It is possible to repair the engine after a broken timing belt, but you will have to spend a lot of effort, money and time on this. Therefore, many car owners do not wait until the belt breaks and the pistons meet the valves, but immediately install other, protected pistons. "Priora" with similar parts works in the same way as with factory ones. But the risk of breakdown due to a broken timing belt is reduced to almost zero.

Now there are several manufacturers that produce spare parts for this engine, including pistons. "Priora" is equipped with products from Russian, "STI" and "Avtramat" from a Ukrainian manufacturer. Let's see what these products are.

general information

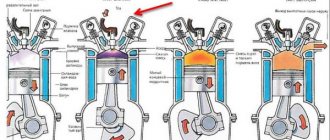

The piston in an internal combustion engine is designed to transmit rotational energy to the crankshaft. This energy is produced by combustion of the mixture. When a mixture of air and gasoline explodes, the gases expand. The latter press on the surface of the part and push it. During operation, the piston surface experiences high thermal loads. The pressure in Priora engines can reach 65-80 bar.

During operation, the Priora pistons accelerate at some intervals to a speed of 100 km/h and then slow down to zero, while the operating frequency at 6000 rpm is 200 Hz. When the fuel-air mixture burns, heating in the chambers can reach 1800-2660 degrees. This is several times higher than the temperature at which metal melts. As a result, the strength of the alloy decreases. Various stresses arise in the piston body due to sudden temperature changes, and in addition, stress from pressure and inertia is added during acceleration-deceleration processes at high frequencies.

What compression should the VAZ-2109 injector and carburetor have?

What is engine compression. How to check the compression of a VAZ 2109? Often, car owners are faced with vibration that unexpectedly occurs when driving at idle speed, and large fuel combustion. There are several reasons for this deficiency, for example, problems with spark plugs or malfunctions of the fuel system.

Poor engine compression can also lead to such consequences. If diagnostics of the fuel system shows that everything is in order, you need to check the compression in the cylinders.

Compression is the maximum pressure in the cylinder that occurs at the end of the compression stroke (at the moment the piston reaches top dead center). To measure compression there is a special device called a compression gauge (a pressure gauge with a hose and a fitting at the end).

What is engine compression. How to check the compression of a VAZ 2109?

Poor compression in the cylinders leads to the following consequences:

- fuel consumption increases;

- dynamics deteriorate (acceleration);

- the accelerator responds poorly to the pedal;

- poor “traction”;

- black exhaust appears.

Checking the compression of the VAZ 2109 engine with your own hands

- Before measuring compression, you need to check the valve clearances and adjust them.

- Warm up the engine to 70-80 degrees.

- Turn off the engine, remove the spark plugs (to do this, use a spark plug wrench).

- Disconnect the fuel hose and clamp it to prevent fuel from leaking.

- Remove the central drive from the ignition coil.

- Use a compression gauge installed in the spark plug socket to determine the indicators. Start checking from the first cylinder. Each cylinder must be checked separately.

- At this time, the assistant must turn the starter so that the compression gauge can record the resulting pressure.

- Record the device indicators. The minimum permissible compression is 10 kg/sq. cm, and the spread between the cylinders should not exceed 1 kg/sq. see. If your readings differ greatly from each other, we can conclude that there is wear on the compression rings, valves that do not fit well on the seats, or problems with the tightness of the cylinder head gasket.

If the cylinder compression is less than the figure indicated above or is different in each cylinder, a major overhaul of the engine is required.

Most likely, you will have to change the cylinder head gasket, grind in and adjust the valves, and install new piston rings. It is possible that the piston rings are stuck, then the engine will have to be decarbonized.

To narrow down the range of possible problems, you need to do a few simple tests with an air compressor.

- Set the piston of the cylinder being tested to the top dead center position.

- Tighten the handbrake, turning on speed 4-5.

- Start the compressor and supply air under pressure to the cylinder.

Monitor the air flow

- If you hear a hissing sound in an adjacent cylinder, there is most likely damage to the gasket between the cylinders. To solve this problem, you need to replace the cylinder head gasket.

- To make sure that there are no breakdowns in the engine cooling system, you need to remove the radiator cap or expansion tank and make sure that the coolant level does not increase when air is pumped. A breakdown may be indicated by air bubbles or a change in the color of the coolant, or the appearance of an exhaust odor.

- If there is a hissing sound in the manifold or exhaust pipe area, it is most likely due to the intake or exhaust valve.

How to diagnose a VAZ 2108-21099 engine using a compressor

Only experienced specialists can visually clearly identify this or that engine problem; it is quite difficult, almost impossible, for an ordinary driver to do this. Of course, you can notice potential problems by the exhaust or sound, but this is only a small part of all possible malfunctions.

More accurate diagnostics are performed using serious instruments. This article will discuss engine diagnostics, which are more complex than visual, using simple, simple instruments.

Diagnosis of the VAZ 21099-2109-2108 engine using simple DIY tools

What is needed for diagnosis:

- a compression meter that measures compression in the cylinders;

- an oily rag that is used to determine the compression stroke of the engine. A tool made by combining a fitting for spark plug holes and a regular whistle will be convenient and effective;

- adapter for spark plug holes, which is used in the process of checking the tightness of the combustion chamber, compressor for inflating wheels.

Diagnostic procedure

The operating algorithm is as follows:

- It's better to start with compression. First, you need to warm up the engine to operating temperature, and then turn off the fuel supply. In this case, the hose on a carburetor engine is removed, compressed and pinched with something, or simply lowered into some container.

- For an injection engine, everything is much simpler - you just need to pull out the fuel pump fuse. Then you need to start the car (there should be some fuel left in the fuel rail) and wait until the engine stalls.

- After this, the ignition system is turned off, for which the central wire is removed from the distributor, and the sensor on the injector that monitors the position of the crankshaft is turned off.

- All debris that has accumulated there must be removed from the spark plug wells so that it does not get into the cylinders. After this, all the candles are unscrewed.

- Next, the compression gauge fitting is screwed in or inserted—it all depends on the model—after which the assistant begins to start the engine. The starter must rotate the engine until the pressure gauge needle stops in one position. Such measurements are carried out on each cylinder, and their results are recorded.

There is a special formula with which the ideal compression can be calculated for any engine. Compression is 1.2* compression ratio.

For example, the VAZ 21083 engine has a compression ratio of 9.8. Thus, its compression will be equal to 1.2 * 9.8 = 11.76.

This means that a compression of 11-12 atmospheres is quite normal for this engine. But each measurement has its own errors.

Device

In order for the crank assembly to serve in such difficult conditions, the part must be light and wear-resistant. The alloy has high thermal conductivity, which ensures rapid cooling when heated.

The outer surface is formed in such a way that there is never a risk of the part jamming inside the combustion chamber. Gases must not enter the engine crankcase. Due to the temperature difference between the piston bottom and the skirt, the element is made in a barrel shape. Therefore, it satisfies all the requirements.

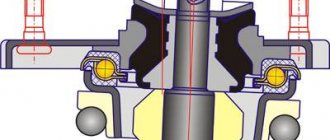

To compensate for skirt deformations during operation, the mechanism is made with a so-called “anti-ellipse”. The major axis of the part is perpendicular to the finger hole. The top part of the piston is the so-called head. It has a bottom and special grooves. O-rings are installed in them. To ensure that the piston head can withstand high loads, a special protective coating is applied to it.

The grooves for the piston rings are made at a slight angle. This ensures that the outer edges of the rings are positioned higher than the inner ones. The manufacturer prevents the groove cross-section from sloping downward at high temperatures. This is not the last characteristic that distinguishes the pistons. Priora is equipped with elements that “slide” in the combustion chamber. To do this, their working surface is coated with special compounds. In order for the part to run in better, coatings are applied that will wear out over time during the running-in process. This is often a phosphated tin compound. This coating also reduces the occurrence of scratches during cold starts. Antifriction materials remain on the piston forever. They prevent cracking of the working part of the part and erosion.

The piston skirt is processed in production with special cutters to create a microrelief. This way the oil stays on the surface better, thereby reducing friction on the pistons. "Priora" will withstand heavy loads on the crankshaft. All these parameters are equally met by third-party pistons that are heavier, as noted by reviews. They are heavier than all other models.

Thermal clearance of piston rings

PCs are spring discs with one cut - when installed on the piston, they expand, and in the sleeve they are pressed tightly against its walls. In order to achieve maximum compression of the working mixture, the cylinder walls must be as smooth as possible (without defects), and the shape of the internal cavity must be perfectly round. On the piston, the PCs are placed in special grooves, moreover, they are not seated tightly, and on a cold piston they move freely in the grooves.

Piston rings have thermal clearances:

The clearances must be certain; if they are larger or smaller than the required value, the piston group will quickly fail. One should take into account the fact that when heated, the metal expands, and if the thermal gap of the PC is too small, the piston group will begin to overheat. With large gaps, tightness is not ensured and power losses occur.

For passenger cars, as a rule, the following clearances are established:

- between the grooves and the PDA - from 0.02 to 0.08 mm (for the upper ring the gap should be slightly larger);

- between grooves and MPC – from 0.05 to 0.06 mm;

- at the junction - from 0.25 to 0.5 mm.

As wear occurs, the gaps in the PC increase, and they should not exceed:

- between the ring and the groove – 0.15 mm;

- at the junction – 1.0 mm.

Reasons for replacement

Everything here is very individual. Car enthusiasts claim that if you fully comply with all regulations regarding maintenance, install spare parts from the original manufacturer or simply high-quality analogues on your Lada Priora car, then the engine will never let you down. Everything will work as normal. But everyone wants to save on spare parts or tune the Priora. This is where questions arise. For example, if they save on the gas distribution mechanism by installing low-quality rollers and a belt, then the replacement interval is slightly reduced. For example, the timing belt should be changed as standard every 50 thousand km. You can drive only up to 10 thousand km using non-original spare parts.

STI pistons

"STI" is a Tolyatti company. Pistons are manufactured using hot pressing technology. If you analyze the reviews of all those who have already bought spare parts of this brand for a Lada Priora car, you can see that they greatly reduce the efficiency of the engine. This can be explained by the fact that, compared to STK and Avtramat products, STI parts have a lower compression ratio. The combustion chamber has a large area due to the recesses for the valves being too deep.

The alloy contains reduced silicon content. This affects the strength characteristics of the part under high thermal loads. A reduced amount of nickel reduces the service life of the part. With these disadvantages, these pistons have a high price. But at the same time, forged products are significantly inferior to other brands. Avtramat pistons (Priora is also equipped with them) do not have these shortcomings, just like STK. However, there have been cases of belt breaks on cars with these mechanisms.

Decarbonization of piston rings

If the engine starts to smoke, there is a possibility that there are rings stuck in the piston grooves. Nowadays, there are many different modern means for decarbonizing piston rings, and many drivers use them to restore engine performance. Among the most popular compositions are:

- Nitrox Power;

- LAVR ML-202;

- Titanium;

- LIQUI MOLY;

- WYNN'S.

"Avtramat"

These are Ukrainian-made parts. Pistons are manufactured at a Kharkov plant. The part is produced by casting. The alloy completely replicates that of the original spare parts. The factory dimensions of the VAZ pistons are also repeated. But unlike the original, the Ukrainian element has deeper samples. This gives it a lot of advantages over the standard part if the timing belt breaks. As for the compression ratio, it remained unchanged. Therefore, if you install these products, the difference in the power characteristics of the engine will not be noticeable.

Due to the fact that the samples are increased, the area of the combustion chamber has increased slightly, the efficiency should be lower compared to standard spare parts. However, the numbers differ slightly. So, the figure is 53.2 cm2 for the original and 53.3 cm2 for the Avtramat. In practice this is completely unnoticeable. There is one more advantage that these pistons have. Priora (the price of parts is 3 times less - 2 thousand rubles, than for products from STI - almost 7 thousand) will be inexpensive to maintain if you use these products.

Benefits of installing aftermarket pistons

Elements with grooves for valves are very durable. Even if the timing belt breaks, the upper camshaft and valves will simply freeze in place. The piston will go down due to the crankshaft, and nothing bad will happen. The valves will fall into the grooves created for them. Next, the owner will need to take the car to a service station, where specialists will restore the timing mechanism. This is a huge plus.

Note that if the pistons do not have these grooves, then as a result of a belt rupture, the owner will face serious repairs. The pistons and valves themselves, as well as the camshaft pastel, are being replaced. The cost of such repairs can start from 30 thousand rubles. Therefore, it is worth installing “STK” pistons or similar ones. Grooves will save you from expensive repairs.

Minuses

If the piston is light (as much as possible), the motor will gain more power. You can achieve an increase in dynamic characteristics by 5-7%. Pistons with grooves cannot be called light. To make a recess at the top of the part, you need to have a fairly thick wall. This makes it heavier, which is why power is lost.

In addition, these grooves change the compression of the combustible mixture. This also affects the traction of the power unit. To summarize, with the installation of such a part, the engine will lose that same 5% of power. For a 150 hp engine. With. this is 10.5 “horses”. Another drawback is higher fuel consumption. The dimensions of the VAZ pistons are the same as the factory ones, but due to the grooves, the volume of the combustion chamber increases, even if only slightly. Finally, due to increased volumes, compression decreases. Detonation is also increasing.

VAZ piston rings

The Volzhsky Automobile Plant produces engines for front-wheel drive and rear-wheel drive cars; piston rings for VAZ engines were originally supplied by the Michurinsky plant. The Michurins produced a lot of defects in their products, and since 1986, their own production was established in Tolyatti. Currently, there are many different manufacturers that produce PCs for VAZ engines, in particular, these are:

- AVTOVAZ (Tolyatti);

- STK (Samara);

- GOETZE (Germany);

- MAHLE (Germany);

- NPR EUROPE (formerly SM, Japan).