The crankshafts of most engines are made by stamping from steel 45, 40Х, 50Т. Some engines have shafts made from high-strength magnesium cast iron. The main defects of crankshafts are wear of the main and connecting rod journals and shaft bending. Less common are damage to threads, cracks, wear of keyways, holes for flywheel mounting bolts, seats for gears and pulleys, and oil drain threads.

Crankshaft restoration

Basic operations:

- Washing

- Troubleshooting

- Grinding

- Polishing

If a part exceeds repair dimensions, the crankshaft journals and seats can be restored using activated arc metallization technology.

Before repair, the crankshaft is washed in a washing machine and the plugs are opened. The cavities for centrifugal oil cleaning and oil channels are washed especially thoroughly.

The crankshaft is rejected if there are cracks, with the exception of small longitudinal cracks on the main and connecting rod journals up to 3 mm long.

If the main and connecting rod journals are worn beyond the last repair size, diesel crankshafts are also rejected.

The need to restore the crankshaft and replace the bearings is determined by exceeding the permissible clearances in the bearings.

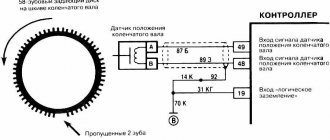

Using a magnetic flaw detector, check for cracks on the shaft journals.

Shaft bending is eliminated by special straightening using local peening.

Worn seats for a gear or pulley are restored by surfacing in a carbon dioxide environment using Sv-18KhGSA wire, followed by processing to the nominal size.

Worn keyways and holes for pins for installing the flywheel are welded semi-automatically in a carbon dioxide environment using Sv-08G2S wire.

The keyway is milled in the same place so as not to disturb the installation of the timing gears. The welded holes, after cleaning the end surface on a lathe, are drilled, countersinked and reamed on a drilling machine.

The most common way to restore the main and connecting rod journals of crankshafts is to grind them to the repair dimensions established for each engine brand. Before grinding the journals, all other shaft defects must be eliminated. The journals are measured in two sections at a distance of 10 mm from the cheeks and in two planes: in the plane of the crank and perpendicular to it.

For grinding crankshaft journals, a universal grinding machine is used, which can be used to grind both main and connecting rod journals, or specialized machines. All journals are ground to the same repair size.

First, the main journals are ground, and then the connecting rods. When grinding the main journals, the mounting bases are taken to be the chamfer of the hole for the ratchet and the chamfer or hole in the end of the shaft for the bearing. These databases are first checked and corrected if necessary.

To check, the crankshaft is installed in the centers and its runout is measured on unworn surfaces. The radial runout of the gear journal and flywheel flange should not exceed 0.03 and 0.05 mm, respectively.

When grinding connecting rod journals, the mounting bases are taken to be the journal under the gear and the outer cylindrical surface of the flywheel flange or the ground outer main journals.

Before grinding, the holes in the oil channels are countersinked on a drilling machine or electric drill with a specially equipped abrasive tool or a drill with a diameter of 14-16 mm with carbide plates.

When grinding the connecting rod journals, the crankshaft is installed in three-jaw chucks of the front and tailstock center shifters. With the help of centrifuges, the axis of the main journals is shifted relative to the axis of the quills of the front and rear stock by the amount of the crank radius. The angular orientation of the shaft is carried out by an indicator device along the grinded neck. A steady rest is used to absorb the force created when cutting into the neck of an abrasive wheel and to prevent shaft deflection.

The crankshaft journals are ground with electrocorundum wheels on a ceramic bond with a grain size of 16-60, hardness CM2, CI, ST1 and ST2. Grinding mode: peripheral speed of the grinding wheel - 25-35 m/s; peripheral speed of the shaft - 18-25 m/min (when grinding main journals) and 7-12 m/min (when grinding connecting rod journals), transverse wheel feed - 0.003-0.006 mm/rev, longitudinal feed - 7-11 mm/rev . In order to prevent the formation of microcracks during grinding, abundant cooling is used.

To obtain a surface roughness Ra of 0.16-0.32 microns, after grinding the journals are polished with GOI paste No. 20-30.

The crankshaft journals of automobile engines, which are beyond repair dimensions, are restored using activated arc metallization technology.

Restored crankshafts are subjected to dynamic balancing.

After grinding and polishing the journals, the crankshafts and oil channels are thoroughly washed and blown with compressed air.

When inspecting restored shafts, the dimensions are checked, the taper, ovality, barrel and saddle shape of all journals are determined using a bracket adjusted according to the end gauges. The relative position of the main and connecting rod journals, the runout of the middle main journals, the flange surfaces under the flywheel, the runout of the surfaces under the pulley and gear, the displacement of the axes of the connecting rod journals relative to the common plane passing through the first main and first connecting rod journals, as well as the radius of the crank are determined by control devices. Surface roughness is determined from roughness samples.

Why is crankshaft grinding necessary?

The need to grind the crankshaft journals arises from their gradual wear, from which the main and connecting rod journals become oval and their diameter becomes slightly smaller, as well as the liners. As a result, the clearances in the plain bearings increase and the oil pressure drops below the required norm. Also, oil pressure drops due to wear of the camshaft and its beds. It should be noted that a drop in oil pressure can also be caused by wear of the oil pump, or wear of the pressure reducing valve interface, and this should be taken into account and the faults in them should be eliminated first before disassembling the engine and removing the crankshaft for grinding. In addition to a drop in oil pressure, wear of the journals and liners also causes knocking and shock loads during engine operation, since the gaps between the worn journals and liners are increased more than normal (the clearance standards will be described below). Typically, the knock of connecting rod bearings is sharper than the knock of the main bearings, and it is heard at idle speed of the engine with a sharp supply of gas. It’s easy to determine which connecting rod bearing is knocking if you turn off the spark plugs (or injectors on a diesel engine) one by one. The knock of the crankshaft main bearings is usually dull and metallic. It also shows up when the gas is applied suddenly at idle. The frequency of knocking increases with increasing crankshaft speed. Excessive axial clearance of the crankshaft causes a sharper knock at uneven intervals, which is especially noticeable when the engine speed gradually increases (or decreases). Of course, you can’t drive with a worn-out (knocking) crankshaft, and if knocking noises appear or if the oil pressure drops (or during a scheduled engine overhaul), the crankshaft should be repaired by grinding and selecting new bearings, which will be described below.

Seizure of crankshaft journals

As a rule, the appearance of scoring on the surface of the crankshaft journals is influenced by the poor condition of the engine lubrication system. A large number of different factors appear here: low quality motor oil, failure to replace it on time, slagging of the oil filter, low pressure in the system. Seizures also form due to problems with cooling the power unit or a violation of its temperature regime, because too high temperatures contribute to the dilution of the oil. Worn piston rings allow fuel particles or combustion products to enter the oil, which also changes its structure. In this case, it is necessary to grind the crankshaft and replace the bearings. You should check the lubrication system, the cooling system, and the engine power supply system, replace the filters, check the oil channels and change the piston rings as necessary. In this case, it will be most financially profitable to carry out a complete overhaul of the power unit instead of performing a large list of work.

Our advantages

Result guarantee

Low prices

Tremendous experience

Operation speed

POLISHING CRANKSHAFT JOINTS

for work₽50,000

- for domestic

POLISHING CRANKSHAFT JOINTS

for work₽20,000

- for imported

CRANKSHAFT STRAIGHTENING DEFLECTION UP TO 0.4mm/more than 0.4mm (without guarantee)

for work₽66000

- for imported

- for imported

CRANKSHAFT STRAIGHTENING DEFLECTION UP TO 0.4mm/more than 0.4mm (without guarantee)

for work₽110000

- for imported

- non-parallel planes

RESTORATION OF OIL KRULLING

for work₽75,000

- for domestic

MACHINING FOR THRUST RINGS

for work₽50,000

- for domestic

GRINDING THE SURFACE UNDER THE SEAL

for work₽25,000

- for domestic

REPLACING PLUGS AND CLEANING THE SHAFT

for work contractual ORDER

REPLACING THE BEARING

for work contractual ORDER

Advantages of crankshaft boring

During operation, the crankshaft is subjected to heavy loads, which leads to the occurrence of a variety of defects. A constant decrease in the level of cleanliness and the formation of irregularities on the surface lead to a deterioration in the performance of the system. The only way to get rid of them is by boring. In addition to the fact that you do not have to buy a completely new crankshaft, the advantages of this procedure include the following:

- Ensures perfect cleanliness of work surfaces. The use of special solutions and tools allows you to rid the part of foreign deposits.

- Correction of defects (barrel shape) that arise due to uneven forces during operation of mechanisms. This leads to gaps in the mating parts.

- The ovality of the journals, which is formed due to the one-sided force from the connecting rod and is a side effect of the design feature of the crankshaft, is eliminated. Ovality occurs after a long operating period.

- The diameter of the necks is restored. The reduction in the diameter of the journals occurs unevenly and depends on the operating mode of the cylinders.

general information

The crankshaft is the main mechanism of the crank group of an internal combustion engine. Designed to convert translational motion into rotational motion. This is realized using complex part geometry. During operation of the internal combustion engine, the entire crank mechanism (hereinafter referred to as the crankshaft mechanism) experiences significant loads. These are inertial loads and gas pressure as a result of combustion of the fuel-air mixture in the cylinders. In total, the loads are not constant, but variable.

In this regard, special requirements are put forward for the manufacture of the crankshaft. It must be resistant to temperature and wear. But any part that is under load for a long time may require repair. In this case, it is boring and grinding crankshafts. Let's take a closer look at what this procedure is and how it is performed.

Let's sum it up

We have already figured out a little about how crankshaft grinding is carried out. Reviews about these works are not always unambiguous. Some people, thanks to the highly qualified craftsman, are extremely satisfied with the quality and timing of the work. But not all specialists treat their work conscientiously, and it is difficult for a simple motorist to visually understand whether all stages were completed correctly and whether the desired result was achieved. In any case, it is necessary to take a responsible approach to choosing a service where repairs will be carried out. Today there are a huge number of thematic forums where owners of a certain brand of car gather. There you can find out where and how well certain types of work are performed at a particular service station.

Crankshaft grinding process itself

Of course, to grind necks you need a special cylindrical grinding machine, which is available in specialized workshops. There is no point in describing the technology for grinding crankshaft journals, since the process itself is more clear in the video below. Before grinding, the most important thing is to align the crankshaft correctly by tapping it and checking it with an indicator. PRICE

I would like to dwell in more detail on the question of how much high-quality crankshaft grinding will cost. The price varies greatly depending on the make of the car and the installed engine. The more cylinders, the more you have to pay. The domestic VAZ is the cheapest to repair, but V8 engines are extremely expensive. Prices for grinding alone can vary from 2,000 rubles to 15,000, and in some cases even higher.

Crankshaft repair in prices

CRANKSHAFT GRINDING (3-4 cylinders)

for work₽240,000

- for domestic

CRANKSHAFT GRINDING (3-4 cylinders)

for work₽300,000

- for imported

CRANKSHAFT GRINDING (5-6 cylinders)

for work₽380,000

- for imported

CRANKSHAFT GRINDING (8 cylinders)

for work₽420,000

- for imported

ORDER

Grinding of connecting rod (or main) journals only from the price.

Grinding of crankshafts with narrow (less than 20 mm) journals, grinding with fillets +50% to the cost of the work.