Any car, even one as reliable and time-tested as the VAZ-2106, sometimes breaks down - this is not surprising. However, the worst thing is when the failure occurs somewhere on the road, far from repair shops. To prevent this problem from happening, it is necessary to regularly inspect the machine and promptly replace worn components.

How to properly connect and install a new ignition coil on a VAZ-2106 car? This is exactly what we will talk about next.

Coil device

The ignition coil, both in the case of the VAZ-2106 and in other cars, is only one of the components of the engine starting system. It also includes:

• lock; • distributor; • candles; • cables.

The coil itself is a completely ordinary pulse high-voltage transformer. Its components:

• a core with a primary winding made of thin wire; • secondary winding - it is made of thicker wire.

Both reels are connected to the machine's battery. The core provides voltage transmission. As a result, a fairly large charge is created on the secondary winding after transformation, which is directed to the spark plugs. These, in turn, spark and ignite the fuel-gas mixture.

Models, manufacturers, reel prices

There are several models of ignition coils on the shelves of car dealerships. For “classics” (2101-2107) - B-117A , and for VAZ cars of the eighth family (2108-21099) - 027.3705 .

Basically, all reels are of domestic production, manufacturing companies: ATE-2, Citron, Stary Oskol. According to numerous reviews, coils from Stary Oskol are considered to be the highest quality.

The average price for a new “reel” in Moscow and the Moscow region is about 400-500 rubles.

Most owners of “classics” from AvtoVAZ, faced with the contact ignition system that was equipped with cars produced in the last century, try to change it to an electronic one. Such modification of the machine can easily be carried out independently. This is what this article is about.

Checking the coil's health

The short circuit is tested in the following order:

• checking spark plugs; • visual inspection of wiring; • voltage measurement; • determination of the resistance value.

When examining the external parts of the coil, you must first of all pay attention to:

• places of connection of wires; • external mechanical damage; • presence of dirt and oil stains.

To make sure that there is voltage, turn on the ignition and measure the readings by connecting a voltmeter to ground and terminal “B”. If there is no breakdown on this side, then you will have 12 volts. If there is no voltage, you will have to deal with the lock.

Before starting work on the vehicle's on-board electrical system, it is mandatory to disconnect the negative terminal from the battery - this is a safety rule.

For the following tests, the short circuit must be completely dismantled. We'll tell you how to do this below.

The primary winding is checked for an open circuit with an ohmmeter (set to 200 Ohms). Here:

• one probe is connected to terminal “B”; • others touch exit “K”. • normally the indicator will be 3.8-4.5 Ohms.

The high voltage part is tested differently:

• the device is set to 20 kOhm; • one probe is placed on “K”; • the second one is on the high-voltage contact (located in the center); • the normal value is from 7 to 8 kOhm.

The last stage is checking for insulation breakdown. Here:

• the device remains at 20 kOhm; • the black probe is applied to the body; • red – alternately to all outputs; • in the absence of breakdown, the ohmmeter readings will not change.

Any deviation from the above standard values means that the closing coil is faulty.

The most common problems with coils are:

• overheating of windings; • short circuit in one of them.

Similar troubles occur when the engine is operated incorrectly with unadjusted (too wide) spark plug gaps or when there is poor contact in the terminals or partial breakage of the wiring.

By the way, installing high-quality spark plugs and their correct adjustment significantly increases the service life of the reel.

What is electronic ignition

The term "electronic ignition" means the same as "contactless ignition". The BSZ unit is assembled from electronic (semiconductor) components, which is reflected in the name of the system. “Contactless” ignition is called because the closing and opening of the low-voltage circuit is carried out by an electronic switch by locking and unlocking the transistor, and not by the distributor contact.

The electronic ignition system of the VAZ 2107 for the carburetor and injection versions is different. Perhaps this is the reason for the erroneous opinion that electronic and contactless ignition are different systems.

How to connect a coil

The ignition coil, in principle, cannot be disassembled, for this reason it cannot be repaired. Thus, if it is possible to find out that it is the short circuit that has failed, it is simply replaced with a working unit.

To complete this task, prepare:

• pliers; • or 8 and 10 mm spanners.

The procedure is as follows:

• first of all, disconnect the battery - the coil is a fairly powerful transformer, so the likelihood of getting an electric shock is quite high; • then remove the high-voltage wire from the corresponding connector; • unscrew the nuts from both terminals of the winding terminals - “K” (or OE) and “B”; • screw together the fasteners holding the unit on the machine body; • dismantle the short circuit and put a working one in its place; • We carry out the assembly in the reverse order.

Selecting an ignition coil for VAZ 2106

The design of classic VAZ cars does not place excessive demands on the ignition coil. The coil must meet certain parameters and produce the required voltage. On the VAZ 2106 you can install coils from the following manufacturers:

- ERA is a domestic manufacturer of components for various cars, offering ignition coils for the VAZ 2106 starting at RUB 1,350. Such coils have a very limited service life.

- MZATE-2 offers reliable ignition coils at prices starting from 600 rubles. In addition to the low price, the products are easy to install and are available in almost every car dealership.

- Bosch is a trusted manufacturer of auto parts. Despite the high price (from 2,700 rubles), German-made coils are extremely reliable and have the longest service life.

- SOATE is another domestic manufacturer that sells ignition coils for the VAZ 2106 at prices starting from 700 rubles.

SOATE offers a complete set of ignition system elements

Usually, VAZ 2106 owners, when purchasing, look for powerful coils at a low price, since the power characteristics of the engine directly depend on the number of turns of the winding. Experienced car owners give the following advice:

Look in the store for a contactless ignition kit specifically for your engine. You can install it yourself - everything is simple, there are many manuals on the Internet. At the same time, change the spark plugs and wires. Then don’t forget to go to a good carburetor specialist. I installed it on a working 4K with a triple engine myself, it started driving better - no failures, and even started in cold weather. So they will tell you this on any specialized forum - look for a VAZ 2106 club or forum in Yandex. It is also recommended to use a thinner oil for winter - for example, something like 5w30; there are not many semi-synthetics like that. Search will help you. By the way, you should always pull out the suction when it’s cold - less in the summer, of course.

SeregaSabir

https://www.mastergrad.com/forums/t193250-kakoe-vybrat-elektronnoe-zazhiganie-navaz-21065/

The most reliable coils are Bosch - these are powerful, high-quality devices with maximum service life.

First signs of trouble

The main signs of ignition coil failure are lack of ignition. If it is a single device with a distributor, then in all cylinders; if it is a double or single device, then in those served by it. The absence of a spark is not necessarily a 100% sign of a faulty coil. Perhaps the limiting resistor has burned out, the spark plug is faulty, the high-voltage wire has broken, or there is a malfunction in the ignition system. A comprehensive fault diagnosis is required.

Visual signs that the ignition coil is not working:

- the presence of “breakdown tracks”, oxides on the coil;

- change in dielectric color;

- burning of contacts and connectors;

- traces of overheating on the body;

- increased pollution.

Let's talk in more detail about these and other points indicating that the ignition coil of the VAZ 2106 is in a faulty state.

Presence of interruption tracks in the ignition coil

Let's figure out why the ignition coil breaks. Firstly, over time, as a result of high temperature changes, the dielectric insulation cracks, and salty moisture, which is a conductor, can enter microcracks.

The photo shows a common malfunction - breakdown of the ignition coil of a VAZ 2106

For voltages of more than 15,000 volts generated in the secondary winding, even pure undistilled water acts as a conductor. Secondly, during operation, the physical properties of the dielectric and rubber insulation of the tips of high-voltage wires, especially those of dubious production, change.

High-voltage breakdown can be caused by the installation of non-standard high-voltage wires in which there is no distributed current-limiting resistance. A breakdown can occur as a result of severe contamination or waterlogging. Even in the event of a single breakdown, irreversible changes occur in the structure; further operation is not recommended.

Burning of contacts and connectors of the ignition coil of a VAZ 2106

The big disadvantage, the disadvantage of CG, is the sparking process, which cannot be eliminated in any way. However, significant minimization of sparking can be achieved by connecting a capacitor. Yes, and be sure to set the correct gap.

Experts say that if you increase the gap above standard values, you can get rid of sparking. In other words, if the distributor contacts are burning, increasing the gap will be the optimal measure to eliminate the problem. However, this also has its drawbacks. In particular, the angle decreases, which leads to a decrease in the additional current voltage.

Traces of overheating on the ignition coil body of a VAZ 2106

Another sign by which you can determine the malfunction of the ignition coil of the VAZ Six is the presence of traces of overheating on the short circuit housing. The photo shows what they look like:

This is what signs of overheating look like on the ignition coil housing

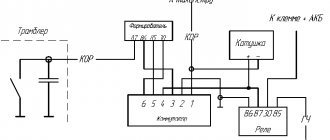

Connection diagram

The connection diagram of several elements is as follows. One of the ends of the coil is connected to the on-board network. The second end is connected to the next one, and in this way every last one is connected. The remaining free contact of the last coil must be connected to the distributor. And a common point is connected to the voltage switch. Once all mounting bolts and nuts are securely tightened, the replacement can be considered complete. Some important tips before replacing and connecting. If you have determined for yourself that the problem with the ignition malfunction is the coil, then it is better to immediately purchase a new one and connect it (the diagram is shown above). This way you will be sure that now there are no problems with it, since it is completely new. If you find any defects on the surface, it is better to replace it immediately. Otherwise, it will work for some more time and you will have to return to this topic again. It’s better to play it safe in advance so as not to stop somewhere on the road. After all, ignition of a car does not forgive mistakes and negligence.

More details about connecting the ignition coil will be discussed in this video:

Published: February 21, 2022

How to install electronic (contactless) ignition

The sequence of installation of electronic ignition components is not particularly important. We can advise you to start by replacing the distributor:

- disconnect high-voltage wires;

- remove the distributor cover;

- rotating the crankshaft, set the slider perpendicular to the engine axis so that it is easy to repeat when installing a new distributor and mark the position of the middle mark of the distributor scale (these actions will facilitate subsequent adjustment of the electronic ignition);

- unscrew the nut securing the distributor and dismantle it;

- install a non-contact sensor-distributor instead of the old distributor, placing the slider and housing in positions corresponding to the previously applied marks;

- put on the distributor cover;

- install high-voltage wires.

Then the coil should be replaced. The operation is simple, but you need to take into account the position of contacts “B” and “K”. If it is different on the new coil, you need to rotate it relative to the fasteners so that the contacts are positioned similarly to the old one.

Useful tips

- To ensure normal ignition operation, high-quality spark plugs should be installed. This is especially important when the car is running on gas.

- Poor quality wires often cause ignition malfunctions. It is better to use wires with silicone insulation, which has better dielectric characteristics and is more durable.

- Poor fixation of the wire block often causes failure of the switch. To avoid this, it is necessary to check the quality of the connector fit.

- On VAZ models older than 1994, when installing electronic ignition, the tachometer stops working. You can fix the problem by installing a 1.2 kOhm resistor or a capacitor in the circuit between the coil and the tachometer.

The only drawback of electronic ignition on a VAZ is its complete inoperability if the hall sensor breaks down. This is not a very common, but quite possible event. To completely protect yourself from this problem, you should buy a spare sensor and carry it with you.

Contact ignition system device

The design of the ignition contact circuit includes the following components:

- lock (switch);

- coil (short circuit);

- breaker (MP);

- distributor (MR);

- regulators, centrifugal and vacuum (CR and VR);

- candles (SZ);

- high-voltage wires (VP).

An ignition coil (IC) with two windings makes it possible to obtain a high current by converting a low voltage.

The mechanical breaker (MP) is structurally made together with a mechanical distributor (MD) in one housing - a distributor. It ensures the opening of the primary winding of the short circuit.

A mechanical distributor (MD) in the form of a rotor with a contact cover distributes current to the spark plugs.

The centrifugal regulator (CR) allows you to change the advance angle (AF) in proportion to the crankshaft speed. Structurally, the CR is made in the form of two weights. During rotation, they act on the movable plate on which the MP cams are located.

The vacuum regulator (VR) makes adjustments to the advance angle (TAA) depending on the load. When the position of the throttle valve (V) changes, the pressure in the cavity behind the V changes. The VR reacts to the degree of vacuum and adjusts the value of the SOP.