The VAZ 2107 clutch is designed to connect the engine crankshaft and the gearbox input shaft with the possibility of briefly stopping the transmission of torque. The reasons for its failure can be very diverse. However, all of them can be easily diagnosed and eliminated on their own.

- Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing the clutch - Clutch adjustment

- Clutch slipping

- Tools and materials

Video: do-it-yourself adjustment of the VAZ 2107 hydraulic clutch

Clutch mechanism of VAZ 2107

The VAZ 2107 clutch is a rather complex mechanism consisting of several dozen elements. The reasons for its malfunction can be very different. However, they can all be divided into two groups:

- Defects in the clutch mechanism itself. These include malfunctions of the driven part of the clutch, pressure device, basket, flywheel, and clutch fork.

- Defects in the hydraulic drive of the clutch mechanism. They can be caused by leakage of the working fluid, the formation of an air lock in it, as well as malfunctions of the main or working cylinders (MCC and RCC) and the pedal mechanism.

The clutch, like any other car part, has a limited service life. First of all, it depends on the skill of the driver, and therefore is not regulated by the manufacturer. To increase the service life of the clutch, it is necessary to adjust it in time, monitor the level of working fluid, avoid off-road driving, and learn the skills of using the clutch correctly.

It must be remembered that in addition, the clutch is a safety device that protects the transmission from serious damage when the rear wheels are blocked by various obstacles. The car is stuck in a quagmire, the drive wheels are stuck, the engine power is enough to turn the stuck tires. In this case, the clutch will begin to slip, protecting the gearbox, cardan and rear axle from damage. Yes, the driven disc linings will burn out. Yes, the clutch will overheat, which can cause the steel flats to warp or weaken the spring plates. But more expensive units will be protected from breakdowns.

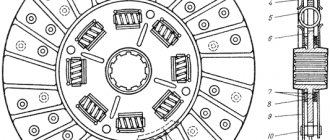

Classic VAZ models have a dry, permanently closed single-plate clutch . It includes two main elements:

- Leading part. It consists of a driven disk, the splined part of which transmits rotation to the gearbox due to friction between the friction linings and the surfaces of the flywheel and pressure plate.

- Non-removable drive unit (basket). The basket is attached to the flywheel and consists of a pressure plate and a diaphragm pressure spring.

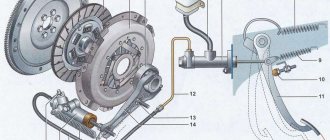

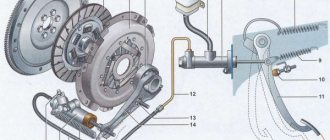

Classic VAZ models use a single-disc dry, permanently closed clutch: 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 — hydraulic clutch release pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

The clutch mechanism must be reliable, durable, and capable of dampening fluctuations in engine torque. The clutch has a hydraulic drive consisting of:

- clutch master cylinder;

- clutch slave cylinder;

- clutch on/off forks;

- release bearing;

- foot pedal.

Adjusting the clutch of VAZ 2107, 2105, 2104 cars

Correct and precise operation of the clutch on VAZ 2107, 2105, 2104 vehicles is ensured by certain adjustments to its drive. There are two of them: adjusting the gap between the pusher and the piston of the clutch master cylinder and adjusting the free play of the clutch pedal.

Adjusting the clutch drive of a VAZ 2107, 2105, 2104

— Adjusting the gap between the pusher and the piston

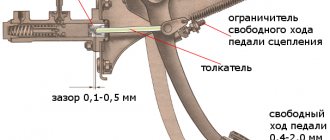

The gap between the pusher and the clutch master cylinder piston is 0.1 - 0.5 mm. It is regulated by rotating the clutch pedal free travel limiter. In this case, a certain free play of 0.4 - 2.0 mm is formed at the clutch pedal, which the driver selects when starting to press the pedal.

The gap between the pusher and the piston, free travel of the clutch pedal for VAZ 2104, 2105, 2107

It is measured with a ruler or tape measure, which is installed from the floor to the middle of the lower part of the pedal platform. We move the platform with our hand relative to the ruler scale by pressing the pedal. If there is a gap, at first the pedal moves very easily, and then with difficulty. If there is no gap, turn the pedal travel limiter out a little. We ensure that the free movement along the ruler fits within the required two millimeters.

This gap is necessary for the clutch to disengage completely. If it is missing, then the piston will not be able to fully return to the rear position when the pedal is released and in the working cavity of the master cylinder, and excess pressure will remain in the entire drive. As a result, the clutch will not disengage completely, since the release bearing will press on the leafs of the pressure spring, and the discs will slip (not be fully pressed against the flywheel). Increasing this gap will lead to the fact that the clutch will not disengage completely and will “drive” (the discs do not fully move away from the flywheel).

— Adjustment of clutch pedal free play

(the gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring)

It is adjusted by a nut on the clutch slave cylinder pusher. With proper adjustment, the free play of the clutch release fork is 4–5 mm (checked by hand: the fork is pulled away from the stop against the adjusting nut on the pusher), and the free play of the clutch pedal is 25–35 mm. It is necessary to unscrew the lock nut on the pusher and rotate the adjusting nut to set the required free play of the fork. The pedal free play of 25 - 35 mm (until the clutch is disengaged) can be checked using a ruler. It is this value that means there is a gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring.

Free movement of the clutch slave cylinder pusher for VAZ 2104, 2105, 2107 cars

In the absence of this gap, the release bearing presses on the pressure spring of the “basket” - the clutch “slips”. With an increased gap, it “leads.”

The clutch pedal free play of 0.4 – 2.0 mm is included in the pedal free play of 25 – 35 mm. That is, 25 - 35 mm is the total required size.

Notes and additions

— The clutch on VAZ 2104, 2105, 2107 cars is of a constantly closed type, that is, constantly engaged: when the pedal is released, the driven disk is pressed by the drive to the flywheel and rotates with it, as well as the release bearing and the input shaft of the gearbox. There is a gap of 1.5 - 2.0 mm between the release bearing and the lining of the thrust flange of the clutch basket pressure leaf spring. This gap is selected when the driver begins to press the pedal.

— The full travel of the clutch pedal on VAZ 2104, 2105, 2107 cars is 140 mm.

— After adjusting the clutch drive, check for smooth gear shifting. Particular attention to reverse gear. The smoothness of its activation is an indicator of successful adjustment.

Twokarburators VK - More information on the topic in our VKontakte group, on Facebook Twokarburators FS and on Odnoklassniki - Twokarburators OK

More articles on VAZ 2104, 2105, 2107 cars

— Body clearances of VAZ 2105, 2107 cars

— Malfunctions of the rear axle of VAZ 2101, 2102, 2103, 2104, 2105, 2106, 2107

— Malfunctions of shock absorbers of VAZ cars

— High fuel consumption by the engine of VAZ 2105, 2107 cars, reasons

— Reasons for increased fuel consumption not related to the carburetor

Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing a VAZ 2107 clutch is a rather labor-intensive and expensive process. Therefore, before replacing, you should consider adjusting the mechanism.

Clutch replacement

To install a new clutch, you will need an inspection hole, overpass or lift. It is important to detect in time the signs indicating the need to replace the clutch (it is impossible to replace it on the road), and take the car to a garage or car service center. Driving with a faulty clutch is very dangerous - you can get into an accident when crossing a railway crossing or a main road.

The VAZ 2107 clutch cannot be repaired, but is replaced as a kit, which includes a basket, driven disc and release bearing

The entire VAZ 2107 clutch is replaced, so auto shops sell a kit consisting of a driven disc, a basket and a release bearing. You should consider replacing the clutch in the following cases:

- the car climbs heavily uphill when the accelerator pedal is pressed all the way down, and you can smell a burning smell - these are signs of slipping of the driven part of the clutch;

- when the clutch is disengaged, noises appear in the area of the flywheel housing - this indicates a malfunction of the release bearing;

- when starting the car, it is difficult to engage first gear (the gearbox “growls”) - this is a sign that the clutch is not completely disengaged (the clutch is moving);

- when accelerating, the car begins to twitch, rattling sounds are heard - the reason for this is usually broken damper springs or loose sockets for them on the driven disk, deformation of segments or loose rivets on the hub.

Any noise, vibration, or whistle in the clutch area requires more detailed diagnostics and diagnosis.

Clutch adjustment

If the clutch pedal becomes too soft, falls down, and does not return to its original position, then most likely air has entered the system or the hydraulic drive adjustments have been disrupted. Clutch slipping after prolonged use usually indicates a failure of the clutch. It will probably have to be changed.

When adjusting the hydraulic clutch of a VAZ 2107, the regulated values of the gaps and the pedal stroke are set

If the clutch drives, that is, shifts gears with difficulty, in about half of the cases the reason is a discrepancy with the required values:

- play between the rod and the piston in the working cylinder;

- clearance between the release bearing and the fifth basket;

- free and working travel of the foot pedal.

Clutch adjustment in an injection VAZ 2107

The clutch adjustment carried out on the VAZ 2107 injector is somewhat different from the similar operation on the “Seven” with a carburetor engine. The fact is that on vehicles with an injection power plant, an additional shield is installed to protect against mud deposits formed from road dirt. In the frontal projection, the protective casing is secured with bolted connections, and in the rear projection - with 2 self-tapping screws.

To dismantle this protective casing, use an 8-type socket wrench to unscrew the 4 fastening bolts. We also dismantle 2 self-tapping stern fastening screws. To carry out such a technological operation as adjusting the clutch pedal of a VAZ 2107, the following work cycle is required:

- Using a scale ruler, measure the distance from the pedal to the surface of the driver's mat. Using the force of your palm, press the pedal until the resistance force of the reverse action of the pedal begins to act and measure the length of free movement of the pedal. It should be 1-3 mm.

- If the measured value does not fall within the required dimensions, then: loosen the lock nut, give the bolt a rotational movement, carry out an adjustment followed by tightening the lock nut.

After carrying out the adjustment work, tighten the fasteners, after which you need to tighten the locking nut. We turn the pusher until the desired stroke value is determined, and finally tighten the locking nut. Care must be taken to maintain the position of the pusher in relation to the main center coupling.

Upon completion of the adjustment of the VAZ 2107 clutch pedal, it is necessary to clarify that the desired length of free movement is normal. Data for control: the stroke of free movement of the pedal is 1-3 mm. The length from the driver's floor to the pedal is 90 mm.