2. Carefully pry up the rubber protective cover 1 with a screwdriver and remove it from the clutch release fork lever 2. Replace the torn or loose rubber protective cover.

3. Squeeze the locking tabs on the inside of the clutch housing with pliers and pry them from the outside with a screwdriver, remove the plastic bushing of the fork axle. Replace the plastic fork axle bushing if it is severely worn or if the locking tabs are damaged.

4. Lifting the fork, remove its axle from the bushing pressed into the clutch housing, and remove the fork by removing the axle, and then the lever from the holes in the clutch housing.

5. Remove the spring clip from the fork by squeezing its ends. Replace a broken or loose spring retainer.

6. Replace the clutch release fork if fork lever 1 is bent or cracked or fork legs 2 are heavily worn at the points of contact with the bearing clutch.

7. Press out the worn metal bushing, then press in the new one until it stops.

8. Before installing the fork, lubricate the metal and plastic bushings with grease.

9. Install the clutch release fork in the reverse order of removal. At the same time, make sure that the protrusion on the plastic bushing fits into the groove on the clutch housing, and its petals securely fix the bushing in the housing from falling out.

Reference manual for servicing VAZ, LADA 110 cars.

Ignition adjustment 2110. Engine compression for VAZ 2112, immobilizer for VAZ 2111. Valve cover for VAZ 2112, cylinder block gasket for VAZ video. The cost of a generator for a VAZ. replacement of fuses for VAZ 2112, design of the oil receiver for VAZ 2112. oil recommended by the factory for the box of VAZ 2112. replacement of the water pump (pump) for VAZ 2112. Replacement of valve stem seals for VAZ 2110.

Changing the clutch fork on a VAZ 2110 yourself

In order for the transmission system to operate without breakdowns, it is necessary to monitor the serviceability of all its components. One of these elements is the clutch fork. It is important to be able to perform repairs yourself. The article describes the function of the clutch fork and how to change it on a VAZ 2110.

The clutch fork (CL) is an important element of the vehicle transmission system. It is a lever with which the pressure plate is retracted, resulting in the clutch being released. The BC is sometimes called the cut-off plug.

BC is mainly part of a mechanical gearbox, less often in hydraulic drives. The design of the VS in the gearbox on a VAZ 2110 is quite simple: a metal rod on which a lever and two legs are attached.

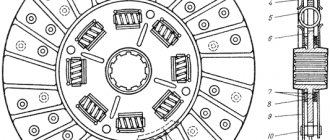

At number 5 VS

When you press the clutch pedal (CS), thanks to the BC, the release bearing clutch moves, thus, the inner edge of the spring moves forward and the device turns off. Naturally, the correct engagement and disengagement of the clutch depends on the serviceability of the aircraft.

Aircraft replacement is required in the following cases:

- Deformation of the part is detected;

- cracks were detected on the body;

- curvature of the aircraft;

- Defects in the tabs were identified at the points of contact with the release bearing coupling;

- paws are worn out.

The photo shows a broken down aircraft.

Aircraft with a broken lever

If there are cracks on the aircraft, then this reduces the quality of the PS operation, late setting occurs, the machine may slip, and the pedal may sink when pressed. There is a need to regulate free play. Along the crack, the aircraft deviates from the release bearing. Regulation is enough for only a few days, and in case of a significant defect it is necessary to adjust after a few hours

Damage must be corrected immediately, as this can lead to rapid wear. If the aircraft breaks down completely, the pedal will fail and the vehicle will be unable to move.

You can detect a crack by visual inspection, place the car on an overpass or inspection hole, and find the fork protective boot on the bottom of the car. Having moved the boot, you need to inspect the fork for cracks; it is more convenient to use a flashlight.

Replacement process

The difficulty of replacing an aircraft with a VAZ 2110 is that it is necessary to dismantle the gearbox; the procedure for replacing the part itself is simple.

Required Tools

To carry out the aircraft replacement procedure, it is necessary to install the machine on a lifting device or inspection groove. You can lift the car with a jack and place it on supports.

From tools and materials you need to prepare:

- new aircraft;

- a set of keys;

- pliers

- screwdriver;

- flashlight;

- jack.

Having prepared all the tools, you can begin the replacement process.

New replacement part

Stages

In order to change the aircraft to a VAZ2110, you need to remove the gearbox. After dismantling the box, the following steps are performed:

- First you need to remove the clutch release bearing.

- Then, using a screwdriver, you need to pry up the protective cover of the aircraft and remove it. If it has signs of wear, abrasion, or has lost elasticity, it should be replaced.

- Next you need to remove the plastic sleeve BC. To do this, use pliers to squeeze the tabs securing the bushing and remove it.

- Next, you need to assess the condition of the bushing. If there is damage, signs of wear, or the locking tabs are broken, the part should be replaced.

- Then you need to lift the BC and remove it from the bushing located in the clutch housing (CC), and also remove the fork lever from the holes of the CL.

- Next, you need to remove the spring retainer from the aircraft. If it is damaged or has lost elasticity, it must be replaced.

- It is advisable to replace the metal sleeve pressed into the KS with a new part.

- Before installing a new aircraft, all bushings inside should be lubricated.

- Installation of the aircraft is performed in reverse order.

- When inserting a plastic bushing, you need to make sure that the petals securely hold the bushing in the joint.

Popular problems and their solutions

There are several characteristic faults that occur on the VAZ 2110. Let's try to understand the reasons for their occurrence, and also consider ways to solve the problem.

- The clutch drives. The reasons may be: The pedal has insufficient travel, the tension is too tight. To eliminate this, you need to adjust the drive;

- The driven disk is deformed. Only replacement will help here;

- The driven disc hub sometimes gets stuck. If so, try washing it and lubricating the input shaft splines. If the element or the shaft itself is worn out, then replace them;

- The friction linings are broken and the rivets are loose. The best solution is a complete replacement of the casing, which includes a spring and a disk;

- The pressure plate is warped or warped. Replace the linings, but first make sure that there are no deviations in the end runout of the disk;

- There were problems with the cable. Pull it up. If there is no result, replace with a new one.

- The friction linings on the driven disk often burn or wear out. There is only one solution - replacement;

- Oil has reached the surface. We have already described how to solve the problem above;

Features of replacing the clutch fork on a VAZ-2110, 2111, 2112

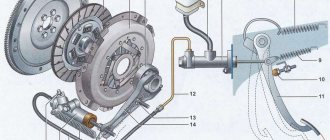

The clutch drive fork is necessary for the proper operation of the entire transmission system. This mechanism is a lever, when pressed, the following occurs: when the pedal is depressed, the clutch and release bearing move, this leads to the inner edge of the spring moving forward, and the clutch is disengaged.

When the pedal moves back, the clutch is engaged, so sometimes this spare part is called the release or engagement fork, respectively.

Typically, the clutch fork is found in mechanical gearboxes, and is occasionally included in hydraulic ones. The drive fork is a metal rod on which a lever and two legs are attached.

What are the usual malfunctions of the VAZ-2110 clutch fork that require replacement?

The clutch fork is subject to wear and tear, just like other parts. Factory defects are also possible, but due to the simplicity of the design, they are much less common.

- The clutch fork breaks. In this case, the pedal drops sharply, making it almost impossible to continue forward.

- Crack. The clutch grabs lower and lower, adjustment is almost ineffective. As the crack gets larger, the clutch pedal goes down again.

- Curvature.

- Paw wear.

- Defects of the paws at the point of contact of the liner coupling.

You need to change the fork in any case, since this part is necessary for the movement of your car. Without it, gear shifting is impossible.

The cost of spare parts is 300-500 rubles. When choosing, pay attention to the quality of the material and the thickness of the metal. Very often, a fork made of thin iron bends almost immediately.

Although the part is simple in design, it may not be so easy to replace it yourself. When contacting a car service center to replace the clutch drive fork of a VAZ-2110, you will have to pay from 1,500 to 2,500 rubles.

Replacement

If you change the fork on a classic without removing the gearbox, you can still do it, but you won’t be able to do the same on a VAZ-2110. The replacement will take 3 to 4 hours depending on experience.

- Remove the gearbox.

- Remove the pressure bearing.

- The next step is to remove the rubber cover by hooking it with a screwdriver. Pull it off the power plug. It also needs to be replaced if it becomes warped, cracked or hard.

- Use pliers to squeeze the locking tabs on one side of the crankcase. Using a screwdriver, pry up the plastic bushing of the fork axle. If there is noticeable damage or signs of wear on the cap, then it also needs to be replaced.

- We unfasten the clutch fork itself: by lifting it, you need to remove its axle from the bushing. First, the axle, then the lever, are removed from the outlets in the crankcase.

- You need to squeeze the ends of the fork spring retainer and remove it. A deformed retainer needs to be replaced.

- We replace the fork that shows signs of wear.

- It is usually recommended to replace the metal bushing as well, especially if it is noticeably worn.

- Before installing a new part, you need to lubricate both the metal and plastic bushings.

- Next, install the shutdown plug. Assembly is carried out in the same order, starting from the end. Carefully secure the plastic sleeve. The protrusion on it should be in the recess on the crankcase. The petals should firmly secure the sleeve, preventing it from falling out.

If you use a spare part of proper quality when replacing, the clutch drive fork will last a long time. Replaced accompanying elements will protect the mechanism and improve its operation.

Preparatory stage

Before changing the clutch on a VAZ 2110, you need to prepare a place for repairs and tools. For this process, the most suitable solutions are: a car lift or an inspection hole.

If there are no such conditions, due to a hopeless situation, it is possible to replace the clutch with a 2110 in “Spartan conditions”.

It is enough to find a flat surface area in a garage box, a parking space or in the yard.

Clutch diagram for VAZ 2110: 1 - release bearing guide sleeve; 2 — gearbox input shaft; 3 — cable lead; 4 — clutch release fork; 5 — fork axle bushing; 6 — pressure disk assembly (basket); 7 — driven disk; 8 - flywheel; 9 — clutch pedal; 10 — mechanism for automatic adjustment of cable length; 13 — clutch release clutch (release bearing); 14 — lower tip of the cable sheath; 15 — bracket installed on the gearbox housing; A - the displacement distance of the leash, checked when installing the cable (27 mm).

Also, for repairs you will need:

- locksmith set with open-end wrenches and sockets up to 22 mm;

- a jack and several short boards (wooden blocks);

- container for possible draining of transmission oil from the gearbox;

- centering shaft (mandrel).

As for the clutch itself, it is sold in sets (3 in one, 2 in one) and parts separately.

The system includes 3 replaceable elements:

- release bearing;

- clutch disc;

- basket.

It is more practical for a car owner to ask in advance how much new clutch parts will cost to replace a VAZ 2110. This will help prepare the necessary budget. The price of spare parts varies and depends on the manufacturer.

Among manufacturers of quality parts, the leaders are: Sachs, Luk, Valeo and Krafttech. These spare parts are guaranteed to fit the vehicle and have a long service life.

Poor quality parts may not fit at all or may fail in the first days after repair.

Replacing the clutch of a VAZ 2110

After the conditions and tools are prepared, you can begin to work. First, remove the front left wheel and securely fix the car. Please note that there are two repair options: with complete dismantling of the gearbox and without it. In our case, we will talk about how to replace the clutch on a VAZ 2110 without removing the box.

The process is made easier by the fact that you don’t have to drain the transmission oil, disconnect the drive axles, and remove the heavy unit from under the car. The smallest set of operations saves time. However, to be on the safe side, you need to have a container ready where you can drain the oil from the gearbox in an emergency.

- After fixing the car, open the hood, disconnect the battery and remove it completely. For easy understanding, the entire further process of replacing the clutch with your own hands on a VAZ 2110 will be described in the form of step-by-step instructions:

necessary tools

- Unscrew the two ball joint bolts (the wheel has already been removed);

- go to the engine compartment and remove the connector for the mass air flow sensor;

- disconnect the air intake corrugation;

- remove the air filter housing;

- disconnect the clutch cable from the gearbox by unscrewing the two fastening nuts;

- unscrew the starter bolt;

- Unscrew the gearbox bolt, located slightly to the right of the starter;

- we find another upper bolt securing the gearbox to the engine and unscrew it;

- disconnect the speed sensor plug;

- go to the bottom and dismantle the longitudinal rod along with the cup (crab);

- we find the lower starter bolt and 2 gearbox mounting bolts, unscrew them;

- remove the torque mount;

- unscrew the gearbox shift lever;

- place a jack under the engine through a wooden spacer (on the edge of the pallet);

- unscrew the nuts of the rear engine mount;

- lower the engine with a jack (it will fall to one side);

- carefully separate the engine and gearbox;

- We carefully lower the disconnected box down until it hangs on the drive axles.

The first stage of replacing the clutch on a VAZ 2110 without removing the box has been completed. As a result of dismantling, there was access to the clutch basket on the engine and the release bearing on the gearbox. Unscrew the bolts securing the basket to the flywheel and remove it. Carefully remove the release bearing from the input shaft.

After a careful examination of the removed parts, it becomes clear whether it is worth changing the entire clutch pack or whether you can limit yourself to changing the disc and bearing. It is worth noting that the replacement of the VAZ 2110 clutch basket occurs every 80 - 150 thousand km, depending on the operating mode. The disc and bearing wear out more often.

After purchasing new spare parts, we proceed to the second part of the repair and do the following:

- install the basket with the disk in place and tighten the fastening bolts;

- insert the centering shaft (mandrel) into the central hole of the crankshaft;

- then tighten the bolts tightly and remove the mandrel. It should fit freely into the hole, simulating the gearbox input shaft.

- Next, install the release bearing on the box;

- carefully lift the gearbox and connect it to the engine, slightly rotating the drive axis;

- Once the box is in place, you can fasten it with bolts and install the dismantled parts in the reverse order.

On a note! It is advisable not to leave the box hanging for a long time (more than 2 days). The fact is that the drive seals are under heavy load and they can be partially deformed. The formation of damage will lead to oil dripping from the transmission during further operation.

Clutch adjustment on a VAZ 2110 after replacement

Setting up the transmission system will help to complete the repair efficiently. To do this, loosen the adjusting nuts on the cable. The clutch pedal will rise. We take a ruler and measure the distance from the front wall to the pedal in the cabin. The working stroke, regulated by the operating instructions, should be 120 mm (±5mm).

Press the pedal several times. Then, tighten the adjusting nut, simultaneously measuring the distance between the pedal and the wall. As soon as the desired value of 12 cm is reached, tighten the nut, holding the lock nut with another wrench. A similar adjustment operation, after replacing the clutch with your own hands, can be performed on a VAZ 2110 with a 16-valve engine.

Which clutch is better to put on a VAZ 2110

Below are the most famous companies that produce clutches for the VAZ 2110, I suggest you familiarize yourself with them and make your choice.

| KraftTech KraftTech – there is no marking on the factory release bearing, but the thrust bearing is designated as X2200C; driven disk – Y 3200A B0206. Main features: four damper springs, there are 18 petals on the diaphragm spring. The box bears the designation: 2110 W3200C B2240. | Luk Luk – the kit does not include a release bearing, its marking is: SKF 500 063820; the pressure plate is branded 2 D24 120 0252 10, and the driven disk is branded 320 030810. The latter has marks for precise orientation during installation. The driven disk has six springs, the basket has 18 petals. The side is last marked. | Valeo Valeo - marking is applied only to the bearing: Valeo SNR BB 126 18S50. The kit includes a mandrel for precise installation. The spring element of the pressure plate consists of 18 petals. There is a mark on the package - 21102-21103-21108-2111-2112 826622. |

| VIS VIS - there are no marked parts, the only special sign is the approval mark - AYA70. The pressure plate spring has 12 lobes, the driven disk has 4 large and 3 small damper springs. On the box: 2110-1601180. | Pilenga Pilenga - there are no markings or designations on the parts, but on the packaging it is noted: CK-P-4005 2110. The driven disk is equipped with 4 small and 4 large damper springs. The pressure plate spring includes 18 lobes. | FINWHALE and QML FINWHALE and QML - smooth start of vehicle movement from a standstill; uniform movement of the car without jerking; the softness of the clutch pedal ensures comfortable driving and reduces driver fatigue; high safety properties make it possible to increase the service life of gearbox synchronizers and other transmission parts; predictable stable resource, reliability and durability; ease of installation, the clutch kit includes a centering mandrel and lubricant, it is possible to replace the clutch in the absence of special tools and materials, there is no need to buy them; and, finally, an excellent price-quality combination. High quality clutch kit at an affordable price. |

Replacing the clutch release fork of a VAZ 2110 Lada

Enter the query you need in the search bar

| EXECUTION ORDER |

| 1. Remove the clutch release bearing (see subsection 3.1.3). | ||

| 2. Carefully pry up the rubber protective cover 1 with a screwdriver and remove it from the clutch release fork lever 2. Replace the torn or loose rubber protective cover. | ||

| 3. Squeeze the locking tabs on the inside of the clutch housing with pliers and pry them from the outside with a screwdriver, remove the plastic bushing of the fork axle. Replace the plastic fork axle bushing if it is severely worn or if the locking tabs are damaged. | ||

| 4. Lifting the fork, remove its axle from the bushing pressed into the clutch housing, and remove the fork by removing the axle, and then the lever from the holes in the clutch housing. | 5. Remove the spring clip from the fork by squeezing its ends. Replace a broken or loose spring retainer. | 6. Replace the clutch release fork if fork lever 1 is bent or cracked or fork legs 2 are heavily worn at the points of contact with the bearing clutch. |

| 7. Press out the worn metal bushing, then press in the new one until it stops. | ||

| 8. Before installing the fork, lubricate the metal and plastic bushings with grease. | ||

| 9. Install the clutch release fork in the reverse order of removal. At the same time, make sure that the protrusion on the plastic bushing fits into the groove on the clutch housing, and its petals securely fix the bushing in the housing from falling out. |

Photo gallery

Pull out the rubber boot

We take out the plastic sleeve

Removing the clutch fork

Checking the metal bushing

Remove the spring clip

Checking the correct installation

Replacing the clutch fork on VAZ 2106-07, 2110-2112 cars

The clutch fork performs the function of disengaging it (hence the name release fork, or clutch drive fork). This is a kind of lever, when acted upon, the pressure plate is retracted and the clutch is disengaged. It can also be called a clutch engagement fork, because with the reverse action, when you release the pedal, the fork engages it.

This part is usually found in manual transmissions, and much less often in hydraulically driven gearboxes. Let's look at the design of the clutch fork using the example of cars from the VAZ 2110-2112 and VAZ 2106-2107 families. The fork consists of a lever and two legs attached to a metal rod.

The classic clutch fork looks a little different.

Symptoms of a faulty plug

Like any other part, it is subject to wear, and manufacturing defects are also possible (however, it is extremely rare due to the simplicity of the design). When the fork breaks right away, the pedal simply sinks and it is unlikely that you will be able to continue moving. But it happens that a crack appears in the fork, and then the clutch begins to grasp lower and lower, and adjustment helps only for a short time, and as the crack expands (increases), the pedal drops again.

Simplicity is simplicity, but replacing this part results in a rather troublesome task, since replacing the clutch fork entails removing the gearbox. If on a classic (VAZ 2016-07) you can try to carry out this procedure without removing the gearbox, as some sources claim, then with the front-wheel drive VAZ family this is completely excluded.

Replacing the fork on 2106, 2107

On classics, a cracked fork is a fairly common occurrence, and car enthusiasts have gotten used to changing it without removing the box. To do this, the ends of the new fork are ground at an angle of 45 degrees so that it can fit under the pressure spring. A hook with the end bent 5 centimeters would also be useful; we will use it to hook the spring. We need to get under the fork support pin (bolt with a ball head), and the paws get between the release bearing hub and the spring. After a certain number of attempts, their number depends on your accuracy and patience, the clutch fork will fall into place.

It is worth noting that on GAZelle cars it is also possible to replace this part without removing the box, using the method described above. For a GAZelle with a 402 series engine, this is generally a weak point, and owners of these models constantly complain about a weak fork and its constant breakdown. One solution to this problem is to install a reinforced fork from another model (Valdai), but it also has its own subtleties and nuances that are undoubtedly worth studying before proceeding with the replacement procedure.

Replacing the clutch fork on 2110, 2112

First of all, remove the clutch fork pressure spring. After this, remove the plastic shaft retaining sleeve and the fork boot. Now you can carefully remove it. Be sure to check the condition of the bushings, both the lower metal and upper plastic, and, if necessary, replace them if there is severe wear. The boot also does not interfere with inspection for breaks.

We install the new fork in the reverse order, not forgetting to lubricate the bushings first.

How to change the fork

clutch for VAZ 2110

Troubleshooting vehicle systems, including clutch

, primarily provides diagnostics. It is performed with serious disruptions in the operation of vehicle components. The discovery of a fault in the clutch system will most likely entail a complete replacement or individual components.

The availability of precise recommendations from automakers and mechanical engineers provides information on when and when to replace the clutch and its parts. However, regulated conditions in real life depend to a greater extent not on the recommendations of specialist developers, but on the driving method, the level of load during auto operation and other factors.

Trouble-shooting

The VAZ 2110 (BC) drive fork is included in the vehicle’s transmission system; without it, the effective operation of all auto mechanics is impossible. The plane is shaped like a lever by which the pressure plate is retracted, causing the clutch to disengage. Sometimes the term "fork" is used to refer to an airplane because in the opposite direction, when the pedal is released, it engages the clutch.

When the pedal is compressed, this part helps move the clutch, releasing the bearing, which allows the inner edge of the spring to move forward, and then the device turns off.

The VAZ 2110 clutch fork requires changes in the following cases:

- deformations;

- crack;

- curvature (astringency);

- defective feet at the point of contact with the cartridge case;

- wearing legs.

Replacing a faulty device

Replacing the VAZ 2110 clutch fork

, as a rule, is accompanied by a complex and lengthy process of removing the automatic transmission. Although there is a more convenient way for drivers, eliminating this time-consuming procedure. The manipulations associated with replacing the VAZ 2110 clutch fork are, in principle, simple and understandable. Therefore, a driver who has initial basic skills in the field of auto mechanics and is not afraid of the difficulties associated with car repairs can begin repairs, which last on average 3-4 hours.