A fuel pressure regulator is necessary to maintain fuel pressure in the machine system, specifically for injectors, when the engine switches to different operating modes. It regulates changing loads on the engine; when the pressure in the intake pipe increases, the regulator increases the fuel pressure; when the pressure in the intake pipe decreases, it weakens the fuel pressure. Moreover, the regulator valve, opening slightly, sends its excess into the tank.

Fuel pressure regulator VAZ 2114

A LITTLE ABOUT THE OPERATION OF THE FUEL SENSOR

The latest developments by the designers of the automobile plant in Togliatti have brought the produced models closer to the best European models, but annoying, minor breakdowns can add “a fly in the ointment.” These fully include problems with the gasoline level sensor in the car tank.

It is located in the same block as the fuel pump. It includes a movable lever with a float, a resistor and a contact group, which turns on the signal lamp for the gasoline reserve in the tank. Among the most common malfunctions of this unit, the most common are problems such as resistor breakage, oxidation of the moving contact or output terminals. It is very rare that the float in the fuel level indicator loses its seal.

In any case, to repair or service this unit, it must be removed from the fuel tank. To perform this work, remove the rear seat cushion and upholstery that blocks access to the gas tank cap. When performing this operation, do not forget that you are working with a flammable substance. Fire safety rules must be strictly followed.

Unscrew all the screws securing the cover, move it slightly forward and remove it from the fuel tank. Before removing the fuel block, it is necessary to relieve the pressure in the fuel line. There are several ways to do this, and the simplest of them is to leave the car idle for about 4 hours.

Disconnect the wires and fuel line from the module, being careful not to spill any remaining gasoline in the hoses. You need to pull out the fuel pump carefully so as not to damage the float. Replacement of the fuel sensor is carried out using a screwdriver with a thin blade.

How does this happen:

- Use a screwdriver to move the locking ring and make it possible to remove the cover from the fuel module;

- Remove all the wires, release the latches on the cover and remove the sensor itself along the grooves;

- The next step is to remove the meter from the block.

To install a new fuel sensor, everything must be done in reverse order.

conclusions

The fuel system check valve is an important component of this system, the failure of which can cause a lot of problems for the driver. This will be especially painful during movement. Therefore, it is worth using only high-quality fuel, and at the slightest sign of a malfunction, which were listed above, diagnosing the fuel system.

After all, the problem may lie not only in the valve, but also in other small parts. Diagnostics at a service station almost always reveals such faults, so do not forget about timely maintenance of the car, even if everything seems to be in good order. Good luck and easy travels!

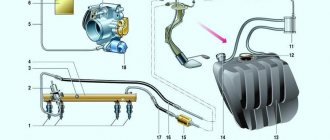

If you look at the fuel system of a modern car, you can state the fact that it is a complex mechanism that requires qualified care and maintenance. This system includes:

- Fuel reserve tank;

- Fuel sensor VAZ 2114;

- Fuel pump;

- Gasoline fine filter;

- Pipeline system for gasoline supply;

- Ramp with nozzles;

- Fuel pressure control.

HOW THE REGULATOR WORKS

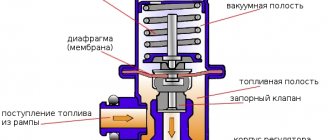

The fuel pressure regulator, or RDT VAZ for short, is a device in the form of a valve with a diaphragm. Its installation location is in the fuel supply rail (fuel rail). The membrane is “pressed” from both sides. On one side the pressure of gasoline presses, and on the other side a spring with air from the intake manifold “rests”.

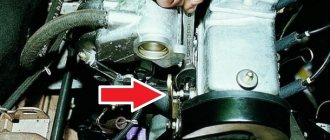

Location of the RTD in the fuel rail

If the valve completely fails, dumping fuel back into the tank becomes impossible. The pressure of gasoline increases approximately twice, and this leads to increased consumption.

When the valve stops holding pressure, there will be free circulation of gasoline in the system, and this is a clear decrease in the operating fuel pressure. This will cause a loss of engine power.

How does the RTD work and where is it located?

There are two variants of RTD - mechanical and electrical type.

The former are designed as relief valves (vacuum type), allowing excess fuel to flow back at high pressure. The second option is a pressure sensor that transmits information to the control unit. Today, in a car, the pressure regulator is located in one of two locations:

- Fuel rail. The unit is connected to the inlet and outlet lines. The first supplies gasoline/diesel from the tank, the second drains excess fuel - in this way low pressure is obtained in the fuel rail.

- In the tank on the pump module. The fuel, having established compression, enters the engine without the use of an additional hose. Gasoline/diesel fuel, with this arrangement, discharged into the tank does not heat up.

- Cases. It is made of metal. Durable and airtight. This prevents fuel leakage and pressure loss.

- Membranes. At high pressure, it slightly opens the fuel line to drain the fuel.

- Check valve. It is located at the input of the device.

- Springs. It presses on the valve diaphragm.

- Fittings. Fuel inlet and outlet lines are secured.

- Sealing elements. Responsible for tightness.

On a note! The mechanical regulator works due to the pressure difference. In a number of systems, instead of an RTD, a solenoid valve controlled by the engine ECU is used.

A mechanical RTD is a valve on which pressure from different sides is exerted by fuel and a spring. If the speed is low, the valve opens, allowing fuel to drain into the tank. Then the pump turns on, pumping fuel through the filter.

OPERATIONAL CHECK

Let's briefly look at the question of how to check the fuel pressure regulator of a VAZ 2114. This fully applies to the VAZ 2113 and VAZ 2115 models. On carburetor engines, the gasoline supply could be checked by disconnecting the fuel hose from the carburetor to see the stream of gasoline supplied. On injection engines this technique is no longer acceptable. The VAZ 2114 fuel pressure regulator is checked by measuring the pressure of the supplied gasoline with a pressure gauge.

Let's look at how to check the fuel pressure regulator yourself in some detail:

- The plug on the fitting is unscrewed, and at the same time the ring that serves as a seal is checked for elasticity;

- The spool valve is unscrewed from the fitting in much the same way as from a tire;

- The pressure gauge is secured to the fitting with a clamp and the generated gasoline pressure is checked in different modes.

Gasoline pressure indicators are marked on the RTD body for comparison with the results obtained during testing. If the readings differ from the recommended ones, the VAZ fuel pressure regulator must be replaced.

DIY diagnostics

Without testing, an accurate diagnosis cannot be made. So let's look at how to do it correctly. In the case of VAZ 2114 cars and similar models, it is wiser to use the simplest diagnostics - using a mechanical pressure gauge. The order is as follows:

- Unscrew the plug located on the fitting. Pay attention to the elasticity of the O-ring.

- Unscrew the spool in the same way as from the wheel chambers.

- Attach the pressure gauge using a suitable clamp to the fuel rail fitting and take measurements in various engine operating modes.

Immediately before checking the pressure control mechanism, inspect it carefully. There are marks on it showing normal pressure values for several operating modes of the VAZ 2114 internal combustion engine. If the measured values differ greatly from the reference values, the pressure regulator must be replaced with a new one.

ABOUT REPLACING RTD

Replacing the VAZ 2114 fuel pressure regulator is carried out with the engine cooled down and the pressure in the fuel system removed. Let's look at how to remove the fuel pressure regulator.

To do this you need:

- Disconnect the battery terminals;

- Remove the brake booster hose;

- Unscrew the nuts on the gasoline drain pipe. In this case, you must carefully unscrew the nut and hold the hose. There may be gasoline left in the system ;

- It is necessary to securely fasten the washer and tube;

- After unscrewing the bolt installed on the clamping bar, remove it;

- You should slightly loosen the nut holding the regulator and drain tube;

- Remove the screws that connect the RTD and the ramp;

- Remove the nut with care and you can remove the RTD with the ramp.

The new regulator is installed on the fuel rail in the reverse order.

The operation of replacing the regulator will not pose any particular problems for experienced car enthusiasts, but if there is even the slightest doubt about your competence, it is better to turn to specialists.

Pressure regulators today do not belong to the category of particularly scarce spare parts. You can purchase them in retail chains, car markets, and service centers. The cost of the regulator can range from 500 to 700 rubles.

What you need to check the pressure in the system

In order to verify the serviceability (malfunction) of the RTD, as well as the entire fuel system, it is necessary to determine the value of the fuel pressure. Naturally, you will need a special tool for this.

It's called a fuel pressure gauge. It is better if it has a mechanical design and a scale of up to 10 kg/cm2. In addition to the fuel pressure gauge, you will need:

- a piece of high pressure hose (internal diameter 8-10 mm);

- several clamps corresponding to the diameter of the hose;

- pliers;

- screwdriver;

- nipple cap;

- fuel collection container;

- dry clean rag.

Purpose of the regulator

A device such as the VAZ 2114 fuel pressure regulator is designed to maintain the same level and, if necessary, correct the gasoline pressure in the system. Structurally, it is a mechanism of a membrane and a valve located inside the fuel rail (also known as the fuel supply rail). On one side, the pressure of gasoline presses on the regulator membrane, and on the other, a spring.

If the fuel pressure in the system is too high, the valve opens and excess gasoline is dumped back into the gas tank, after which the pressure returns to normal.

If the turbocharger becomes jammed, releasing gasoline (and with it excess pressure) becomes impossible. As a result, the total pressure in the fuel system increases by 2 or more times, which entails severe excess fuel consumption.

In a situation where the valve completely stops holding the fuel pressure, there is a constant discharge of gasoline and its free circulation through the system. This, in turn, leads to a sharp drop in pressure and, as a consequence, a strong drop in engine power. For the same reason, starting the engine (especially after a long stay) becomes difficult; you have to spin the starter for a long time before the engine starts.

As you can see from the above, a jammed or, conversely, weakened pressure regulator valve cannot lead to anything good. That is why, at the first sign of a malfunction, the entire device should be replaced. We’ll talk about how to do this correctly below, but first let’s say a few words about checking the device yourself.

Causes of malfunctions

There are not many reasons why the fuel regulator fails. The element cannot be called ultra-reliable; it works, as they say, under wear and tear, and is very dependent on the quality of the fuel.

- Marriage. This is not a common reason, but sometimes you come across defective products from domestic automakers. It is recommended to check the spare part before purchasing.

- Wear. Usually observed after 100-200 thousand kilometers. In the regulator, the membrane becomes less elastic, the pressure control valve gets stuck, and the spring becomes weaker.

- Bad fuel. Gasoline and diesel car engine fuel often contains too much moisture, debris, and foreign toxins. Water in fuel causes rusting of the metal parts of the regulator. Increasing over time, they interfere with its normal functioning and lead to weakening of the spring.

- The fuel filter is clogged. Garbage fractions in the fuel clog the system, including the RTD, and become clogged. This leads to spring wear and valve jamming.

Checking the pressure regulator

You can check the performance of the VAZ 2114 RDT using a pressure gauge. It should be connected between the fitting and the gas hose, having first disconnected the vacuum hose.

Connect in the following order:

- Unscrew the fitting plug.

- Unscrew the spool from the inner cavity of the fitting.

- Connect the pressure gauge hose to the fitting.

- Secure the hose with a clamp.

It is important to note that before checking the functionality of the regulator, all fuel system hoses should be inspected for damage. Even if there are small holes or cracks, the pressure measurements will be incorrect.

Measurements are performed in four different modes, in which the pressure should be equal to:

- immediately after turning on the ignition - 3 atm or a little more;

- at idle - about 2.5 atm;

- with the fuel pressure pipe removed from the regulator - 3.3 atm;

- with the return flow hose completely pinched - about 7 atm.

If the measurement results correspond to the values given above, then the regulator is working; if not, it will have to be replaced.

It is worth noting that the main reasons leading to regulator failure are either a very long downtime of the car or low quality gasoline.

If you don’t have a pressure gauge at hand, you can determine the failure of the device by a number of indirect signs, namely:

- difficulty starting the engine;

- Unstable engine operation at low and idle speeds. “Podgazovka” practically does not add power;

- sudden jumps in speed, most often at idle;

- jerking of the car while driving, unstable behavior on the road;

- loss of acceleration and speed jumps after changing gears;

- a strong increase in fuel consumption;

- traces of fuel, leaks on the fuel system hoses (however, replacing hoses and clamps does not give the desired result).

All these signs, especially if they manifest themselves in complex ways, are a direct indication for replacing the pressure regulator.

Pressure measurement modes

Before checking the pressure in the fuel rail, it is a good idea to find out how this process is carried out. To be able to more accurately determine a possible malfunction, pressure measurements must be carried out in several modes:

- with the ignition on (without starting the power unit);

- with the engine running at idle speed;

- with the vacuum hose disconnected from the regulator (to check the operation of the RTD);

- with a blocked fuel return hose;

- in overdrive mode.

Replacing the device

In order to replace the VAZ 2114 fuel pressure sensor with a new one, you need to turn off the car’s engine and wait until it cools completely (replacing it while the engine is hot or, especially, running is strictly prohibited).

After the engine has cooled down, drain the fuel from the system and perform the following steps:

- Disconnect the negative terminal from the battery.

- Remove the vacuum brake booster hose.

- Unscrew the nuts on the gasoline drain pipe, supporting the hose with your hand.

- Connect the washer to the tube using a rubber ring.

- Unscrew the screw securing the clamping bar.

- Remove the clamping bar.

- Slightly unscrew the nut holding the drain tube and pressure regulator.

- Remove the screws securing the regulator to the fuel rail.

- Unscrew the fastening nut and remove the regulator from the fuel rail.

The new regulator should be installed in exactly the same order, but in reverse order. To replace a failed sensor, you should purchase a device of exactly the same model (the price of the regulators is not so high and is about 500 rubles). You can buy a new sensor at almost any auto store.

The most common device malfunctions

One of the possible symptoms was discussed above - constant “idle” operation of the electric pump. In this case, the VAZ 2114 fuel pressure sensor is, of course, completely faulty, and further operation of the vehicle is not possible. But in case of minor defects, the following symptoms will appear:

- Increased gasoline consumption.

- Engine stops, unstable idle.

- A noticeable decrease in the vehicle's traction characteristics.

- Difficulty starting the engine.

As a rule, if the fuel pressure sensor on a VAZ 2114 car fails, gasoline does not flow into the return line. Consequently, excess fuel remains in the rail and the pressure is pumped up to the maximum value. But a reverse breakdown can also occur - when the fixation disappears and the pump constantly pumps gasoline in a circle, while the pressure in the ramp decreases. And at idle speed, the engine’s performance can be more or less satisfactory, but when it increases, it begins to choke, it lacks “food”.

Fuel pressure control

So I started to get sick of the fact that the car starts 3 times in the morning. Many people said “kill it.” But it would be nice if -20 was overboard, and even then, people are launching... In general, I re-read all possible forums, watched a bunch of videos. I compared the readings of the outside temperature sensor and the DTOZH, they were the same. DMRV. his numbers are normal...

Based on what I had read and, again, my observations, I was leaning towards a pump or RTD. I didn’t have a pressure gauge, so I went to a man over the weekend and he measured it for me - 3.7 (system without return). When the gas was on, it jumped a little more than 4. As he said, it’s not ideal, but the pump is alive and the pressure supposedly holds after the engine is stopped. (I didn’t see it myself, because I was sitting inside the car; by the time I got out, he had already removed the pressure gauge). Naturally, no one has measured how long it lasts. I was told to "start with the temperature sensor". However, this topic with RTD still haunted me.

On Monday I picked up a new RTD from the store. His appearance, of course, confused me. Made in rank yet. It cost 400 rubles and is designed for 400 kpa. I came home, removed the pump, installed the RTD, and put it back. I turn the key and the car refuses to start. I go to the ramp, press the spool - it’s empty. What the hell. It was late and there was nothing left to do but return the old RTD to its place. I didn’t want to walk to work in the morning, and I still have to return the part. I saw some dirt on the mesh of the old RTD, so I sprayed it with carb cleaner and installed it. Started up. And it seemed to me that the speed was kept as even as ever.

On Tuesday morning it started with half a stick. She didn't go deaf. I was delighted. I went to work. At lunchtime I returned the purchased RDT. It's Wednesday. And again in the morning, immediately after the first start, the engine stalled. Second try - the same thing. 3 times is fine. After work I bought this fucking pressure gauge and decided to let it be. And I immediately took the RDT. It’s 380 and looks like a Russian one))) I connected a pressure gauge (I still have an old RTD). I turn on the ignition, the arrow also jumped to 3.7 and immediately quickly went to 0. What the hell.

I understand that my theory about the malfunction of the RTD was justified. I installed a new one. I'm measuring again. It got pumped up even closer to 4. When wound up, it was also a little more than 4 and the needle didn’t jerk as much as with the old one. However, after stopping, the pressure also went to 0, but it dropped slowly. And as I suspect, it was the pressure gauge itself that was lowering through the outlet; a little gasoline flowed from it.

That's how it is with the old RTD. I didn’t record it with the new one.

Old RTD

I'll look at her behavior tomorrow.

New RTD

Replace with a new one or not

If the malfunction concerns a mechanical part, the motorist has two ways to solve the problem. The first is purchasing a repair kit. It includes all the necessary parts that may break in the pump. The second is replacing the entire element with a new one. This is a more accurate and reliable method. But it is worth considering that submersible pumps are very expensive. Among the manufacturers on the market there are both originals and analogues.

Experts advise buying pumps and Masuma. The productivity of these elements is 130 liters per hour. This is quite enough for both cars, minibuses and frame SUVs. The price is around two and a half thousand rubles. Also, when replacing the pump, a new fuel filter is installed. Among the good producers o

When replacing the filter, pay attention to the arrow. It indicates the direction of the fuel

If they are mixed up, all the dirt from the tank will flow to the injectors.

Replacing the fuel pressure regulator on a VAZ 2114

On cars, a fuel pressure regulator is necessary to maintain the required level of fuel pressure inside the fuel system. This directly affects the injectors when switching the power unit to different operating modes. The regulator allows you to control and change the load on the motor.

So, when the pressure in the intake pipe increases, the regulator increases the fuel pressure. If the pressure in the pipe drops, then the device reduces the pressure accordingly. To get rid of excess fuel, the valve on the device opens slightly, from where gasoline flows back into the gas tank of your VAZ 2114.

Some useful tips

To ensure that the fuel pressure regulator does not cause you trouble and works as long as possible, use these tips.

- When planning to replace an RTD, buy only a branded device recommended by the manufacturer.

- Fill your car tank with only high-quality fuel. Do not use fuel additives of unknown origin.

- Do not forget to promptly replace the fuel filter.

- At each maintenance check the fuel pressure in the system. If problems are identified, correct them promptly.

- If you find problems with the regulator, do not delay replacing it.

Perhaps all motorists have heard about such a small part as the VAZ 2114 pressure regulator, but few know that if it fails, big problems can happen. In today's article we will analyze the purpose, operating principle and repair rules of this regulator.

Signs of breakdown

The car itself often informs the driver that problems have arisen in a particular system. Therefore, the main task of the car owner is to learn to recognize these signs. Thus, determining the cause of the breakdown and eliminating it becomes a matter of technology.

Regulator problems

Signs of a malfunctioning fuel pressure regulator include:

- Fuel consumption increases;

- When idling, the engine suddenly stops;

- While driving, there is a significant decrease in engine power;

- It is possible to start the engine with a certain effort.

Valve problems

Loosening the nut

- If the valve of this device fails, excess fuel will not be able to pour back into the gas tank, causing the pressure in the fuel system to increase to higher values. The norm is 2.5 kg/cm2. As a result, the amount of gasoline entering the combustion chamber will increase, which is why it will not be able to burn completely.

- If the valve stops holding back the pressure, fuel will move freely throughout the entire fuel system, which will result in a drop in pressure. By increasing the speed, you simply won’t have enough fuel to accelerate. Engine power will drop noticeably. When the car stops, the pressure is maintained if the valve is working properly. But since it cannot withstand the pressure, in order to start the engine again, you will have to turn the starter for a long time in order to achieve the required level of pressure.

Preparatory work

- We take a pre-prepared pressure gauge, and to prevent fuel spills and air leakage, we wrap flax or fum tape around the tip.

- We are preparing a hose with a maximum internal diameter of 9 millimeters, and clamps will be needed to secure them.

- We place the prepared rags on the engine in such a way that the hose and pressure gauge fixed on it cannot roll off the surface. This is done to prevent excess fuel from spilling over the surface of the engine.

- We wrap flax or tape around the pressure gauge, then fix the hose on it and tighten everything with a clamp.

- On the ramp, unscrew the spool valve from the nipple (in this case, fuel splashes are possible due to the presence of residual pressure - approx.).

A regular wheel cap came in handy.

Pressure gauge with pipe assembly.

We place the pressure gauge on a previously prepared rag, and the preparatory work can be considered completed.

Measurement procedure

Before you start working, you can try to relieve the pressure in the fuel system. To do this, remove the fuel pump fuse (which is located on the right side of the panel, under the front passenger’s left foot - approx.). Where 3 relays and 3 fuses are located. In the photo below it is located under the number “5”. After removing the fuse, turn on the ignition and check by ear that the fuel pump is not pumping. We start the car and wait for the engine to stall.

- After everything is ready, we check the already attached end of the pressure gauge with the hose for a secure connection.

- Next, start the engine and look at the readings that appear.

Thus, we diagnose the results that appear and compare them with the results of the norm.

After all the work has been done, unscrew the hose with the pressure gauge, screw in the spool and return everything to its original state.

Note!

The peculiarity of measuring pressure using a pressure gauge is such that its initial value on the scale has a certain inaccuracy. That is, when the air analogue has a measurement period of 15-20 atmospheres, and for fuel control the required maximum value is 5-7 atmospheres, then all measurements taken will have an error equal to the initial values on the device. Therefore, pressure testing should be carried out on a pressure gauge with maximum values of up to 8 atmospheres.

We measure the pressure in the system without a check valve

If it happens that your engine does not have a check valve, then you need to know that in such a ramp there is a constant pressure of 3.6 to 4.0 atmospheres. But the order of measurements in general is completely similar to what is described above.

Source

Checking the head pressure

To determine if your fuel pressure regulator is faulty, it will have to be thoroughly checked. If you have experience, this work can be easily done with your own hands. If you don’t have the skills, it’s better to go to a service station.

The quality and efficiency of the regulator can be determined independently using a pressure gauge. You will use it to measure the pressure in the system.

Diagnostics is performed in three modes. Before starting the inspection, be sure to make sure that there is no damage in the fuel line and that fuel is not leaking anywhere. If there is damage to the line, checking the pressure pressure will not give an objective result.

After checking the line and making sure that it is solid and has no defects, proceed to measurements in four modes.

| Diagnostic mode | Standard pressure indicator |

| Check when ignition is turned on | 2.5 Atm |

| Idle check | 3 atm |

| Checking with the tube removed from the regulator | 3.3 Atm |

| Checking if the return flow tube is pinched | 7 atm |

You will need to connect a pressure gauge to the gap between the fitting and the fuel hose, disconnecting the vacuum hose.

By pressing the gas pedal, the parameter will first rise to 3 Atm, but then drop to the normal 2.5 Atm. But this is only provided that the device that regulates the fuel pressure in the system works well and has no malfunctions.

If the pressure does not begin to increase during the check, replace the vacuum hose and take repeated measurements with it. If there are no changes in measurements, this indicates a malfunction of the regulator. There is no point in repairing it. It’s easier to immediately replace the device with a new one, and one of the highest quality and reliability.

For reference. Almost all valves indicate optimal readings. Compare the obtained measurement data with them when checking.

What is a check valve

The check valve in the fuel system should only allow fuel to flow in one direction. This is the main purpose of OKDT. When the fuel pump is not working, the device automatically closes the return fuel line to prevent unused fuel from flowing into the tank.

When the valves are working properly, the pressure in the main pipes does not drop for a long time after the engine stops. The small part is calibrated. The design consists of several elements:

- housing with outputs;

- ball-type valve with a seat made of soft metal;

- membrane;

- spring.

Improving the starting characteristics of the internal combustion engine is the main function of the exhaust valve. A working part installed in a certain location in the fuel line maintains the optimal value of the residual pressure.

It is not difficult to understand how a valve installed on a ramp works:

- When the fuel injection pump is running, OKDT does not interfere with the movement of fuel in the forward direction.

- When the fuel pump turns off (when the engine stops), a reverse flow of working fluid occurs in the line.

- The reverse flow of fuel creates pressure, which closes the valve.

- The fuel remains in the line, creating residual pressure.

The operation of the entire fuel system of the vehicle depends on the small device. If there is no residual pressure in the line, it must be created every time the engine is started. The driver is forced to spend extra time cranking the starter.

How to find your device

There are models in which the valve is mounted in the fuel rail housing. A common installation location is the section of the fuel line located between the injectors and the tank.

There are vehicles in which the part is mounted directly into the fuel pump housing. In modern cars equipped with a fuel preheating system, the OKDT housing is located before the preheater. The installation location depends on the make of the machine:

Source

Why does the device fail?

Fuel pipe

The regulator stops working normally mainly for two reasons.

- Low-grade fuel is used, which contains a large amount of water.

- The car sits idle for a long time, is not used and does not start even for the purpose of prevention.

Design Features

The gasoline pressure regulator is one of the few elements of the system that is not controlled from an electronic unit. This unit is completely mechanical and its operation is based on pressure differences. Although in systems without recirculation, the sensor is triggered by the ECU. Since they do not occur often, we will not consider such nodes further.

It is worth noting that the RTD does not operate in strictly specified values, it adapts to the operating mode of the engine. That is, if necessary, it increases or decreases the pressure in the system to ensure optimal mixture formation.

Structurally, this element is very simple and consists of a housing on which fittings and leads are located for connection to the power system. Inside, this housing is divided by a membrane into two chambers - fuel and vacuum.

There are outlets suitable for the fuel cavity - one is used to supply fuel to the chamber, and the second leads to the line for draining gasoline into the tank (return). But the second channel is closed by a valve, which is connected to the membrane.

A spring is installed on the side of the vacuum cavity, which acts on the membrane, ensuring that the drain channel is closed by the valve. This chamber is connected to the intake manifold by means of a fitting via a tube.

Troubleshooting

To find problems, we suggest you use the appropriate methods.

- Pump fuel into the system, turn off the ignition and monitor the behavior of the pressure gauge. In a normal situation, the pressure drops to 0.7 Bar and stops at this level. If the regulator fails, the pressure gauge will tend to zero. The problem may lie in the device itself, or in the fuel pump motor valve.

- Increase the engine speed to 3 thousand and again look at the pressure gauge readings. If the arrow points down, the fuel pump is broken. It needs to be replaced.

- If the pump takes a long time to build up pressure, the problem lies in the filter or mesh of the tank, which is clogged with debris.

Which way to go

There are two options for eliminating the problem. Take the car to a service station and wait for the repairs to be completed. In this case, you need to shell out a certain amount of money, it’s a pity.

Having knowledge and understanding of the car’s structure, you can carry out repairs yourself. Saving money in person. However, there is a possibility of stepping on a pitfall. Can't deal with the problem.

Then you will have to shell out additional money for repairs in a specialized center, how do you like this prospect? In any case, the decision is yours to make.

Experts recommend not to reinvent the wheel, but to give the car to professionals who will replace it quickly, with a guarantee of quality.

Decide what is more important to you: savings or stable operation of the power unit, good luck to everyone!

Return problem. Where is the check valve, 8 valve, 1.5 engine injector located? Is it in the gasoline pump itself or not??

1.6 8kl. Where is the check valve located? Is it the RTD or on the fuel pump motor itself?

Now 2nd gear won't hold

by Adminrive · Published 03/26/2015

New at a very good price

by Adminrive · Published 04/11/2017

Replacement

Replacement process

By following the instructions step by step, you can independently remove and install a new fuel pressure regulator without any problems.

- Work on dismantling the device can only be carried out if the engine is cold. If you just drove into the garage, give the car some time to cool down.

- When the engine is running, high pressure remains inside the system, so it must be reduced before work.

- Disconnect the negative terminal from the battery to avoid electric shock and damage to the wiring.

- Remove the vacuum hose.

- Unscrew the nuts on the drain pipe and gradually reduce the fuel pressure level in this way. Be sure to hold the hose fitting with one hand.

- The tube and the washer are connected to each other by a regular rubber ring.

- The screw that holds the clamping bar is unscrewed.

- Now this very bar can be put aside for a while.

- Slightly unscrew the fixing nut that holds the drain tube and the regulator itself.

- Remove the fastening screws of the regulator holding it to the ramp.

- Carefully remove the nut, which will ultimately allow you to remove the object we are looking for.

- Install the new device by following the reverse dismantling sequence.

Be sure to check the fuel pressure in the injectors with the engine off, ignition on and the electric fuel pump on. During normal operation of the device, the pressure should be about 300 kPa. If the level you checked is below normal, this can lead to disruption of the functionality of the entire engine power system. Therefore, be careful, do the work step by step, and do not forget about the importance of each stage of repair.

Replacing the fuel pressure regulating device yourself is not difficult. Just keep in mind that for optimal engine operation after replacement, you will need to not only follow the sequence of work and do everything as competently as possible, but also use a new, high-quality device as a replacement. The regulator is not expensive, so such repairs will not entail significant costs for your VAZ 2114.

Installing a new sensor

Before removing, be sure to relieve the fuel pressure in the rail. To do this, turn off the power to the fuel pump and start the engine. Or carefully unscrew the spool valve from the fitting in the ramp (this option will be more suitable if the internal combustion engine does not start at all). Then you work according to this scheme:

- Disconnect the negative terminal from the battery.

- Disconnect the hose from the VAZ 2114 vacuum pump.

- Unscrew the nuts and drain the gasoline. Please note that there may still be pressurized gasoline in the fuel system. Therefore, take precautions.

- Fix the tube and washer.

- Unscrew the bolt screwed into the clamping element.

- Remove the clamping element.

- Unscrew the nut that holds the drain hose and pressure sensor.

- Remove the bolts connecting the fuel rail to the pressure sensor.

- Dismantle the pressure regulator in the system.

How to change the fuel pressure regulator on a VAZ 2114

Withdrawal procedure

- The first step is to relieve the fuel pressure in the fuel line.

- Then remove the air supply hose to the throttle valve.

- Using a screwdriver, unscrew the screw securing the pressure plate and remove it.

- Disconnect the hose from the fuel pressure regulator.

- Using a 24mm wrench, unscrew the nut of the fuel drain pipe.

- Using a 5 mm hex wrench, unscrew the 2 bolts securing the regulator to the fuel rail.

- Remove the pressure regulator.

- Before installing the regulator, check the condition of the O-rings at the connections. Damaged rings need to be replaced.

- Lubricate the O-rings with oil and install the pressure regulator in place.

Lada 2114 › Logbook › Let's move on. RDT. ECU.

Continued search for the cause of jerking and floating speed.

The New Year's fuss is over, I decided to check what pressure the RTD holds in the new fuel pump module, which I wrote about earlier. It's easy to check:

Maintains 3.4 bar from the stated 3.8 bar. To check and compare the results, I took the old RTD and the new one, which I had previously purchased separately. Here the top part from the old module helped me.

The result is the same 3.4. what's new, what's old. But as we remember, when I measured the fuel pressure at the service center, their monomer, as well as mine, after double-checking, showed 3 bar (300 kPa). I assumed that the pressure was being lost somewhere in the pipes, but the bottom was all dry and did not smell of gasoline. I decided to check if the injectors are leaking? It's easy to check: take them out of the intake, put a cloth on them and turn on the ignition.

After checking, the rag is dry and does not smell at all). Then I probably watched all the videos on YouTube, where the malfunction was low fuel pressure, but the symptoms are not the same as mine. My video is below:

https://youtube.com/watch?v=lmJTs5OfX3w

Yeah, block 21114–1411020-11 doesn’t give me anything, so I went to google its possible breakdowns and malfunctions. I found out that this is the M73 block, it comes from two manufacturers: Itelma No. 21114–1411020-12 and Avtel No. 21114–1411020 -11, I didn’t find any common problems with them. But I came across an interesting article on flashing this unit, which said that firmware from different ECU manufacturers is not interchangeable and you should not even try to upload it, in order to avoid problems, one of which may be related to XX. Then I jumped out of my chair, grabbed the Launch X-431 EasyDiag 2.0, which happened to be at hand, and rushed to put the tablet on charge. I charged the tablet and went to look at the firmware version of my brain. I was plunged into a stupor by what I saw, see for yourself.

The exact opposite of what is indicated on the body of the unit that is on my car. Those. I have an Avtel block, and the firmware is from Itelma. There were obvious reasons for its dismantling on the unit; who changed the firmware and why will remain a mystery. I assume that this is due to the lack of an absorber. The four taught me to double-check everything 10 times, so I’ll google it again. It turned out that everyone unanimously said that firmware cannot be uploaded from a unit from another manufacturer! Then I look for guys in the city who can upload factory firmware, and I am faced with the fact that they are all a little surprised, why do I want standard firmware? Let us fill you with an improved one - the price will be the same. everywhere from 3000 rubles. Honestly! The toad strangled me to give 3000 rubles. Can you explain to me why these prices are so high? I understand the improved one, someone sat there, did something with it, it costs time and money, but what happens with the serial one? I even have it on my PC, all I have to do is upload it, and judging by the video on YouTube, it takes about 10 minutes. In fact, I ordered a K-line wire, I will assemble the cord for the firmware and try to fill it myself. One embroiderer nevertheless suggested to me that before flashing, it is worth achieving normal fuel pressure and checking the valve clearances, since before flashing, the car must be in good working order. I'll try to install a GAZ RTD at 4 bar and buy a set of feeler gauges to check the gaps.

PS I would like to thank the authors of these materials, which they made freely available. Thank you very much! I wouldn’t have figured it out without you.www.drive2.ru/l/464646468146299435/chiptuner.ru/content/ser_m73/www.drive2.ru/c/933584/

Source

How to check without dismantling? Signs

There are several symptoms by which you can determine the malfunction of this unit:

- Jerking while moving.

- Difficulty starting the car.

- Deterioration in acceleration dynamics. The car picks up speed slowly, even if the trigger is pressed fully.

Also note that similar symptoms can occur due to malfunctions of the mass fuel flow sensor or throttle position. It would be a good idea to check and replace the filter, both gasoline and air. The resource of the latter is 10 thousand kilometers. You can determine its wear visually. If it is in this condition, it needs to be replaced immediately. As for fuel filters, they are produced in an opaque housing. Therefore, it is necessary to write down the replacement schedule. On gasoline cars it changes every 50 thousand kilometers. On diesel engines - every 10 thousand (fine cleaning).