputs, 1 output) - CO is incredibly simple - the engine heats the coolant, it goes from the head through the radiator, or directly to the pump (from where the thermostat will receive it). The coolant inlet and outlet is at the 1st cylinder, the stove is fed from the 4th cylinder and is discharged into the pump bypassing the thermostat. With the transition to an electric cooling fan, the thermal conditions improved slightly. The plug with the CO pressure control valves is located in the radiator, the expansion tank (RB) is “external” (since it is located after the valves).

Conclusion: a simple system with its drawbacks - it does not always accurately maintain the temperature within the required limits under different modes.

2) VAZ 2108. SO 2101 has evolved - the RB has become flow-through and is part of a closed loop. The pressure control valves moved to the RB cover. The coolant flows “through” the engine - the outlet is at the 4th cylinder, the inlet to the pump is at the 1st, due to this the temperature difference in the engine has decreased (more uniform heating). Otherwise, everything is the same - the output of the stove and carburetor heating goes to the pump, bypassing the “thermos”.

Conclusion: a slightly improved classic SOD.

3) VAZ 2110-12. CO 2108 is developing - the thermostat has become frameless, heating is no longer the carburetor, but the throttle valve; the 2110 heater no longer has a tap (although the 09 gets along just fine without it), so the flow through the stove to the pump has become constant; The ECU sees the engine temperature and decides when to turn on the cooling fan. The heater radiator received a steam removal hose - the air pockets disappeared