The automatic transmission selector is no less important than the gear lever on a manual transmission. In fact, this device allows the driver to control the transmission, that is, to turn on the main and additional automatic transmission modes, taking into account certain conditions.

As a rule, the automatic transmission selector is made in the form of a lever, which can be located on the central tunnel or closer to the steering column. In parallel, there are also separate buttons for additional operating modes of the machine.

At the same time, there are also car models where the usual lever is completely absent. Next, we will look at what types of automatic transmission selectors there are, as well as what malfunctions associated with this element may arise during operation.

Types of automatic transmission selectors

What is an automatic transmission selector and where is it located?

Externally, the selector resembles a gear shift lever in a manual transmission with additional buttons. The automatic transmission gear selector has no lateral movement left/right; it can only move up/down. Depending on the design of the control lever and the interior of the cabin, manufacturers place the gear shift lever in different places. According to their location, automatic transmission selectors are divided into the following types:

- Steering column type.

- Push-button located on the instrument panel.

- Floor.

Features of the location of the automatic transmission selector

Volkswagen Passat Das graue Auto Logbook Replacing the gear shift cable

Convenient placement of the device under the steering column allows you to change gears without interference. Thanks to this interior design, there is an additional opportunity to use a solid seat in front, where a third passenger can fit. Similar designs were widely used in American-made cars at the end of the last century.

Push-button selectors were actively used in cars equipped with high-slung seats. In the fifties, such selectors were very popular and were installed in automatic machines of minibuses, minivans, jeeps and other models of that time. The main manufacturers of cars with push-button selector for automatic transmissions at that time were such well-known companies as Chrysler, Honda and some Japanese brands.

Modern vehicles manufactured in Europe and Japan are most often equipped with floor-mounted automatic gearshift levers. Here, the selectors are located in the middle of the cabin between the driver's seat and the front passenger seat.

How does the gear shift process occur?

avtoexperts.ru Is the oil in the Kia Rio automatic transmission changed?

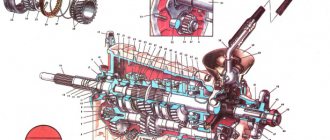

It doesn’t matter what kind of drive your car has, front or rear, a special lever is always responsible for the gear shifting process. If you look at a manual transmission in cross-section, you will notice that the location of the lever on front-wheel drive is significantly different from its location on rear-wheel drive

Cars with rear-wheel drive have a simpler gearshift lever layout, which simplifies their repair and maintenance. The lever is located directly on the gearbox housing, the shift mechanism is hidden inside the housing. This location has many advantages, but, unfortunately, it is not without its disadvantages.

Design advantages:

- A very simple solution, which greatly simplifies the DIY repair process;

- Gear shifting occurs very clearly;

- Due to the absence of “extra” components, this design is very durable.

Design disadvantages:

- This system cannot be installed on front-wheel drive vehicles;

- If a car with rear-wheel drive has an engine located at the rear, then this also makes it impossible to use this design (there are very few such cars).

On front-wheel drive vehicles, the gearshift lever may be located in the following locations:

- On the floor, in the space between the front seats;

- Directly on the steering column;

- Near the instrument panel.

This feature leads to the fact that the multi-stage manual transmission on front-wheel drive vehicles operates only remotely, using rockers or rods. This design feature also has its pros and cons:

- The lever is located more comfortably for the driver, since its position does not depend on where the manual transmission is located;

- The vibration that is created in the gearbox is not transmitted to the gearshift lever;

- Opens up a wide field of activity for automotive designers, who can place the gearshift lever in any place convenient for them.

The disadvantages of this design are as follows:

- A more technically complex system requires more attention and is less durable;

- After long-term use, backlashes often appear;

- There is no such clarity of gear shifting as in the version with a gearbox on a rear-wheel drive car;

- From time to time it is necessary to adjust the thrust, which may require qualified intervention from car service specialists.

Problems when paying with bank cards

ZIL-130 car gearbox: shift diagram

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at [email protected] .

Types of automatic transmission selectors

As mentioned above, automatic transmissions do not always have the usual lever (selector). Taking into account the fact that the automatic transmission appeared a little later than the manual transmission, this unit has constantly evolved, that is, it has many types.

As for the automatic transmission selector, if we talk about controlling the gearbox, today we can distinguish three main types of selectors:

- steering columns;

- push-button;

- floor;

First of all, the location of this element directly depends on the model and type of vehicle. For example, a paddle shifter is often found on cars in the United States that were produced in the late 80s.

This arrangement on the steering column not only facilitated interaction, but also made it possible to place a large continuous sofa-style seat in front, which could accommodate two passengers at once next to the driver.

The installation of a selector on the instrument panel was common on American cars and Japanese models, which were mainly produced for the US market. As a rule, this option with a push-button automatic transmission selector could be found on SUVs, minibuses and minivans, that is, on cars with a high seating position.

The floor arrangement is ubiquitous on various models that are produced in Europe and Japan. The automatic transmission selector is located between the driver and passenger seats. Also, modern versions of machines may not have a lever that physically moves between modes. Instead, the driver uses light touches to activate one or another automatic transmission mode.

Let us also add that among the main functions of the selector we should highlight both the ability to switch different transmission modes and protection against accidental activation. Some automatic transmissions may have a lock button.

Also, the lever can move according to a strictly defined algorithm, when the driver first needs to move the selector towards himself, after which it becomes possible to turn on the desired mode. Sometimes a solution is found when the lever must first be “pushed” down, after which it will be possible to turn on one or another mode of operation of the transmission.

Today, in the vast majority of cases, the locking system has become “tied” to the brake pedal. Banerių kūrimas adface.lt . There is also usually a separate button right on the selector lever that allows you to remove the lock to enable certain modes.

For example, if you do not press the brake, on some cars it is simply impossible to start the engine, and you will also not be able to turn on the low gear mode L2 and 1 without pressing a special button located on the selector.

Special cases of functions in the electronic transmission control system EGS

Remembering a change in direction of movement

The driver wants to move the selector lever from position "D" to position "R" or from position "R" to position "D".

- When driving speed is below 5 km/h:

The electronic transmission system (EGS) implements the driver's intentions.

- At driving speeds between 5 and 10 km/h:

The electronic transmission control system includes the selector lever position "N". The engaged position indication changes to the driver-specified selector lever position “D” or “R”. The value set by the driver is stored in memory. If within 1 second the speed drops below 5 km/h, the control unit implements the driver’s intention, that is, it turns on the “D” or “R” position. If the speed does not drop, then the “N” position remains on and the “N” indication appears on the indicator.

- At driving speeds above 10 km/h:

The electronic transmission control system includes the selector lever position "N".

Memorizing the transmission lock in parking

The driver wants to engage the “P” position (transmission lock in parking)

- At driving speeds below 2 km/h:

The electronic transmission control system includes the selector lever position "P".

- At driving speeds between 2 and 5 km/h:

The current position of the selector lever does not change; the value set by the driver is stored in memory. If the vehicle speed drops below 2 km/h within 1 second, the electronic transmission control switches the selector lever to “P”.

- At driving speeds above 5 km/h:

The driver's intention is ignored. The current position of the selector lever does not change. The display shows the automatic diagnostic system message “Transmission position “P” only when parked.”

“N” position holding period

When driving at a speed below 2 km/h and the engine is off:

When the selector lever position "N" is engaged, a 30-minute period of holding the "N" position begins. The function indicator remains illuminated and the selector lever position “N” is illuminated in the shift diagram.

At the end of the “N” position holding period, the display begins to flash. After 10 seconds, the Electronic Gearbox Control (EGS) switches to selector lever position "P".

If the selector lever is moved during the holding period, a new 30-minute holding period begins.

We reserve the right to make typographical errors, semantic errors and technical changes.

Range D (Drive) is the main mode for moving forward.

This mode performs automatic sequential gear shifting (in this mode, all gears are usually involved except for upshifts). This mode is recommended under normal driving conditions. Range 3 (Number 3 on some types of automatic transmission) - the first three gears are engaged while driving. This mode is active, it is great for city driving, and turns off when the ignition is turned off. Especially at high operating speeds of the automatic transmission, it will not be possible to save fuel; this mode does not allow the torque converter clutch to be repeatedly locked and unlocked in rough city driving conditions (no more than 80 km/h), and is also partially blocked when switching to higher gears. Most suitable for driving when frequent stops are inevitable and for driving on roads with ups and downs. Engine braking is possible in this mode. Range 2 (Number 2 on automatic transmission) - in this mode, driving is only allowed in second and first gear. Most suitable for use on winding mountain roads. Switching to fourth and third gear is prohibited. Range 1 (L or Low) - low gear. In this mode, driving is only allowed in first gear. The traction capabilities of the engine in this range are realized to the maximum, since the torque transmitted to the wheels only in first gear is maximum. Engine braking is especially effective in this mode. Driving on steep descents and ascents must be done in first gear.

Overdrive (O/D)

Some automatic transmissions have a mode in which automatic upshifting is possible. The O/D (Overdrive) button is used to activate this automatic transmission mode. Its recessed position when the Drive mode is on allows you to switch to a higher gear. If you release this button, switching to the last gear will again become impossible. The O/D OFF indicator indicates the status of the control system. If the indicator is on, then using the Overdrive mode is impossible, but otherwise there is such a possibility.

It is recommended to use overdrive mainly on the highway for more economical and measured movement. Interestingly, some four-speed automatic transmissions (for example, (Toyota)aisin 241e) can disable 4th gear with gear ratio 1, which is not an overdrive!

One of the differences between an automatic transmission and a manual transmission is the inability to perform engine braking in each mode. In overrunning clutches, in modes that do not allow engine braking, the transmission slips and the car coasts. And when driver position 1 is selected, engine braking is applied in first gear. In the first gear in position D, such braking is impossible.

Restoring the operation of the automatic transmission selector

Like any unit of complex design, the gear shift lever in an automatic transmission can also break or fail. A large number of options for insurance systems does not exclude possible breakdowns of the automatic transmission selector. Timely diagnostics, high-quality repairs and replacement of individual selector elements are a guarantee of safety on the road.

Depending on the car model, the elements of the automatic transmission control system have unique specifics. If the selector is out of order and does not respond to influences, it is recommended to seek help from specialized service companies. Here, computer diagnostics of the device will be performed. Without eliminating the causes of problems in the automatic transmission selector, center workers are in no hurry to delete error codes.

Procedure for repairing the selector:

- Computer diagnostics of the device.

- Disassembly.

- Visual inspection.

- Washing and cleaning contacts.

- Lubrication of parts and components.

- Replacement of individual elements.

- Selector assembly.

If the selector is not suitable for further use or is damaged beyond repair, the technicians recommend replacing it with a new copy of the corresponding model.

Disassembling the mechanism

In order to repair the automatic transmission selector, it is necessary to disassemble it after dismantling. To do this, it is recommended to adhere to the following sequence:

- Unscrew all screws connecting the housing;

- Effortlessly separate the body into halves;

If the tracks are destroyed, it is better to replace the contact group with a new one. During disassembly, avoid getting debris and abrasive objects inside the selector. If necessary, it is recommended to put marks to facilitate subsequent assembly.

General instructions

Emergency transmission unlock

If the transmission parking lock cannot be removed hydraulically, then depending on the model range and series of the vehicle, it can be removed mechanically or electronically using an emergency release mechanism. This will allow the car to be towed if necessary.

If the electronic emergency release mechanism is activated, the vehicle may only be maneuvered. If this requirement is not met, a record is made in the fault memory.

Manual transmission diagnostics: how to find out the oil level?

One of the most important tasks that every driver must periodically perform is checking the oil level in the manual transmission.

It is necessary to check it if you suddenly notice oil stains appearing under the car. Usually it is performed by service specialists during a technical inspection or various repair work - this is quite enough

But still, extra precaution won’t hurt - if you check the level periodically, nothing bad will happen

The verification process may differ in different car models, but the essence is the same for almost all. We will consider the procedure using the example of an excerpt from the instructions for the Opel Vectra B:

- The vehicle is installed on a flat surface (after all, when tilted, there is no way to accurately determine the level) above the inspection hole.

- Turn off the engine and start checking no earlier than 5 minutes after stopping.

- Locate and unscrew the gearbox oil level plug. It is located behind the drive shaft.

- The oil should be level with the bottom edge of the hole - under the plug that you removed.

- If necessary - if there is noticeably less oil - it must be added. To do this, unscrew the breather located in the upper part of the gearbox housing and add oil through the hole until it begins to flow out.

- Wipe off excess with a rag and replace the plugs.

Removing the automatic transmission selector

Removing the selector may differ on different car models, but the basic sequence of actions is the same for all. To dismantle the unit you need:

- Open the hood. In this case, the car should be secured with a hand brake;

- For ease of access to the selector, it is recommended to remove the battery, its platform and the air filter;

- Set the lever to the “N” position;

- Disconnect the electrical connector.;

- Disconnect the rod and cable. This operation can be conveniently performed using a screwdriver;

- The rod is removed upward from the rod by gentle rocking. If jamming occurs, it is advisable to help with a screwdriver. You should work carefully to avoid gear shifting;

- Disconnect the sensor that controls what position the automatic transmission selector is set to;

- Loosen all the plastic clamps and remove the block from the casing, working on the retaining antennae;

- Remove the dipstick inserted through the rubber seal;

- Unscrew the selector housing fasteners. There is no need to remove the connector;

- Pull out the knot with a slight movement. If a jam is observed, do not apply force as there is a risk of damaging the housing.

Features of working with the selector on various cars

In Toyota Crown jzs171, the selector is located under the bottom near the right wheel. You can find it by the cable coming from the lever. The unit has low mechanical strength, so it may fall apart when disassembled. Before you disassemble the contact group, you need to find the pinout of the contacts for your car, since the Toyota Crown has several connector options.

Selector Toyota Crown

When performing work on the Land Rover selector, it is advisable to have an assistant. Checking the gearbox's response to lever positions is only possible from inside the car. When disassembling the unit, it is necessary to check the functionality of the backlight bulbs, as they often fail.

Citroen C5 has contacts that are poorly resistant to corrosion, so most unit malfunctions are associated with oxidation deposits. It is recommended to clean contacts using acetone. When choosing a lubricant, you should check for the presence of corrosion inhibitors and high dielectric properties.

If a selector malfunction is detected, further operation of the car can lead to serious problems with the automatic transmission. Irregularities in the operation of the automatic transmission jeopardize the safety of driving a car. Also, breakdowns of the unit are accompanied by a loss of comfort from driving a car, since you have to switch the lever several times to operate.

What's the result?

As you can see, the automatic transmission selector is an important element in the design of an automatic transmission. In this case, we are talking not only about hydromechanical automatic transmissions, but also about CVT variators, single-disc AMT robots and preselective robotic gearboxes with two DSG type clutches.

In any case, not only the comfort of operating the car, but also the overall safety of the driver, passengers and other road users depends on the correct operation of this device.

In practice, there have been cases when the inability to engage one or another automatic transmission mode due to a malfunction of the selector caused serious damage to the automatic transmission itself or accidents due to the fault of the driver of a faulty vehicle.

Finally, we note that in order to restore the functionality of this device, it is optimal to immediately contact specialized automatic transmission repair services, since in this case they usually have not only the necessary diagnostic equipment, but also the necessary spare parts.

As a result, repair of the automatic transmission selector can be completed in the shortest possible time, while the owner, as part of the service, also receives a general idea of the condition of the automatic transmission after in-depth professional diagnostics.

Optional equipment

The main auxiliary device of the automatic transmission is the automatic transmission selector position sensor. It is needed to display the engaged gear on the dashboard.

Like all car devices, this sensor tends to break. Breakdowns often occur due to the fact that there is no protective casing for this device. Because of this, dust, debris, and sometimes water gets into the sensor, as a result of which it cannot read readings from the selector.

Because the sensor cannot indicate the lever position, the automatic transmission may go into limp mode. Such a sensor cannot be repaired; in any case, it will have to be replaced. In order to replace the sensor, you must first buy it. You can purchase the sensor you need online or at your local automotive store. You can replace it yourself or at a car service center.

In order to correctly replace the sensor that is responsible for determining the gear engaged, you need to read the instructions in detail on how to do this for your car.