Sometimes car owners are faced with a situation when the cooling system fan turns on and starts working when the engine is cold. Although, under normal operating conditions of this element, it must be activated only when the temperature of the internal combustion engine reaches certain values.

There are many reasons why this situation occurs on modern cars. Some of them can lead to serious negative consequences if measures are not taken in time to eliminate the causes and provoking factors.

To understand the situation, you need to find out the reasons for turning on the fan, understand its operation and find the best methods to solve the problem.

Diagnostics

Before trying to determine why cooling system fans may turn on when the engine is cold in cars, it is recommended that you understand the operation of this unit.

The fan is turned on due to the operation of a special sensor, which activates the rotation of the blades. This controller is located at the bottom of the cooling radiator.

There are some modern cars where the engine control unit is responsible for starting, although this is rather a rarity and the exception and the rule.

When the cooling liquid (coolant) reaches the required temperature, which is usually in the range of 100-105 degrees Celsius, the sensor closes the electrical circuit, and this allows the fan to turn on. It starts blowing on the radiator. This achieves a better cooling effect, since the air and liquid systems are combined.

At the same time, there are situations when the engine is still absolutely cold, it does not require any additional cooling, but the fan still turns on. This is not a normal condition. It is necessary to look for the reason for this behavior of the cooling system and eliminate any malfunctions that have arisen.

If you continue to ignore the constantly running fan, the initially simple discomfort will give way to more serious problems. But here it is important to note that the constant operation of the blades is not as dangerous as a complete failure of the device. Although this fact is absolutely not a reason to do nothing.

It all starts with diagnosis. The simplest and most convenient in this regard are injection engines. To detect a malfunction, it is enough to conduct computer diagnostics. This is done both in a car service center and in the garage with your own hands.

Connecting to an electronic control unit makes it possible to obtain error codes that are not difficult to decipher and understand the true reasons for this behavior of the cooling system fan.

There are situations when the ECU detects a malfunction in the cooling system and causes the fan to spin constantly, even when the engine is cold. This is a kind of protective function aimed at preventing possible overheating of the internal combustion engine. Therefore, when errors are detected and after troubleshooting, a reset is required. To erase errors, you should look at the owner's manual for your car. On some cars, it is enough to remove the terminal from the battery, and the errors will be erased. On other cars, errors are erased using connected diagnostic equipment.

If the option of computer diagnostics does not suit you or it cannot be used for one reason or another, you will have to use the method of elimination to check all potential sources of trouble.

How everything works

The boiling point of antifreeze fluctuates around 130-140 degrees Celsius. Whereas normal engine operation is accompanied by a temperature of 85-100 degrees. At this indicator, the coolant circulates, taking some of the heat from the engine. Thus, preventing it from increasing the temperature.

With the help of a pump, the liquid passes through the system, moving to the radiator to cool. Then the circle repeats. If you turn off the engine, the fluid will stop moving and cooling, as a result of which its temperature will increase

.

But it is worth saying that the engine is capable of heating antifreeze only during its operation. That is, the liquid cannot heat up from the motor more than it is after it is turned off. Temperature readings will drop as the engine cools. This means you shouldn’t be afraid to turn off the engine.

with the radiator fan running.

If the liquid boils after turning off the engine

, which means it

was already overheated

. Therefore, it is worth checking for problems such as: lack of antifreeze, damage to the cooling system or improper fluid circulation (large and small circle).

Common faults

Since the fan is spinning, it needs to be forced to stop and turn on only when there is a real need for it.

There are several main reasons why cooling system fans may turn on when the engine is cold. This is related to:

- switch on sensor;

- coolant;

- mass;

- thermostat;

- temperature sensor;

- contacts;

- air conditioning.

Each of the points may be the reason why the fan turns on and starts rotating when the engine is cold.

Power sensor

One of the most common reasons why a fan runs on a cold engine is a short circuit in the controller, that is, the sensor.

Quite often it happens that the fan starts when the ignition is turned on. If this occurs at the same time, the contacts on the controller have probably shorted. As a result, the airflow works constantly.

Main types of radiator cooling fans

Today there are only two types of fans:

- Mechanical;

- electronic.

Mechanical (works when the crankshaft rotates). To maintain the integrity of the device and blades at high speeds, the fan impeller is connected to the pulley via a hydromechanical drive.

When the crankshaft rotation speed increases, the clutch performs light braking to prevent damage to the device. Although earlier the first models of vases did not have such a device.

Electronic. With the development of technology, electronic drives began to be in demand. It consists of two main components - a control system and an electric motor. The use of electronics made it possible to ensure uniform cooling of the power unit and eliminate the risk of damage to the fan.

Checking and replacing the Kalina cooling fan resistor

Removing the additional fan resistor is done as follows:

- put the car on the “handbrake”;

- open the hood;

- remove the ground wire from the battery;

- remove the engine splash guard;

- unscrew and remove the engine crankcase protection (if installed);

- press the block latch and unplug the electric fan power supply wiring harness;

- Using a Phillips screwdriver, unscrew the two screws holding the additional resistor;

- move aside the resistor mounting bracket together with the block;

- pull out the resistor.

Checking the resistor consists of two stages:

- visual inspection of the integrity of the spiral;

- checking the resistor winding for open circuit using an ohmmeter.

If a winding malfunction is detected, the resistor must be replaced with a new one. If the thermal fuse is faulty, then all you can do is replace it. To do this, you will need a soldering iron to remove the burnt fuse and solder a new one in its place. All that remains is to put the parts in their original places. Installation of the Kalina cooling fan resistor is carried out strictly in the reverse order of removal.

Without maintaining normal temperature conditions, it is impossible to imagine the operation of an internal combustion engine, which is why automakers pay special attention to ODS. The Lada Kalina uses liquid cooling

It is more complex than air and consists of more elements. One of them is the cooling system fan. If it does not work or does not work correctly, it will not be possible to effectively cool the engine.

Lack of fluid in the unit

The sensor partially fails with the smallest amount of liquid. Even in the presence of antifreeze, the sensor immediately warms up. This process can disrupt the entire function of the system and cause many problems. Such a malfunction is characterized by a banal oversight.

With careful monitoring, you can get rid of serious problems and breakdowns. To do this, you need to check the amount of liquid. Since during evaporation there is no liquid in the radiator

If there is a small amount of liquid, the temperature reaches the unit temperature. For example, if you start the engine, it will not be completely heated, but the fan will immediately cool down. This process occurs due to the fact that the liquid heats up very quickly in the unit. Problems can be resolved in the simplest way. By adding a little antifreeze, you can avoid air locks in the system.

Tuning VAZ → XX rises after Carlson's work

I found an explanation of this problem on the Internet, but I still don’t understand where these wires need to be cut off and which ones, because... The article doesn’t say this, maybe someone has encountered this and can suggest something.

——————————VAZ-2115 with ECU VS-5.1 (V5V13L05). Complaint about a jump in idle speed when the engine is fully warmed up. The defect was reproduced by me in a workshop. The following happens: while the warm-up is in progress and there has not been a single turn on of the fan, the throttle valve position (THR) obediently stands at zero and returns to zero after repeated throttle changes of varying depths. After turning the fan on, the throttle is still at zero, but after turning the fan OFF it jumps by 1 or 2 percent. With a steady unit in the throttle, the return after throttling sets the THR to 2% or 3% with the idle raised to 2400 rpm. Nothing helps other than turning off the engine and starting it again. As soon as the fan turns on and off for the first time, the speed jump will repeat. One more detail - if the fan turns on when the idle is stuck (2% - 3% in the throttle), then the THR drops to 0% and the idle drops to normal. As soon as the fan turns off, the idle rises to the previous 1200-2400 rpm and the throttle is again 2-3 percent open. Of course, the throttle in all these observations is physically completely closed. The PDZ sensor was changed by the client and by me, I also changed the ECU - it’s not their fault. It was also noticed that when the fan is turned on, the temperature readings in the MT jump up by several degrees. Suspicions of a poor sensor mass are confirmed by measuring the mass of the TPS relative to the mass of the engine. When the fan is not running, the potential difference is zero, but turning on the fan results in an excess of the TPS mass by 0.08 volts according to the digital voltmeter. I removed, scraped, and tightened the brown masses of the ECU on the block, compressed all the branching masses in the interior bundle - no effect. I would be surprised if it did - all the connections that I cleaned and crimped were in perfect condition. I connect the TPS ground and the engine ground with an additional wire - there is no effect. Desperate to achieve equality of the masses COMING FROM THE SAME POINT (cylinder block), I cut off the mass of the fan from the mass of the ECU (yes, the mass is supplied to the fan from the crimping of large brown wires in the ECU bundle) and put it directly on the body - victory! All the glitches with a jump in THR and speed are gone, and the temperature readings also stopped jumping when the fan is turned on. I wonder what idiot thought of designing the wiring in such a way, where the mass of the power consumer (fan) is physically combined with the mass of the electronics, where the count is in hundredths of a volt! (https://www.autodevice.ru/praktica4.htm) collapse thread

what do not you understand ? I think everything is clearly and clearly described. There are masses. on 5.1-61 they are two brown wires that hang on the cylinder head studs on the side where the thermostat is.

I won’t go into the assignments, but in general terms, one wire supplies ground to the sensors, one goes to the brains. This is what the article says about this.

In short, read it several times and you will understand everything yourself. + find the mass diagram.

Personally, I advise you to check whether these brown wires are on different bolts or on one. must be on different ones. clean them again.

materials on the topic https://chiptuner.ru/content/ground/https://chiptuner.ru/content/ground2/https://chiptuner.ru/content/pub_05/

The diagrams are here somewhere. search and you will find https://chiptuner.ru/content/docs/ collapse thread

Dmitry https://atomic-dm.ru Thank you Kudryavtsev, with your explanation it became more clear!

Dmitrius “Bad” boy ツ Kozhemyakin if I put the mass of the fan on the body, the fan will always rotate, even when the car is turned off. After all, plus it goes from the battery to collapse the branch

Source

The main reasons why the radiator cooling fan does not work

Let's look at the main options and places to look for faults:

- Thermostat.

Thermostat removed from Lada Kalina

If it fails, this is the reason why the cooling fan does not work properly. To diagnose this malfunction, you should touch the lower pipe. If it is cold, then the thermostat is dead. Many Kalina car owners are accustomed to this phenomenon, since it often breaks down, and they carry a spare one with them. If it's not the thermostat, then the next step is the fuses. You need to make sure that they are working and all controllers too. The easiest way is to test them using a tester or ohmmeter. The fuse diagram is here.

Relay and fuse box

If the fuse is alive, then you will have to remove the additional fan control unit. To do this, it is worth moving the warm air duct and using a 10 mm wrench to unscrew the fastenings of the unit. Now you can get it freely. It has two relays that are responsible for turning on the fan and for high speeds. Let's diagnose both.

The fan comes on when the engine starts on the Priora

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

There are several options here.

(If you are absolutely sure that the Temperature Sensor and relay you replaced are working.)

An error was once entered into the controller, which it no longer displays, but simply turns on Carlson. But as far as I remember, usually the Carlson does not turn off and keeps pounding even for some time after the ignition is turned off.

In general, it still looks like a low-quality, sticky relay.

ALL errors on the controller are erased by disconnecting the battery. but that's not the point. I went to the diagnostics, there was only one error (invalid value of the temp sensor), but after replacing it with a new one, the situation continues. I changed the relay myself, although I’m not 100% sure that I changed the right thing.. there were three of them.. on the market they said the one opposite the fan fuse

In the description of any sensor error, there is a continuation, read in the injection primer: like “The sensor or its circuit is faulty”

So, in your case, most likely the chain, i.e. either the wires, and the wires to the DTOZH are always taut, or the wires are sealed in the connector. And a break in the DTOZh circuit, with the ignition on, will definitely cause the fan to turn on. Turn on the ignition and move it, swing the wires to the sensor.

The wires to the sensor were moving, nothing was wrong... the contacts were good, and I changed the relay correctly. k7. What other wires can be moved and where?

Not a single relay in the switching unit is responsible for injection. The fan relay is one of three under the center console next to the ECU, the fuse is there. And you can move at least the entire injection harness. There have been miracles with wires breaking in the harness itself. Once even in the passage through the motor wall. But usually at the connectors of both the sensor and the ECU.

Yes, there was one ten with the spontaneous inclusion of Carlson. I fucked with her for two evenings. Only the scanner helped. It turned out that there was a short in the harness along the command circuit for requesting to turn on the air conditioner (which was not there, but there was wiring to it in the harness), and a request to turn on the air conditioner causes the radiator fan to turn on. Since the owner of the car had no plans to install an air conditioner, he simply cut off the air conditioning request wires right at the ECU connector.

Source

water pump

In many cases, the reason for the increase in coolant temperature in the radiator is poor operation of the water pump. In this case, the antifreeze moves slowly through the system and heats up too much. Once it gets into the radiator, it does not have time to cool down to normal temperature, and goes around the next circle, heating up even more. If the pump at least works, then this problem is expressed only by the constant operation of the fan. If the pump fails completely, then the car will “boil” in a matter of minutes. This is an extremely dangerous condition that almost always leaves consequences in the form of engine problems.

Usually the water pump does not suddenly fail. First, it gives signals about its malfunction. The first warning sign is an increase in the frequency of operation of the radiator fan. The main cause of failure is destruction and jamming of the bearing. Therefore, a manifestation of a breakdown may be a howling noise from under the hood or a knocking sound that is clearly audible when idling. Often a knocking sound from the pump is mistaken for a camshaft fault. The breakdown is eliminated by replacing the pump; in some models it is possible to replace only the front part of the pump along with the bearing.

Troubleshooting

To more accurately determine the malfunction, it is first recommended to carry out a full diagnosis. If you don’t have the time or money to take your car to a service station, we recommend using a personal ODBII scanner. In our case, it will be a Korean-made model Scan Tool Pro Black Edition

.

This scanner operates on a 32-bit chip (analogues in the budget segment have an 8-bit controller) and is assembled only from high-quality components, thanks to which it is capable of diagnosing not only the engine, but also other components of the car.

In most cases, the main cause of high speed will be a dirty air filter, a malfunction of the throttle position sensor, idle speed sensor or mass air flow sensor. In addition to detecting errors for more detailed diagnostics, Scan Tool Pro is able to monitor the performance of all available sensors in real time, which will help you quickly determine the exact cause of the malfunction.

Air filter

The first thing you should check when you notice high engine speeds at idle in a VAZ 2114 is the air filter. When it becomes dirty, it begins to pass air poorly, as a result of which the working mixture entering the engine becomes over-enriched and causes an increase in speed. To get rid of this problem, simply replace the filter with a new one.

Air filter VAZ 2114

Throttle position sensor

If this does not help, then you should move on to checking the sensors, namely the throttle position sensor, since it most often fails. To do this, you need to measure the voltage at its contacts at idle speed (the voltage value should be close to zero).

Throttle position sensor VAZ-2114

If it turns out that voltage close to normal in the on-board network constantly passes through the sensor, it means that acidification has occurred in it, and cleaning should be performed.

To do this you need:

- Disconnect the wires from the sensor terminals.

- Unscrew the pair of mounting screws holding its body.

- Fill the internal cavity with WD-40 or a similar penetrating lubricant.

- Turn the sensor wheel using a screwdriver or thin blade.

- Reinstall the device.

Idle speed sensor

If the reason was precisely the gas sensor, then the idle speed should immediately return to normal. If this does not happen, then you should proceed to cleaning the idle speed sensor (since it also often oxidizes and fails).

Idle speed sensor VAZ 2114

This operation is performed as follows:

- Disconnect the wiring and dismantle the device by unscrewing the mounting screws (the sensor itself is located not far from the throttle valve, opposite its cable).

- Connect the wires to the device and turn on the ignition. If the moving needle of the sensor moves slightly inside the housing, then it is working; if not, the sensor is soured and requires cleaning.

- Wipe the entire surface of the sensor with WD-40 or purified gasoline, removing all traces of oxides, oil and other contaminants.

- Mount the sensor in place, start the engine and check its operation.

If after cleaning it turns out that the speed is still too high and the sensor does not work normally, then it should be replaced with a new one of a similar model.

Mass air flow sensor

In the case when all the previous operations did not help, and the VAZ 2114 still has high idle speeds, you should check the mass air flow sensor.

This is quite simple to do - you just need to disconnect the wires coming to it, then start the car and drive it for some distance at a crankshaft speed of more than 2,000 per minute. If at the same time it “feels” like the car has begun to behave more dynamically than a car with a connected sensor, then the cause of the malfunction will become more than obvious.

DMRV VAZ 2114

To eliminate it, you will need to dismantle the sensor and replace it with a new one, since, unlike previous sensors, this one is practically irreparable.

It is replaced like this:

- Disconnect the wires leading to the contacts of the air flow sensor.

- Loosen the hose clamp on the inlet pipe.

- Remove the hose from the pipe.

- Remove the damaged sensor.

- Install a new device by performing all operations in reverse order.

To check the effectiveness of the repair, just start the engine and look at the idle speed - if they return to normal, then the problem is solved.

Design and principle of operation of the fan

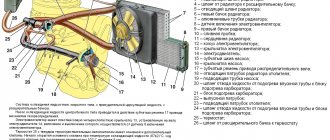

Before you move on to repairing the fan, you should understand the principle of its installation on the cooling system. To do this, it is better to use the following simple diagram, on which the following main parts are indicated by numbers:

- — cooling radiator.

- - cork.

- - electric fan motor.

- - protective casing.

- - fan impeller.

- — damper pillows.

- - coolant drain plug.

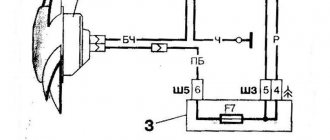

In addition, a diagram of the electrical equipment of the cooling system, which looks like this, will also be very helpful in repairs:

As you can see, the start of the cooling fan is controlled by a relay, which starts after receiving a signal from the temperature sensor.

Once the liquid in the radiator reaches a certain temperature, the temperature sensor closes and thus triggers the fan to start.

Once the temperature of the liquid in the radiator drops below a certain point, the sensor will open and the fan will automatically turn off. But, as already mentioned, sometimes this does not always happen.