Economical car enthusiasts, or those who are accustomed to performing all repair operations with their own hands, think about boring the cylinder block themselves. In this regard, most drivers immediately have a question: how advisable is it to carry out such a procedure, which cannot be called easy, in a garage box? After all, grinding a block without special equipment and certain skills is quite problematic. In addition, it is impossible to be completely sure of the accuracy of this procedure, but still many car owners undertake boring the cylinder block at home.

Note that experienced mechanics do not approve of such a procedure. Although it can be used as a last resort to restore the performance of motorcycle or moped engines. There are several ways to bore the cylinder block of an automobile power unit, each of which requires certain efforts and costs. Still, it is best to perform this procedure on a special boring machine, since in this case the risk of damaging the block is minimized. On a machine you can get an ideal cylinder bore (if it is done by a professional), but with manual execution such results are unlikely to be achieved.

What is it for?

The very concept of “block boring” implies the process of restoring the geometry of the power unit cylinders using special machines. The main prerequisite for block boring is a major overhaul of the engine, but now the procedure is mainly carried out to increase its power.

It is necessary to bore cylinders during a major overhaul because the pistons in them, under the influence of high temperatures, pressure and other constant loads, cause a violation of the geometric shape of the cylinders. To put it simply, due to constant friction and high loads, the cylinder, instead of a perfectly round shape, takes on the shape of an ellipse. Because of this, the piston can no longer fully adhere to its walls, resulting in a significant gap through which exhaust gases or fuel penetrate into the crankcase, and engine oil into the combustion chamber.

Naturally, because of all this, the power unit significantly loses its power, fuel and oil consumption increases. One of the sure signs indicating the need for engine boring is increased engine oil consumption. In addition, you should pay attention to the color of the exhaust gases. If bluish-blue smoke begins to appear from the exhaust pipe, a major overhaul of the power unit is not far off.

Just a few decades ago it was impossible to find good quality motor oil or coolant, which caused frequent overheating of engines. It even got to the point where it was necessary to overhaul the engine of a new car after 30-50 thousand kilometers. And units on trucks and special vehicles had to be restored much more often.

Today the situation has changed dramatically. Modern lubricants and coolants can significantly increase the service life of a car engine. Now the average mileage before major repairs is approximately 200-250 thousand km, and not every motorist drives even 12-15 thousand km in a year. It turns out that this resource of the power unit should be enough for more than 15 years of operation. Not every vehicle can withstand that much.

Block boring has recently been extremely rarely used as a necessary repair measure. This procedure is mainly used for tuning to increase engine volume and power. But, in the second case, boring is carried out only when the condition of the cylinder walls allows it to be performed. In this case, it is necessary to install pistons with a larger diameter. Also, to ensure correct operation of the power unit, a larger amount of fuel mixture will be required, since its volume will increase, and accordingly, the power will increase.

Why us

Our company has been operating on the market for several years and during this time we have assembled only experienced specialists and masters of their craft into our team. They will help to identify the true cause of the malfunction of the propulsion system, eliminate it as quickly and efficiently as possible, thereby restoring the normal operation of the vehicle. We work with propulsion systems of cars and trucks. Before carrying out work, a full consultation is provided to determine the best ways to restore the system at minimal cost.

Which motors can be sharpened and which cannot?

As you know, the cylinder block can be made of cast iron or aluminum. The first option, despite some disadvantages, which include high mass and low heat dissipation, has good strength and is ideal for turning. An aluminum block, on the contrary, is much lighter and more efficient at removing heat.

However, the walls of its cylinders are coated with a special wear-resistant compound, which is why it is not recommended to grind them. This procedure will simply remove the coating from the walls, causing the cylinders to lose their strength and not last long.

Some difficulties of engine tuning

True, in order to ensure this result, it will be necessary to intervene in the arrangement of air and gas lines, and to alter the fuel and exhaust mechanisms.

In the easiest case of tuning, you can simply replace the connecting rods with longer ones and install repair sleeves, pre-bored to the required parameters.

Pros and cons of boring

Among the advantages are the following:

- Power increase

- Increased service life

- Reduced oil consumption

- Increase compression

- Improving the dynamics of the unit

The disadvantages include:

- Reduced engine efficiency

- Reducing the size of the cylinder walls, which causes the engine to heat up faster

- Violation of the factory characteristics of the power unit, which may negatively affect the passage of maintenance

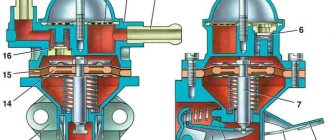

Boring, polishing, honing

Then the master himself or in the process of negotiations with the client decides what kind of repair actions should be carried out. The most important task of a car mechanic at this stage is to accurately adhere to the dimensions of the bore.

It itself does not take much time, especially if it is carried out automatically under the full control of a computer.

Next, grinding to a mirror smoothness or honing is carried out. Given that there will not be even the slightest deviation from the ideal cylinder on the mirror surface of the cup, practice shows that standard honing creates the prerequisites for more successful grinding of piston rings to cups.

Methods for boring a block yourself

You can perform this procedure at home in two ways, which are practically no different from each other. We warn you in advance that the process of self-boring is quite labor-intensive, and after it is completed, an ideal result cannot be guaranteed.

To perform the first boring method, you will need a high-speed electric drill, an old piston and a set of sandpaper of various grain sizes on a moisture-resistant fabric base. The process itself can be described as follows:

- in the upper central part of the piston it is necessary to drill a hole for the pin, then insert and tighten it tightly;

- Using a hacksaw for metal, you need to make a cut in the side of the piston, insert the edge of coarse sandpaper into it, wrap it around the piston and fix it in the same cut;

- Boring should begin at minimum speed, gradually adding it. When boring, the drill should be moved up and down in smooth movements;

- when the piston used for boring will freely penetrate 2/3 of the cylinder, change the sandpaper to finer sandpaper and sharpen it with it;

- after all manipulations, final grinding should be done with a “zero”;

Careful control measurements

Before starting work, the boring mill mechanic measures the parameters of the glass with his hands or on a special stand. This moment is the most critical in the entire boring procedure and therefore must be carried out with special care.

If the master correctly fixes the cylinder block on the frame, then the measurements will be made flawlessly.

If inaccuracies are made, the principle of alignment will be violated, a right angle will not be ensured during measurement, and the subsequent tuning will lead to accelerated wear of the car engine.

Video

After a certain mileage, boring the cylinder block on a VAZ 2109 becomes a necessity, because severe wear of parts disrupts the proper operation of the engine and increases fuel and oil consumption. The block is also bored in order to increase power. By boring the cylinders to their maximum size and installing the appropriate piston group, you can achieve a volume of 1.8 liters, which will give a noticeable increase in power.

Boring the cylinder block on a VAZ 2109 is included in the concept of a major overhaul. The cylinders are bored to the next repair size and the pistons of the next repair size are installed. Such work should only be carried out by an experienced master, because experience and the quality of the machines play a role here. So it’s worth taking the time to find good specialists with good equipment in your city.

During operation, engine parts experience natural wear and tear. As for the cylinders, they do not wear out along the entire plane, but mainly in the area of the piston stroke. As a result, the cylinders take on the shape of an ellipse. Due to the ellipse, the gap between the piston rings and the cylinder walls increases significantly, as a result of which compression decreases, as does power, and consumption of both oil and fuel increases.

The wear and shape of the cylinders are measured with special instruments, dial gauges. It is worth saying that if there is severe wear, replacing the piston rings or rings together with the pistons will not help. After all, new pistons will move along the same ellipse and will quickly wear out. So, when the mileage arrives and a major overhaul is required, cylinder boring is a very important part. It is impossible not to bore the cylinders during a major overhaul.

The resource of the VAZ engine of the ninth family is 150 thousand km. mileage This is according to the manufacturer's statement. But, as practice shows, these engines run for 200 thousand or more without any problems. There are even examples that have traveled more than 300 thousand km. mileage without major repairs. But these are rather exceptions. There are cases when major repairs are required even at lower mileages than 150 thousand. Motors do not withstand the declared service life due to improper assembly and selection of parts or due to aggressive driving.

So, if your car’s mileage has exceeded 130-170 thousand km. mileage, it is worth conducting diagnostics and adding up all the symptoms in order to understand whether a major repair is needed. You can check cylinder wear without disassembling the engine by simply measuring the compression. If the compression measurement gives readings of less than 10 atmospheres in all cylinders, then this is the first symptom of an upcoming major overhaul. Compression should not differ by more than 10% between all cylinders.

But, low compression may also be due to the fact that the valves have lost their tightness. Without opening the engine, this cannot be determined. Therefore, there are other symptoms of a worn cylinder-piston group. Among these symptoms is increased oil consumption, more than 0.5 liters per 1000 km. mileage, increased fuel consumption and reduced power. Also, when the engine is not warmed up, a metallic ringing can be heard. By combining all these symptoms, we can conclude that capital is needed.

Many car enthusiasts who want to increase the power of their car resort to boring cylinders and installing pistons with the largest possible diameter. The maximum piston diameter for block 21083 is 84 mm, with the standard being 82 mm. At the same time, you need to be especially careful in selecting a boring specialist, because when boring pistons up to 84 mm, the cylinder walls become very thin and can be easily damaged, thereby making the cylinder block unsuitable for further use.

Simply installing 84 pistons will not bring a special increase in power. In addition to this, you also need to install a crankshaft with a stroke of 81 mm. Such manipulations will make it possible to make a volume of 1.8 liters, which is the maximum possible for this block. About 20-25% more horsepower can be extracted from a 1.8-liter engine compared to the standard.

Different mileage figures before major repairs mainly depend on driving style, fuel quality, correct settings of the power system and timely maintenance. If you comply with all these parameters, then the engine will last a long time and boring the cylinder block on the VAZ 2109 will be required no earlier than after 200 thousand kilometers. In order not to get to the capital before the due time, you need to change the oil in a timely manner, refuel only in proven places, monitor the correct operation of the carburetor or injector, and do not turn your standard car into a racing car.

We offer profitable engine boring

If the engine, practically its heart, breaks down in a car, then further operation of such a vehicle is physically impossible. You need to find a suitable service center that will help solve the problem. offers its services in the field of propulsion system repair. Our specialists carry out engine restoration regardless of the complexity of the task. Extensive experience and a high level of qualifications help in this. At the same time, the price is always affordable. The website provides a complete list of services; you can obtain additional information from the managers in any convenient way.

Why bore the cylinder block?

Block boring is a special process through which the geometry of the machine’s engine cylinders can be restored.

It is necessary to bore the cylinder block for a number of reasons:

- Thanks to this procedure, the natural position of the mating components of the power unit relative to each other is restored.

- To restore optimal wearability and correct positioning of components relative to the surface, cylinder geometry alone is not enough. The latter will also break during operation of the power unit.

- As a result of the increased friction and stress that occurs with a lack of tolerance, other dependent units will continue to collapse. This will lead to the formation of additional loads on all moving parts of the internal combustion engine involved in the operation of the unit. As a result, cracks and bends will form on the devices, and the unit will be deformed.

- Also, the boring or honing procedure is often performed to increase the motor power parameter. Although the cylinder walls of internal combustion engines are made of high-strength steel, this material tends to wear out when the pistons operate. The shape of the cylinders ends up being more oval than round, causing the piston rings to fit together.

- As a result, due to detonation of the combustible mixture, exhaust gases enter the engine crankcase along with the mixture. This leads to a decrease in the overall power parameter of the internal combustion engine and the power unit begins to consume motor fluid.

Boring interval

The fact that the boring procedure is performed less frequently these days than it was 30 years ago is due to high technology. At that time, it was difficult to find quality oil or antifreeze for the engine. Therefore, the procedure for overhauling the unit and boring could be carried out after 50-60 thousand kilometers.

Today, thanks to the use of additives and additives in liquids by various manufacturers, wear of the unit can occur after 200 thousand kilometers. The honing procedure itself for the purpose of tuning or repair is performed on special machines where the devices are ground down. Then new, larger pistons are mounted on the power unit, which makes it possible to increase the service life of the internal combustion engine.

Artem Krupin spoke in detail about the goals pursued by cutting the channels of the motor BC head.

Erasing the cylinder with piston rings

A typical reason for distortion of the factory geometry at a certain stage of the run is the friction of the rings on the glass. Under the influence of the pistons, it acquires an oval or conical shape.

This defect cannot be detected with your own eyes, but high-precision instrumental measurements can reveal it.

Cylinder block boring instructions

At home, boring a classic or other car with an 8 or 16 valve engine is problematic. This will take a long time because the process requires high precision.

Tools

To bore a cylinder block with your own hands, you will need:

- Boring machine. Not every service station can afford such equipment; therefore, buying it for your own needs is not advisable from a financial point of view. You can rent a machine.

- Sandpaper. You will need sandpaper of different densities, from fine-grained to coarser.

- Sharoshki.

- Drill.

- Locksmith tools - a set of screwdrivers, wrenches, etc.

- Pipe branch. The hose size should be smaller compared to the bored channel.

- Calipers.

Boring process

Boring cannot be done on the machine, so the power unit must be dismantled.

The cylinder block boring procedure consists of several stages:

- Consumables are drained from the power unit. You need to find a drain plug under the bottom of the machine; place an old container under it into which the working fluid will be drained. The engine oil drain plug is unscrewed, and you will have to wait at least 30 minutes for the substance to come out completely. The refrigerant is drained from the engine cooling system in the same way.

- After draining the liquids, the power unit is disassembled. The consumer needs to dismantle the spark plugs, disconnect all wires and pipes from the engine. The contacts from the sensors are disconnected, the motor mounts are removed, and if necessary, stops are placed under the motor. The procedure is extensive and will take time. After disassembling the main components, the unit itself is dismantled.

- The next step is to install the cylinder head on the machine bed that will be used for boring. Correct level fixation gives the best result, so the head must be optimally fixed.

- If the repair procedure is carried out due to ovalization of the canals, then before performing the task, all measurements are taken using micrometric devices. This is done to determine the degree of wear. After taking measurements, you can understand which side and how many mm of steel need to be removed.

- Then the boring repair work begins. It is impossible to perform them correctly on your own, in particular if the procedure is performed by the car owner for the first time. The master must have qualifications. If the machine is not able to maintain the required size, achieving an optimal result will be problematic. This may generally affect the operation of the engine cylinder head.

- If the boring procedure is completed, then the internal surfaces of the cylinders are honed.

- The next stage is checking the actions performed. Measurements are made using measuring instruments; the diameter of the holes must be identical. The power unit is assembled in the reverse order and the engine is installed on the machine. The engine is being refueled with consumables.

Honing the cylinder block

Separately, we should talk about the features of cylinder head honing:

- The procedure is performed in two stages. The first uses a tool for grinding working surfaces with a coarse abrasive. This stage is a rough surface treatment, during which the defective layer of metal is removed. It is necessary to achieve alignment of the cylindrical sleeves and their optimal shape, and to get rid of large roughnesses. To complete the task, diamond honbrus made on a copper base are used.

- The rough honing procedure is performed with surface treatment with lubricating and cooling consumables. This is done in order to completely remove abrasive residues, as well as mechanical particles, from the surface where the hone is applied.

- Then finishing sanding is carried out, which requires a fine abrasive. It will allow you to complete the task with increased accuracy. To ensure high smoothness of the cylinder liners, you can additionally treat the surface with an abrasive paste.

- The next step will be to perform additional quartzing. This procedure is not intended for boring; it is performed to clean the surface from traces of abrasives and its residues. If the cylinder head is made of cast iron, then quartzization will provide the opportunity to open the graphite grains. In the case of cast iron units, this makes it possible to remove friction and reduce mechanical losses, as well as prevent rapid wear of the internal combustion engine. Quartz plating is performed using special brushes based on nylon threads and crystals.

- When the last stage of honing is completed, the power unit is flushed to remove any remaining metal shavings and dust.

Finding a well-equipped workshop

It is better to entrust the boring of the cylinder block not to a simple person who likes to tinker with cars in the garage, or even not to a local famous Kulibin, but to a professional specializing in this field of car service. True, you will have to look hard for such a master.

Even after finding him, you should definitely ask what kind of equipment he intends to use.

It must not only be in good condition, but also new, meeting the current standards of processing accuracy, speed of the process, automation of cutter control and cooling.

Why bore channels in the cylinder head?

The channel boring procedure is performed in order to increase the power parameter of the power unit at higher speeds. If tuning is necessary, the procedure is performed in the same way, only the owner of the car needs to select the amount of grinding of the cylinders. In this case, there is no need to remove oval shapes on the cylinder head. After boring and installing large-sized pistons, you can achieve an increase in the power parameter.

The larger the piston size, the more combustible mixture can enter the engine. Accordingly, the more fuel is burned during the operation of the internal combustion engine, the greater the pressure will be when the mixture ignites. This causes the power parameter to increase.

Undeniable economic benefit

At the same time, the cost of boring makes it much more profitable than purchasing a new similar block. There is no great need to expand the cylinders only for the owner of a Soviet car made in the 1980s and 1990s, any spare parts for which can be found almost free of charge.

The process of boring head channels

To complete the task of boring channels, you will need a ball cutter. The diameter of the cutter must correspond to the required bore size. It can be 29, 31 or 32 mm. Before creating channel geometry, keep in mind that it must ultimately match the geometry of the machined manifolds. To comply with this condition, it is important to connect the pipeline to the head and, in accordance with the resulting traces, set the desired geometry using the boring method. To achieve a clear mark, plasticine or solid oil is used, and the end part of the head is treated with these substances.

The channel boring procedure is performed until the following diameters are achieved:

- the size of the head inlet channel should be 3.1-3.2 cm;

- the diameter of the outlet channel will be 2.9 cm.

The boring process consists of the following steps:

- The head is being modified. The size is increased, as well as the geometry, if required. The measurement method is used to determine the required diameter of the roundings.

- Valve seats are being upgraded. Sharp edges are removed from these components because they create high resistance when the valves open.

- The holes on the intake manifold side are aligned with the head channels. Using a milling cutter, you need to bore the hole to the bushing. If inconsistencies remain, this will cause the combustible mixture to slow down.

- Boring is performed from the side of the combustion chamber. You need to make sure that the seats for the new valves are installed.

- The geometry is bored using cutters; for this, elements of different sizes are used.

- The final stage will be sanding the channels. The procedure is performed until the surface of the canals is as mirror-like as possible.

Indirect signs of the appearance of an ellipse

In a number of cases, the fact that the cylinder is no longer round can be guessed by the following deviations from the standard parameters:

- Reduced compression;

- Excessive consumption of engine oil;

- Oil clogging of spark plugs;

- Exhausts acquire a bluish tint.

Aluminum block and sleeves

Guys, this is a VERY broad topic, perhaps I will write about it a little later. In the meantime, I’ll let you understand a few basic postulates.

Aluminum options are indeed often not recommended to be bored (although not all of them) and this is the point. First, let’s look at the manufacturing technology of modern blocks:

- When casting, thin-walled thin cast iron sleeves are installed at the factory, the wall thickness is 2 - 3 mm. Such options are called “dry with cast iron sleeves . Boring of this option is acceptable, and repair pistons and rings are produced for them. Installed on cars such as VOLVO, Land Rover, HONDA, SUBARU, NISSAN, SUZUKI and some others.

- All-aluminum monoblocks using SILUMAL (developed by MAHLE). There is a cast aluminum body here, but the walls from the inside are subjected to complex chemical-thermal treatment, after which a high concentration of silicon is formed on the walls; this material prevents the rings and pistons from quickly wearing out the walls and the resource increases to 150 - 200,000 km. The layer is quite thick and can also be bored out a LITTLE; for such engines, repair kits are available that increase the cylinder size by 0.5 - 1 mm. Such options are installed on many models of Mercedes, BMW, AUDI, PORSCHE and some other cars.

- NICASIL monoblock technology . Here, too, a durable coating of only a mixture of nickel and silicon carbide is applied to the surface of the cylinder walls. It is much thinner than its predecessor, and therefore cannot be repaired! The manufacturer has not provided repair capabilities and does not provide repair kits. Installed on some BMW models and others.

“Dry liners” and SILUMAL are quite repairable, that is, if your compression has dropped due to wear from high mileage, then you can easily remove 0.5 - 1 mm, install a repair piston group and continue riding. ALSO, for some SILUMAL variants, manufacturers produce ORIGINAL aluminum sleeves; they are needed when the bore is more than 1mm. True, their cost simply goes off scale, up to 200 EUROS per one, but there is an exceptional ratio of metals and the possibility of complete restoration (also in some cases you can buy one piece for one cylinder). The only EXCEPTION can be that the block wall is very badly damaged, to a depth greater than repair boring is possible. However, such blocks may not be saved by anything; fatal damage may occur, for example, the piston has turned.

NICASIL – it is virtually impossible to restore! That is, as the manufacturer assures, this is actually a disposable motor. As I wrote above, he does not have spare parts approved by the manufacturer. But in the country we live in, there are a lot of companies that make sleeves specifically for Nicasil, and cast iron with a small wall (2 - 3 mm), there are also craftsmen who can combine this whole thing! However, you need to remember about thermal expansion and various metals. Most likely, Uncle Vasya will not be able to do it efficiently in the garage. However, prices for new units, if you take top-end BMWs, can reach up to 5000 - 7000 EURO, force you to look for such masters.

Sleeves as a method of repair

And in cast iron and aluminum blocks, there is such a thing as “Sleeve”, that is, special sleeves are installed - these are cylindrical (usually cast iron) hollow parts similar to a large piece of pipe.

They are pressed into the engine block under temperature and sit firmly in place. The main purpose is to make the motor stronger (in the case of the aluminum version), make the structure maintainable, and increase its service life. The sleeves can be made of high-strength alloy gray cast iron, as well as regular ones (it is worth noting that there are options with thin steel sleeves; this also exists, for example, ISUZU machines), there are also aluminum options, but they are not so common.

The big advantage is that when the liner wears out, it seems to take the entire blow upon itself. You simply pull it out (grind it out), install a repair one, or even one of the same size. Change the pistons and rings (most likely, repairs will be needed). And the engine runs normally again.

However, there are engines that are not “lined” from factories, both aluminum and cast iron. If we can bore a cast-iron block, and also “sleeve” it with a version of gray cast iron - install larger pistons (or the same ones) and roll on - because there is no difference in the thermal expansion of the metal. But aluminum, due to its complex manufacturing technology, is often not subject to this. A fair question arises - is it possible to put cartridges in it?

Aluminum and cast iron

Before telling you about the process itself, it’s worth mentioning that there are different materials for making blocks. These are cast iron (it appeared first) and aluminum. I will have a separate article about them, but today I will simply tell you which ones can be SHARPENED AND WHICH NOT!

Cast iron is an almost ideal option, cheap, reliable, durable. They last for a long time, and often give in to grooving. We remove the required size, install new repair pistons, and the engine is back in service. However, they also have significant disadvantages - weight (it is three times heavier than aluminum), heat dissipation (more passages and channels are needed to effectively cool it), and corrosion (the walls can rust from prolonged inactivity).

Aluminum is lightweight, has the best heat dissipation, and is not subject to corrosion. A big plus is its weight; now many manufacturers are chasing to reduce the weight of their cars; the aluminum version gives them greater savings, and therefore lower fuel consumption of the car. BUT this metal is soft and short-lived compared to cast iron. For better wear resistance, the inner walls are coated with a special coating with a high silicon content. THEN and only then can the motors operate for a sufficiently long time.

THAT'S WHY aluminum motors are often not sharpened; many craftsmen call them disposable! Because the durable top layer in the cylinders cannot be removed