water pump

, also known as a car engine water pump, is a pump that creates forced circulation of coolant in the internal combustion engine cooling system.

The water pump

is intended to organize the circulation of antifreeze or other composition in the cooling system.

A malfunction of the pump leads to a serious disruption of the internal thermal regime of the engine, which is why it “boils” quite quickly. photo gallery:

This cannot be allowed to happen, so to make sure that the engine pump is working, you need to periodically listen and inspect the motor in order to repair or replace the failed unit in time.

Water pump design

Pump device

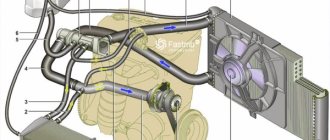

in most cars it is very similar, especially for domestic cars. And you won’t have to search for long to find where the pump is located either, since it is driven by the timing belt and is located near the radiator.

Structurally, the pump looks like this: a shaft is mounted in the cover. An impeller is mounted on it, the movement of which initiates the movement of liquid in the system. A drive pulley is mounted on the other side of the shaft, and in some car models there is also a fan. Through the timing belt and drive pulley, the rotational energy of the engine is transmitted to the shaft, the shaft drives the impeller and the entire system operates.

Pump device.

An oil seal is mounted between the housing and the impeller, the wear of which is associated with many pump problems. If this seal is bad, antifreeze or antifreeze gradually seeps into the cavity towards the bearings, washing away their lubricant. Because of this, the bearings begin to work much louder and wear out quickly, which leads to the pump jamming.

THE MAGIC OF CANDLE COLOR

In addition to church candles, you can use ordinary candles to achieve your goals, but you should know some features. There is a huge variety of candles: in size, shape and design, as you can see by visiting a good candle store. In a magical sense, beeswax candles are ideal - because of the symbolism of the bee and because it is a natural product. Since each color has its own distinctive property, you will need to choose a candle for your need. Knowing the meaning of different candle colors makes it easier to achieve certain goals. For rituals, and in general, it is worth buying good candles, made of colored paraffin or wax. You should not take dousing candles; with them you will not be able to feel the energy. Proper use of the color of a candle allows in many cases to reduce one’s own work to creating an intention, and everything else is done “according to the program” with a burning candle. Magic matches for candle color:

White - Purity, purification, protection. Any goals

Black - Revenge, curses, damage, love spell at any cost, getting rid of negative emotions, contact with the dead Red - Love, happiness, improving health, driving out evil, improving fate. Passion and creativity.

Pink - Love, friendship, happiness Orange - Attracting sympathy, success. Work, career.

Yellow - Predictions, fortune telling, removing obstacles and everything that brings misfortune. Intelligence.

Green - Prosperity, material well-being, rebirth, good luck. Money, healing.

Blue - Development and strengthening of parapsychic capabilities Blue - Fighting fear, protection from otherworldly forces. Calmness, wisdom Violet - Strengthening fortitude, treatment of serious illnesses, magic. Spirituality.

Purple - Contact with otherworldly forces, achieving power, overcoming something.

Brown - Treatment of pets, all housing problems. Silver - Animism, animal powers

Causes and consequences of water pump failure

Since the car pump is a fairly simple mechanism, it does not break down too often, especially with normal engine care. However, even the most reliable pump can fail. There may be several reasons for the breakdown, including:

- wear of device components, including aging of the oil seal;

- initially low quality pump;

- unprofessional repairs.

If the system remains sealed, but the pump does not initiate fluid circulation through it, this will lead to an increase in engine temperature, as indicated by the gauge on the dashboard. Driving for a short time in this mode will cause the radiator to boil or the engine to seize.

If a pump leak occurs, you need to take action to eliminate it as quickly as possible.

Another sign of a pump failure is an antifreeze leak in the area where it is installed. If the leak is not very severe, this is not so scary, since the liquid circulating in the system will still perform its functions normally, it just needs to be topped up regularly. But still, if such a breakdown is detected, it is best to eliminate it immediately, because leaks tend to increase in intensively used engines.

Effect of high and low temperature

The average battery life is also affected by weather conditions, in particular air temperature. Frosts adversely affect the viscosity of the electrolyte, and this, in turn, increases the resistance of the passing charge. As a result, such unfavorable processes are observed as:

- freezing (thickening) of the electrolyte;

- shedding of electrodes;

- capacity reduction;

- body deformation;

- reduction in service life with simultaneous failure.

On the other hand, the high air temperature also affects how many years your battery will last. It leads to evaporation of the liquid inside the cans, which leads to undercharging and overdischarging, and increases the likelihood of corrosion processes. There is an acceptable level of battery discharge, which is no more than 25% in winter, and no more than 50% in summer.

Common water pump failures

There are not very many types of failures due to which a water pump can fail, which is due to the relative simplicity of its design. The most common are:

- Problems with the impeller are the most common, but wedge bearings also happen.

- impeller failure;

- deterioration of fastening of the impeller to the shaft;

- bearing jamming;

- deterioration of joint tightness due to engine vibrations, leading to coolant leakage.

What does the number of spikes affect?

As I have said more than once, winter studded tires have only a few tasks:

- This is cross-country ability in the snow

- Working in slushy snow, that is, above-zero temperatures in winter, when you need to remove moisture from the tread

- Ice work, braking and starting assistance

So, as you understand, the spikes only work on an icy surface (in deep snow and slush, they are actually not needed), and here it is logical to think - the more spikes, the better the performance. This is almost always the case, I won’t run all sorts of tests now, I’ll just say that if you compare the option with 130 and 190 studded elements, the second one has a braking distance of almost a meter less. And this is noticeable!

However, it is worth noting that now there are a lot of advanced technical innovations that have only 96 elements on the entire tire surface. Their efficiency is approximately the same as that of options with 130 – 190 elements. This is because new technologies are used here (for example, rubber composition, number of lamellas, shape and fit of the stud, etc.). The braking distance of these new products is at the level of the most “toothy analogues”, so there is room for improvement.

Well, now I want to take several manufacturers and count the number of studs on a tire, so let’s start.

Water pump repair

The engine pump is a repairable, dismountable unit. Here it is possible to replace both the entire mechanism and its individual elements, such as bearings. The fact that a car pump does not have to be completely replaced is good news, since this can significantly reduce the cost of repairs. True, access to this unit for partial or complete disassembly can be difficult. So, in some car models, this requires partially unscrewing the engine mounts, working from below from the inspection hole. Very often, the pump is replaced every second time the timing belt/chain is replaced, but if symptoms of a malfunction occur, the water pump is replaced even earlier, it all depends on the quality of the part and the level of work performed during the previous change of the timing drive and the part itself.

Now about the version with “tucked” claws.

Within the same limits (half a millimeter), there is a decrease in grip - 2.1–3.3% for every 0.1 mm - in acceleration and braking with electronic assistants. Moreover, in the cases of ABS and ESP, from a decrease in the protrusion of the studs, the adhesion properties lose from 3.0 to 3.3% for every tenth of a millimeter. But the losses for a car without electronic “limiters” are slightly less - 2.1–2.4% for every “tens” of a millimeter. Transverse properties also deteriorate, but not so noticeably - 0.5–1.3% for every 0.1 mm. The car’s behavior on ice is “smeared” and is characterized by sluggish reactions. It feels like the rubber is doing more work than the studs. The handling rating is also 6 points.

FAQ

Where is the pump located in the car?

The pump is mounted on the engine housing because its shaft is driven by a timing belt or an attachment belt (very rarely). Moreover, it is located on the side of the engine that is closer to the radiator. This makes it possible to reduce the length of the pipes, because the coolant must pass through the radiator, give off heat and flow further into the pump, already cooled.

Where does the pump go?

The pump always pumps away from itself, that is, it pushes, but does not suck. This is ensured by the fact that the rotating impeller creates a centrifugal force, which pushes the antifreeze further. The purpose of the pump is to ensure the movement and pressure of the fluid from the radiator to the engine, so it pumps coolant into the engine. Structurally, the impeller can rotate both clockwise and counterclockwise.

Types of cooling system pumps

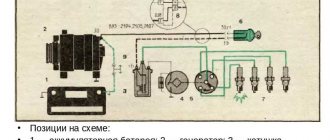

Types of cooling system pumps Coolant pumps used in the modern automotive industry do not have any fundamental design differences. But they can be divided depending on the type of drive, purpose and housing design. The pump can be driven in two ways:

- Mechanical - the pump shaft is connected via a belt drive to the crankshaft or camshaft of the engine. In this case, it is set in motion synchronously with the engine starting.

- Electric - in this scheme, the pump shaft is driven by an additional electric motor, the operation of which is controlled by the electronic engine control unit (ECU).

According to its intended purpose, a car engine pump can be:

- Basic. Such a pump directly pumps liquid in the cooling system.

- Additional. It is not installed on all cars and can be intended for auxiliary cooling in regions with very hot climates, reducing exhaust gas temperatures, cooling the turbocharger in turbocharged engines, and additional cooling of the engine after stopping. Unlike the main pump, the additional one is driven by an individual electric motor.

The service life of a coolant pump depends on the type of construction of its housing. This parameter distinguishes between:

- Collapsible. This type is used in old and domestic cars. This design allows you to repair and flush the pump.

- Non-separable. In most countries, an engine pump is considered an inexpensive consumable spare part, and therefore many manufacturers have switched to producing non-separable pumps. They must be completely replaced every 60 thousand kilometers of the car. When installing a new pump, the drive belt must be replaced.

In addition to the designs described above, there are also switchable pumps. They allow you to turn off the flow of coolant until it warms up to a temperature of 30°C. This allows for faster engine warm-up and improved fuel consumption.

Liquid pump

Multipliers or booster compressors are sometimes used as liquid pumps, for example, the ultra-high pressure compressor of the High Pressure Institute (Fig. 65) works well at a pressure of 5000 atm and, as a liquid pump, with a capacity of up to 60 l/hour. Although the amount of harmful space in this compressor is very small (5 - 6%), its performance nevertheless increases when working on liquids that are less compressed than gases.

If you have a liquid pump or multiplier, it is more advisable to replace the bomb / with them, the cooling and heating of which (even one-time) requires time and coolant consumption. If a mercury seal is installed in front of the reactor / / (Fig. 89), and the reactor itself and part of the seal are filled with gas from a cylinder or compressor, then experiments with gases can be carried out at the installation.

When the liquid pump operates, oxygen or nitrogen leaks (through the gap between the plunger and the cylinder liner), which returns back to the column, passing along the way through a filter 15 made of porous metal to remove graphite particles.

Note that piston liquid pumps allow suction of gas with the same success as a compressor.

Unlike liquid pumps, air and other gas compressors (except low pressure compressors) are cooled by water or other means (surface cooling) to remove the heat that the compressor generates.

Surface pumps

Surface units are located in an area that is located in close proximity to a water source. A hose is connected to the suction pipe of the pump, its other end is immersed in the liquid. Such devices are:

- garden pumps: they are used only for watering the garden or vegetable garden;

- pressure devices: these devices become an element of the engineering system, their task is to provide the necessary water pressure;

- pumping stations, which in addition to the pump include a hydraulic accumulator - a device that accumulates water and also regulates the pressure in the system.

The advantage of surface structures is ease of maintenance and operation. The downside is the impossibility of extracting water from deep sources.

Pumps located at the source

Submersible pumps operate directly in the water column. The liquid rises up through a hose or intake pipe. Since this equipment does not suck, but creates a constant pressure, they are used for sources whose depth is already significant - from 100 meters or more. Submersible equipment is divided into several types.

- Wells. These pumps can work with sources whose depth is 10 meters. Their features are better cooling, less sensitivity to solid, large inclusions, and low noise levels.

- Borehole pump pumps. Such elongated cylindrical equipment has maximum power. It is designed for pumping liquid from deep, narrow sources with a large flow rate.

- Drainage Their purpose is to combat flooding in basements, pits, ditches or trenches. Drainage devices are recommended if the diameter of particles in the liquid does not exceed 30 mm.

- Fecal. This equipment does the most thankless job. Its task is to pump out highly contaminated water, which has various impurities.

As you can see, the choice of device depends entirely on the quality of the liquid, the type and depth of the source. Since many of them are threatened by water loss, the best option for a well or well in any case remains a submersible device. In addition, this equipment can be used to drain pits, empty tanks and other reservoirs.

Possible problems after replacement

Unfortunately, behind the apparent ease of removing and installing the pump, several problems can be hidden. For example, the pump is very sensitive to tightening - as soon as you twist the bolts a little, the gasket is squeezed out. Many such nuances may arise after replacement.

There was a noise

Noise and whistling sounds from the pump while driving are the most common problem after replacement. There may be several reasons for new sounds:

the bolts are tightened too tightly;

If noise does not affect the performance of the cooling system in any way, that is, fluid circulation is carried out normally, then the part does not need to be changed.

The stove began to heat poorly

If, after replacement, the stove in the cabin began to produce slightly warm air or stopped heating altogether, then there is an air lock in the cooling system. It is necessary to warm up the car to operating temperature and sharply accelerate it - as a rule, these measures are enough for the traffic jam to be overcome and the heater to work as usual.

Also, problems with “heating” can arise due to the fact that the impeller blades on the new part have a slightly different gap. It is impossible to solve this problem, so it is recommended that you initially select a pump from the same manufacturer as the old product, with identical markings.

It is recommended to give it a good throttle to break through the air lock.

Good night! a couple of days ago I changed the pump on the Hunter 409 engine, and the heater at idle began to blow slightly warm air, when you put it on the gas and keep it at rpm it starts blowing hot, the temperature floats from 80 to about 100 when the idle is about 100 at rpm it drops to 80. When the old pump was standing, it was hot in the cabin in the cold, but it rattled, the impeller on the old one was like a textolite round one in the middle with slots like a spiral, and on the new one the impeller was like blades. Due to the difference in the impellers, can the fluid be driven worse? and it seems like they write that since 2007, only impellers have been installed on pumps, or what about blades?

Chink

https://forum.uazbuka.ru/archive/index.php/t-124342.html

The motor gets very hot

Engine overheating can only be associated with poor performance of the cooling system. Consequently, if after replacement the engine begins to get very hot, the pump does not perform its functions or works “at half strength.” Immediate replacement is recommended.