Defects that appeared after replacing the clutch

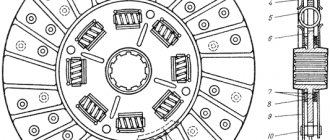

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

Replacing the release bearing

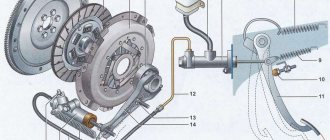

Replacing the release bearing yourself is quite possible, provided that “your hands are in the right position” and you have everything you need for the job. The work is carried out in the following sequence: drain the oil, unscrew the bolts connecting the gearbox and the engine, then dismantle the box (although there is a way to replace the clutch without removing the box and draining the oil) and disconnect the bearing from the fork. Afterwards, the VM itself is removed, and a new one is installed in its place. After completing all the work, you need to adjust the clutch, you can learn how to do this from this article.

Let's sum it up

The release bearing, like most other components, suffers from non-compliance with operating rules, as well as the habit of driving with the clutch depressed. At the first sign of a faulty release bearing, take action, otherwise you will have to replace the entire clutch assembly, which costs much more.

That’s all I have, thank you for reading to the end, write in the comments about how long it takes to change the release bearing and what signs you use to determine if it’s faulty. If you liked the article, share it with your friends on social networks using the special buttons below. Good luck, take care of yourself!

Source

If after replacing the clutch the car jerks

For example, before the repair, the car did not pick up speed well, it was slipping, and the clutch pedal was activated at the very top. All the signs of a worn driven disc were present. After replacing the disk, the car began to jerk. What could happen after the repairs were carried out?

- The issue may be a defective part. This is not so rare when it comes to non-original spare parts. In Russian-made cars (VAZ, GAZ, AZLK, IZH), defects also occur in factory parts. That is, the driven disk is simply curved. On the clutch basket (drive disc), the pressure petals may be at different levels, then the release occurs unevenly and the car jerks.

- The car may jerk due to clutch adjustment. More precisely, it was not performed after replacing the disk. The linings of the new part are much thicker; in this case, the clutch pedal “takes at the very end”. When starting off, the car moves jerkily, and the gear shifts into gear with a crunch.

- The car jerks due to the replacement of not all the parts that needed it. In particular, the cause of jerking is the worn surface of the flywheel under the driven disk. If the flywheel has not been replaced, there may be jerking when driving, and the car may also slip.

There is an opinion that the car may jerk due to incorrect installation of the clutch disc, that is, it was installed on the wrong side. Theoretically, this is possible on some car models. But the disc is designed in such a way that even depressing the pedal normally and moving off will not work with this installation.

Possible causes of failure

Loads on the release bearing occur when the clutch is disengaged. The higher the engine speed at the moment of gear shifting, the more intense its operating mode. The most common reasons for part failure are:

- Holding the clutch pedal down for a long time. High rotation speed and large axial forces from the diaphragm spring lead to rapid wear of the device elements.

- Abrupt engagement and disengagement of the clutch. Characteristic of aggressive driving style. Instant uneven loads occur on the bearing, which can lead to failure of not only the rotating part and the pressure fork, but also the clutch elements.

- Poor adjustment of pedal or cable travel. The bearing is in constant contact with the surface of the spring. Constant rotation causes heating of the rolling elements, which leads to rapid wear.

Part destruction may occur due to the installation of a low-quality product or lack of grease in the release clutch cavity.

If there is a noise or whistle after replacing the clutch

Many car owners often complain that after replacement, a noise or whistle appears that was not there before. What could be the reasons for the extraneous sound and why does this happen?

- The new release bearing turned out to be of poor quality or does not contain enough factory lubricant. A whistling or noise appears when you press the clutch pedal. Many people mistakenly believe that the bearing makes noise when the clutch is disengaged. But this is even illogical, in this state the part does not bear the load, and accordingly the noise (whistle) in this state is minimal.

- The clutch basket has unevenness and roughness at the tips of the pressure petals. Typically, spare parts from Russian manufacturers have such a defect. It should be noted that as the parts are ground in, the whistle that appeared initially disappears. You can temporarily eliminate the noise by lubricating the petals with lithol. But this can be done without disassembly on GAZ cars; on front-wheel drive cars, to perform a similar procedure it is necessary to dismantle the gearbox.

- It is possible that before replacing parts, the car owner did not pay attention to extraneous noises such as whistling, as he was expecting repairs. But after replacing the clutch, extraneous sounds remained, which the owner of the car did not expect. Noises are often caused by the gearbox. If, when the clutch is depressed, the unpleasant sound disappears or noticeably subsides, then most likely this indicates wear on the gearbox input shaft bearing.

- The driven disc linings have roughness. A rustling noise occurs when changing gears. There is no need to worry too much ahead of time - the new parts will get used to it, and the defect will disappear during the operation of the car quite quickly.

- The input shaft bearing in the crankshaft may also make noise. When disassembling the car, you should do an external inspection of the bearing. If it is very dry, it must be lubricated with lithol or other suitable lubricant. It is better to replace a clearly worn part immediately.

Clutch release bearing VAZ 2115 signs of malfunction

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

In your case, it is OBVIOUSLY not the release bearing, but the input shaft bearing.

Treatment: drain the fuck out of the gearbox (obviously motor oil) and pour in transmission oil for front-wheel drive.

Then everything will be happy for you.

and when I press (release) the clutch, it starts to buzz (something rubs). and today the car even started to lean forward a little (it began to pull a little)... and when it warms up, this effect seems to become weaker, but does not disappear completely.

the same thing - it’s rubbing, I’m going to at least change the oil to a “cool” synthetic, although this should have been done before winter :ooo:

In your case, it is OBVIOUSLY not the release bearing, but the input shaft bearing.

Treatment: drain the fuck out of the gearbox (obviously motor oil) and pour in transmission oil for front-wheel drive.

Then everything will be happy for you.

It should be the other way around - engine oil is thinner than transmission oil, even special for front-wheel drive (if the first is not mineral oil, and the second is not synthetic). So in the cold, even with a normal gearbox, until it warms up, when you release the clutch pedal in neutral, the car jerks slightly.

Regarding the release: the noise when pressing (squeezing) is the bearing, when releasing it is the box. I agree here.

Source

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.

Clutch slipping after replacing all its parts

After replacing all elements, adjustment is required, but many car owners ignore this point. The cause is slipping, the car accelerates slowly, the engine speed does not correspond to the speed of the car. The engine just roars, and the car is driving quite slowly, as they say, slipping.

In cars with a mechanical clutch cable, adjustment is made by the cable itself. In hydraulically driven machines, this process is carried out using a clutch rod. In modern cars, you often come across rods that do not have adjustments. But this does not mean at all that it cannot be produced. In such cases, adjustment of the clutch pedal itself is provided, but not everyone knows about this possibility.

The machine often slips due to wear on the flywheel surface in the place where the surface works in tandem with the driven disk. The mistake of many car owners is that they first of all change the disk, while completely forgetting about the flywheel. As a result, you have to disassemble the car twice to fix the problem.

Resource extension

Warranty obligations do not apply to parts that fail early, because its wear and tear depends entirely on the actions of the driver. However, there are several recommendations that, if followed, will extend the life of the unit.

To extend the life of a part you need:

- avoid abruptly moving the car;

- do not allow the pedal to be slowly released at high engine speeds;

- drive with the clutch pedal fully released and do not press it while braking;

- Avoid situations in which the car may slip.

But the main recommendation is to minimize holding the pedal down for a long time. The release mechanism will last longer if the clutch pedal is used only to change speed.

Source

Vibration that occurs after replacing clutch elements

There are few reasons why vibration occurs after replacing a clutch. Vibration usually appears in two forms:

- The pressure plate (clutch basket) is not balanced;

- During assembly, the driveshaft was installed in a different position from the original installation (but this only applies to rear-wheel drive or all-wheel drive vehicles).

By and large, on cars with front-wheel drive, you can inaccurately secure the wheel drive (CV joint), and the movement of the car will be accompanied by vibration and knocking, but this does not happen often.

If the clutch basket creates vibration, you can try moving it to a different position. As a rule, the pressure plate mounts are symmetrical. On many models, the basket is attached to the flywheel with six bolts, and the basket can be placed in three positions. In one position the vibration may disappear completely or be minimal. But it is better to exchange the warranty part immediately for another one. This will be less hassle for the car owner.

For what reasons does the clutch in a car begin to make suspicious loud noises?

Almost anything that makes a clearly audible and often hard to detect noise coming from the transmission is considered a loud clutch. Typically, these noises can be quite obviously related to the clutch as it engages or disappears depending on how it operates. These noises can be: • ringing; • knocking; • rattling; • thud; • whistles; • howl; as well as a number of suspicious sounds of varying intensity and frequency. If something like this starts to appear regularly in your car, you should start diagnosing the entire system and identifying the source of the noise as soon as possible.