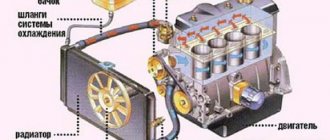

Stable operation of the vehicle cooling system, regardless of the type of engine, is an unconditional condition that ensures trouble-free operation of the unit throughout its entire service life. To ensure optimal temperature conditions, this unit speeds up the engine warm-up period and prevents it from overheating, effectively removing excess heat. As a rule, the temperature is maintained in the range of 80-95 °C, however, with increased loads on the car or a malfunction of the cooling system, it can reach 200 °C. If this indicator is maintained for a sufficiently long period of time, then the cylinders may jam, parts may fail, the engine box may become deformed, etc.

On the other hand, regular overcooling of the power unit or even insufficient heating also harms it - corrosion processes are activated, fuel consumption unreasonably increases, and components wear out prematurely. For this reason, you should not miss engine maintenance deadlines, fill in refrigerant on time, change mechanisms that have become unusable, and in general, immediately eliminate at least the main malfunctions of the cooling system.

Why is the antifreeze circulation system ineffective?

Typically engine cooling system malfunctions are caused by:

mechanical defects;

violation of the mode of use of the engine and the requirements of its manufacturer;

natural wear and tear of elements - this usually means abrasion of the metal, the appearance of cracks, etc.

However, no less dangerous are the problems called hidden - local overheating, detonation caused by high-temperature operation of the unit, etc. In the end, the radiator, into which a lot of dirt and fluff can accumulate outside during the season, also causes an increase in the temperature of the antifreeze. And yet, detonation is perhaps the most serious phenomenon that has a super-negative effect on the power unit. Indeed, because of it, a lot of serious defects very often appear:

the gasket between the engine body and the cylinder head burns out;

The cylinder head is deformed and microcracks appear in it;

Both the crank mechanism and the cylinder-piston group are physically destroyed.

As for violations of the rules for operating the machine, they most often include the bad habit of mixing antifreeze with antifreeze - if such a procedure is not carried out once, but regularly - the use of refrigerant of dubious quality and non-original spare parts. The same list includes the professionalism of people who are directly involved in malfunctions of the cooling system and other components of the car - auto mechanics, “Uncle Vasya” from the neighboring garage and just acquaintances who allegedly meticulously understand the structure of vehicles.

Troubleshooting

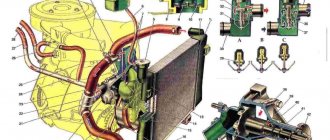

If the cause of the breakdown has been identified, you can begin to eliminate it. Problems with the expansion tank plug are usually resolved by replacing the faulty valve. If the valves are working properly, but the seal of the tank is broken, try replacing the gasket in the lid, which wears out quickly. To eliminate leaks, it may also be necessary to replace hardened hoses with new elastic ones, and the clamps need to be tightened more tightly, but not pinched, so as not to damage the pipes. If the tank itself is damaged, small cracks are sealed, large cracks are covered with patches, and dents are straightened out.

A clogged radiator needs to be cleaned with a jet of water under pressure or compressed air, the outer surface is cleaned with a special solvent, and mechanical damage is sealed. If an individual tube is seriously damaged, it can be excluded from the circuit by being completely soldered at the top and bottom, but more than three tubes cannot be soldered in one radiator. In case of extensive damage, it is more cost-effective to replace the radiator. New radiators with a plastic barrel and an aluminum core cannot be repaired. A pipe cracked at the edge can be cut off if its length allows, and if the crack is closer to the center, it can be extended using a metal tube. But these are temporary measures, so after such operations it is recommended to contact the service for professional repair.

Other malfunctions of the engine cooling system, as a rule, are repaired in workshops. If you need to replace worn out, damaged parts, you can save a lot by ordering high-quality spare parts from disassembly centers from JapZap. When using high-quality coolant and regularly monitoring its level, routine maintenance and timely replacement of worn-out parts are usually sufficient to maintain the functionality of the engine cooling system.

Daily, scheduled and seasonal cooling system maintenance

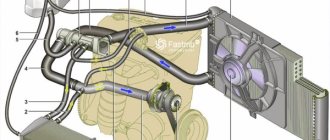

The main work related to the maintenance of the cooling system of the power unit begins with diagnostic ones: you need to check the tightness, thermal condition, operation of the thermostat and fan belt. In this case, on a fully warmed-up engine, you should measure the temperature between the lower and upper radiator tanks: the difference in readings should not exceed 10-12 degrees.

The tightness of the system, on the contrary, is checked in the engine “cold”. Moreover, under pressure and in a certain temperature range specified in the vehicle registration certificate. If it is discovered that the thermostat is faulty, it must be replaced. During the inspection, special attention should be paid to the most problematic points, which are the water pump oil seal and the connections of the pipes. All other work is carried out in accordance with technical regulations approved by the vehicle manufacturer.

Daily Maintenance (EO)

First of all, it involves adding antifreeze. Its level should be 2-3 cm below the end of the filler neck. In addition, if threaded connections are found to be loose, they must be tightened.

Maintenance No. 1 (TO-1).

The list of work carried out includes removing oil and dirt from the engine body by washing with a strong stream of water. The radiator undergoes a similar procedure. It is also necessary to check the functionality of the valves, plug and radiator drive. After checking the tension belts of both the water pump and the fan, if necessary, they are adjusted at several points. The number of points depends on the design features of the node. Finally, lubrication work is required on the fan pulley and water pump bearings.

Maintenance No. 2 (TO-2)

consists of checking the correct operation of the hydraulic and electric couplings for turning on the fan, the antifreeze temperature indicator and the sensor.

Seasonal Maintenance (MS)

carried out after approximately 50 thousand km, however, this figure is often individual for each car. The main task of the CO is to flush the system with water under pressure to remove sludge when the thermostat is turned off. Moreover, the jet must be kept in the direction opposite to the movement of antifreeze.

LIFE HACK.

The worst thing that can happen in winter is the complete defrosting of the cooling system. To prevent this from happening, if there is a risk of high temperatures, it is recommended to fill the neck with refrigerant with a freezing point of around -40 degrees. And since such antifreeze has a significant expansion coefficient, the system will need to be filled to a maximum of 95%.

The nuances of flushing the system

The cooling system - faults and solutions have already been discussed - is always prone to scale formation. It is this that often becomes the culprit of increased fuel consumption, a decrease in the power indicators of the unit, the appearance of detonation and, in general, premature wear of many elements of the cylinder-piston group. Therefore, the system periodically needs to be washed not just with water, but with the addition of hydrochloric acid and a chemical that speeds up the cleaning process. The algorithm for this process is simple:

remove the thermostat;

pour the solution;

start the power unit and warm up the improvised “antifreeze” to about 60 degrees;

stop the engine and drain the liquid from the system after 10-15 minutes;

flush the refrigerant circulation system with hot water.

To prevent scale formation less intensively, it is advisable to use water with a minimum hardness level. This hardness can be achieved in a variety of ways - by adding anti-scale additives, soda, lime, by magnetic filtration, boiling, etc.

Why does the engine take a long time to warm up?

The thermostat is stuck open or has changed temperature characteristics.

Everything is very simple - the thermostat is the main element that sets the temperature regime of the engine, its task is to limit the amount of antifreeze entering the main radiator. If all the coolant passes through the main radiator, the engine will take a very long time to warm up, and in winter it will not be able to warm up at all.

The viscous coupling is jammed.

Some vehicles use a mechanically driven cooling fan. In most cases, it is done through the so-called. viscous coupling. Here's how it works:

If the viscous coupling is stuck, the cooling fan will constantly rotate at maximum speed, and engine warming up will slow down, but if the thermostat is working, the engine will still maintain temperature.

Common “opinions” and myths

Among motorists there are always enough people who have a “special” view on the intricacies of vehicle maintenance and repair. For example, many believe - and this is especially true for novice drivers - that adding water to antifreeze is strictly not recommended. They say this leads to premature breakdowns of the cooling system. Meanwhile, situations when this manipulation is required often occur. For example, the coolant level is low, but there is no auto shop nearby, and technical assistance is not close. In such cases, it is better to replenish the fluid in the radiator than to go “dry”. After all, no one bothers you when you get to the repair point or upon arrival at the garage, drain all the antifreeze with water and fill the system with 100% refrigerant.

There are also a number of myths and prejudices that often plague the lion's share of car owners.

1. In a well-worn engine, the cooling system always overheats. This statement is not true, because even in an old engine it is possible to maintain a normal temperature. Especially if the technical characteristics of the unit require low compression. The main thing is that the radiator works properly, as does the thermostat, and in addition, the water pump performs its function correctly.

2. You cannot mix different brands of antifreeze and add water to it. The falsity of this opinion lies in the fact that all modern coolants are made on an alcohol basis. Yes, alcohols are different, but they “get along” with each other quite successfully. Moreover, the memorable antifreeze is just a type of outdated, but at one time very popular antifreeze, the basic component of which is diethylene glycol. Modern liquids of this kind are much more effective, in addition, they have additives that resist scale.

Of course, driving “on water” is a bad habit. Still, adding water to the refrigerant is acceptable in critical situations. Another question is that it is more expensive to use liquid from the tap, as this risks clogging the pump and radiator. Therefore, it is permissible to add either distilled water or well water to antifreeze. After all, it is in the well that the least amount of iron is contained, which, when heated, falls out in the form of a brown precipitate, which becomes the cause of a number of malfunctions of the cooling system.

3. There are many rubber tubes in the coolant circulation unit that mice can chew through. The ridiculousness of such a statement lies in the fact that these small animals always have something to put on their teeth, besides tasteless rubber... Moreover, the cooling system uses high-temperature types of this material, which are difficult to mechanically destroy.

4. If you operate the engine for a long time, then clogging of the “jacket” of the cylinder block will inevitably lead to the need to replace the unit - it is no longer repairable. This opinion is only partly true, since in order for the “jacket” channels to truly become impassable for antifreeze, it will take 200-300 years of continuous operation of the car. It is more likely that black, oily dirt, the source of which may be engine oil entering the cooling system, will clog the radiator. And washing it, even in a garage, is a familiar, standard and highly effective procedure.

Prevention of normal operation

A properly functioning cooling system of any car is able to ensure normal engine operation even at very high ambient temperatures. A decrease in its effectiveness is usually caused by the fact that the car owner does not pay due attention to checking the operation of the system. In fact, in order for the cooling system to work smoothly and without interruption, you need to follow a few simple rules:

- While driving, constantly monitor the coolant temperature gauge, as well as the warning light that lights up when it boils. If the indicator lights up, you must stop the car as soon as possible and try to find out the reason.

- Constantly monitor the coolant level in the system. Typically, according to regulations, antifreeze is changed after approximately 60...120 thousand kilometers. Other automakers recommend changing it every two to three years. However, it would not be superfluous to monitor the appropriate level during the service interval, especially if you suspect that the engine cooling system is not working correctly.

- Use antifreeze with the prescribed characteristics. In the documentation for any car, the manufacturer directly indicates what coolant needs to be poured into the system. This applies to its class, compliance standard and quantity. The manufacturer is also less often indicated, but this is rather an exception and direct advertising.

- Check the cooling system for leaks. In particular, whether there are external or internal antifreeze leaks. Along with eliminating the leak (if any), you must also remember to add fluid to the required level or replace it with a new one.

- Check the condition of the radiator. Often its outer surface becomes clogged with dust and dirt, which significantly reduces its performance.

- Do not overload the engine. In particular, it is not recommended to frequently develop excess power on the engine. For example, when driving an overloaded car, using a sporty driving style (at high speeds, with slipping, sudden starts), towing heavy trailers. All this significantly wears out both the engine as a whole and its cooling system in particular.

- Periodically clean the cooling system. This can be done when replacing antifreeze with a new one, or when clear signs appear that the efficiency of the system has decreased.

By following such direct advice, the car owner can not only ensure the normal operation of the cooling system, but also significantly extend its service life.

conclusions

It is logical that the cooling system as part of the engine affects the service life of the entire unit. Therefore, timely maintenance, and especially constant monitoring of the level of antifreeze - by the way, its complete replacement must be accompanied by flushing of the entire system - is an invariable condition for any car owner.

Secondly, after this procedure, you need to bleed the unit to remove air pockets. To do this, just unscrew the cap of the expansion tank and actively press the accelerator pedal. At the same time, to ensure full performance, the engine must run at idle speed.

Thirdly, any violation of the tightness of components should be a reason for a careful inspection and detection of leaks. In this case, in no case should you forget about the radiator of the interior heater. Since in many models of modern cars it is included in the engine cooling system circuit and is clearly prone to depressurization, it should be monitored especially carefully. And as soon as streaks appear and the floor around the driver’s seat becomes wet, the stove should be immediately repaired or replaced with a new one.

Finally, if the antifreeze level began to drop noticeably, and the cylinder head began to lose its geometry, then this is a clear sign of a complex and expensive repair. It is almost impossible to carry out it yourself without being an experienced mechanic-motorist. In such cases, it is better not to do anything on your own, but to consult a specialist: perhaps the upcoming repair costs are not commensurate with the insignificant remaining service life of the engine, and it is better to replace it.

| Tweet |