alt=”Decoding error codes Lada 4×4 (VAZ 2121, 2131)” width=”150″ height=”89″ />

The main driver symptom of P0223 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up.

- Unstable or low idle speed.

- Increased engine speed at idle.

- The engine stalls or has trouble starting.

- The motor does not operate smoothly (pulsates).

- There is no response to the gas pedal.

Other symptoms may also be present.

How to reset an error on a grant

In the Lada Granta, the check error “pops up” relatively often. This is caused by the presence of a large number of auxiliary equipment and electronic modules in the engine compartment. Partial error reset on a car can be done mechanically:

- warm up the engine to normal temperature;

- disconnect the battery from the on-board network for 15-20 minutes;

- reconnect the battery;

- turn the key in the ignition lock cylinder to position No. 2 and leave it alone for 1-2 minutes;

- return the key to position “0”.

If everything is done correctly, the errors will be cleared. The method is not suitable for complex failures - some errors cannot be canceled this way.

To completely remove codes from the on-board computer’s memory, it is performed using special diagnostic equipment. Devices must be purchased separately in case of constant need. Purchasing a scanner to service one car is not economically feasible.

Diagnosis of Kalina

There are two ways to determine malfunctions in the Lada Kalina engine management system. Through self-diagnosis, as well as testing using a computer and a special adapter. The first option is simpler, but less accurate. Computer diagnostics of a car allows you to get a detailed answer about the causes of malfunctions.

Self-diagnosis

This procedure is performed using the dashboard inside the car:

- The vehicle's ignition must be turned off. The daily mileage reset button on the control panel is clicked. While holding this key, you need to turn the key in the lock to turn on the ignition.

- The control panel automatically enters self-diagnosis mode. All component positions and the LED indicator will light up on its screen. The arrows on the sensors will begin to move from the minimum value to the maximum.

- Using the control button located on the steering column switch, you can switch from one mode to another. The user has the opportunity to go to the self-diagnosis menu, view the software version, and also determine combinations of errors.

- To leave the menu, you need to take no action for thirty seconds.

An Arbix user showed the procedure for self-testing a Lada Kalina car.

Computer diagnostics

To complete the task you will need the following:

- Computer, you can use a laptop. The use of a tablet device is allowed.

- USB cable for connecting to the diagnostic connector.

- The software that will be used for testing. There are many firmwares for computer diagnostics. Reviews show that the best option would be the VAZ utility. It is designed specifically for AvtoVAZ models - Kalina, Priora and Grants.

For computer diagnostics of a Lada Kalina car, you need to find the connector; it is located in front of the gear lever, in the compartment above the cigarette lighter.

The verification procedure is carried out as follows:

- Testing software is installed on the computer.

- A plastic cover opens in front of the gear lever, and underneath it is an OBD-2 or K-Line output.

- The next step is to connect the wire to the block. One end of it is connected to the connector, and the other to the computer.

- After this, the presence of a connection is diagnosed. To do this, you need to go to the “Task Manager” on your computer. By going to the “Hardware” tab, you can see whether there is a connection or not. If available, testing activities continue.

- Then the firmware is launched, which will be performed for testing. If the program does not read the codes, then you need to click on “File” and select the “conduct diagnostics” item. A table will appear showing all fault combinations.

- By going to the "Options" menu, you can see the status of the vehicle. The “Codes” tab displays information about existing faults.

- After receiving the combinations, you need to decipher them and fix the problem.

The mileage reset button is clicked on the dashboard

Press the button located on the right steering column switch

Errors p0363 and p1304

You can detect these errors if you use a self-diagnostic adapter. Each of them has its own decoding and provides the car owner with certain information about the breakdown that occurred in the car. So, the number 0363 (error code) on 2114 indicates that misfire occurred in one of the engine cylinders and the supply of the fuel mixture to it was stopped.

In most modern cars, an electronic control system automatically stops the flow of fuel to the cylinder if any problems occur in it.

The next error - 1301...1304 indicates that in a specific cylinder (the number of which is equal to the last digit in the error number) there were ignition delays, which are critical for the converter.

Often these errors are accompanied by errors of type 0300 - exceeding the threshold of danger (toxicity) of the exhaust as a result of misfire.

On which cars is this problem most common?

The problem with code P0830 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Cadillac

- Chevrolet

- Chrysler (Chrysler PT Cruiser)

- Datsun (Datsun on-DO)

- Dodge

- Ford (Ford Transit, Focus)

- GMC

- Hyundai (Hyundai Grand Starex, H1, Starex)

- Jaguar

- Jeep (Jeep Wrangler)

- Kia (Kia Bongo, Rio, Sorento)

- Nissan

- Pontiac

- Renault (Renault Kangu, Megan)

- Saturn

- Ssangyong

- Lada Granta, Kalina, Largus, Niva, Priora

You can sometimes encounter other errors with fault code P0830. The most common are the following: P0831, P0832, P0833, P0834, P0835, P083F.

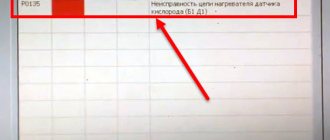

Trunk units intended for air supply (0100)

- 101-103 – Mass air flow sensor incorrect element readings or open circuit;

- 107-108 – incorrect pressure in the intake manifold;

- 112/113 – incorrect reading of the air temperature on the intake manifold;

- 115-118 – DTOZH incorrect readings, breakdown or break of the corresponding line;

- 122/123 – TPS unit breakdown or large discrepancy between actual and measured data.

- 130-135 – oxygen sensor No. 1, there is a network problem or a break in the lines.

- 136-141 – similar for oxygen sensor No. 2;

- 171/172 – excessively lean or enriched fuel mixture.

How to Troubleshoot or Reset Trouble Code P0223

Some suggested steps to troubleshoot and fix error code P0223:

- Read all stored data and error codes using an OBD-II scanner. To find out when and under what circumstances the error appeared.

- Clear the error codes from your computer's memory and test drive the vehicle to see if the problem reappears.

- Visually inspect the electrical wires and connections related to the throttle position sensor "B" for looseness or damage.

- Compare the readings of the throttle position sensors “A” and “B” using a scanner, and if necessary, replace the faulty sensor.

- Clear the error code from your computer memory again and test drive the vehicle to find out if the problem is resolved.

Diagnosis and problem solving

Carefully check the Throttle Position Sensor (TPS), wiring connector and wiring for opens, etc. Repair or replace as necessary to resolve P0223.

Check the voltage at the TPS (see your vehicle's service manual for more information). If the voltage is too high, this indicates a problem. Replace the sensor if necessary.

If recently replaced, the TPS may need to be adjusted. On some vehicles, installation instructions require proper adjustment (see repair manual for details).

If there are no symptoms, the problem may be intermittent and cleaning the code may temporarily resolve it. In this case, you should definitely check the wiring to make sure that it is not rubbing anywhere, is not worn out, etc.

Diagnosis and problem solving

To eliminate all options for the occurrence of error P0830, you should visually inspect the wiring going to the input and output speed sensors. Check all system fuses and replace blown ones if necessary. Also check the battery under load, cable connections and generator power.

Find the diagnostic connector, connect the scanner and get all the stored codes and data. Write down this information as it may help you with further diagnosis. Clear the codes and test drive the vehicle to see if the P0830 code appears again after resetting.

Voltage check

Locate the clutch position sensor switch and inspect for obvious physical damage. Perform a thorough visual inspection for obvious defects such as scratches, abrasions, exposed wires, or burn marks.

When the clutch is disengaged, there should be 12 volts on one side of the switch. When the clutch is engaged you should have voltage on both sides of the shifter. The starter solenoid or starter motor must also be energized depending on the configuration.

VAZ Granta errors indicating a malfunction in the gasoline supply system (0200)

- 200 – the wiring on the injector control module is broken, the unit itself may also be damaged;

- 201-204 – break in the supply line of injectors for No. 1-4, respectively;

- 217 – the motor has overheated, the second value is a breakdown of the internal combustion engine temperature sensor;

- 222/223 – TPS excess or critical decrease in signal level from the unit;

- 261/264/267/270 – injector control lines for numbers 1-4, respectively, a short circuit to body weight was detected;

- 262/265/268/271 – similar, only with a short circuit to the on-board wiring.

List of automatic transmission error codes

| Automatic transmission error code Lada Granta | Description of the error |

| P0720 “Output shaft speed sensor is faulty” P0717 “Turbine speed sensor” P0706 “Automatic transmission selector. No signal" P0705 "Automatic transmission selector. Several signals at the same time" P0974 "On-off solenoid. Open circuit" P0973 "On-off solenoid. Circuit shorted to ground" P0963 "Pressure control solenoid. Open circuit" P0962 "Pressure control solenoid. Circuit shorted to ground" P0740 "LOCK UP SOL(Open)" P0743 "LOCK UP SOL(GND short)" P17AB "L/C SOL(Open)" P17AA "L/C SOL(GND short)" P17AE "2-4 /B SOL(Open)" P17AD "2-4/B SOL(GND short)" P17B1 "H/C&L&R/B SOL(Open)" P17B0 "H/C&L&R/B SOL(GND short)" P1735 "INTER LOCK FUNCTION (1st)" P1736 "INTER LOCK FUNCTION(2nd)" P1737 "INTER LOCK FUNCTION(3rd)" P1738 "INTER LOCK FUNCTION(4th)" P0744 "LU CLUTCH(Lock-up)" P1744 "LU CLUTCH(Slip Lock-up) )" P0731 "Incorrect automatic transmission ratio in 1st gear" P0732 "Incorrect automatic transmission ratio in 2nd gear" P0733 "Incorrect automatic transmission ratio in 3rd gear" P0734 "Incorrect automatic transmission ratio in 4th gear" P17A1 "NEUTRAL FUNCTION(1st)" P17A2 "NEUTRAL FUNCTION(2nd)" P17A3 "NEUTRAL FUNCTION(3rd)" P17A4 "NEUTRAL FUNCTION(4th)" P17A0 "NEUTRAL FUNCTION(Rev)" P0712 "Oil temperature sensor, low reading" P0713 "Oil temperature sensor, high reading" P0711 “Oil temperature sensor, frozen” P0863 “CAN bus connection (initialization)” P062F “BACKUP MEMORY” P1701 “Controller supply voltage” | |

Technical description and interpretation of error P0223

This diagnostic trouble code (DTC) is a generic powertrain code. The P0223 code is considered a common code because it applies to all makes and models of vehicles. Although the specific repair steps may vary slightly depending on the model.

The throttle position sensor (TPS) responds to movement of the accelerator pedal. It is a type of potentiometer. Which converts the throttle position into a voltage output and supplies a voltage signal to the Engine Control Module (ECM). It also detects the opening and closing speed of the throttle valve and provides a voltage signal to the ECM.

When the throttle valve is closed, the signal from the position sensor is about 0.45 volts. If the TPS signal voltage approaches 5 volts, trouble code P0223 is set. The control unit recognizes the problem as a high signal level in the throttle position sensor “B” circuit.

Simply put, the throttle position sensor is used to determine what position the throttle valve is in. If the signal value exceeds the normal upper limit, the PCM sets this code.

Error P1602

Code P1602 is entered if the following conditions are met:

The codes should be cleared using a scan tool. If the code is entered again, check the power supply circuit from the battery to pin “12” of the controller.

What errors have you encountered on Chevrolet Niva? You will find other reference information on ChevyNiva here.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Lada Granta computer errors that are not directly related to the ESD (0400)

- 422 - a common Lada Granta engine error indicates that the catalyst is clogged or its efficiency has critically decreased, may be accompanied by a drop in engine power, can be eliminated by replacing the module;

- 441 – the adsorber purge valve does not work correctly or is jammed;

- 443-445 – damage to the control lines of the above element;

- 458/459 – short circuit of the canister purge valve lines to ground or 12 volts;

- 480/481 – respectively for the first and second central fan control relays, open circuit or short circuit;

- 485 – the head fan is faulty or the module control has failed.

Today we will talk about error P0830 (clutch pedal switch, circuit faulty) in the Lada Granta. The mistake is that when we are driving in second gear, we begin to depress the clutch and shift to third gear, at this moment the engine speed increases. No matter what gear, downshift or upshift, the revs increase. Let's try to figure out the problem.

Raise the steering wheel to the maximum position and also move the seat back. Near the clutch pedal we see the following picture:

The clutch sensor is marked in red, next to it is a green harness that needs to be disconnected in order to remove the sensor itself and check its functionality. The sensor is also secured with two screws on the side that need to be unscrewed; for these purposes, use a small screwdriver; it will be difficult to get another one in there. We remove the clutch sensor and test it using a multimeter. In our case, “ringing” is carried out but the readings “jump”; in the video you can see the diagnostics of the new sensor, there these readings are stable. After installing a new clutch sensor, the error disappeared, the problem with increased speed when switching gears disappeared.

Video solving the problem with error P0830, replacing the clutch sensor in a Lada Granta:

Backup video on how to solve the problem with the clutch sensor and replace it, error P0830 in Lada Granta:

Hello dear subscribers! Today you will clearly see how to overcome error P0830 Clutch pedal switch, the circuit is faulty! In total, I tried to photograph everything in the smallest detail. So there seems to be nothing more to add! So watch, comment and just stock up on experience! Enjoy watching.

Thank you for your attention! Always yours Kazakov Dmitry.

When changing gears, the check light began to light up. Bortovik - BK-STAT showed P0830 - malfunction of the clutch switch. The clutch status is transmitted to the vehicle's ECU via the clutch switch. Pressing the clutch pedal while driving takes the load off the engine. However, the ECU assumes that there is a load because it receives signals from the VSS sensor and therefore controls the unloaded engine as if it were loaded. Since in this case the optimal control of fuel injection is disrupted, the engine speed becomes uneven and smoke is generated. The clutch status signal is transmitted from the clutch switch. This signal allows the ECM to process sudden changes in load on the vehicle's engine. In addition, the clutch switch signal, along with vehicle speed and engine speed signals, is used to determine which gear is engaged.

Carrying out diagnostics on Lada Kalina

When the usual operation of your own car begins to be accompanied by the appearance of problematic symptoms, and various types of problems arise, then you should think carefully about how important it is at the moment to carry out diagnostic measures for all systems.

It is always useful to remember that you can always use a standard connector, since not every car has special devices that allow you to work with a professional and specific connector.

- It is very important to analyze code combinations, since in this case both the problem itself and its location are clearly represented by displaying a message on the monitor.

- This is a good help for the car owner, who can then carry out the appropriate replacement or repair. A scanner is attached to the connector for convenience. It makes scanning the problem the most extensive and detailed.

What repairs can fix the P0523 code?

If, after clearing the code from the PCM and test driving the vehicle, the oil pressure warning light comes back on, have a mechanic check the engine oil pressure sensor wires and connectors. If necessary, the mechanic will repair or replace any damaged components and recheck the system. If the problem persists, the mechanic will check the engine and oil passages. He will also check for leaks. If the engine is seriously damaged, it may need to be replaced.

Check Engine

When the ignition is turned on, the indicator should light up, so the ECM checks the serviceability of the lamp and control circuit. After starting the engine, the indicator should go out if the controller memory does not contain the conditions for turning it on.

To protect against random, short-term errors that may be caused by loss of contact in electrical connectors or unstable engine operation, the warning light turns on after a certain period of time after detecting a malfunction in the ECM. During this period, the on-board diagnostic system checks for a malfunction.

Additional comments for troubleshooting P0523

If the Check Engine light comes on and you notice that the oil pressure is too high, this could indicate a serious problem. We should not forget that the problem may not only be a malfunction of the engine oil pressure sensor (which is often found in older cars with mileage of more than 130,000 km), but also engine damage. If error P0523 appears, it is recommended that you contact a qualified technician as soon as possible to diagnose and resolve the error in order to avoid complete engine failure.

Symptoms of malfunction

The main driver symptom of P0830 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up (the code will be stored in memory as a malfunction).

- The engine will not start.

- The engine will start without engaging the clutch.

The severity of the P0830 code is usually moderate, but it can be serious if the vehicle is started with the clutch disengaged, creating a safety hazard.

How serious is P0523?

The P0523 code is very serious because it can indicate not only a problem with the engine oil pressure sensor, but also a problem with the vehicle's oil system. The car owner may be using the wrong type of oil, or the car's oil level may be too low, for example due to a leak. To avoid serious engine damage, if a P0523 code is detected, it is recommended that you have the fault diagnosed and repaired by a qualified technician as soon as possible.

Troubleshooting

After finding out the reason why the Priora or Kalina does not drive, it is necessary to correct the situation. If the coding indicates a break in the power supply to a structural element, you need to completely check the entire line and the device itself. It is better to do this by replacing parts with known good ones (new ones). It is also taken into account that standard connectors may become loose or fail over time. In such a situation, the computer will show errors even with a 100% working network. To detect such “surprises”, it is necessary to check all terminals and connections for oxidation, broken contacts or loosening - the elements must fit tightly in the sockets, without play.

Note! If you are unsure of your own abilities, the motorist is strongly recommended to seek help from a specialized workshop or a qualified technician.

If you have the necessary equipment, you can determine whether 8 or 16 valves are broken in a Lada Priora car yourself. Due to the simple design of the machine, repairs do not require the user to have in-depth knowledge of mechanics, electronics or other sciences.

Source

Diagnostics of LADA Granta, error codes and methods for eliminating them

On the latest models of VAZ cars equipped with an electronic gas pedal, a clutch pedal position sensor . Let's consider why it is needed, the principle of operation and possible malfunctions. Where is the clutch sensor installed?

The clutch pedal position sensor on VAZ is installed directly on the clutch pedal bracket; it can be seen by looking under the steering column.

The clutch pedal position sensor is one of the elements of the engine management system with an electronic gas pedal. This sensor provides a more flexible control scheme for engine modes. It simplifies the process of starting to move, eliminates “drops” and jerks of the car when changing gears in the manual transmission, and also allows for a reduction in fuel consumption.

By providing information to the engine controller about the moment the clutch is engaged and disengaged, the clutch pedal position sensor allows it to reduce or increase engine speed at the right moment, as well as adjust the ignition timing.

The clutch pedal position sensor is an ordinary limit switch with two positions - “on” and “off”.

Its normal position is open, that is, it turns on only when the clutch pedal is pressed.

The following symptoms may indicate a malfunction of the clutch pedal position sensor

- car "pecks" when changing gears

- a sharp increase or decrease in engine speed when the clutch is disengaged

Also, if a malfunction occurs in the clutch pedal position sensor , error 0830 “Clutch pedal sensor error” is recorded in the engine controller and the “Check Engine” light in the instrument cluster turns on.

Error 0830 is detected if the engine controller does not receive a signal from the clutch sensor:

- within 2 seconds after changing gear while driving

- after four gear changes at speeds above 10 km/h and engine speeds above 1000 rpm

The main reasons for error 0830:

- malfunction of the clutch sensor itself

- short circuit or open circuit

- Incorrect clutch pedal height

We encountered error 0830 while preparing the material “How to get there without a clutch?” We recorded video instructions on how to change gears without a clutch. After several gear changes without disengaging the clutch, the “Check Engine” light came on on the panel, which went out only after several dozen gear changes in normal mode.

Clutch sensor price

On many VAZ cars with an electronic gas pedal there is a connector for this sensor, but there is no sensor itself. It is not clear whether they forget to install it at the factory, or whether careless dealers remove it. The second option is also quite possible, since this sensor is still in great short supply. It costs an average of 350 rubles, but finding it on sale is almost impossible.

of clutch pedal position sensors for VAZ cars:

21214-3720020-02 for Lada 4×4 cars with electronic gas pedal

1118-3720015 for Kalina, Grant and Priora cars with an electronic gas pedal.

Reasons for the error

A P0830 code may mean that one or more of the following problems have occurred:

- The clutch position sensor switch is faulty.

- Incorrectly adjusted clutch pedal position switch.

- The fuse or fuse link has blown.

- Corroded or damaged connector.

- Faulty or damaged wiring.

- Poor electrical connection in the circuit.

- Sometimes the cause is a faulty PCM.

Auxiliary valves grant 8 valve (2000)

- 100-103 – the throttle valve drive is broken or there is damage to the wiring;

- 105 – monitoring system is faulty;

- 122-123/127-128 – pedal position sensor A/B low or high value;

- 187-188 – incorrect adjustment of the fuel mixture at idle, lean or excessively rich;

- 135/138 – resynchronization of throttle/gas pedal position sensors;

- 176/178 – incorrect adaptation of the remote control drive;

- 270-271 – oxygen sensor No. 2 in the exhaust system does not respond to enrichment or leanness of the mixture;

- 301/304/307/310 – the ignition coil is closed to 12V, respectively, for all combustion chambers in series;

- 500/501 – generator excitation starts incorrectly.

Video response about error 0830

A video made by our friend Grantovod will help you solve the problem.

We had the same garbage, check the wires under the pedals. If everything is fine there, then it’s better to go for diagnostics

Another option is to change the clutch pedal sensor. Everything is done very quickly and for pennies. It should help.

Immediately after this, I took the car for diagnostics. It's safer than fixing it yourself.

It's something to do with the clutch. Well, more precisely, everything is fine with him, but the wires either came off or were broken. If you have a clue about cars, fix it yourself; if you don’t, take it to a service station.

Thank you - it’s a breeze to repair..... I’m worried about why BC told me this - why didn’t the check light come on?

Dmitry the check light will light up in 10-15 minutes, checked for other errors.

We need to talk less and get closer to the point.

Disassemble the old sensor and clean the contact area in it, and a multimeter will show the same resistance as on the new one. It’s just that over time a film, soot, oxide, etc. appears on the contacts.

I also got this error, but everything is fine with the car, except for the constantly beeping handbrake warning light. It would be nice if the light just came on, but this squeak is killing (I turned the music up louder, it also gets boring). The fault was with the button under the handbrake lever, but replacing it didn’t help. The car is 5 years old, 106,000 miles, the clutch sensor was changed at about 90,000. Otherwise, there are no problems, the car is unpretentious, but even an old woman can get into trouble. If anyone has encountered such a problem. Write how you found the solution. Thank you.

Hello! Lada Granta automatic transmission is blocked. Please advise what to do. I drove it to a hundred, but to no avail. What could be the reason? The battery was not in the car for 3 days. Please advise what to do? Thank you

This is not a sensor. An ordinary microswitch costs 300 rubles per bucket, not per piece. Go to a radio store, buy and re-solder two wires.

Error codes that are logged as errors by the engine control module memory belong to a specific type of diagnostic information. The interpretation of codes is useful for any owner, including the owner of a Lada Kalina.

Through these encrypted information units, the process of self-diagnosis of all on-board electronic components in the car is carried out. This is very useful because it provides the ability to identify a malfunction before a critical failure of a system component occurs.

Chevrolet Niva error diagnosis

The most reliable way to identify what is wrong with a car is to diagnose electrical appliances and equipment. The procedure allows you to accurately identify breakdowns and quickly repair your car.

There are two ways to detect a problem in a car.

Self-diagnosis VAZ 2123

The simplest procedure allows the motorist to independently identify the damaged area and repair the damage. Thanks to the successful firmware of the on-board computer, some errors are displayed on the standard display. In this case, nothing happens on its own - you will need to perform several steps manually:

If the manipulations are correct, one of the indicated codes will appear on the display, and each Niva Chevrolet error number will be responsible for its own section of the highway:

At the same time, you need to accurately understand that, for example, when error 10 is on the display, the Chevrolet Niva tells the driver that there are several problems (standard, unambiguous codes are summed up).

You should also know that Niva Chevrolet self-diagnosis errors do not reflect the exact location of the breakdown. Codings can only show the section of the wiring where you need to look for the cause of the malfunction. Also, these encryptions may be the result of a software failure after an unsuccessful wash or disconnection of the battery. To obtain more accurate data, the user needs to connect a special diagnostic scanner.

How does the self-diagnosis complex work?

This system is self-regulated in automatic mode. Its structural composition includes several electronic devices. Based on sensor impulses, a variety of information flows into the ECU memory, among which there are faults. They are presented in the form of designated fault codes. Car manufacturers do not support the idea that owners are inclined to independently maintain electronic systems of cars, therefore they tend not to disclose the meaning of the codes. Here we can see the noble motive of the developers, because they understand that in this way scammers can take advantage of the situation and change the settings of the electronic module, for example, reduce the odometer readings before selling the Lada Kalina car, etc.

This situation forces the manufacturer and dealers to persuade owners to service the self-diagnosis system in specialized services.

A particularly important component of this system is the on-board controller. With its help, information collected from sensors is processed and displayed on the display. Lada Kalina does not have such a device, which deprives the owner of the ability to visually read information regarding breakdowns. This is where scanning equipment comes to the rescue. Thanks to it, self-diagnosis occurs.

Diagnostics using third-party equipment

More precisely, errors on Chevy Niva can be identified by connecting additional equipment. The technique is more technically complex, but allows us to determine the cause of a breakdown or failure with minimal error. In this case, the sequence of actions is as follows:

- turn off the engine;

- find the contact connector under the dashboard, the connector is located at the bottom of the steering column;

- connect the configured computer to the ECU output;

- turn on the ignition;

- follow the program instructions.

If all actions are performed correctly, all available information and any errors in the form of encrypted codes will be displayed in the desktop window.

There are also specialized scanners designed specifically for Chevrolet NIVA. Dealer devices are connected to the place of the standard signaling unit through an output cable.

Separately, we should highlight modern devices designed to connect a smartphone to a car, while reading encodings and controlling operating modes occurs directly from the gadget’s display.

At the same time, you should know what the encodings displayed during diagnostics mean. The code consists of several elements.

- P – the motor electronics have failed;

- C – there are problems with the chassis;

- B – interior space, a problem has been detected;

- U – there are problems when establishing pairing of on-board systems.

The next element is a single digit:

- 0 – OBD 2;

- 1-2 – standard code of the manufacturer;

- 3 – reserve part of electrical equipment.

The following digit determines the exact serial number of the line in which the defect was detected:

- 0 – exhaust system device;

- 1-2 – violation of the fuel or air supply device to the engine;

- 3 – ignition does not work correctly;

- 4 – additional equipment control;

- 5 – monitoring the engine idle state;

- 7-8 – transmission and chassis design.

Diagnostic methods

There are two proven methods for finding problems on this modification of the car. Each has its own advantages and disadvantages.

Self-diagnosis using on-board computer

This method does not require the user to have additional equipment. All the necessary systems are already installed inside the machine. The processing sequence looks like this:

- Find the odometer reset key on the daily mileage;

- While holding the button, turn the ignition key.

If everything is done correctly, all the lamps on the dashboard will light up, the arrow indicators will make a full revolution and drop to the “0” position. In this way, the functionality of all vehicle systems is checked. If there is no response from any indicator, you need to check the circuit following the indicator. To more accurately determine the source of the problem, you can, in the same mode, press the mode scroll key to the “error codes” position, which in 90% of cases provokes the appearance of one of these indicators:

- 2 – short circuit or high voltage flow on the BS;

- 3 – the fuel level sensor in the gas tank is covered;

- 4 – antifreeze temperature sensor has burned out;

- 5 – error of the sea thermometer;

- 6 – severe overheating of the internal combustion engine;

- 7 – you need to check the oil level – the pressure has dropped;

- 8 – failure or jamming of the calipers, the pressure inside the line has dropped;

- 9 – battery “died”;

- E – failure or violation of the integrity of the EEPROM data packet.

To exit the menu, you must leave the on-board computer alone for 30 seconds. The main disadvantage of the method is its mediocre accuracy. The light only shows a broad problem in the design of the entrusted part of the machine. Thus, to more specifically identify the problem, you will need to resort to the following technology.

Checking via connected unit

Modern computers connect to the car's network via a diagnostic connector. The block is located inside the cabin, under the dashboard on the front passenger side. To work you will need a laptop or PC with the necessary software. After establishing a stable connection, an error code will appear on the unit’s display, explaining why the machine is acting up.

Standard codings were developed due to the sale of cars for export. It is inconvenient for the manufacturer to program each ECU for a different language. The standard cipher consists of 5 characters, each of which is responsible for a narrow range of information. One of these elements always comes first:

- P – malfunction of the power plant electronics;

- C – chassis electronics failure;

- B – problem inside the cabin;

- U – synchronization of two or more circuits is disrupted.

- 0 – OBD 2;

- 1/2 – enterprise code;

- 3- reserve

The data indicates a malfunction. The following indicates the serial number of the circuit containing the breakdown:

- 0 – exhaust gas system;

- 1/2 – fuel/air supply;

- 3 – ignition distribution system;

- 4 – additional control;

- 5 – violation of idle speed;

- 7/8 – gearboxes, differentials and drive axles.

The last two indices indicate the serial number of the breakdown.

Diagnostics using the dashboard

It is advisable for the owner of the Russian model we are considering to remember all the error codes that may periodically occur in the system. In addition, it is recommended that you learn how to diagnose the dashboard yourself. It is designed to reflect error codes that occur in the electronic components of the Lada Kalina.

To start the diagnostic process, you will need to press a button that records the daily mileage. While holding it, turn on the ignition by turning the appropriate key. If this manipulation is performed correctly, the arrows on the scales of the speedometer, tachometer and auxiliary indicators will begin to move along a circular path, moving from the initial to the final position.

Upon completion of this movement of the arrows, the owner will need to switch the screen to another mode. This will be done by a special button located on the wiper switch under the steering wheel. Pressing displays a picture with performance indicators of a wide range of devices controlled by the ECU. The software version of the complex is also displayed here - self-diagnosis.

After updating the information three times, the error codes themselves appear on the device, expressed in digital form.

Let's look at the list of errors by number:

- No. 2 – the error indicates the presence of a deviation of the voltage indicator in the on-board network from the nominal parameter;

- No. 3 – “speaks” of a failed fuel level sensor in the tank;

- No. 4 - the so-called error 4 is activated if there is a break in the antifreeze temperature sensor circuit in the cooling circuit or the component itself has become unusable;

- No. 5 – indicates a breakdown of the outside temperature sensor;

- No. 6 - confirms the fact of engine overheating;

- No. 7 – states a critically low level of oil pressure in the corresponding engine circuit;

- No. 8 – error 8 for non-working brake components of the car;

- No. 9 – confirms the fact of battery discharge.

The “E” symbol deserves special attention, which indicates the presence of errors contained in the “EEPROM”. Each malfunction, including error 4 and error 8, requires attention from the car owner.

How to decipher errors?

During testing, fault codes on the Lada on-board computer are displayed in four-digit form. In this case, the error itself is usually preceded by a letter.

Designation of the first character that appears in the code:

- B – problems with the car body. In particular, we can talk about electric windows and airbags, if the car is equipped with them, as well as central locking.

- C – malfunction in the operation of the suspension or chassis of the vehicle or the power steering.

- P is the letter that is displayed more often than others during verification. It means a malfunction in the power unit or transmission system.

The second symbol in the combination means:

- 0 – general code for OBD-2;

- 1 – symbol of the vehicle manufacturer;

- 2 – designation similar to the previous one;

- 3 – reserve code.

The symbol that comes third in the combination determines the type of breakdown:

- 1 – malfunction in the functioning of the fuel unit or air supply system;

- 2 – code designation similar to the previous one;

- 3 – the on-board computer has detected problems with the functioning of the ignition system;

- 4 – auxiliary control symbol;

- 5 – problems associated with the idle speed of the vehicle;

- 6 – errors in the functioning of the ECU or the electrical circuit to which the device is connected;

- 7 and 8 – malfunctions in the operation of the transmission unit.

The 24 Hours channel talked about the verification and decoding of the resulting combinations.

Self-diagnosis

When performing independent testing, the ECU will generate errors in a clear code; their interpretation can be seen in the table.

| Malfunction | Description |

| 2 | The microprocessor module has detected an increase in voltage in the machine's electrical network. A detailed check of the generator set as well as the battery is required |

| 3 | This code indicates a malfunction in the functioning of the fuel level controller in the tank. There is a possibility of a break or damage to the electrical circuit. You need to check the device contacts |

| 4 | Malfunction of the coolant temperature controller. The instrument panel may display incorrect data. The reason may be acidification of the contact elements on the connector or damage to the wiring |

| 5 | Errors appear in the operation of the outside air temperature controller. A check of the device and its wiring is required. |

| 6 | The microprocessor module has detected overheating of the power unit. There are many reasons for such a malfunction; it is necessary to perform detailed diagnostics before further travel. |

| 7 | Increased oil pressure has been detected in the engine lubrication system. The reason may be that the sensor is not working. You need to check the operation of the motor |

| 8 | Diagnostics of the vehicle's braking system is required. Sometimes the error appears due to lack of fluid |

| 9 | Low car battery charge. It is necessary to perform a detailed check of the battery, measure the voltage with the engine running and turned off. |

| E | The microprocessor module detected errors in the operation of the data packet stored in the EEPROM memory |

EMUR malfunctions

Lada Kalina cars are equipped with an electromechanical power steering wheel. If malfunctions occur in the operation of this system, they are displayed with the index C.

The interpretation of errors in the operation of EMUR is presented in the table.

| Fault codes | Description and recommendations for elimination |

| 1011, 1012 | Errors in the operation of the rotation sensor of the amplification device. It is necessary to test the operation of the controller, check its wiring and the electrical circuit to which it is connected. If the sensor breaks, it must be replaced |

| 1013, 1014 | The supply voltage parameter is outside the permissible range. There can be many reasons for the problem, from the operation of the microprocessor module to a malfunction of the generator voltage regulator |

| 1021, 1024 | Problems in the functioning of the torque controller; a detailed check of the sensor is required. It is necessary to diagnose the contacts, as well as the integrity of the electrical circuit |

| 1031, 1033 | There is no signal from the steering shaft position controller. Sensor, contacts and wiring need to be checked |

| 1041-1045 | One of these errors indicates that the control unit was unable to determine the position of the auxiliary motor rotor mechanism. Need to check the node |

| 1050-1061 | These fault combinations indicate a break or short circuit in the winding of the electric motor of the power steering pump. |

| 1070-1079 | Malfunctions in the functioning of the control module of the power steering system |

User CompsMaster talked about repairing the electromechanical power steering on Kalina.

ABS errors

Malfunctions in the operation of the anti-lock braking system can occur as a result of sensor failures.

Deciphering ABS error codes.

| Code | Description |

| 0035, 0040 | Malfunctions in the operation of speed controllers installed on the front wheels. More detailed device diagnostics are required. It is necessary to check the quality of their connections and the integrity of the connectors. Problems may occur as a result of damaged wiring |

| 0045, 0050 | The same malfunction, only indicating problems in the operation of the sensors installed on the rear wheels |

| 0060, 0065, 0070, 0075, 0080, 0085, 0090, 0095 | The microprocessor unit detected malfunctions in the operation of the valves located in the anti-lock unit module. A detailed check of the devices, as well as the unit itself, is required. If testing shows that the valves are faulty, they must be replaced |

| 0161 | Stop light bulbs malfunction. The reason should be sought in the contacts and wiring. Sometimes the problem lies in a damaged or burnt-out safety device. If necessary, light bulbs must be replaced |

| 0550, 0640 | Malfunctions in the functioning of the anti-lock braking system control module. Detailed diagnostics of the device is required. Sometimes the problem is caused by poor contact between the unit and the wiring as a result of a clogged connector |

| 0800 | Low voltage in the electrical circuit of the ABS control module. The problem may be with the wiring or the generator unit. |

User Sasha42Rus spoke about diagnosing the ABS system in a Lada Kalina car.

Sensor malfunctions

The table shows a list of controller errors that in practice occur most often when diagnosing the Lada Kalina.

| Fault code | Description and recommendations for elimination |

| 0030-0032, 0036-0038 | The microprocessor module detected malfunctions in the operation of the lambda probe heating device. We are talking about sensors installed before and after the neutralizer. The problem may be a burnt-out spiral or a short circuit of the device to ground or ground. A detailed check of the controllers, including wiring, is required |

| 0101-0103 | Malfunctions in the operation of the sensor responsible for supplying air to the cylinders of the power unit. Its parameters may be out of tolerance or the signal may be too high or low |

| 0112-0118 | The microprocessor module detected malfunctions in the temperature controller. The signal coming from the sensor may be too high or too low. Also, the device sometimes produces incorrect data. A detailed check of the regulator is required |

| 0122, 0123 | Malfunctions in the operation of the throttle angle controller. The signals produced by the sensor can be increased or decreased. It is necessary to check the device as well as the electrical circuit |

| 0130-0134 | Problems with the first oxygen controller. There may be problems with the sensor itself, as well as the wiring. |

| 0132 | Malfunction of the crankshaft position regulator. If the controller fails, detailed diagnostics will be required. With such a breakdown, the engine will not be able to start. The problem may be a clogged sensor connector |

| 0135 | The heating device of the first oxygen regulator is not working correctly. Detailed check required |

| 0365 | The microprocessor module detected a short circuit of the second oxygen regulator |

| 0137, 0138 | An incorrect signal is coming from the same sensor. You need to check the wiring of the device |

| 0140, 0141 | The heating element of the second oxygen sensor is not working properly. Detailed device diagnostics required |

| 0326-0328 | Malfunction of the knock controller or camshaft sensor. Detailed check required |

| 0335-0338 | The microprocessor module has detected damage to the electrical signal circuit from the crankshaft controller. Wiring diagnostics required |

| 0340 | The camshaft sensor has failed. There may be malfunctions in the machine's engine. This error is accompanied by the appearance of a Check indicator on the dashboard. It is typical only for power units equipped with 16 valves |

| 0342-0346 | The control unit has detected a fault in the phase controller. The problem appears only in 16-valve units |

| 0500 | The microprocessor module reports problems in the operation of the speed controller |

| 0504 | Brake pedal position sensor malfunction. Possible wiring problems |

| 0511 | There is no signal from the idle speed controller. It is necessary to check the serviceability of the wiring and connector |

| 1135 | The electrical circuit of the heating device of the first oxygen sensor has shorted. Check the wiring with a multimeter |

| 1171, 1172 | The CO sensor does not work correctly, a violation of its operating parameters is reported |

| 1386 | Problems in the electrical data transmission circuit from the detonation controller |

| 1606, 1616 | Malfunction of the rough road sensor. You need to check the device itself and the wiring |

| 2122-2128 | Problems with the gas pedal position controller. A detailed diagnosis of the mechanism is required. Possible damage to wiring |

| 0720 | Malfunction of the output shaft controller. The error is specific only to vehicles equipped with an automatic transmission. |

| 0717 | Damage to the turbine speed control sensor. This error also appears only on cars with automatic transmission. |

| 0711-0713 | Malfunction of the automatic transmission oil temperature controller |

User Alexander Skripchenko spoke in detail about troubleshooting the Lada Kalina, as well as reading combinations.

Engine malfunctions

Separately, we should highlight the explanations of problems characteristic of power units of the Lada Kalina.

| Code | Description |

| 0171, 0172 | The microprocessor module has detected depletion or re-enrichment of the combustible mixture that is formed in the cylinders of the internal combustion engine. The problem may be due to a malfunction of sensors, for example, a lambda probe |

| 0201-0204 | There is a break in the injector control wiring. One of the errors reports malfunctions in the functioning of elements of cylinders 1-4 |

| 0217 | An excess of the permissible engine temperature has been recorded; it may overheat |

| 0230 | Malfunctions in the operation of the fuel pump relay; diagnostics of the part is required. With such a problem, difficulties will arise in starting the internal combustion engine. |

| 0261-0271 | The microprocessor module detected a breakdown to minus or plus in the injector control circuit. We are talking about elements installed in one of the four cylinders. It is necessary to carry out detailed diagnostics of the devices |

| 0300-0304 | Interruptions in the ignition of one or all cylinders are reported. You need to check the engine |

| 0351-0354 | The microprocessor module detected a breakdown of one of the ignition coils. Such error codes appear only when diagnosing 16-valve engines. |

| 0363 | As a result of misfires, the fuel supply to form the air-fuel mixture is limited. Possible malfunctions in engine functionality |

| 0422 | Incorrect operation of the motor neutralizer. You need to check the unit in detail |

| 0441-0445 | The microprocessor module detected malfunctions in the functioning of the adsorber. Trouble code P0441 requires a detailed check |

| 0480, 0481 | There have been problems with the functioning of the fan unit of the radiator unit. Possible wiring problems |

| 0500 | Problems with the speed controller. The dashboard may display incorrect information for this parameter. |

| 0506, 0507 | Malfunctions in the idle speed maintenance system. The power unit of the machine may not function correctly |

| 0560-0563 | There have been problems with the voltage in the electrical network, surges are possible. Battery and alternator check required |

| 0601 | The microprocessor unit reports a memory error in the ECM. Detailed module check required |

| 0615-0617 | Malfunction of the starter relay. Possible difficulty starting the engine |

| 0627-0629 | A detailed diagnosis of the fuel pump relay is required. If this element fails, the engine will not be able to start. |

| 0645-0647 | Malfunctions in the electrical power supply circuit through the relay to the clutch of the compressor device activation system |

| 0650 | Problems with the indicator designed to alert you to problems |

| 0654 | The electrical circuit of the car's tachometer has been damaged. Engine speed may be displayed incorrectly |

| 0685-0687 | Short circuit of the main relay wiring. Detailed check required |

| 0691, 0692 | Short circuit in the operation of the relay of the ventilation device. You need to check the electrical circuit |

| 0102, 0115 | The microprocessor unit registered a decrease in the resistance level of the oxygen sensor heating system spiral |

| 1123-1128 | A violation of the proportions during the formation of a combustible mixture is reported when the engine is idling or at medium load |

| 1335, 1336 | The microprocessor module has detected an incorrect position of the throttle valve. The node needs to be diagnosed |

| 1136, 1137 | At medium engine speeds, a violation of the parameters for the formation of a combustible mixture occurred |

| 1410, 1425, 1426 | Malfunction of the adsorber purge device |

| 1500-1502 | The control unit has detected an open or shorted circuit in the fuel pump relay circuit |

| 1509, 1513, 1514 | There is damage to the wiring to which the idle speed controller is connected. Possible engine malfunctions |

| 1620-1622 | The microprocessor module reports problems in the operation of its memory units. A detailed check of the device is required. Perhaps the only way to solve the problem is by reflashing it. |

| 2070, 2071 | Malfunctions in the operation of the valve for changing the length of the intake ducts |

| 2100-2103 | The control unit has detected an open circuit or a short circuit on the electric drive of the throttle valve. Detailed check required |

| 2187, 2188 | When the engine was running at idle speed, a violation of the composition of the combustible mixture was detected. |

| 2135, 2138 | Asynchronous operation of throttle position controllers |

| 2187, 2188 | There was a violation in the composition of the air-fuel mixture when the engine was idling. |

| 2301-2310 | Short circuit in the control wires connected to the ignition coils |

| 2500, 2501 | The microprocessor module reports that the operating parameters of the electrical circuit of the generating device are outside the normalized limits. There may be surges in the vehicle's on-board network. A detailed inspection of the unit is required |

| 0706, 0705 | A malfunction was detected in the operation of the contact elements in the automatic transmission selector. The error is typical only for vehicles equipped with automatic transmission |

| 0962, 0963 | The control unit reported a breakdown of the pressure control solenoid in the automatic transmission. It is necessary to test the operation of the device in detail |

| 0973, 0974 | Failure of the solenoid element for activating and deactivating gears in an automatic transmission. Unit diagnostics required |

| 0731-0734 | Gear malfunction in automatic transmission |

| 0744, 1744 | Problems with the automatic transmission clutch. Need diagnostics of the unit |

| 0830 | Malfunctions in the functioning of the clutch system |

| 0863 | The microprocessor module reports a communication error with the automatic transmission unit via the CAN bus |

| 1735-1738 | Gear selection locked |

| 062F | Resetting the memory of the microprocessor control unit of the automatic transmission |

| 263-272 | Malfunctions in the operation of the control device of the engine injection injector driver |

| 650 | The wiring of the Check Engine light bulb has burned out or the indicator itself has been damaged |

User Ainur Volk spoke briefly about troubleshooting engine problems, as well as car diagnostics.

Security system and other errors

Fault codes that are not included in other sections are presented in the table.

| Combination | Description |

| 9000 | Microprocessor device malfunction |

| 9001, 9002 | Malfunctions in the functioning of seat belts have been recorded. The problem may be with the sensors |

| 9042 | Incorrect parameters in the power system are reported |

| 9003, 9004 | The microprocessor unit reported a failure in the functioning of the front airbags. Detailed system diagnostics required |

| 9501 | Malfunction of the windshield drop control controller |

| 9502 | The microprocessor unit reported incorrect functioning of the device designed to adjust the sensitivity of the sensor |

| 9503-9506 | The control module has detected errors in the operation of the windshield wiper system. Possible malfunctions in the operation of the wiper motor |

| 9504 | Malfunctions in the operation of the optics activation relay |

| 9244-9251 | One of these errors indicates problems with the electric side mirror tilting system. Relevant only for machines that are equipped with such equipment |

| 0001-0004 | Failure to operate the light indicators installed in the turning lights. A detailed check of the light bulbs is required |

| 0005-0018 | Malfunctions in the functioning of electric window motors. Possible oxidation of contacts or damage to wiring |

| 0019-0026 | Malfunctions in the electrical power circuit of the mirror rotation system |

| 0027, 0028 | The microprocessor module reports malfunctions in the functioning of the fog lights. Possible damage to lamp contacts |

| 0039-0043 | Break in the electrical circuit of the systems:

|

| 0044-0046 | Malfunctions in the functioning of the engine blocker. The immobilizer may not be able to read the chip installed in the key. |

| 1375-1378 | Malfunction of the evaporative controllers of the air conditioning system |

VAZ Granta errors indicating a malfunction in the gasoline supply system (0200)

- 200 – the wiring on the injector control module is broken, the unit itself may also be damaged;

- 201-204 – break in the supply line of injectors for No. 1-4, respectively;

- 217 – the motor has overheated, the second value is a breakdown of the internal combustion engine temperature sensor;

- 222/223 – TPS excess or critical decrease in signal level from the unit;

- 261/264/267/270 – injector control lines for numbers 1-4, respectively, a short circuit to body weight was detected;

- 262/265/268/271 – similar, only with a short circuit to the on-board wiring.

How to diagnose and reset error codes?

In addition to the instrument panel, in Lada Kalina you can diagnose a controller that monitors the functioning of a specific electronic component of the LADA Kalina car. For example, the Bosch-ME-7.9.7 controller is capable of informing about the presence of an engine error. Reference books or a special program will help you decipher the meanings of the codes. Mechanics remember the interpretation of all codes by heart, but beginners and owners with a similar desire have only to step on the path of an amateur diagnostician.

More specifically about some code examples:

- error “0441” indicates a malfunction of the oxygen sensor;

- code “1602” will indicate a loss of voltage in the ECU power circuit;

- error “0363” will inform you about a coil failure.

The nature of the autonomous diagnostic module is such that the breakdown of a specific part is not displayed, but a specific area is localized, in which the owner needs to solve the existing problems through more accurate diagnostic measures and subsequent repairs. Many car owners will find a table of codes and their decoding useful.

For example, when error “0504” is displayed, this only hints at a malfunction in the brake system. The owner will find out exactly what has gone wrong if he performs a thorough inspection of the brake circuit. This is also true for other systems and components.

Error "0343". The decoding shows that the sensor responsible for the correctness of the signal in the phase circuit overestimates the readings. To find out the reasons why the sensor operates in this mode, you will need to perform manual diagnostics.

Self-diagnosis is designed to make it easier for the LADA Kalina owner in troubleshooting, as it allows you to focus suspicion on certain areas of action, saving time. For example, a clutch problem will be indicated by error “0830”. Its decoding is given in the table.

Note that error codes can change their meanings when the ECU software is changed. This forces the owner to have an up-to-date table to avoid confusion.