Author: Muravyov Konstantin

27 July 2016 16:34

Tags: auto vases history

9601

23

Almost 30 years ago, in 1984, AVTOVAZ produced a pilot production batch of G8s, and last December it finally stopped production of the VAZ-2114, its direct descendant. We will try to put into place the facts of the history of the creation and production of this wonderful car.

0

Source:

See all photos in the gallery

Author: Orlov Denis

People called the VAZ-2108 a “chisel”. This nickname arose not so much because of the sharp wedge-shaped silhouette of the VAZ-2108, but because of the obscurely shaped radiator lining. It is unknown which designer proposed this “beak”. In general, the authorship of the G8’s appearance is still being debated. By the way, the car was also “lucky” with official designations. Tolyatti residents even tried to give names to projects that remained forever in plasticine. “Artek”, “Bylina”, “Afalina”... It sounded somehow stereotypically Soviet. So the VAZ-2108, at the suggestion of the designers, was called “Sputnik” - from the same opera. The chief designer of AVTOVAZ, Georgy Konstantinovich Mirzoev, approved the name, despite the fact that “at the top” it had not yet been approved. The car will become “Samara” much later.

×

Pull or push?

0

Source:

By the mid-1970s, it became quite obvious that in the Lad size, automakers were irrevocably switching to front-wheel drive. This was indirectly confirmed by the Italians, who did not want to have another competitor in AVTOVAZ. They refused to cooperate on a front-wheel drive model and suspiciously insistently imposed on us some kind of Polish Polonaise, built on the basis of the “classic” Fiat 125. Therefore, they decided to create a front-wheel drive model on their own, involving an independent engineering company in the work.

0

Source:

Sketch by V.I. Pashko, which determined the final plastic body of the future G8, 1978

By that time, Tolyatti had accumulated some developments in the field of compact front-wheel drive vehicles. And the VAZ-2108 prototype, assembled on December 31, 1978, had all the features of a modern car: a transverse power unit, independent suspension, a negative shoulder for the front wheels, rack and pinion steering, front disc brakes with a floating caliper, electronic ignition, integrated plastic bumpers, solidly molded panels salon The prototype was shown to members of the CPSU Central Committee, and on May 29, 1979, Council of Ministers issued Resolution No. 470 “On the development and development of a family of front-wheel drive vehicles at the Volzhsky Automobile Plant.”

Latest prototype models

A sample of the car, which was to be exported to Europe, underwent very stringent tests. In a short period of time, the car traveled about 80,000 km, and this made it possible to find the weak points of the model and correct them.

Towards the end of 1981, a version of the car appeared, the so-called “two hundredth”. It was tested even more seriously, because this car was supposed to be distributed throughout the Union. The tests took place in harsh climatic conditions, sometimes in the Caucasus, sometimes in Turkmenistan, sometimes in the far north.

The “three hundredth” model rolled off the production line in 1983; this car was practically a copy of what you can see on the streets of the country.

Project "Gamma"

0

Source:

The Minister of Automotive Industry Polyakov became very dissatisfied when in 1975, the deputy chief designer of AZLK Pavel Taranenko, after a business trip to Porsche, delivered to him a plump folder of proposals for modernizing the 412th Moskvich... How so? This is a gross violation of subordination! Nevertheless, a meeting soon took place between Polyakov and Porsche President Dr. Ernst Fuhrmann, which led to long-term cooperation - albeit not with the Moscow AZLK, but with the Togliatti AVTOVAZ.

In July 1979, a massive German assault landed in Tolyatti. The “authorities” report on that trip has been preserved: how this or that guest behaved, whether he understood Russian, whether he made sketches at the factory. The guests were shown “everything”. As is clear from the report, half of them at least “fershteinil” in Russian, and some also “shprekhali”. When the question was asked how much it would cost the plant to create the VAZ-2108/09/10 family, the Germans announced the amount of 200 million West German marks. — Did the minister talk about 15–20 million?! - Mirzoev was surprised. - But this is only for a consultation, and you want us to design! - the guests retorted and, citing the approaching holiday period, promised to give a final answer in September. As a result, according to some sources, the four-year cooperation cost our country half a billion marks. So, exceeding the budget for the Olympics in Sochi by almost an order of magnitude is by no means a sign of the times...

0

Source:

The public premiere of the VAZ-2108 took place at the Avtoprom-84 exhibition, which opened in pavilion No. 3 (the so-called Montreal) at VDNKh (now the All-Russian Exhibition Center) in Moscow in the fall of 1984.

0

Source:

The project was assigned the code Gamma. The agreement was signed in Stuttgart on January 8, 1980. The first VAZ working group arrived in the small German town of Weissach (where the Porsche testing ground is located) in April. A carrier of the units of the future car, disguised as a VAZ-21011 (a total of 20 of these will be built), was also delivered from Tolyatti. The painstaking work began.

0

Source:

The first five samples of the VAZ-2108, built in Togliatti, were significantly different from what the consumer ultimately saw. The frameless rear door alone was worth it! The load-bearing function was performed by the glass itself (which almost immediately burst on the cobblestone pavement of the UGK test site), to which an aluminum locking panel was glued at the bottom. The hood, front fenders and outer door panels were also aluminum. Instead of door handles there were buttons with a recess in the back of the body (like on the Oka). The design of the front side members was changed twice, which, at Porsche’s suggestion, were “rested” on the body sills, a steering mechanism with central rods was installed, and the transmission control scheme was changed. Porsche chief designer Anatoly Lapin, according to the recollections of designer Vladimir Yartsev, personally attached door handles from a Porsche 924 to the car. But other people’s parts and components cannot be used just like that, and the country began to purchase licenses. 80% of all funds allocated to the powerful SCNT (State Committee on Science and Technology) for the purchase of licenses and new types of equipment for all industries of the USSR were mastered by AVTOVAZ at that time. In total, about 20 were purchased. In particular, from Lucas - for front disc brakes and a vacuum brake booster, from Zahnradfabrik - for rack and pinion steering and gearbox synchronizers, from Automotiv Prodax - for clutch, from Way-Assauto - for front suspension struts , for Hardy Spicer - on constant velocity joints, in Solex - on the carburetor. Later we bought a rear suspension beam from Volkswagen.

0

Source:

Michelin acquired a license and technological equipment for the production of a tubeless radial tire with steel cord size 165/70R13 (later an option with a profile width of 175 mm was added to it). The Nizhnekamsk Tire Plant began producing it under the EX-85 brand. But then it turned out that the letter “X” was patented by Michelin. We had to quickly rename the tire, so as to re-engrave the molds at the lowest cost. As a result, it became known as Bl-85 (l - half of the horizontally cut letter X).

Fiat's technological partner, the UTS company, provided assistance to AVTOVAZ in organizing new production and setting up equipment - the roots of the plant were Italian!

Implementation of knowledge of foreign engineers

This was done with the aim that the authorities were going to distribute this car model not only in the Union, but also export it to European countries. Europe had already become saturated with conventional front-wheel drive cars, which meant they needed to deliver a product that could surprise. To finalize the engine and chassis, Soviet engineers turned to Porsche specialists for help. Thus, foreign engineers also had a hand in the history of the VAZ 2108.

Foreign engineers found several flaws in the VAZ 2108 designs and made their own adjustments. Thanks to their intervention, cars were equipped with Solex carburetors, which were new at that time. And in the rear part of the car body they made a small hump so that while driving the car would be pressed harder to the ground. The vehicle's stability, handling and dynamics have also been improved. As for the appearance of the VAZ 2108, this is the merit of the designers from Tolyatti, who decided to use the trends of the canons of the Italian automobile industry in their work.

Taking into account the assistance of foreign engineers in the creation, the first VAZ 2108 had a set of most Western parts. And this is glass from Sweden, French tires, etc. Thanks to these introductions, the car was competitive in the European market. The emphasis in the first cars was on safety and high ergonomics.

In the morning in the newspaper...

0

Source:

The serial Sputnik was launched only six months later than expected. “Every 22 seconds a new car rolls off the assembly line!” - the press proudly reported. VAZ-2108 became the first car of the Volzhsky plant, on the trunk lid of which “Lada” was written in Russian. So “Lada” became the third trade name of AVTOVAZ on the domestic market after “Zhiguli” and “Niva”.

0

Source:

However, Soviet citizens continued to languish in queues. The priority remained the export of Lads for hard currency (for those who don’t remember, this abbreviation meant freely convertible currency). With the entry of the G8 into Western markets, there was a sharp jump in interest in the Lada brand: from 76.5 thousand in 1985 to 137 thousand exported cars in 1986. Exports reached their peak in 1988 - Avtoexport sold 157 thousand Samaras. The investments were justified: up to 90% of the proceeds from the export of mechanical engineering products came from Volga machines.

Cars delivered abroad were subject to serious modifications by Autoexport’s partners. There were quite a few of them: the Belgian Scaldia-Volga, the German Deutsche-Lada, the Finnish Konela, the French Sepma... The cars were repainted, the seats were reupholstered, Western electrical equipment and tires were installed. Otherwise, it was difficult to sell Ladas even for the meager money that was asked for them (in Europe, in terms of price, the Lada Samara was at the level of cars of a lower class, for example, the Citroen AX, Fiat Panda or Ford Fiesta).

0

Source:

The sports prototype Lada Samara T3, created on the basis of the all-wheel drive Porsche 911 Carrera S4, has proven itself quite well on rally-raid tracks, but has not won championship laurels.

0

Source:

The foreign buyer needed variety. Only “eights” and “nines” with a 1.1 liter engine were exported (it was developed by Volga engineers simultaneously with 1.3 and 1.5 liter engines and also refined by Porsche specialists). The choice was quite representative: three- and five-door hatchbacks, a four-door sedan, and a Natacha convertible. We expanded the range by selecting wheels, sunroofs, optics, steering wheels, and even installing a Hitachi air conditioner in the base heater housing. The most exotic version, perhaps, was the Samara Enterprise (or Samara Van and Samara Bizivan) - a van in a standard three-door hatchback body with blind side windows. Imagine, this “format” is very common in Europe! By removing the rear seat and installing a demarcation grid, we got a cargo compartment with a volume of a cubic meter. The carrying capacity was 415 kg, and the car cost, for example, in France (1.3 l, 65 hp) 44,300 francs - 18.6% more expensive than a standard hatchback.

0

Source:

With the help of Russian designer V. Yartsev, a version of “Samara” was created with a powerful plastic body kit, which bore the name Carlota

0

Source:

The Natacha convertible received the most radical design changes. The project was carried out by the Brussels company Scaldia-Volga. On the Soviet side, VAZ designer Vladimir Yartsev participated - the one thanks to whom the only President of the USSR M.S. Gorbachev, during his historic visit to AVTOVAZ on April 8, 1986, learned about the existence of the designer profession and short-sightedly wished the plant to become a trendsetter in world fashion...

0

Source:

from 2002 to 2004 it produced light commercial vehicles VIS-2347. According to some reports, about four thousand were built.

Serial VAZ 2108 and modifications

The first production car was produced in 1984, December 19 to be precise. But mass production and the arrival of the car on the market happened only a year later.

VAZ did not have a grandiose debut. The fact is that it was almost impossible to find spare parts for the VAZ 2108, then there was a total shortage, and a very unreliable part was found in the model - the switch. The interior was lined with plastic, which did not create any sound insulation at all, but was also noisy. These nuances dealt a blow to the reputation of the new product. However, a few years later, when these problems were corrected and spare parts were already supplied to stores, Soviet car enthusiasts appreciated the superiority of the VAZ 2108 over other cars.

As a result of constant improvements, the eight was produced with engines ranging from 1.1 to 1.5 liters. Many modifications were released, so you can find the 2108 with right-hand drive, a 16-valve power unit, and even in a convertible body.

Production of this model ceased in October 2003, but since the car was ultimately very successful and sales were high, it was put back into production a few years later. Only this time the model was again slightly changed and given a new marking 2113. This was the history of the creation of the VAZ 2108. The video will show you all the modifications of this car.

Variety of species

0

Source:

The production of the 2108/09/099 family coincided with profound changes in the Fatherland. Aged general secretaries, stagnation, perestroika with acceleration and glasnost, privatization and cooperatives. Remember the hit of the Saratov group “Combination” from the early 90s: “Your cherry “nine” drove me completely crazy”? It was the VAZ-2109, produced since 1987, that became the first model with the word “Samara” on the back door. The cherry VAZ-2109 has become a symbol of successful entrepreneurship. The Snow Queen color, the first Soviet metallic, was no less successful. Well, the classic of the genre is the rich red color “Ruby”. Graphite “Wet Asphalt” seemed like a pipe dream. The interiors were initially beige, but after restyling (this is when the “beak” disappeared, and the front fenders and hood were slightly modified) they acquired a gray tint.

0

Source:

Speaking of restyling. In December 1990, 50 VAZ-21099 sedan cars rolled off the main VAZ assembly line, which, in addition to a different front panel (later called “high”), had a new heater and a different front end design. The concept of “long wing” quickly entered the jargon of motorists. Actually, the plant parted with the “ski” (aka “beak”) - a plastic radiator mask that looked very unaesthetic - on the five-door hatchback VAZ-21093 with a 75-horsepower 1.5 liter engine back in the spring of 1989. “Short” wings were no longer quoted after that, although such Samaras were still on the assembly line until 1994. With the release of the VAZ-21099 sedan, the “nine” lost another design element - “gills” in the corner of the third side window.

DESIGN

EXTERIOR

Initially, the car was produced with a so-called “short” front wing, but this turned out to be impractical, since the plastic trim on the front end quickly “moved away” from the wings and became deformed from exposure to the sun. Starting in 1991, a new front end design was developed, with fenders and a hood of increased length. In addition, the false radiator grille has changed, which gives the car a more modern look (facelift).

INTERIOR

From the beginning of production, the car was equipped with a “low” instrument panel. Since 1991, the VAZ-2108 began to install a “high” instrument panel, which was distinguished by the presence of a tachometer and the absence of a voltmeter, as well as modified ergonomics.

DESIGN DESCRIPTION

BODY

The VAZ-2108 body has a three-door all-metal welded load-bearing structure. The car has both passenger and cargo-passenger body options. All parts and components of the body, except for the hinged ones, form a single whole, welded by resistance spot welding, and heavily loaded parts are additionally welded by electric arc welding. The main body parts are stamped from low-carbon steel sheets. The thickness of the main body parts is 0.8 mm, the outer panels of the doors and front wings are 0.7 mm, and the thickness of the reinforcements is 1-1.2 mm. Small parts are stamped from steel with a thickness of 0.8-2.5 mm.

ENGINE AND GEARBOX

The car is equipped with a four-cylinder, four-stroke carburetor or injection engine with a cylinder capacity of 1100 cm3, 1300 cm3, or 1500 cm3 (depending on the modification) with an in-line arrangement of cylinders and a camshaft located on the cylinder head. The engine is specifically designed for transverse mounting in a front-wheel drive vehicle. The engine combined with the gearbox and clutch form the power unit. It is installed on the vehicle on three elastic supports.

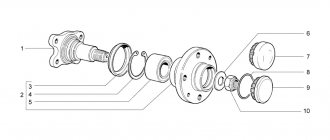

Depending on the vehicle configuration, a four- or five-speed gearbox is installed. Structurally, the gearbox is combined with the main gear and differential. Torque from the gearbox is transmitted to the drive wheels through the front wheel drive.

FRONT SUSPENSION

The car is equipped with a "swinging candle" or MacPherson type suspension

REAR SUSPENSION

The car has a torsion bar suspension for the rear wheels. The suspension guiding device is two longitudinal arms connected to each other by an elastic connector. The independence of the movement of each wheel is ensured by twisting the amplifier, which has a U-shaped cross-section, which has high bending rigidity and low torsional rigidity.

The rear suspension shock absorber is hydraulic telescopic, double-acting. The elastic elements of the suspension consist of a spring and a compression stroke buffer. The spring is made of spring steel of round section. It is installed on the shock absorber. The springs of the rear suspension, as well as the front, under a control load along the length are divided into two classes - A and B. Springs of class A are marked with yellow paint on the outside of the middle coils, class B - green.

STEERING GEAR

The vehicle is equipped with a rack-and-pinion steering mechanism.

BRAKE SYSTEM

The front brake mechanism is open disc. The rear one is drum-type, with automatic adjustment of the gap between the shoes and the drum.

ELECTRICAL EQUIPMENT

The VAZ-2108 uses a single-wire connection diagram - one wire comes from the energy source, and the role of the second is played by the mass of the car.

The VAZ-21083 modification is equipped with a microprocessor engine control system.