Valve lapping is considered a simple technological operation of fitting the valve face chamfer to the seat. This process is relevant when repairing an old valve. Grinding is also carried out when updating the valve. During the procedure, a special paste or sandpaper with oil is applied to the valve chamfer. The whole process occurs with the help of the oscillatory movement of the knob. In parallel, the whole process continues until the gray color of the valve chamfer and seat is obtained. In a car service center, a special machine is used for the procedure, which processes 3-5 products at once. You can also perform grinding yourself without contacting specialists.

What is lapping and why do you need to lap valves?

Valve lapping is basically grinding along the surface of the valves (which allow fuel and air to flow freely) and where they meet each other. This is done by applying a special paste to the edges of the valves. The result is a perfect seal that will prevent gases from escaping while the engine is in use.

An internal combustion engine works by achieving a certain compression ratio, which differs between models, and burning an air-fuel mixture, which is compressed to a certain volume, set by the compression ratio. And if the air-fuel mixture leaks through the seat, the volume of the air-fuel mixture will change and the combustion process will not be accurate, resulting in poor engine performance.

Benefits of the procedure:

- Creates maximum seal between valve and head, which will prevent gases from escaping while the engine is running.

- The large contact area ensures heat dissipation from the valves to the head, which will prevent the valves from burning.

As a result, the entire process will lead to thinner surfaces, the elimination of minor defects, and the creation of a more reliable seal.

Machine for grinding valve chamfer PT 823 - Community "Garage Equipment and Tools" on DRIVE2

We will continue to fill garages, workshops and other premises for car repairs and modifications! A friend gave me a machine for grinding the chamfers of car cylinder head valves.

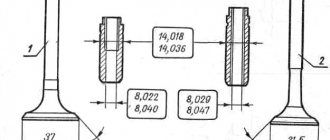

Of course, the device is very old and not complete, everything will have to be restored and completed, its model is PT-823, produced by the Evpatoria Repair Plant back in 1972. The data that we were able to find on the Internet from the plate on it: The largest grindable diameter of the valve plate, mm - 80, diameter of ground valve stems, mm. – from 7 to 16, chamfer cone, deg. – 30, 45, 60, 90, grinding wheel size, mm: diameter – 75-100; width – 10-15; hole diameter – 14, number of grinding wheel revolutions per minute – 6500, number of collet chuck revolutions per minute – 160, electric motor power, kW – 0.6.***********But there is no information on engine speed and the dimensions of the engine pulleys and spindle, the model of the collet chuck is also not known so that the collets themselves of different sizes can be ordered somewhere - because there are none of them. But I hope that I’ll find something similar somewhere else so I can take measurements and get other more detailed information! And if you don’t find anything, you’ll have to calculate from the initial data and select the engine and pulley sizes. The collet chuck may also have to be purchased with a set of collets for different valve stem diameters. So if anyone has just such a machine in an accessible place, please share the missing information.

And a couple of these photos were found online: www.chipmaker.ru/uploads/…00%201402248973_thumb.jpgwww.chipmaker.ru/uploads/…00%201402247945_thumb.jpg

Create interesting posts, invite friends, share with subscribers about our community! Thank you for your attention !

Under a layer of paint, a plate with the model and year of manufacture has been preserved.

What is needed for grinding in

All lapping tools work the same way. This means that the tool is attached to the valve head, lapping compound is applied to the valve seat or surface, and the tool is rotated in different directions to ensure a firm hold.

The procedure will also require:

- kerosene;

- lapping paste;

- a spring, along the outer diameter, which passes directly into the valve seats.

Valve grinding tools

There are certain tools for grinding valves. They will be discussed below.

So, the devices that are used for grinding valves with your own hands:

- Dry cloth . Necessary for wiping treated surfaces.

- Solvent . A special product that provides high-quality cleaning of work surfaces.

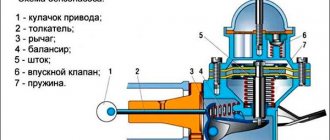

- Hose and spring . The springs must have a sufficiently reduced stiffness. Their diameter is 2 or 3 millimeters, slightly larger than the diameter of the valve stem. It can be placed on a rod. You can also use a small clamp to secure it securely. You also need a short metal rod with a diameter similar to the piston rod so that it fits comfortably into the rubber hose.

- Kerosene . Used in all lapping procedures.

It is also necessary to check the grinding in thoroughly after the procedure. It is very important to carry out the procedure very efficiently.

Why are hands bad?

The disadvantage of such processing is quality, which significantly affects reliability. Usually, after this type of treatment, the engine travels 10-20,000 km, and then it needs to be repaired again. But even during this mileage the engine will operate unstably; gas breakthrough is inevitable. This is due to the fact that it is impossible to correctly center the valve relative to the seat during lapping. Therefore, if you have the opportunity to process a part using professional equipment, you should not look for freebies and do mechanical processing “on your knees”, do not forget - “Krailovo leads to padalovo” (c).

Valve lapping tools

The main tools for lapping valves include:

- Manual valve holder . One of the most frequently used tools. Often the holder comes complete with a special paste for grinding valves. You can also buy this tool separately at any auto parts store.

- Drill or electric screwdriver . Considering that this procedure is always performed in two directions of rotation, many prefer to use a drill. A drill that rotates in two directions at once and provides more efficient grinding. Also, for these purposes, some people choose an electric screwdriver. Its operating principle is very similar to a drill.

- Lapping paste for valves. You can buy a ready-made composition in automobile workshops. If you have some knowledge and skills, then save money and you can do it yourself.

Valve disc grinding machine — logbook Ford Sierra 1984 on DRIVE2

I don’t trust anyone, so I decided to edit the valve plates myself.

I bought a suitable bracket and bearings from the store. A start.

At the market I bought a motor from a Soviet video recorder to drive the valve rotation.

I attached the motor to the back. I used a piece of inner tube from a bicycle as a belt.

The belt presses the valve well against the rollers.

Test of valve rotation from the built-in motor -

Using a metal plate, I built a valve movement limiter.

Using another metal plate, I pressed the valve from above.

Now the valve has nowhere to go. Just rotate.

I organized the valve grinding itself in two ways.

The first method is a drill with a grinding attachment. The advantage is adjustable rotation speed. Since the revolutions of the drill almost completely coincide with the revolutions of the valve drive motor, I chose this option as the final one.

The second option is an electric sharpener. The advantage is noiselessness, the ability to spin it from a rotating valve without connecting to a 220 V network.

The electric sharpener was specially tilted slightly in order to grind at a slight angle to the plane of rotation of the valve.

Here is the result. There is no longer a deep groove.

View of the valve after finer grinding.

The grinding works well.

And this is an experimental valve with a large chamfer roughness after grinding.

In any case, nothing will work without editing the stone. I spent a lot of time solving this problem. This tool saved me. Simple and reliable. I didn’t even believe that it would work.

Valve lapping methods

This procedure can be completed quite successfully without visiting a workshop, but it does require some mechanical skills.

Manual grinding method

For maintenance purposes, valve grinding is considered a mandatory procedure. Most modern engines do not require valve lapping because they are made of aluminum, and if engine parts are damaged, the risk of valve replacement is higher. However, on the VAZ 2109 this is a necessary procedure.

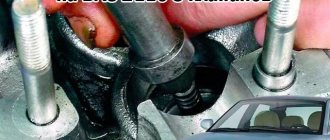

So, what does lapping valves on a VAZ 2109 look like:

- You need to remove the valves from the head. They always start by removing the valves from the head. It is recommended to take advantage of this and remove any carbon deposits using a brass wire brush. Whether regrinding will be necessary depends on the condition of the head, but in this case new valves will be installed and slammed shut to create a perfect seal. Valve lapper kits may include special tools for lapping valves, and there are also options with four suction cups for different valve sizes.

- Then you need to carefully insert the valve. You should ensure that the valve is as clean as possible before applying a small amount of sanding paste to its surface. You need to insert this valve into the port it belongs to and press the appropriate suction cup onto the valve head - a little water or grease will do a good job of holding it in place.

- Identify changes in tone. Now you just need to turn the valve, rubbing it between your hands, and listen for the change in tone from the loud grinding sound. When the tone changes, you will need to lift the valve and again spread the paste over the face of the valve.

- You should continue to do this until the surface of the valve is uniformly bright and shiny with no signs of dull spots. It is important to thoroughly clean each valve and head and then reinstall the valve.

- Ready! This is all that is required to grind the valves yourself.

Grinding in valves with a drill

Using a drill for lapping is a great solution to save time and effort.

- You need to take a pre-prepared metal rod.

- A rubber hose of the same diameter should be placed on the rod. It is recommended to use a clamp for this.

- You need to fix it to a metal rod in the socket or to an electric screwdriver.

- Place the spring on the valve stem and install it on the seat.

- It is necessary to remove the valve from the cylinder head and carefully distribute the lapping paste over the entire surface of its plate.

- Insert the valve stem into the rubber hose and, if necessary, use a clamp of the same diameter for better fastening.

- Use the drill at low speed and grind the valve by moving the drill back and forth. As a result, the installed spring will be especially effective. After this, you need to turn the drill in the opposite direction until a matte surface appears on the valve body.

- After grinding in, it is necessary to wipe the valve from residual paste, preferably with a solvent. It is necessary to remove the paste not only from the valve plate, but also from its seat. There is no need to change valves, because grinding is performed for each valve individually.

How to properly lap valves using a pneumatic tool using the rotary method

Another way to lap the valve is to use a pneumatic tool. Such tools work well in removing fuel and oil contaminants. When performing this procedure, be sure to spray cleaner only into the probe tip and the holes on the sides. You can use duct tape to cover the ends of the connectors and prevent them from spraying. To use the tool, you must be connected to a source of compressed air. You need to place a suction cup of suitable size on the pin, which will then be installed on the valve plate. This is the easiest method for cleaning as it provides good results in a short period of time.

How to grind valves on a 16 valve engine using a pneumatic machine using the tapping method

Do-it-yourself valve lapping can be prone to errors. This is why it is recommended to use an air machine that will do this automatically. Do-it-yourself valve grinding is possible using a pneumatic machine. In this case, the valve will not be cleaned by rotating movements, but only by tapping. This method resembles real engine operation.

So, this is what the whole process looks like step by step:

- You need to place one of the suction cups on the rod of the device (included in the kit).

- The suction cup must be securely attached to the valve plate.

- Using the wheel you can control the operation of the tool.

- The tool has a wheel to control the speed.

- Grinding occurs through constant repetition of reciprocating movements.

This method does not require any special skills. If you have no experience, you can learn during the grinding process. In addition, this method fully guarantees high efficiency and safety. When using this machine, you don’t have to worry about the risks of damaging parts or getting hurt yourself.

By repeating the operation of the valve, the engine achieves the most precise grinding possible.

Grinding in new valves

Valve lapping is considered an integral part of engine rebuilding and must be performed even when new valves are installed to match the valve head. Accordingly, new valves may also be subject to grinding.

Is it necessary to grind the valves on a new cylinder head?

The selection of valves for a new cylinder head must be treated with special attention. You should supply quality options and not save on their purchase. In this case, you will not need to do anything. However, some still prefer to carry out grinding, but in this case it is not necessary.

Do-it-yourself valve lapping video

Below are videos with which you can perform valve grinding yourself without the help of specialists.

Solving the problem of valve burnout

If a fairly accurate diagnosis can be performed without removing the cylinder head, then repair will require replacement, which is impossible without partial disassembly of the power unit.

So, what to do if a valve burns out, but the engine stalls in all modes and refuses to work?

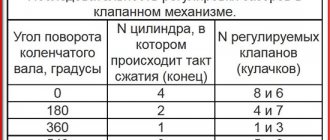

Disassembly of the gas distribution mechanism may vary depending on the vehicle model, but in general the dismantling/assembly process is approximately the same. First, we will need to disconnect the negative terminal from the battery, the tubes and hoses supplying technical fluids to the power unit, dismantle the attachments (the carburetor can be touched in this case), and unscrew the spark plugs. After this, you can begin to remove the GB cover by unscrewing the corresponding mounting bolts.

Subsequently, the procedure is carried out in the following sequence:

- the drive belt is removed;

- the pulley is dismantled;

- the bolts holding the camshaft housing are unscrewed;

- the cover is dismantled along with the seals;

- The camshaft itself is removed from the cylinder head.

The valves are desiccated either using a special tool, or, in the absence of one, using the old proven method. Its essence is as follows:

- in order not to lose the cracker, place a rag or a small rubber mat under the hole;

- We place a tube with a diameter smaller than that of the washer on the end of the rod;

- We make a sharp and powerful blow with a hammer on the plate to completely compress the spring, which will cause the crackers to fall out.

Without experience, such a method can result in such troubles as a bent valve stem, so it is better for beginners to get a desiccant - it is relatively inexpensive. As a last resort, you can simply borrow the tool.

How to check valve lapping

If there are defects in the valve seals and seats, the air-fuel mixture can enter the combustion chambers. This will result in reduced engine performance. Therefore, special attention should be paid to carrying out a detailed check of the perfect lapping of the valves.

During valve lapping, it is important to observe the valve seat area. This will help you understand whether further lapping of the valve is required. After the valve grinding process, the most common test method is the gasoline method. After completing the work, you need to place the valve in the exact location in the cylinder head and pour gasoline into the valve stem. Then there is a gasoline leak. If gasoline flows through the valve seat, then we can conclude that the work was not successful. If gasoline does not flow through the valve seat, then we can say that the procedure was performed correctly.

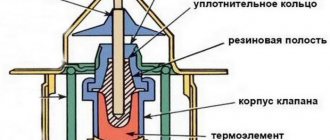

Checking valve tightness after lapping using an EGR valve

The check requires that when the engine is idling, the valve is disconnected from the hose through which the vacuum (vacuum) flows. If you have a vacuum pump, you can connect it to the valve opening. Due to this, a vacuum will be created. If there are malfunctions and problems, the engine will “suffocate” and the speed will drop sharply.

Compressor test

To ensure that the valves have been properly ground in, it is recommended to use the compressor test method. This is the fastest way. You need to measure the compression, pour about 20g of oil into the spark plug compartment and take the measurement. If the compressor performance has increased, then everything is fine with the valves.

Valve chamfer grinding machine PT 823 — Community “Garage Equipment and Tools” on DRIVE2

We will continue to fill garages, workshops and other premises for car repairs and modifications! A friend gave me a machine for grinding the chamfers of car cylinder head valves. Of course, the device is very old and not complete, everything will have to be restored and completed, its model is PT-823, produced by the Evpatoria Repair Plant back in 1972. The data that we were able to find on the Internet from the plate on it: The largest grindable diameter of the valve plate, mm - 80, diameter of ground valve stems, mm. – from 7 to 16, chamfer cone, deg. – 30, 45, 60, 90, grinding wheel size, mm: diameter – 75-100; width – 10-15; hole diameter – 14, number of grinding wheel revolutions per minute – 6500, number of collet chuck revolutions per minute – 160, electric motor power, kW – 0.6.***********But there is no information on engine speed and the sizes of the engine pulleys and spindle, the model of the collet chuck is also not known so that the collets themselves of different sizes can be ordered somewhere - because there are none of them. But I hope that I’ll find the same one somewhere so I can take measurements and get other more detailed information! And if you don’t find anything, you’ll have to calculate from the initial data and select the engine and pulley sizes. The collet chuck may also have to be purchased with a set of collets for different valve stem diameters.

What does a ground valve look like?

Valve lapping refers to the procedure to ensure proper seating for the intake and exhaust valves in the engine cylinders. Often this procedure is performed after a major engine overhaul or in case of valve renewal. The valves ensure maximum tightness in the combustion chamber, thereby guaranteeing the normal functioning of the engine and its technical characteristics, and also guaranteeing a high level of compression and efficient operation of the engine. After grinding in, there should be absolutely no lines left on the valve, and the surface should be painted over evenly and neatly. If any defects are noticed, it is recommended to carry out the grinding again.

Finally, valve lapping is one means of improving the efficiency of a car engine. As the engine improves its performance, it will improve fuel efficiency. Fuel combustion will be greatly improved.

Ashico-Racing › Blog › Grinding valves

Grinding of valves on a KWIK-WAY machine, machine model SVS SERIES II DELUXE for high-quality repair of engine valves.

difference between a ground valve and a non-polished one

Comments 14

Hi, we also have such a machine at work, only from a different company. Why are you milling the intake and exhaust planes?

So, I’ve worn more than one valve in my life, I don’t need to tell you any fairy tales