The VAZ 2107 clutch is designed to connect the engine crankshaft and the gearbox input shaft with the possibility of briefly stopping the transmission of torque. The reasons for its failure can be very diverse. However, all of them can be easily diagnosed and eliminated on their own.

- Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing the clutch - Clutch adjustment

- Clutch slipping

- Tools and materials

Video: do-it-yourself adjustment of the VAZ 2107 hydraulic clutch

Clutch mechanism of VAZ 2107

The VAZ 2107 clutch is a rather complex mechanism consisting of several dozen elements. The reasons for its malfunction can be very different. However, they can all be divided into two groups:

- Defects in the clutch mechanism itself. These include malfunctions of the driven part of the clutch, pressure device, basket, flywheel, and clutch fork.

- Defects in the hydraulic drive of the clutch mechanism. They can be caused by leakage of the working fluid, the formation of an air lock in it, as well as malfunctions of the main or working cylinders (MCC and RCC) and the pedal mechanism.

The clutch, like any other car part, has a limited service life. First of all, it depends on the skill of the driver, and therefore is not regulated by the manufacturer. To increase the service life of the clutch, it is necessary to adjust it in time, monitor the level of working fluid, avoid off-road driving, and learn the skills of using the clutch correctly.

It must be remembered that in addition, the clutch is a safety device that protects the transmission from serious damage when the rear wheels are blocked by various obstacles. The car is stuck in a quagmire, the drive wheels are stuck, the engine power is enough to turn the stuck tires. In this case, the clutch will begin to slip, protecting the gearbox, cardan and rear axle from damage. Yes, the driven disc linings will burn out. Yes, the clutch will overheat, which can cause the steel flats to warp or weaken the spring plates. But more expensive units will be protected from breakdowns.

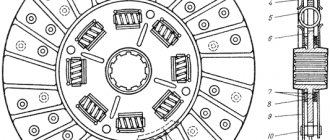

Classic VAZ models have a dry, permanently closed single-plate clutch . It includes two main elements:

- Leading part. It consists of a driven disk, the splined part of which transmits rotation to the gearbox due to friction between the friction linings and the surfaces of the flywheel and pressure plate.

- Non-removable drive unit (basket). The basket is attached to the flywheel and consists of a pressure plate and a diaphragm pressure spring.

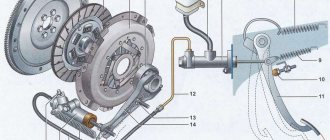

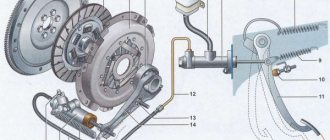

Classic VAZ models use a single-disc dry, permanently closed clutch: 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 — hydraulic clutch release pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

The clutch mechanism must be reliable, durable, and capable of dampening fluctuations in engine torque. The clutch has a hydraulic drive consisting of:

- clutch master cylinder;

- clutch slave cylinder;

- clutch on/off forks;

- release bearing;

- foot pedal.

How the clutch works

The system consists of a crankshaft flywheel and two discs. It is put into operation using a cable that leads to the pedal. When pressed, the transmission and engine are disconnected. The operating principle is based on the combination of two disks. One of them is installed on the motor shaft, and the other on the gearbox.

Car clutch device

The drive disk transmits the engine power. It is attached to the metal casing, which is located on the crankshaft flywheel, with a swivel joint. Thanks to this design, it is possible to change the distance between the disk and the elements of the mechanism. During longitudinal movement, the disks are connected. Sliding the parts until they make full contact ensures smooth activation.

Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing a VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Clutch replacement

To install a new clutch, you will need an inspection hole, overpass or lift. It is important to detect in time the signs indicating the need to replace the clutch (it is impossible to replace it on the road), and take the car to a garage or car service center. Driving with a faulty clutch is very dangerous - you can get into an accident when crossing a railway crossing or a main road.

The VAZ 2107 clutch cannot be repaired, but is replaced as a kit, which includes a basket, driven disc and release bearing

The entire VAZ 2107 clutch is replaced, so auto shops sell a kit consisting of a driven disc, a basket and a release bearing. You should consider replacing the clutch in the following cases:

- the car climbs heavily uphill when the accelerator pedal is pressed all the way down, and you can smell a burning smell - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of the flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, it is difficult to engage first gear (the gearbox “growls”) - this is a sign that the clutch is not completely disengaged (the clutch is moving);

- when accelerating, the car begins to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose sockets for them on the driven disk, deformation of segments or loose rivets on the hub.

Any noise, vibration, or whistle in the clutch area requires more detailed diagnostics and diagnosis.

Clutch adjustment

If the clutch pedal becomes too soft, falls down, and does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been disrupted. Clutch slipping after prolonged use usually indicates a failure of the clutch. It will probably have to be changed.

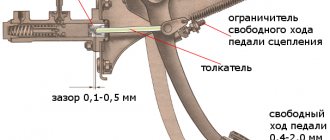

When adjusting the hydraulic clutch of a VAZ 2107, the regulated values of the gaps and the pedal stroke are set

If the clutch drives, that is, shifts gears with difficulty, in about half of the cases the reason is a discrepancy with the required values:

- play between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working travel of the foot pedal.

Classification

There are several types by which clutch can be classified into one category or another:

- depending on the number of disks: single-disk (most widely used), double-disk, multi-disk;

- depending on the type of drive: mechanical control, hydraulic control, electrical control and combined circuit;

- taking into account the location of the springs: central location of the springs, peripheral location of the springs;

- taking into account the type of friction used: dry (the operating environment of the friction linings is air) and “wet” (they use an oil bath for operation).

Sectional view of the basket

This list can be supplemented with other types.

Starting a car on a hill

Many novice drivers experience serious difficulties when starting a car on an incline. But, knowing the principle of operation of the manual transmission clutch and the sequence of actions, they will do it much more confidently. This sequence of actions can be used when the handbrake in the car does not work well:

Why does a partially released clutch replace the brake pedal? This effect is the result of the captured force balance between the force of gravitational attraction and the static friction force of the wheels. Their immobility is ensured by the balance of the engine force that pushes the cars forward and the same static friction force. But such work with the clutch when stopping increases wear on the friction material of the clutch disc.

Features of the clutch device in a car with a gearbox

A separate category is the clutch in a car with an automatic transmission. Its operating principle differs in that hydraulic or electric servo drives (actuators) are used for squeezing force. They do not require driver participation to control them. This function is performed by a hydraulic distributor or an electronic control unit.

Electronic actuators disengage and engage the vehicle's clutch based on engine speed. The value is measured and transmitted to the control unit by the sensor. The hydraulic servo drive is more reliable. It disconnects the flywheel from the transmission when the required pressure values are reached when a certain number of revolutions is reached.

Car with manual transmission

Photo: clutch pedal - left side

In a car, the clutch pedal is located in the leftmost position of the three pedals - the pedal in the center is the brake, the pedal on the right side is the gas, the left pedal is the clutch - and with its help the driver controls the connection of the engine to the gearbox.

Manual operation requires more attention compared to automatic, but for many users this is a matter of habit and a matter of price.

A car with an automatic transmission will be much more expensive to purchase and maintain, which is why many drivers choose cars with manual controls that have a clutch pedal.

Correct use of the clutch pedal

It will be useful for a beginner to learn how experienced motorists use a car clutch correctly and how the clutch works.

By applying simple recommendations in everyday driving, a beginner will achieve mastery much faster if he learns to change gears correctly and engage the desired speed, reducing the load on the tires and brake discs.

This applies to such driving moments as short stops, for example, at traffic lights and on turns.

How to properly depress the clutch

In essence, the correct use of a friction clutch involves the precise execution of two interrelated operations - the pedal must be pressed and then released.

Simple tips will tell you how to properly squeeze the clutch:

The pedal is pressed all the way and without delay. Since the main thing is experience, it is better not to waste time on training, finding a suitable platform for this and hiring an experienced driver for the company.

At the very beginning of training, shoes are important - to make the sensations more pronounced, they should have thin soles and no heels.

How to release the clutch correctly

By releasing pressure on the pedal, the driver begins to connect the engine flywheel and the driven disk to transmit rotation to the gearbox.

This must be done very carefully and smoothly - there are several recommendations for novice car enthusiasts on how to release the clutch so that the ride is as comfortable as possible:

The pedal should not be depressed for a long time; the pedal should be gradually released without sudden thrusts, pausing slightly when it is pressed halfway.

The car must start moving from first gear. You can start from second gear only in winter, when the road or some sections of the road are very slippery (if you start on slippery ground in first gear, the wheels will slip and it will be difficult to move at all).

Video: How to properly use the clutch in a car

Video: How to properly release the clutch and operate the pedals in a car

Source

Schematic diagram of clutch operation

The clutch operating mechanism is based on the friction of the pressure plate against the driven one. The pusher is part of the engine, and the driven is the transmission. When the clutch pedal is released, the springs press both discs against each other. They grind in and rotate together at the same angular velocity. The degree of friction depends on the pressure of the petals.

When the clutch in a car is depressed, the base on the drive moves the fork, which in turn acts on the bearing, and it moves to its extreme position. The discs are separated and the fork thus breaks the contact between the transmission and the engine flywheel. Any shocks that occur when the pedal is suddenly released are absorbed by a separate group of springs.

Release bearing

Where: 1 - thrust ring (outer / outer ring), 2 - inner ring, 3 - mount for the unlocking fork

The clutch release bearing serves as a connection between the stationary part (lever) and the movable rotating part (diaphragm spring). The inner ring contacts the pusher arm while the outer ring pushes against the diaphragm spring. The clutch release bearing can be used to drive a rotating diaphragm spring with a fixed lever.