The marking of pistons allows us to judge not only their geometric dimensions, but also the material of manufacture, production technology, permissible installation gap, manufacturer's trademark, installation direction and much more. Due to the fact that there are both domestic and imported pistons on sale, car owners sometimes face the problem of deciphering certain designations. This material contains as much information as possible, allowing you to obtain information about the markings on the piston and understand what the numbers, letters and arrows mean.

1

— Designation of the brand under which the piston is manufactured.

2

— Product serial number.

3

- The diameter is increased by 0.5 mm, that is, in this case it is a repair piston.

4

— Value of the outer diameter of the piston, in mm.

5

— Thermal gap value.

In this case it is equal to 0.05 mm. 6

- Arrow indicating the direction of installation of the piston in the direction of movement of the machine.

7

— Manufacturer’s technical information (necessary when processing the engine).

Information on the piston surface

Discussing the question of what markings on pistons mean, it is worth starting with what information the manufacturer puts on the product.

- Piston size . In some cases, in the markings on the bottom of the piston you can find numbers indicating its size, expressed in hundredths of a millimeter. Example - 83.93. This information means that the diameter does not exceed the specified value, taking into account the tolerance (tolerance groups will be discussed below; they differ for different brands of cars). Measurement is carried out at a temperature of +20°C.

- Installation gap . Its other name is temperature (since it can change along with changes in the temperature regime in the engine). Designated as Sp. It is given in fractional numbers, meaning millimeters. For example, the marking on the SP0.03 piston indicates that the gap in this case should be 0.03 mm, taking into account the tolerance range.

- Trademark . Or an emblem. In this way, manufacturers not only identify themselves, but also provide information to craftsmen about whose documentation (product catalogs) should be used when selecting a new piston.

- Installation direction . This information answers the question - what does the arrow on the piston point to? It “tells” how the piston should be mounted, in particular, the arrow is drawn in the direction of forward movement of the car. On cars where the engine is located at the rear, instead of an arrow, a symbolic crankshaft with a flywheel is often depicted.

- Casting number . These are numbers and letters that schematically indicate the geometric dimensions of the piston. Typically, such designations can be found on European machines, for which the piston group elements are manufactured by companies such as MAHLE, Kolbenschmidt, AE, Nural and others. To be fair, it is worth noting that casting is now used less and less. However, if you need to identify the piston using this information, then you need to use a paper or electronic catalog of a specific manufacturer.

In addition to these designations, there are also others, and they may differ from one manufacturer to another.

Table of contents

A bore gauge is a measuring tool that is designed to obtain data on the distance between two surfaces, as well as determine the internal diameter of various parts. On average, the measurement accuracy of this device is 0.01 mm. A bore gauge for measuring cylinder diameter consists of replaceable gauge rods, which are extensions, and a head. The head itself consists of the following parts:

- Replaceable tip;

- Locking device;

- Stem;

- Cap;

- Drum;

- Micrometer screw

Thanks to the presence of replaceable tips, you can increase the measuring range. For those devices with a measurement accuracy of 0.01 mm, the current GOST is 868-82, and for devices with a division value of 0.001 or 0.002 mm - 9244-75.

The advantages of bore gauges are their fairly high measurement accuracy, both for private and industrial applications. The cost of the device is also not high. The main thing is that the advantages of all mechanical devices are preserved here, which includes durability. At the same time, they require special care and special storage conditions. When a device breaks down, repairs are often very complicated and it is easier to replace the device with a new one than to repair it. During some measurements, deformations may remain on soft parts if there is strong pressure. When it comes to measuring cylinders, difficulties arise in places where there are windows.

What types of bore gauges can be used to measure the diameter of a cylinder?

Bore gauges are often used to measure the diameter of a cylinder. Micrometers are not suitable for this operation, so specialists use these types of devices. The measurement of cylinders with a bore gauge is carried out in two perpendicular planes and four zones. The most popular types of bore gauges are suitable for this.

The indicator type of device is more suitable for those cylinders whose diameter is relatively small. They can work with sizes from 6 mm and larger. It is easy to use, but uses a relative measurement method, so the device has two scales. Although it can work with small values, its error is higher than that of other types of these devices.

photo: indicator bore gauge for measuring cylinder diameter

A micrometric bore gauge uses an absolute measurement method, which, at the same division price as the indicator type, gives a significantly smaller error. The measurement limit here ranges from 50 to 4000 mm, which depends on the specific model. People often use two instruments to get more accurate data.

Selecting a bore gauge for measuring cylinder diameter

To measure a cylinder with a bore gauge, you need to select the device itself correctly. The accuracy of the result, as well as ease of use, will directly depend on this. First of all, you should decide on the appropriate dimensions, since the micrometric and indicator types have too much variation in the minimum limit. If you need to work with parts with a diameter of up to 5 cm, then an indicator bore gauge is suitable, if larger, a micrometric one.

Next, you need to decide which replacement caliber rods should be included in the kit. They expand and contract the operating range of the instrument, so that to obtain correct data you need to have a wide supply of replacement parts. The higher the accuracy class, the smaller the error, so modern high-precision devices allow you to obtain the most accurate data for further work.

Naturally, the device must pass verification, be free of damage and comply with accepted GOST standards. If possible, specialists carry out measurements using several devices simultaneously.

VAZ pistons marking

According to statistics, owners or engine repair technicians of VAZ cars are most often interested in the marking of repair pistons. Below we provide information on various pistons.

VAZ 2110

For example, let's take the engine of a VAZ-2110 car. Most often, this model uses pistons marked 1004015. The product is produced directly at AvtoVAZ OJSC. Brief technical information:

- nominal piston diameter - 82.0 mm;

- piston diameter after first repair - 82.4 mm;

- piston diameter after the second repair - 82.8 mm;

- piston height - 65.9;

- compression height - 37.9 mm;

- The recommended clearance in the cylinder is 0.025...0.045 mm.

Additional information can be printed directly on the piston body. For example:

- “21” and “10” in the area of the hole for the finger - designation of the product model (other options - “213” indicates the VAZ 21213 engine, and for example, “23” - VAZ 2123);

- “VAZ” on the inside of the skirt is the manufacturer’s designation;

- letters and numbers on the inside of the skirt are a specific designation of foundry equipment (you can decipher it using the manufacturer’s documentation, but in most cases this information is useless);

- “AL34” on the inner side of the skirt is the designation of the cast alloy.

The main marking symbols applied to the piston crown:

- The arrow is an orientation marker indicating the direction towards the camshaft drive. On the so-called “classic” VAZ models, sometimes instead of an arrow you can see the letter “P”, which means “in front”. Likewise, the edge where the letter is depicted should be directed towards the direction of movement of the car.

- One of the following symbols is A, B, C, D, E. These are diameter class markers that show the deviation in the outside diameter value. Below is a table with specific values.

- Piston mass group markers. “G” is normal weight, “+” is weight increased by 5 grams, “-” is weight decreased by 5 grams.

- One of the numbers is 1, 2, 3. This is a piston pin hole class marker that determines the deviation in the diameter of the piston pin hole. In addition to this, there is a color designation for this parameter. So, the paint is applied to the inside of the bottom. Blue color - 1st grade, green - 2nd grade, red - 3rd grade. The following provides additional information.

For VAZ repair pistons there are also two separate designations:

- triangle - first repair (diameter increased by 0.4 mm from the nominal size);

- square - second repair (diameter increased by 0.8 mm from the nominal size).

For cars of other brands, repair pistons are usually increased by 0.2 mm, 0.4 mm and 0.6 mm, but without breakdown by class.

Please note that for different brands of cars (including for different engines), the difference between repair pistons should be found in the reference information.

VAZ 21083

Another popular VAZ piston is 21083-1004015. It is also produced at OJSC AvtoVAZ. Its technical dimensions and parameters:

- nominal diameter - 82 mm;

- diameter after first repair - 82.4 mm;

- diameter after the second repair - 82.8 mm;

- piston pin diameter - 22 mm.

It has similar designations as VAZ 2110-1004015. Let us dwell in a little more detail on the class of the piston in terms of outer diameter and the class of the hole for the piston pin. The relevant information is summarized in tables.

Outside diameter:

| Piston class by outer diameter | A | B | C | D | E |

| Piston diameter 82.0 (mm) | 81,965-81,975 | 81,975-81,985 | 81,985-81,995 | 81,995-82,005 | 82,005-82,015 |

| Piston diameter 82.4 (mm) | 82,365-82,375 | 82,375-82,385 | 82,385-82,395 | 82,395-82,405 | 82,405-82,415 |

| Piston diameter 82.8 (mm) | 82,765-82,775 | 82,775-82,785 | 82,785-82,795 | 82,795-82,805 | 82,805-82,815 |

It is interesting that the VAZ 11194 and VAZ 21126 piston models are produced only in three classes - A, B and C. In this case, the step size corresponds to 0.01 mm.

Correspondence table between piston models and engine models (brand) of VAZ cars.

| VAZ engine model | Piston model | ||||||||||||

| 2101 | 21011 | 2105 | 21213 | 2123 | 2108 | 21083 | 2110 | 2112 | 21124 | 21126 | 21128 | 11194 | |

| 2101 | |||||||||||||

| 21011 | |||||||||||||

| 2103 | |||||||||||||

| 2104 | |||||||||||||

| 2105 | |||||||||||||

| 2106 | |||||||||||||

| 21073 | |||||||||||||

| 2121 | |||||||||||||

| 21213 | |||||||||||||

| 21214 | |||||||||||||

| 2123 | |||||||||||||

| 2130 | |||||||||||||

| 2108 | |||||||||||||

| 21081 | |||||||||||||

| 21083 | |||||||||||||

| 2110 | |||||||||||||

| 2111 | |||||||||||||

| 21114 | |||||||||||||

| 11183 | |||||||||||||

| 2112 | |||||||||||||

| 21124 | |||||||||||||

| 21126 | |||||||||||||

| 21128 | |||||||||||||

| 11194 | |||||||||||||

Piston pin holes:

| Piston pin hole class | 1 | 2 | 3 |

| Piston pin hole diameter(mm) | 21,982-21,986 | 21,986-21,990 | 21,990-21,994 |

Signs and causes of wear (breakage) of piston rings

On VAZ cars, the engine wears out during operation, and the PCs also fail. Rings can:

- break into two or more parts;

- wear out in thickness;

- have general wear and tear.

Parts often break down due to overheating of the internal combustion engine; in this case, compression in the cylinders decreases and the engine loses power. Signs of a faulty PC are:

- bluish smoke from the muffler pipe, especially often it appears after a long period of idling when the gas pedal is sharply pressed;

- increased engine oil consumption;

- drop in power, the motor stops pulling;

- coking of spark plugs.

If there are signs of a malfunction in the piston group, the piston rings are replaced first. But replacing a PC does not always give the desired effect; often after repair the engine continues to smoke and consume oil. The reason for this is simple - there is wear in the cylinders themselves. In the block, the liners usually wear out unevenly - they take on an oval shape; due to wear, the piston rings do not fit tightly to the cylinder walls and do not provide a tight seal.

Piston ring sizes: table (VAZ)

VAZ-produced cars are equipped with engines of the following types:

- 2101/2103/ 2105/2106 (VAZ classic);

- 21213/21214/2130 (Niva);

- 2108/21083 (VAZ 2108-09-099);

- 2111/2112 (VAZ 2110-11-12);

- 21114 (VAZ 2113-14-15);

- 11186 (Lada Granta);

- 11194 (Lada Kalina).

There are also many other modifications of internal combustion engines, all VAZ engines are four-cylinder in-line, with a total number of valves of 8 or 16. VAZ engines have several standard cylinder sizes:

For each size, a repair increase of 0.4 and 0.8 mm is provided; factories produce repair pistons and rings of the first and second repair sizes. Piston rings with a diameter of 76 millimeters are available for engines:

The first repair size of the PC for these motors is 76.4 mm, the second repair size is 76.8 mm. Pistons, as well as 79 mm piston rings, are produced for internal combustion engines:

All these motors also have two repair PC sizes - 79.4 mm (first repair) and 79.8 mm (second repair). The most common PC size is 82 mm; many modern VAZ cars use a piston group of this exact size. Piston ring diameter 82 mm can be found on engines:

The VAZ internal combustion engine also has deviations from the typical dimensions, for example, on the 11194 engine with a volume of 1.4 liters, pistons and PCs with a diameter of 76.5 mm are installed; this internal combustion engine is equipped with the Ladv Kalina. There is also a non-standard power unit 1800 cm³ VAZ-21128 with a nominal cylinder diameter of 82.5 mm, but the engine is not mass-produced by AvtoVAZ.

Marking of ZMZ pistons

Another category of car owners interested in piston markings have ZMZ brand motors at their disposal. They are installed on GAZ cars - Volga, Gazelle, Sobol and others. Let's look at the symbols on their bodies.

The designation “406” means that the piston is intended for installation in the ZMZ-406 engine. There are two markings stamped on the piston crown. According to the letter painted on the new block, the piston is matched to the cylinder. When repairing with cylinder boring, the required clearances are made during the process of boring and honing for pre-purchased pistons with the required size.

The Roman numeral on the piston indicates the correct piston pin group. The diameters of the holes in the piston bosses, the connecting rod head, as well as the outer diameters of the piston pin are divided into four groups, marked with paint: I - white, II - green, III - yellow, IV - red. On the fingers, the group number is also marked with paint on the inner surface or on the ends. It must match the group indicated on the piston.

The group number should similarly be marked with paint directly on the connecting rod. In this case, the mentioned number must either coincide or be next to the number of the finger group. This selection ensures a situation where the lubricated pin moves with little effort in the connecting rod head, but does not fall out of it. Unlike VAZ pistons, where the direction is indicated by an arrow, on ZMZ pistons the manufacturer directly writes the word “FRONT” or simply puts the letter “P”. During assembly, the protrusion on the lower head of the connecting rod must coincide with this inscription (be on the same side).

There are five groups, with a pitch of 0.012 mm, which are designated by the letters A, B, C, D, D. These size groups are selected according to the outer diameter of the skirt. They correspond to:

- A - 91.988...92.000 mm;

- B - 92,000...92,012 mm;

- B - 92.012...92.024 mm;

- G - 92.024...92.036 mm;

- D - 92.036...92.048 mm.

The value of the piston group is stamped on its bottom. So, there are four size groups, which are marked with paint on the piston bosses:

- 1 - white (22.0000...21.9975 mm);

- 2 - green (21.9975...21.9950 mm);

- 3 - yellow (21.9950...21.9925 mm);

- 4 - red (21.9925...21.9900 mm).

Pin hole group marks can also be applied to the piston bottom in Roman numerals, with each digit corresponding to its own color (I - white, II - green, III - yellow, IV - red). The size groups of the selected pistons and piston pins must match.

The ZMZ-405 engine is installed on the GAZ-3302 “Gazelle Business” and GAZ-2752 “Sobol” vehicles. The calculated gap between the piston skirt and the cylinder (for new parts) should be 0.024...0.048 mm. It is defined as the difference between the minimum cylinder diameter and the maximum piston skirt diameter. There are five groups, with a pitch of 0.012 mm, which are designated by the letters A, B, C, D, D. These size groups are selected according to the outer diameter of the skirt. They correspond to:

- A - 95.488...95.500 mm;

- B - 95.500...95.512 mm;

- B - 95.512...95.524 mm;

- G - 95.524...95.536 mm;

- D - 95.536...95.548 mm.

The value of the piston group is stamped on its bottom. So, there are four size groups, which are marked with paint on the piston bosses:

- 1 - white (22.0000...21.9975 mm);

- 2 - green (21.9975...21.9950 mm);

- 3 - yellow (21.9950...21.9925 mm);

- 4 - red (21.9925...21.9900 mm).

Thus, if, for example, the letter B is written on the piston of a GAZ engine, this means that the engine has been overhauled twice.

In ZMZ 409, almost all dimensions are the same as in ZMZ 405, with the exception of the recess (puddle), it is deeper than in 405. This is done to compensate for the compression ratio, the size h increases on the pistons 409. Also, the compression height of 409 is 34 mm, and for 405 - 38 mm.

We provide similar information for the ZMZ 402 engine.

- A - 91.988...92.000 mm;

- B - 92,000...92,012 mm;

- B - 92.012...92.024 mm;

- G - 92.024...92.036 mm;

- D - 92.036...92.048 mm.

Size groups:

“Selective selection” inscription on pistons

- 1 - white; 25.0000…24.9975 mm;

- 2 - green; 24.9975…24.9950 mm;

- 3 - yellow; 24.9950…24.9925 mm;

- 4 - red; 24.9925…24.9900 mm.

Please note that since October 2005, on pistons 53, 523, 524 (installed on many models of ZMZ engines, among others), the “Selective Selection” seal is installed on their bottom. Such pistons are manufactured using more advanced technology, which is described separately in the technical documentation for them.

| Piston brand ZMZ | Marking applied | Where is the designation applied? | Lettering method |

| 53-1004015-22; «523.1004015»; «524.1004015»; «410.1004014». | Trademark ZMZ | On the hub near the piston pin hole | Casting |

| Piston model designation | On the hub near the piston pin hole | Casting | |

| "Before" | On the hub near the piston pin hole | Casting | |

| Piston diameter markings A, B, C, D, D. | On the piston bottom | Etching | |

| BTK stamp | On the piston bottom | paint | |

| Finger diameter marking (white, green, yellow) | On a weight lug | paint |

Similar information for piston 406.1004015:

| Piston brand ZMZ | Marking applied | Where is the designation applied? | Lettering method |

| 4061004015; «405.1004015»; «4061.1004015»; «409.1004015». | Trademark ZMZ | On the hub near the piston pin hole | Casting |

| "Before" | |||

| Model “406, 405, 4061,409” (406-AR; 406-BR) | |||

| Piston diameter markings A, B, C, D, D | On the piston bottom | Shock | |

| Finger diameter marking (white, green, yellow, red) | On a weight lug | paint | |

| Manufacturing material "AK12MMgN" | In the area of the piston pin hole | Casting | |

| BTK stamp | On the piston bottom | Etching |

Body parts most susceptible to deformation

Sharp braking or untimely start provoke, first of all, damage to the bumper. If it is insignificant, then during repairs it is possible to achieve the performance of standard geometry. In the presence of complex deformations, this cannot be done, so it is easier to replace the damaged body part with a new one.

If the owner of the car does not take enough care of the condition of the body, then those parts that have close contact with the road surface are quickly eaten away by corrosion. And repairing the hood, doors and hidden body parts instead of timely prevention is already more difficult and expensive.

Toyota pistons markings

The pistons on Toyota engines also have their own designations and sizes. For example, on the popular Land Cruiser, the pistons are designated by the English letters A, B and C, as well as numbers from 1 to 3. Accordingly, the letters indicate the size of the hole for the piston pin, and the numbers indicate the size of the piston diameter in the “skirt” area. The repair piston has +0.5 mm compared to the standard diameter. That is, only the letter designations change for repair shops.

Please note that when purchasing a used piston, it is necessary to measure the thermal gap between the piston skirt and the cylinder wall. It should be within 0.04...0.06 mm. Otherwise, it is necessary to carry out additional diagnostics of the engine and, if necessary, carry out repairs.

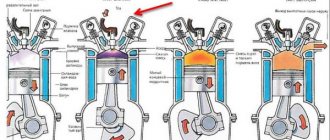

Engine piston rings

In an internal combustion engine (ICE), piston rings (PR) serve as a seal between the cylinder walls (liners) and the piston, due to which compression is created in the cylinders.

If you forget to put the PC into the engine during assembly, the engine will not start, since the necessary compression of the working air-fuel mixture will not be ensured. In passenger cars, three rings are standardly installed on each piston - two compression rings and one oil scraper ring, and oil scraper rings can be stacked, that is, consist of several elements. Compression piston rings (CPRs) are used to create compression in the cylinders and are always made of high-strength cast iron with various additives. The upper CPC has the greatest strength, since it operates in the most severe temperature conditions and experiences maximum loads.

Engine oil piston rings (OPRs) are needed to drain oil from the cylinder walls; if the rings do not perform their function, the engine will consume oil. MPKs can be either cast iron or steel, and cast iron PCs are almost always made in one piece, but steel oil scraper rings can only be assembled (composite). Steel MPC for one cylinder consists of:

- two spring steel rings;

- axial expander;

- radial expander.

Pistons

Many domestic and imported cars use repair pistons manufactured at the production facilities of the Kostroma manufacturer of piston groups, Motordetal-Kostroma. This company produces pistons with a diameter from 76 to 150 mm. Today the following types of pistons are produced:

- solid cast;

- with thermostatic insert;

- with an insert for the upper compression ring;

- with oil cooling channel.

Pistons produced under the specified brand have their own designations. In this case, information (marking) can be applied in two ways - laser and micro-impact. First, let’s look at specific examples of markings made using laser engraving:

- EAL - compliance with the technical regulations of the customs union;

- Made in Russia - direct indication of the country of origin;

- 1 - group by mass;

- H1—diameter group;

- 20-0305A-1 - product number;

- K1 (in a circle) - sign of the technical control department (QCD);

- 05/15/2016 - a direct indication of the production date of the piston;

- Sp 0.2 - gap between the piston and cylinder (temperature).

Now let's look at the designations applied using the so-called micro-impact, using specific examples:

- 95.5 - overall diameter size;

- B - diameter group;

- III - group according to finger diameter;

- K (in a circle) - quality control (quality control) sign;

- 04/26/2017 - direct indication of the production date of the piston.

It is worth noting here that for the production of different pistons, different aluminum alloys with alloying additives are used. However, this information is not indicated directly on the piston body, but is recorded in its technical documentation.

Thermal clearance of piston rings

PCs are spring discs with one cut - when installed on the piston, they expand, and in the sleeve they are pressed tightly against its walls. In order to achieve maximum compression of the working mixture, the cylinder walls must be as smooth as possible (without defects), and the shape of the internal cavity must be perfectly round. On the piston, the PCs are placed in special grooves, moreover, they are not seated tightly, and on a cold piston they move freely in the grooves.

Piston rings have thermal clearances:

The clearances must be certain; if they are larger or smaller than the required value, the piston group will quickly fail. One should take into account the fact that when heated, the metal expands, and if the thermal gap of the PC is too small, the piston group will begin to overheat. With large gaps, tightness is not ensured and power losses occur.

For passenger cars, as a rule, the following clearances are established:

- between the grooves and the PDA - from 0.02 to 0.08 mm (for the upper ring the gap should be slightly larger);

- between grooves and MPC – from 0.05 to 0.06 mm;

- at the junction - from 0.25 to 0.5 mm.

As wear occurs, the gaps in the PC increase, and they should not exceed:

- between the ring and the groove – 0.15 mm;

- at the junction – 1.0 mm.